Patents

Literature

35 results about "Batch processor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

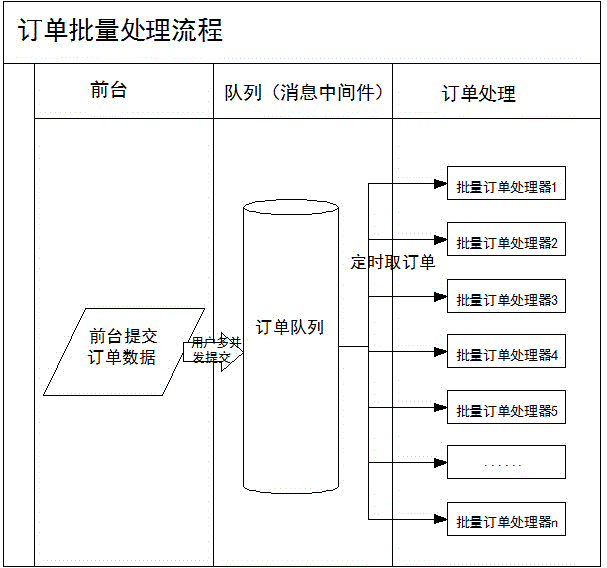

Batch processor overview. The batch processor is a multithreaded, long-running application that can process large volumes of batch data. The batch processor can process multiple records from the same batch input simultaneously, and increase the throughput.

