Intelligent control system for mixing plant

A technology of intelligent control system and mixing station, applied in general control system, control/regulation system, mixing plant, etc., can solve the problems of inconvenient operation of man-machine interface, high system failure rate, low production efficiency, etc., to improve batching Accuracy and system stability, strong interactivity and beautiful interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

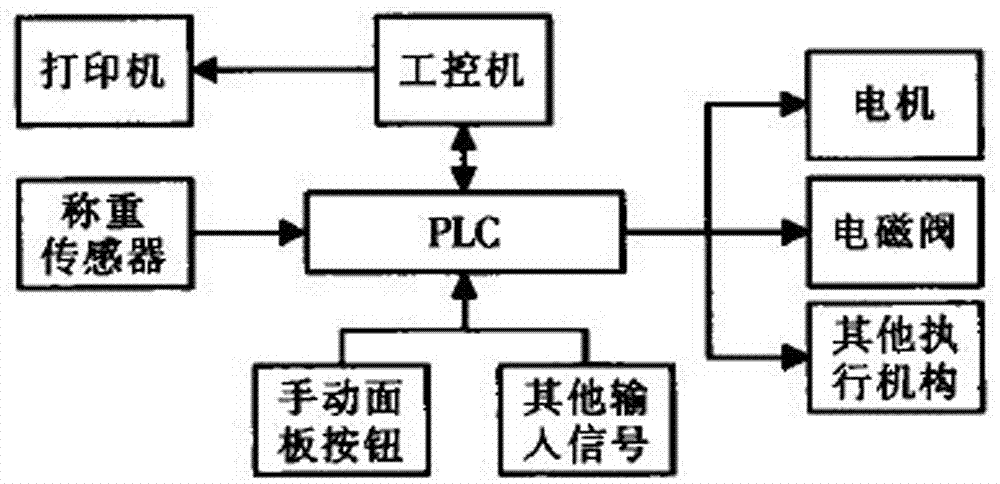

[0018] Such as figure 1 As shown, the intelligent control system of the mixing plant consists of a hardware system and a software system. The system hardware is mainly composed of industrial computer and PLC. The control mode of the upper computer and the lower computer is used to divide the control task of the system into two parts. Among them, the industrial computer as the upper computer mainly completes the management of concrete formulas, the collection and storage of batching data, the dynamic display of the status screen, the prompting of alarm information and the printing of reports, etc.: PLC as the lower computer receives the motion control signal sent from the industrial computer to perform production Various actions required in the process, such as the start and stop of equipment, various complex movements that require logical judgment, and the control of mixing time. This typical upper and lower computer system structure model improves the operating speed, stabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com