Cloth rolling machine

A cloth rolling machine and cloth technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve problems such as affecting the quality of weaving, increasing the area occupied by the rolling machine, and reducing the overall productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

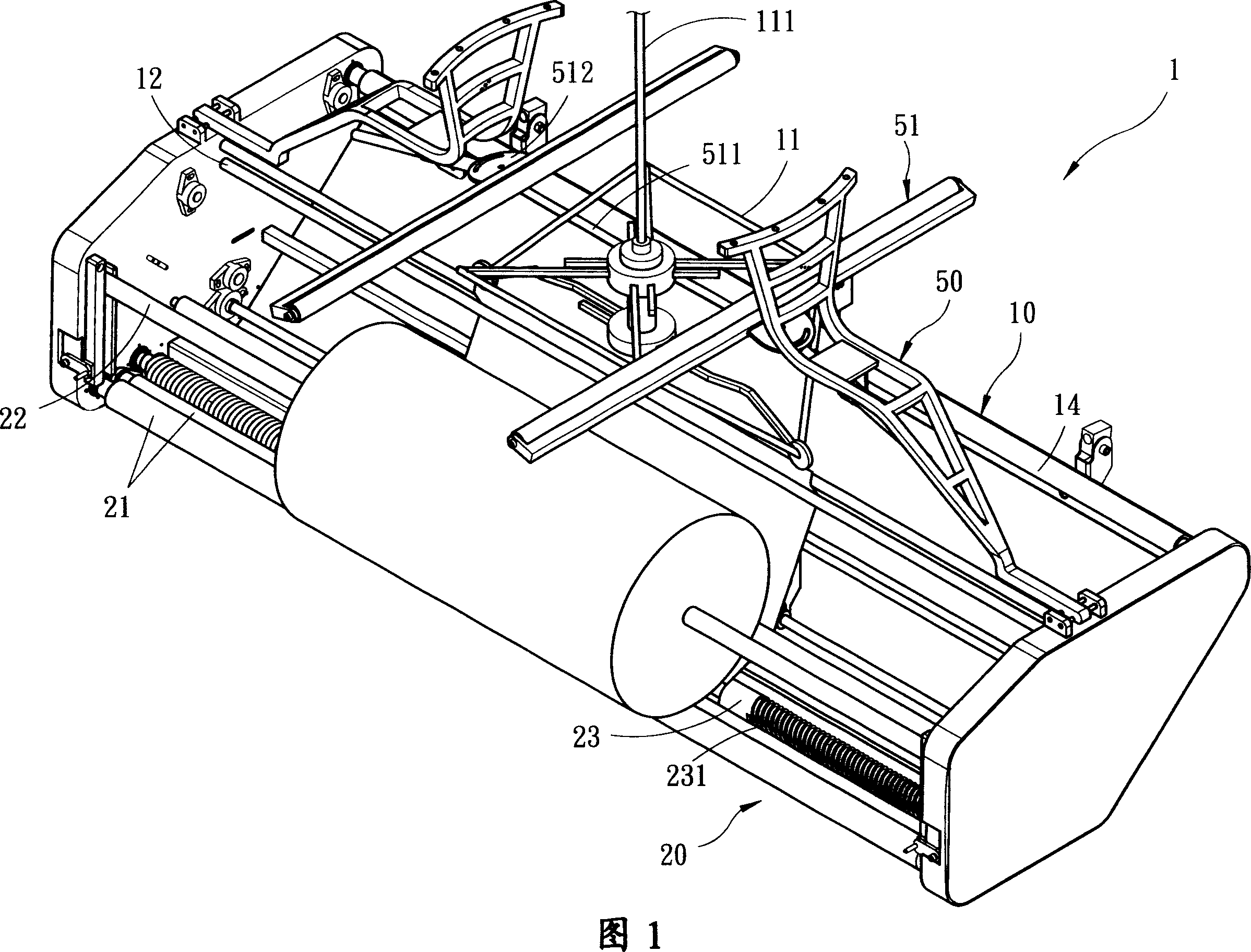

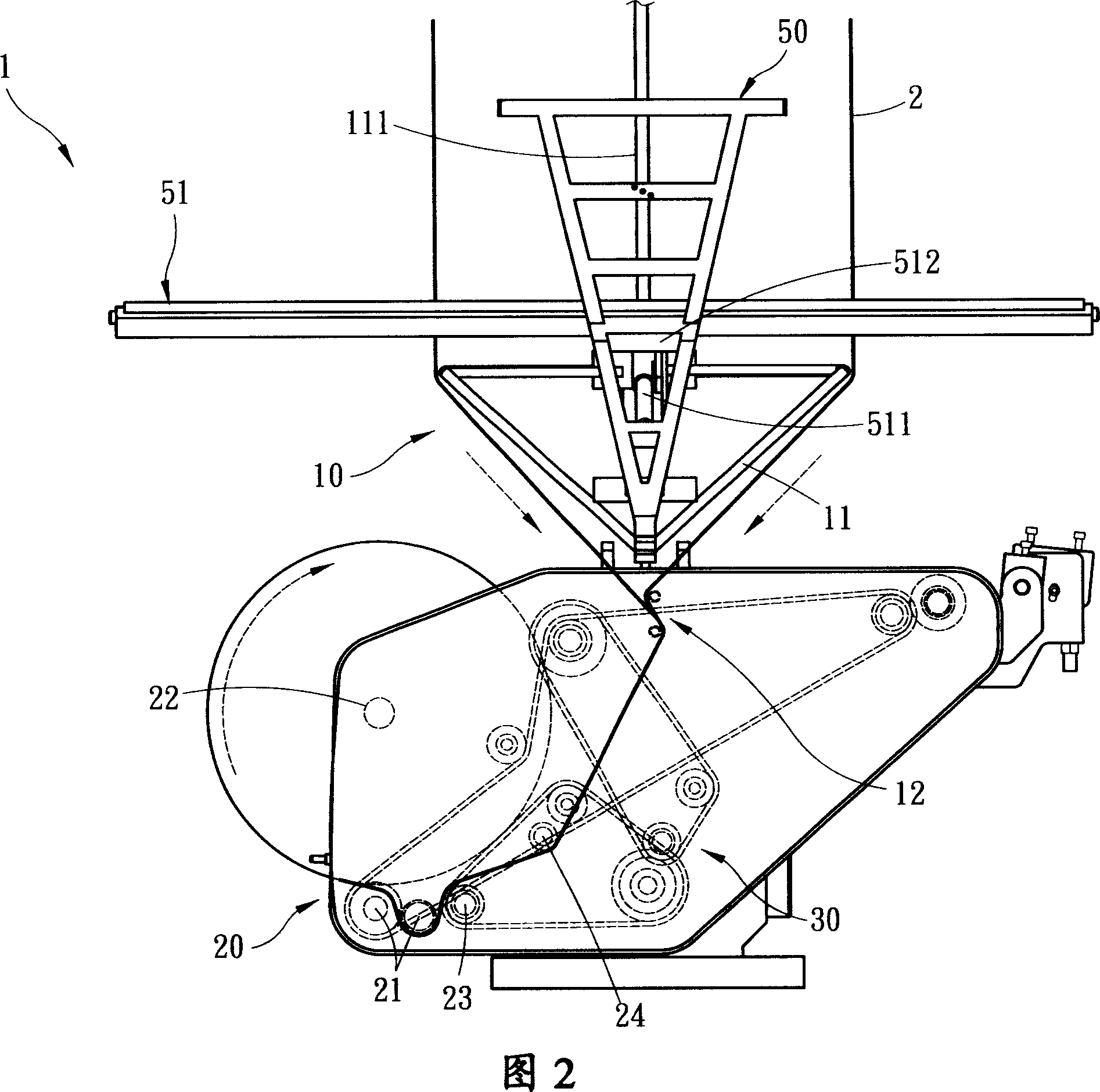

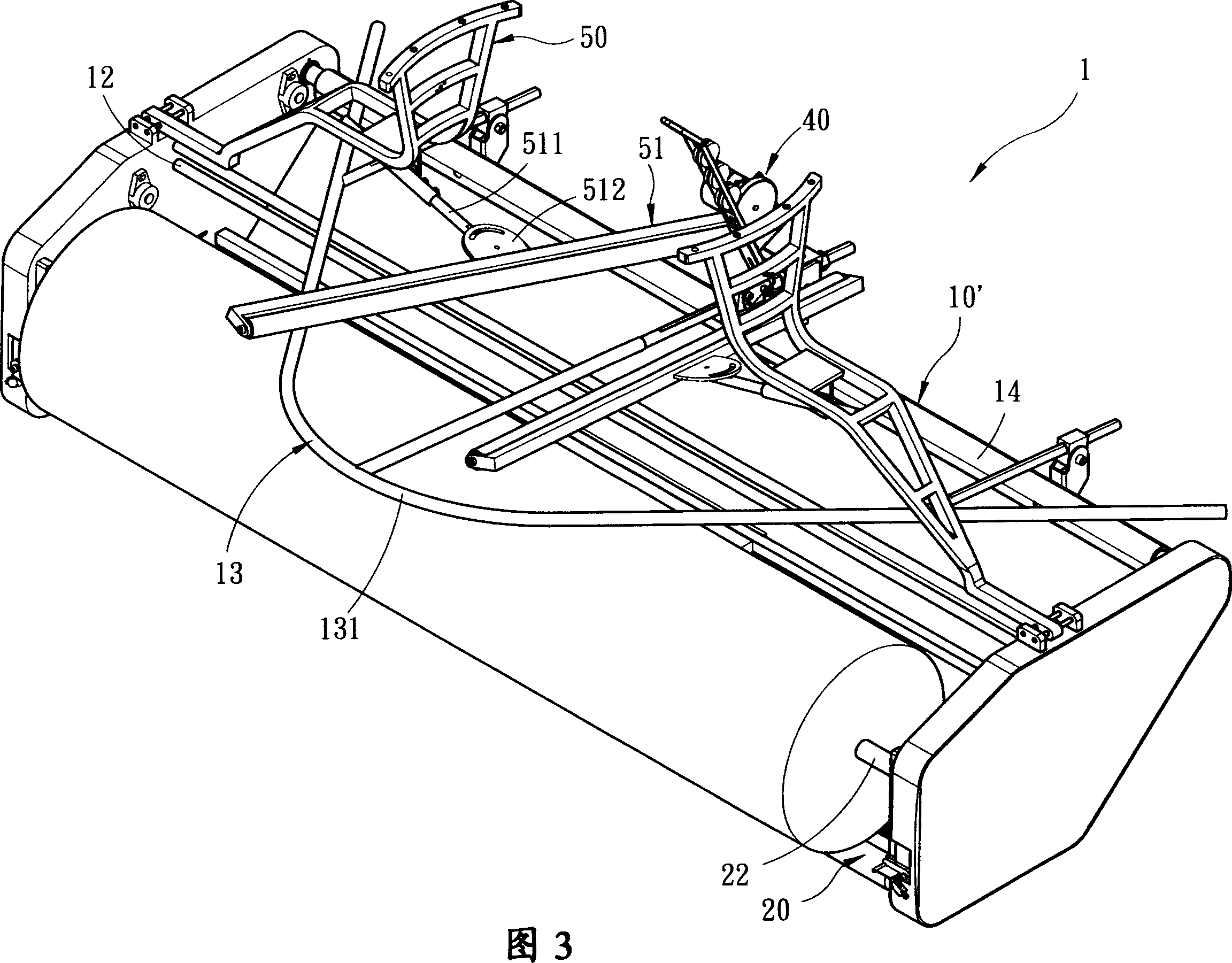

[0015] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

[0016] Please refer to Fig. 1 to Fig. 4 at the same time, which are the three-dimensional schematic diagrams of the appearance of the non-cut cloth and the cloth-cut type cloth winding machine of the present invention and the schematic diagrams of the cloth receiving route. As shown in the figure, the present invention is in a circle The knitting machine is equipped with a cloth winding machine 1, which is connected to the circular knitting machine (not shown in the figure) with a set of transmission frames 50, and the transmission frame 50 transmits the rotational force, so that the cloth winding machine 1 It rotates synchronously with the dial and needle cylinder (not shown in the figure) of the circular knitting machine, and is used to accept and take up the endless cloth 2 woven by the circular knitting machine. The transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com