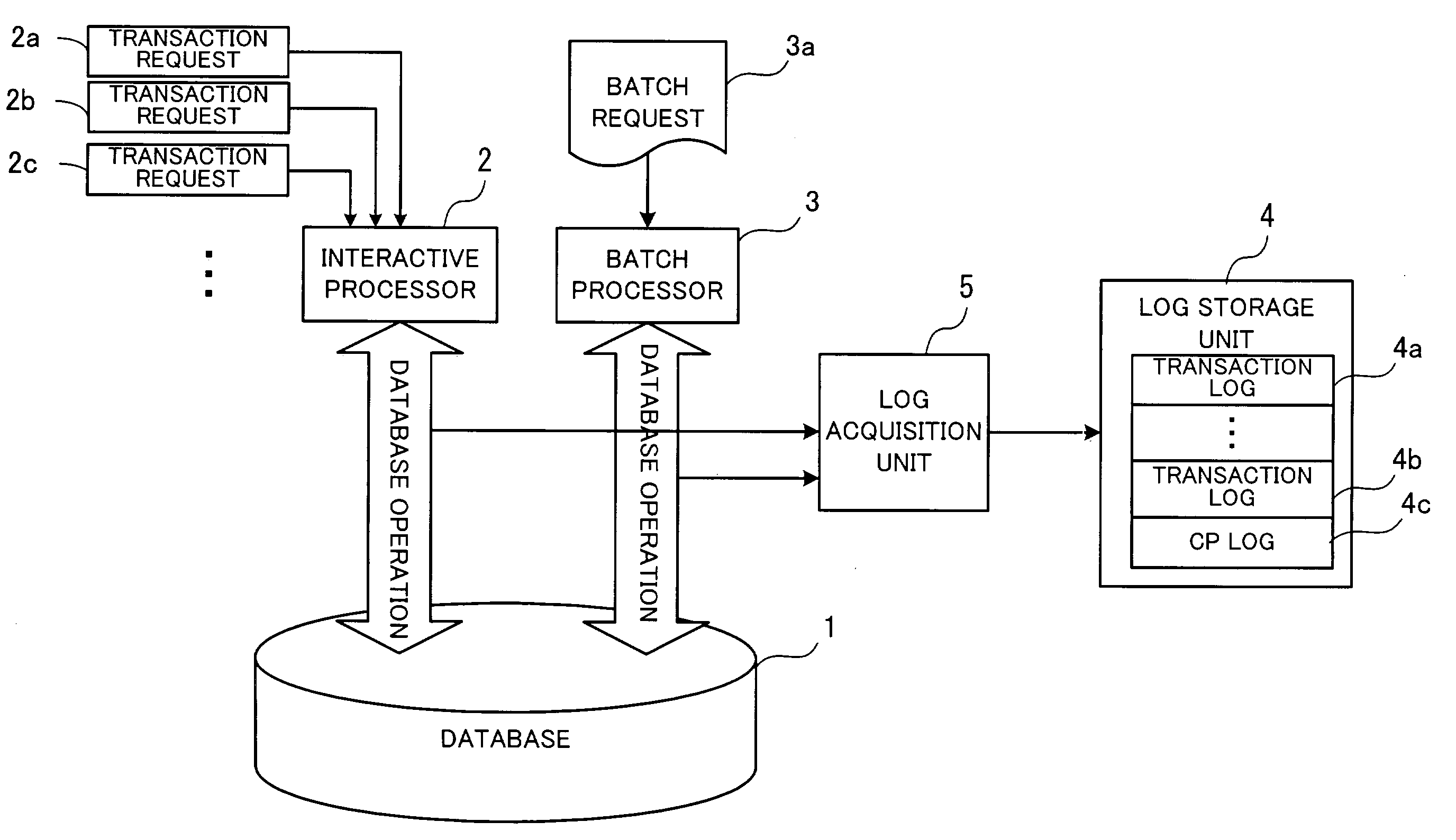

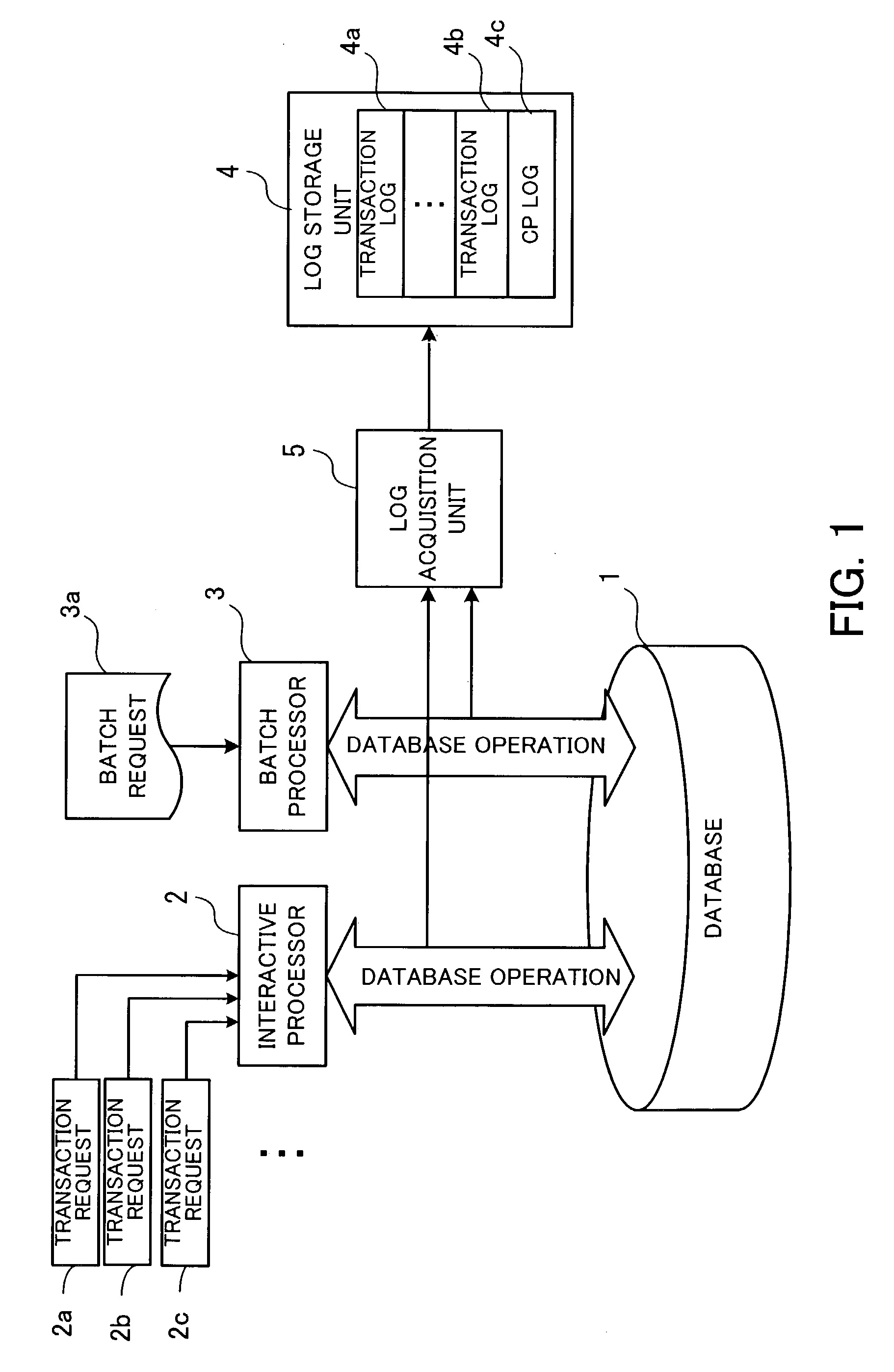

Apparatus, method and program for managing database logs

InactiveUS20040044642A1Digital data information retrievalDigital computer detailsTransaction logInteractive processing

An apparatus for managing database logs provides more efficient system operations. An interactive processor operates a database through interactive processing in response to transaction requests inputted. A batch processor operates the database through batch processing in response to a batch request comprising a series of batch instructions. A log storage unit stores database logs in a time series. A log acquisition unit stores in the log storage unit a transaction log indicating the transaction every time when the interactive processor operates the database while the batch processing is not performed. And after the batch processor starts the batch processing, the log acquisition unit stores a checkpoint log indicative of the execution of the batch processing in the log storage unit.

