Dynamic batching digital control system and method

A digital control system, control system technology, applied in the direction of control/regulation system, non-electric variable control, chemical instruments and methods, etc., can solve the problems of slow system response, heavy workload, high construction cost, etc., to reduce the use and maintenance The effect of reducing cost, improving batching accuracy, and reducing engineering construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

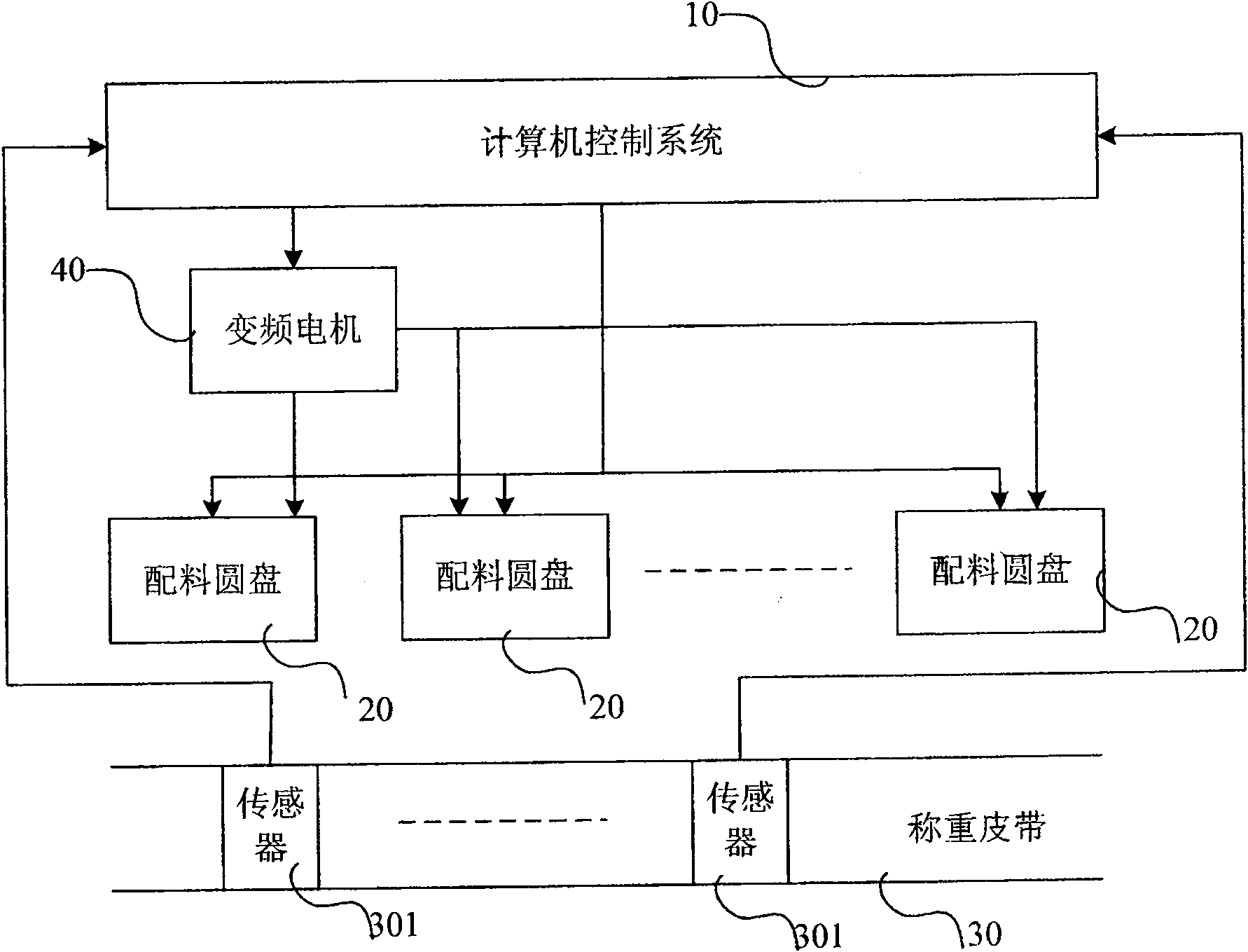

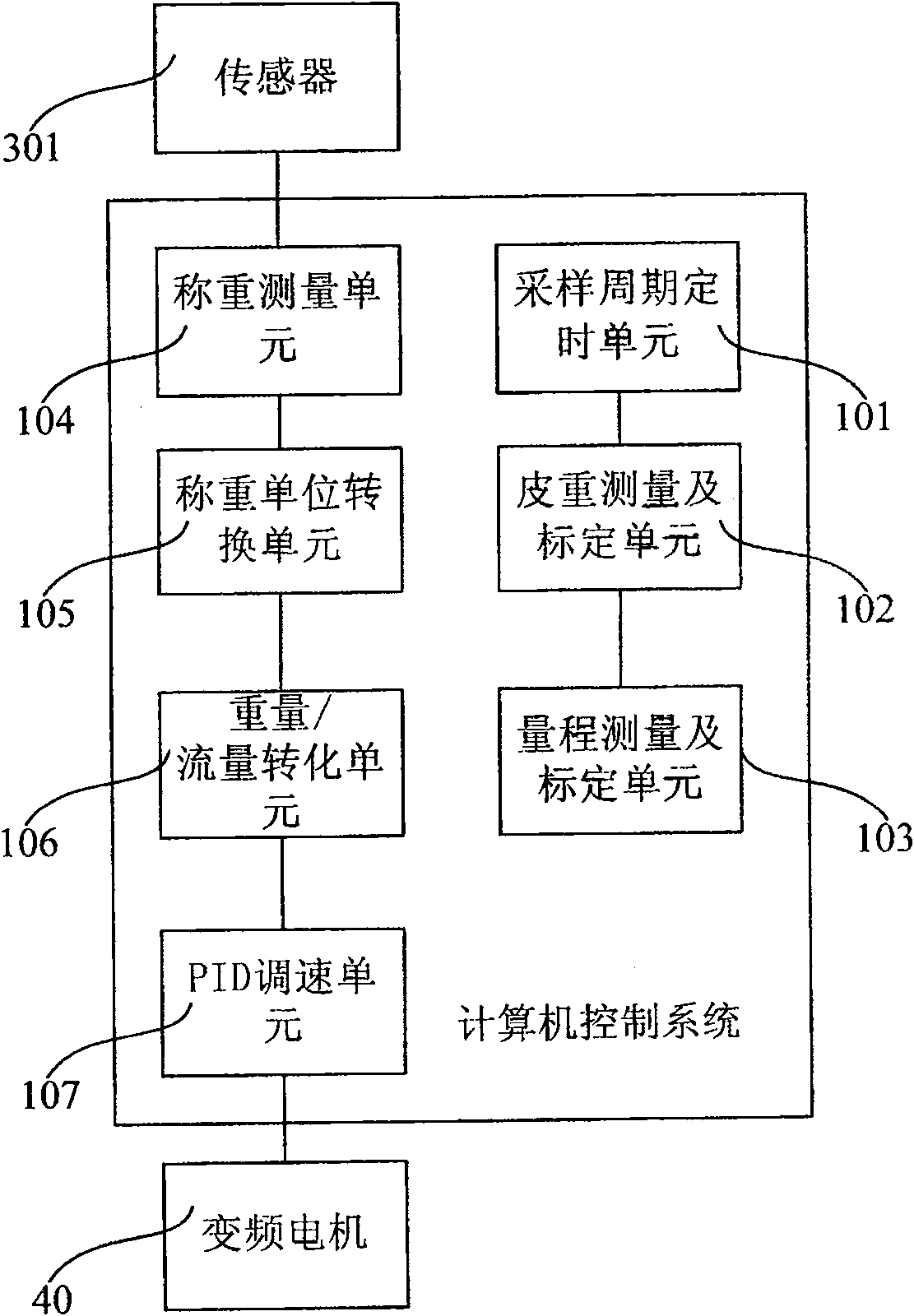

[0031] Such as figure 1 Shown is a schematic structural diagram of the dynamic batching digital control system of the present invention. As shown in the figure, the system hardware for digitally controlling dynamic batching includes a computer control system 10 , a batching disc 20 , a weighing sensor 301 and a variable frequency motor 40 . The computer control system 10 is used to determine the total flow rate according to the production plan to automatically generate the batching list and distribute it, and perform A / D conversion and obtain the output frequency of the frequency converter; the batching disc 20 is connected to the computer control system 10 for communication. Based on the specific batching flow rate given according to the batching list; the load cell 301 is installed on the weighing belt to communicate with the computer control system 10, detects the weight of ore distributed by the batching disc and feeds back the detected data To the computer control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com