Owner:FUJITSU LTD

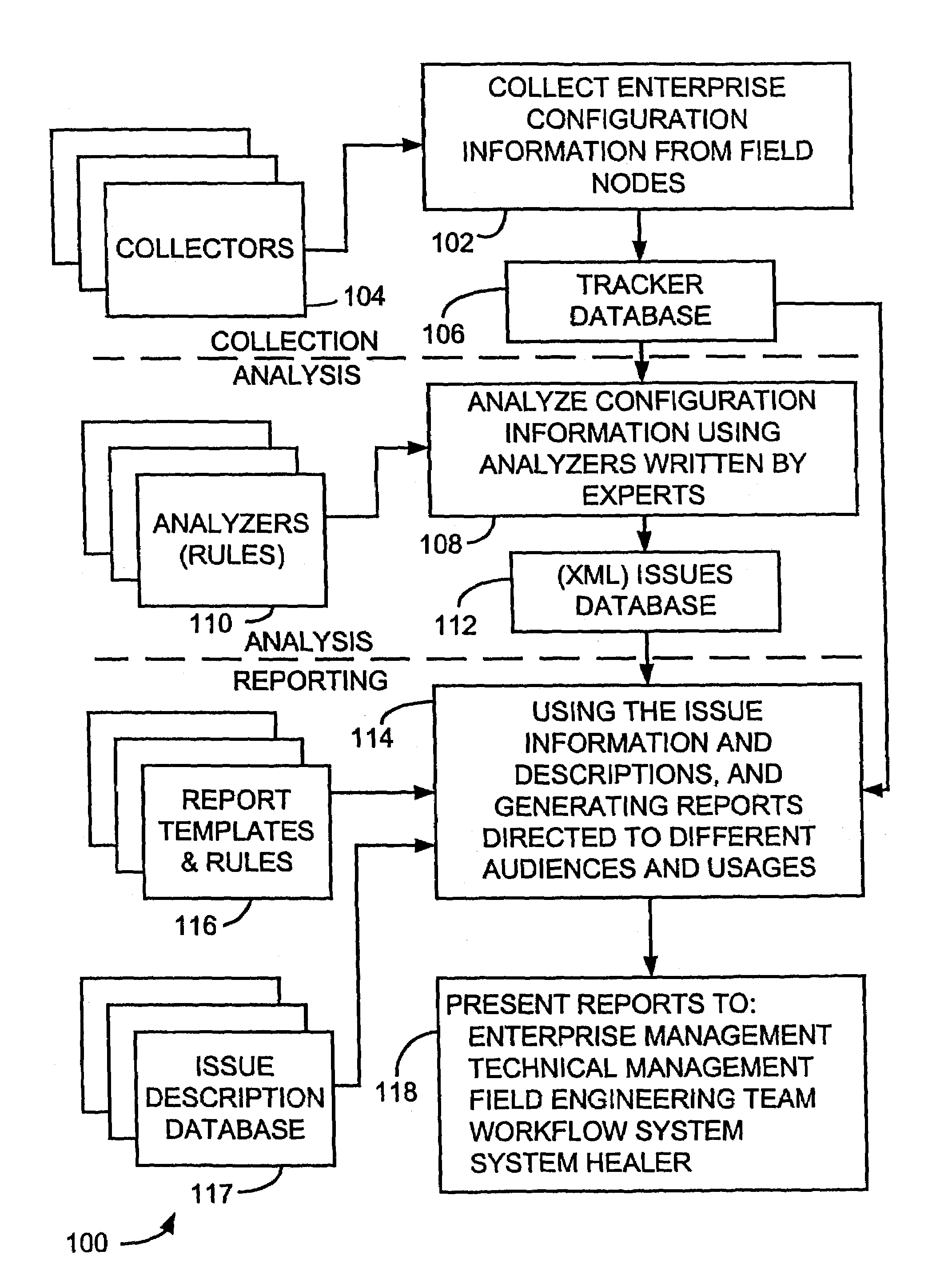

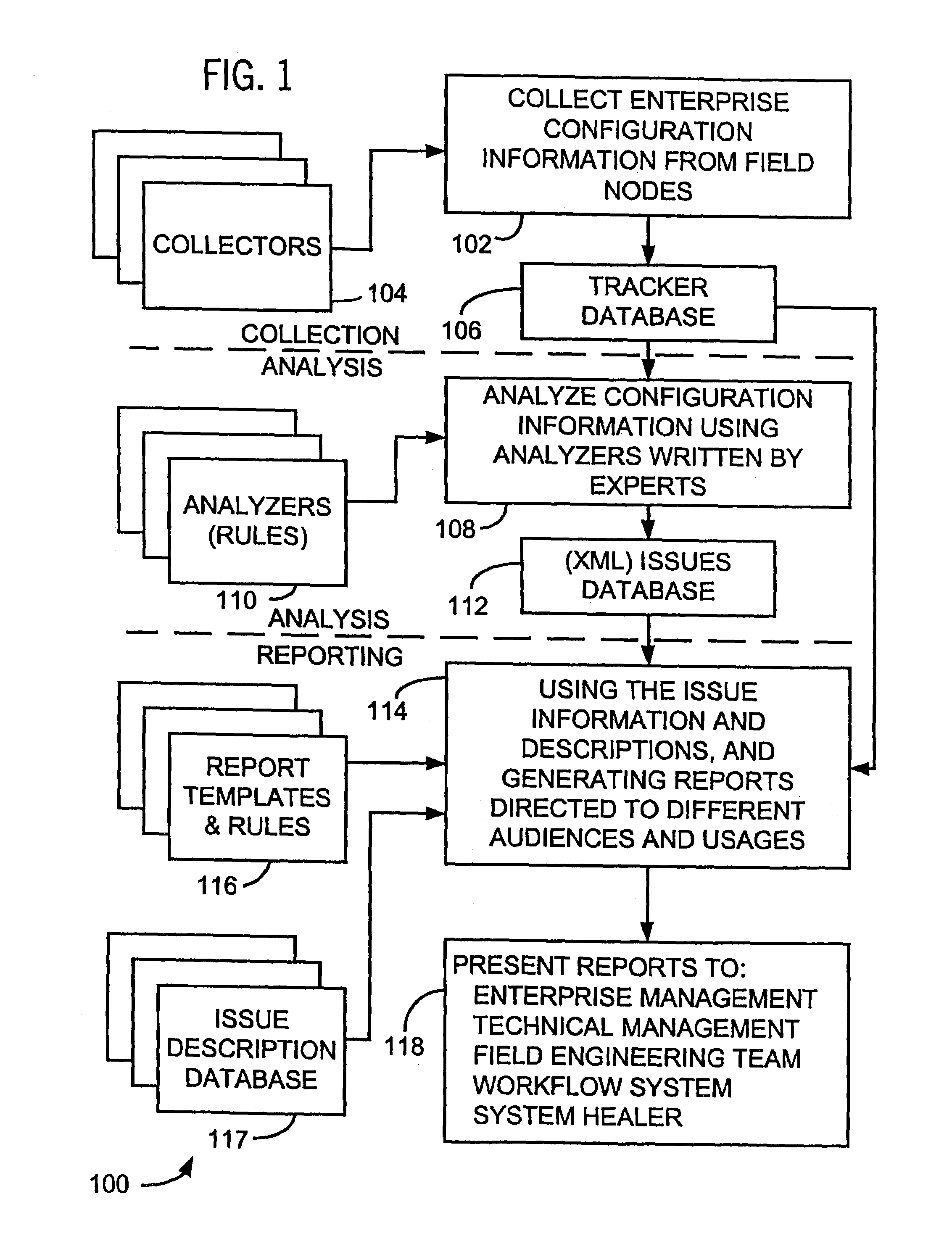

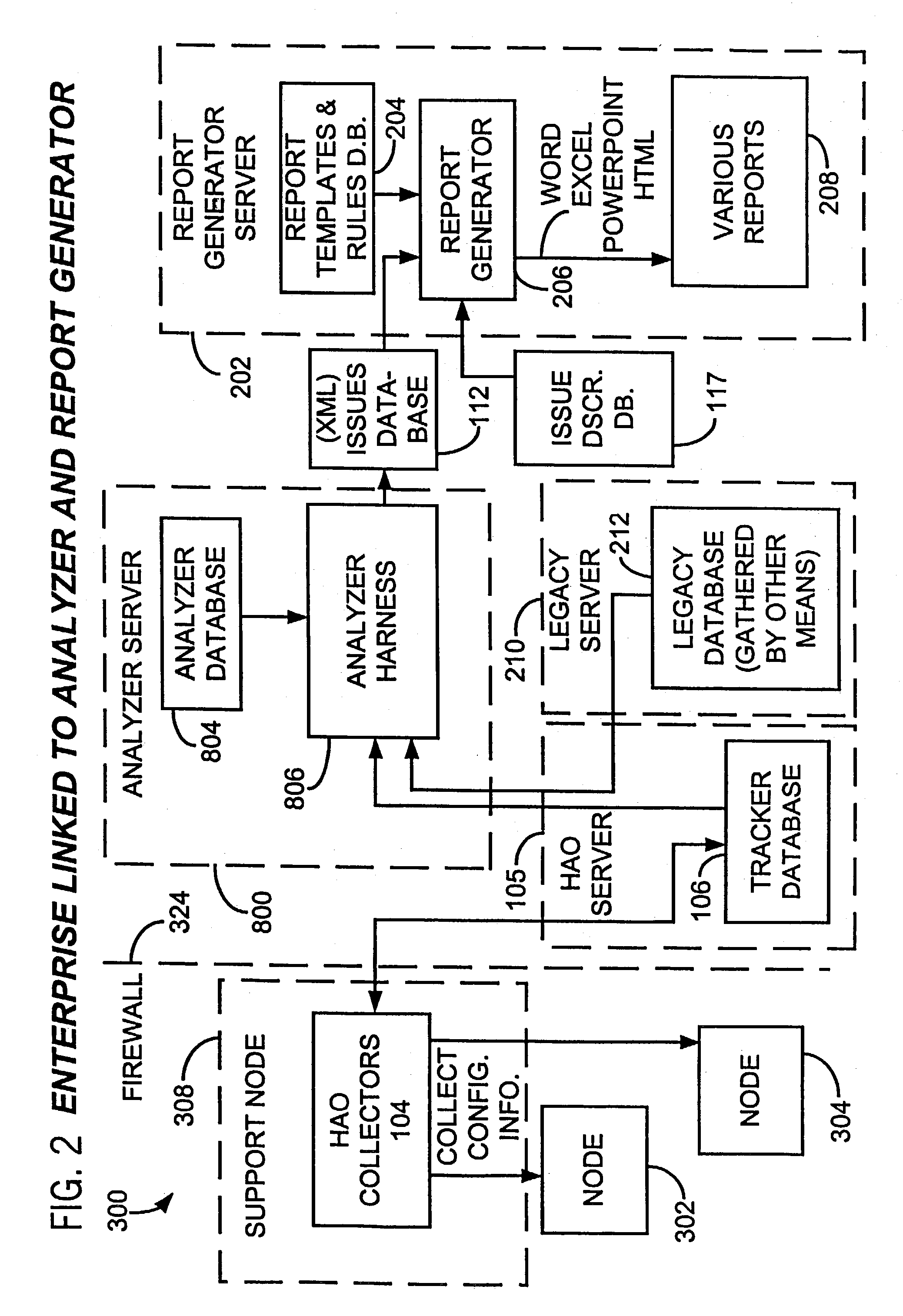

Static and dynamic assessment procedures

Owner:HEWLETT PACKARD DEV CO LP

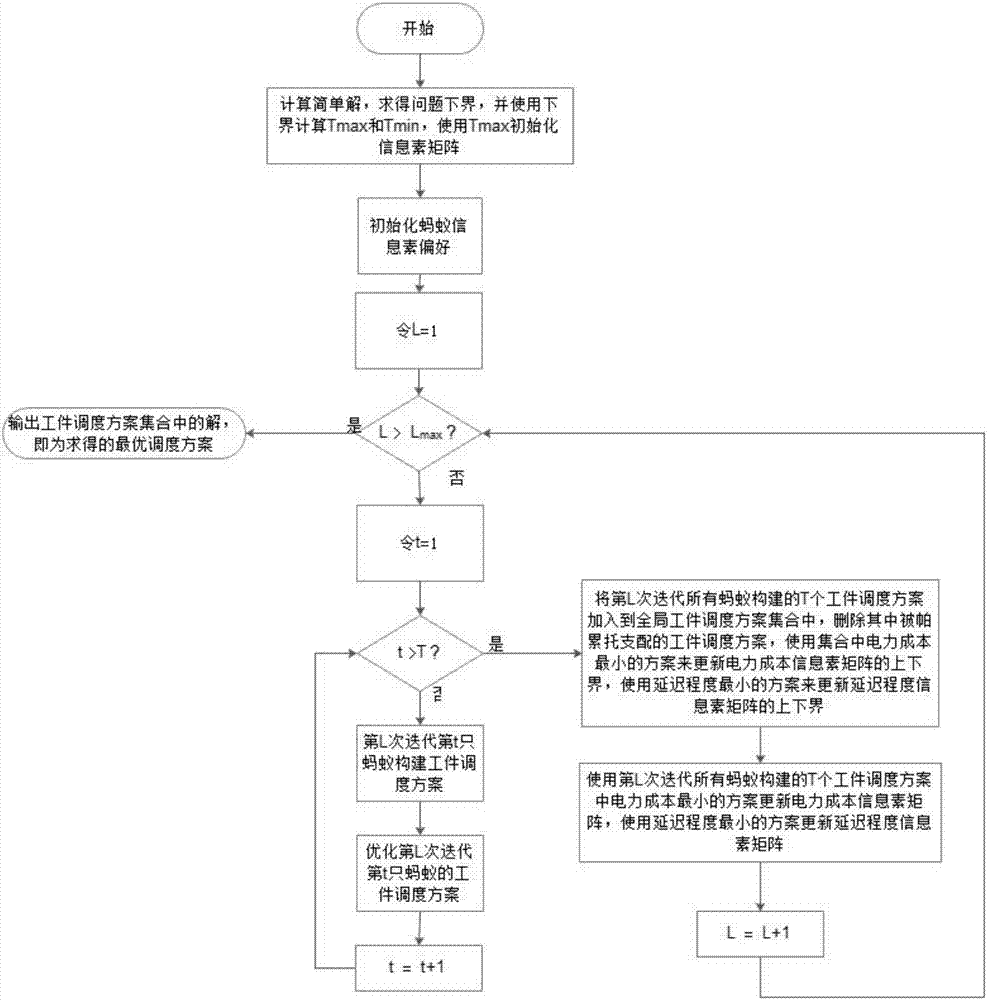

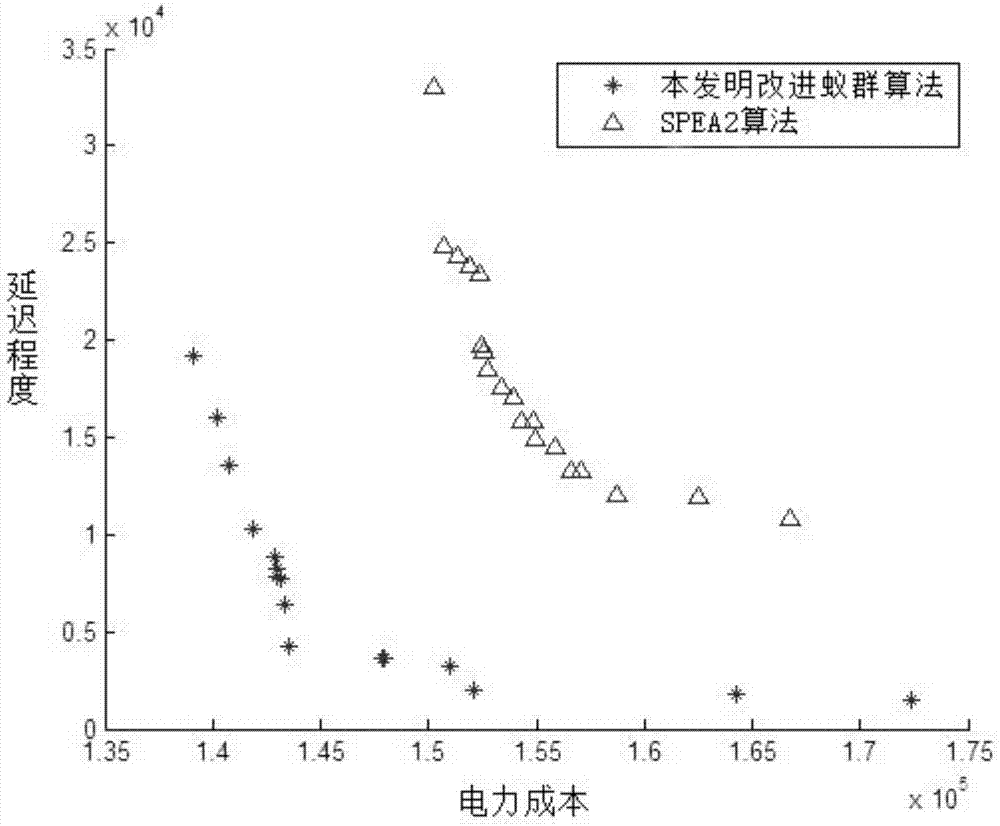

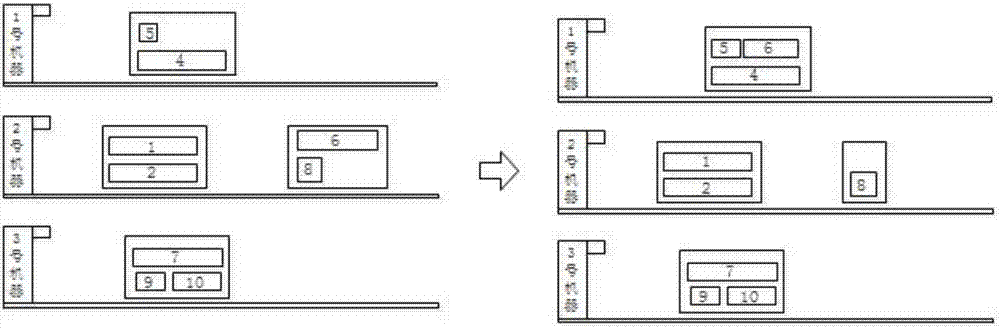

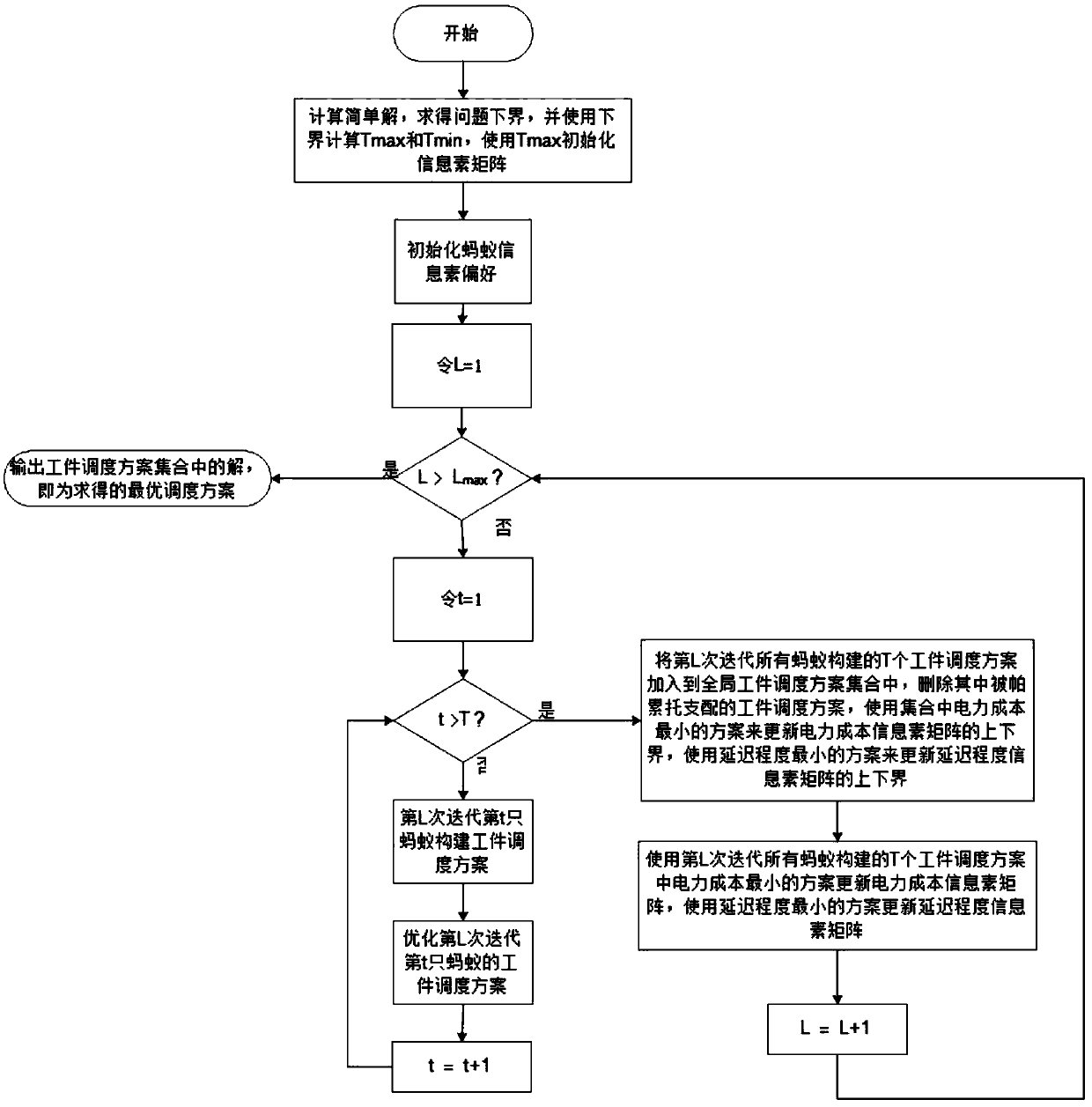

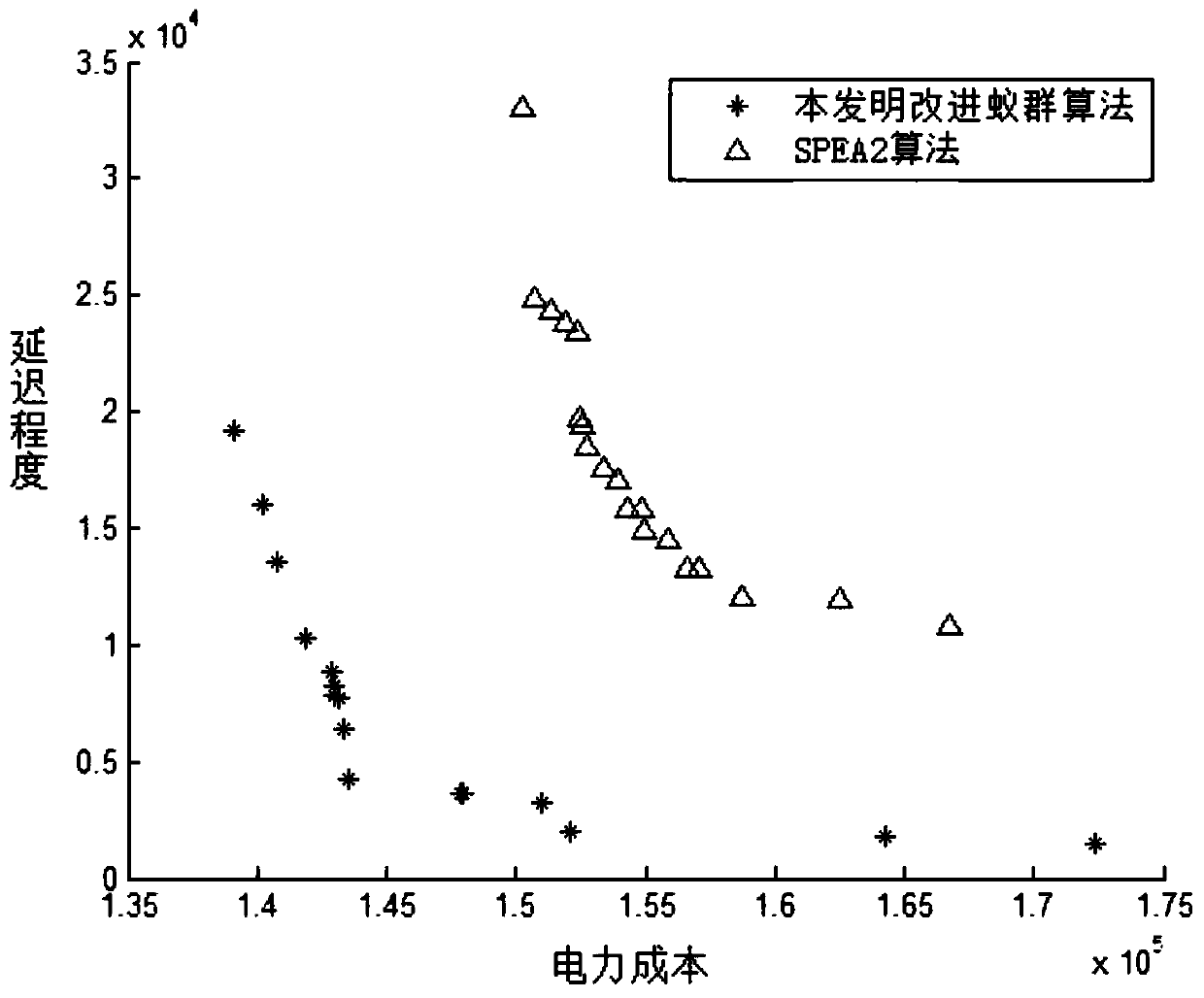

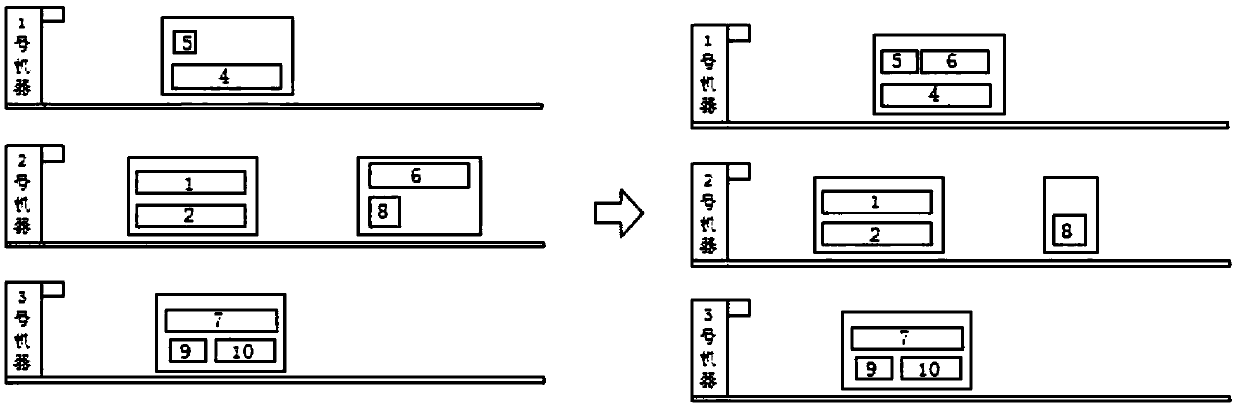

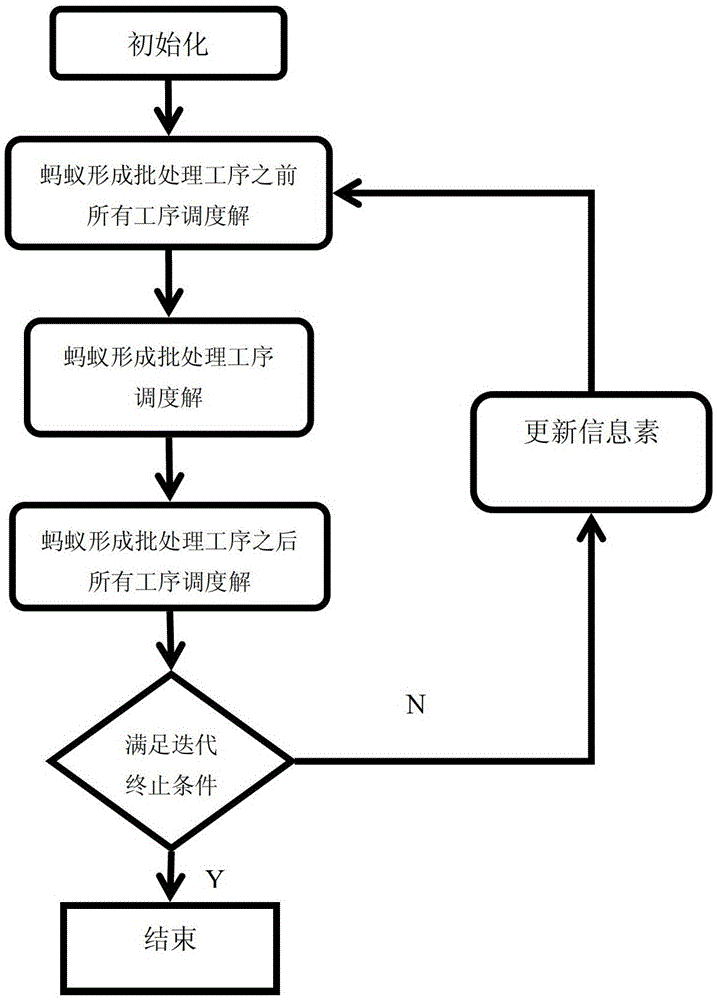

Multi-objective workpiece scheduling algorithm based on ant colony algorithm

ActiveCN106970604AEvenly distributedRich demandEnergy industryTotal factory controlElectricity priceProduction effect

The invention discloses a workpiece scheduling method based on an ant colony optimization algorithm. The workpiece scheduling method is characterized in that workpieces are effectively selected in the scheduling process through the workpiece characteristics by using a Pareto multi-objective method, and production is performed by preferentially using the low-electricity-price period so that two objectives of optimizing electric power cost A and delay degree B can be realized. A better workpiece scheduling scheme is calculated under the environment of the parallel batch processor of the background of industrial time-of-use electricity price so that the utilization rate of enterprise resources and the energy use efficiency can be maximized, optimization of cost control and the production effect of the enterprise production process can be achieved and the market competitiveness of the enterprise can be enhanced.

Owner:ANHUI UNIVERSITY

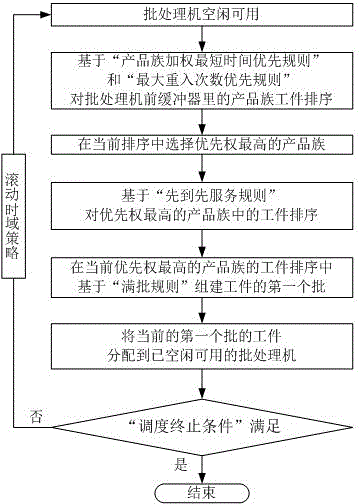

Batch scheduling method achieving minimum total completion time based on product family sorting

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

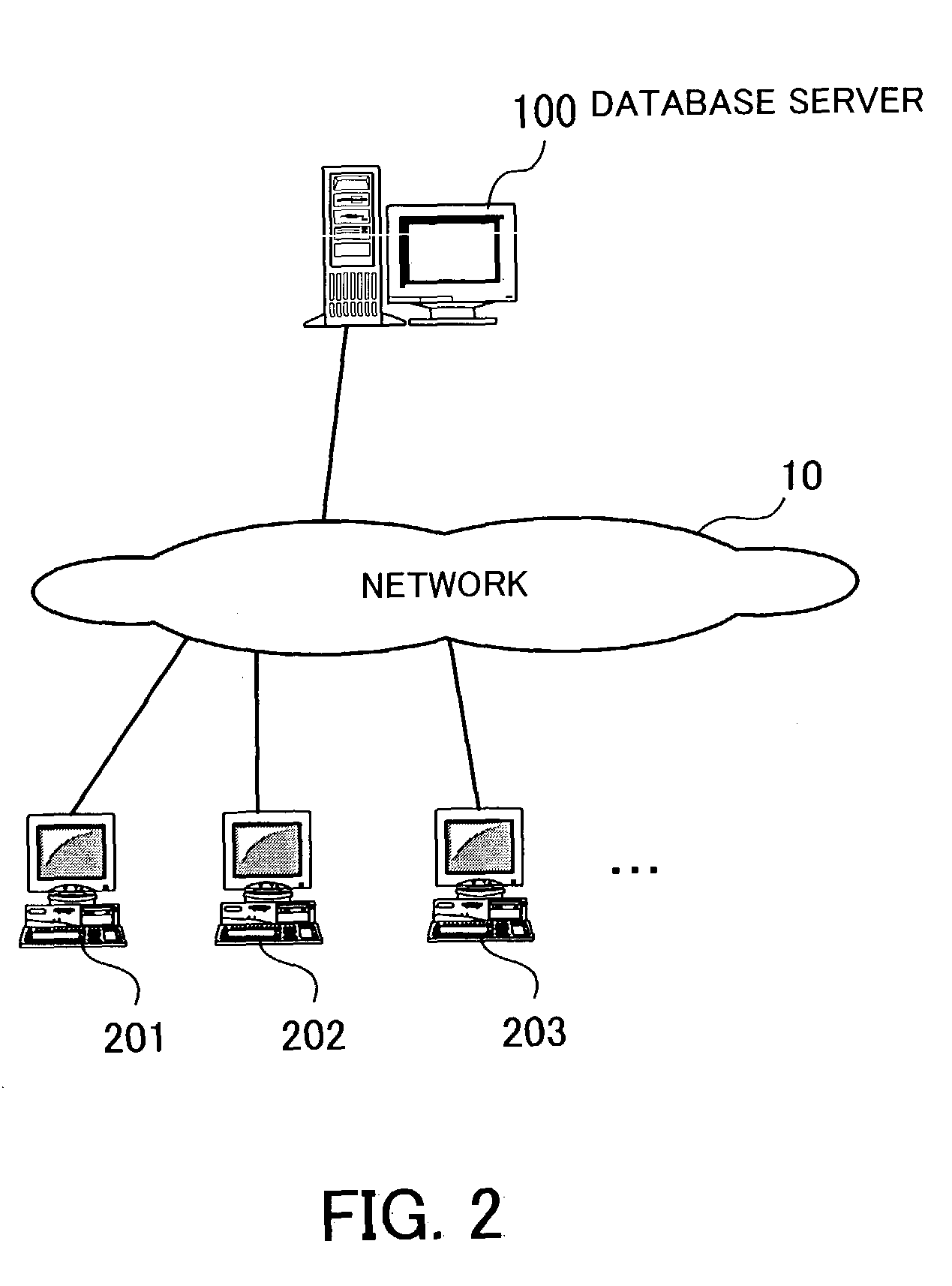

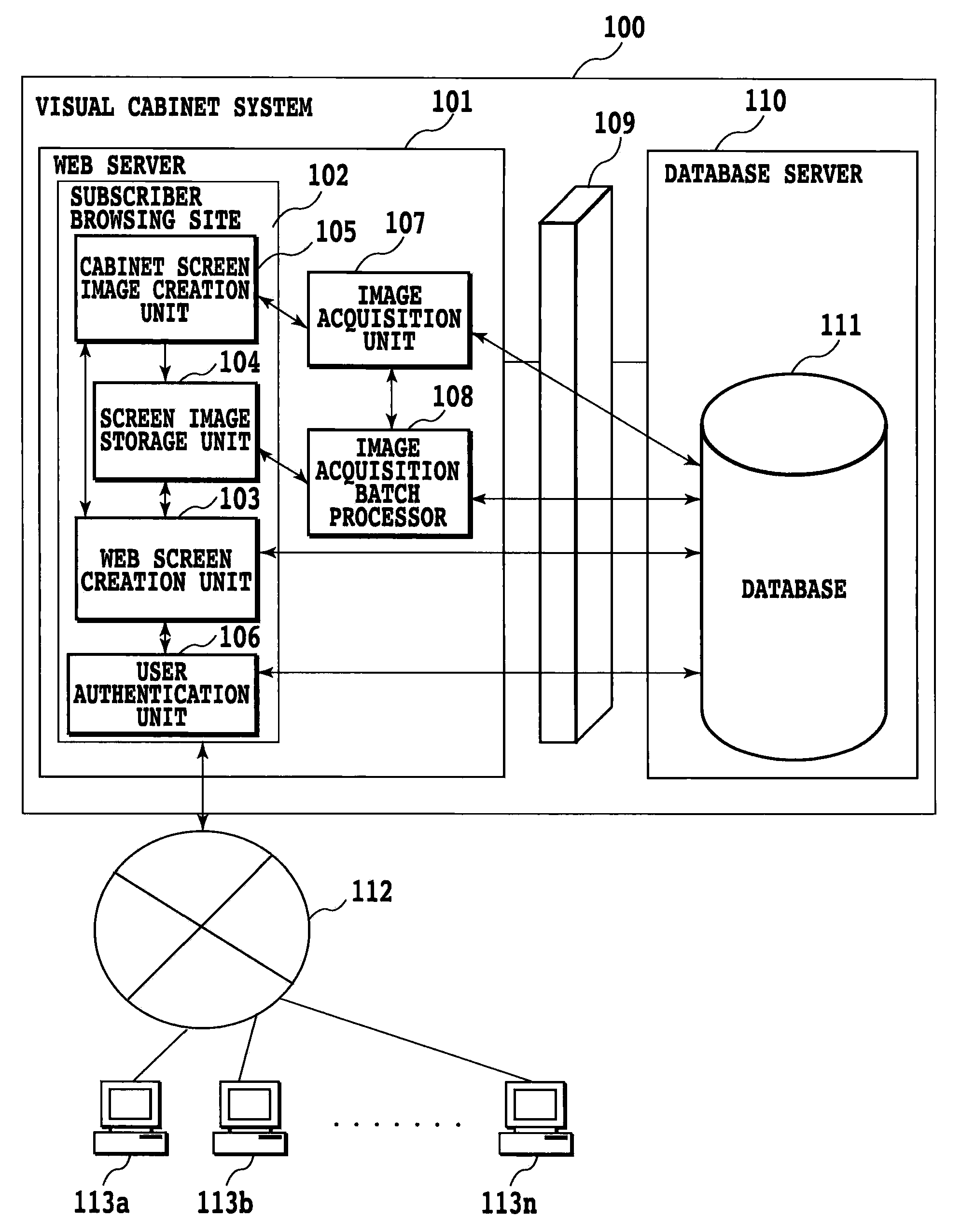

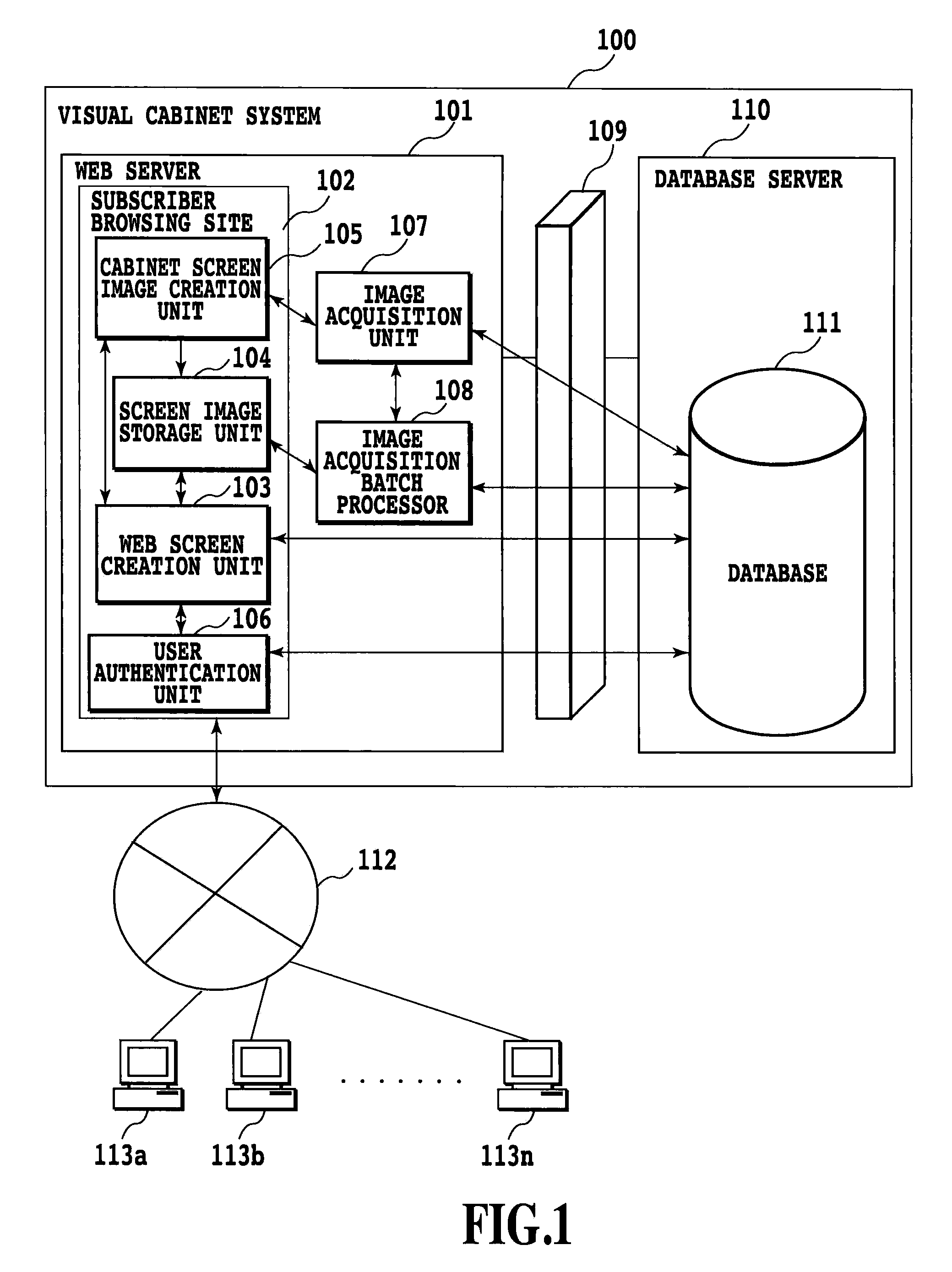

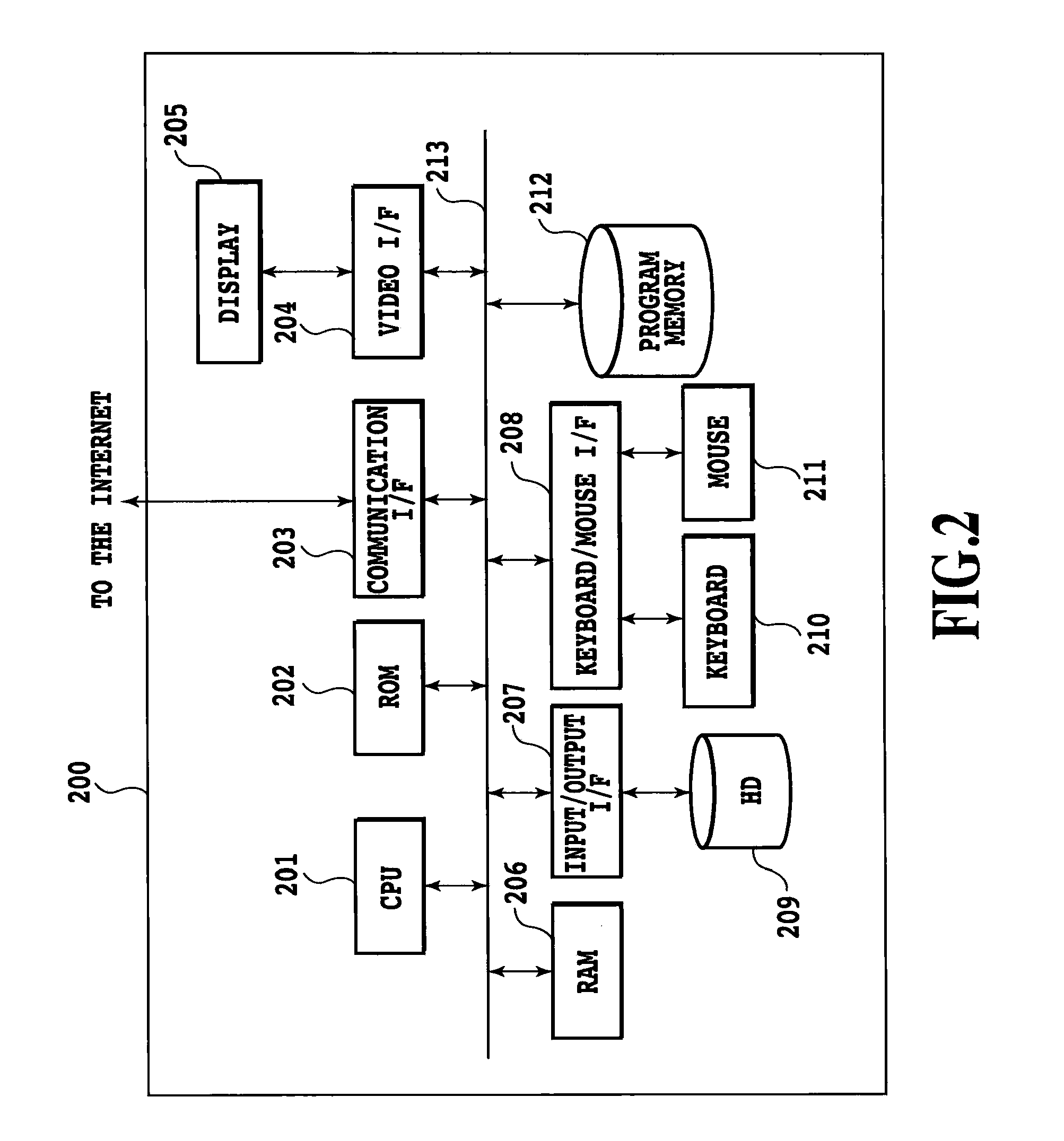

Visual cabinet system for data display method using its system

InactiveUS20100122179A1User identity/authority verificationMultiple digital computer combinationsData displayWeb service

A client-oriented system whereby a user can visually comprehend an itemized outline to immediately confirm the contents of data is provided. This system includes a WEB server and a database server. The WEB server includes a user browsing site, an image acquisition site and a screen image batch processor that accesses the data table of a database for a predetermined period of time and requests the image acquisition site to create a screen image associated with the new / updated data and obtains the screen image if there is new data and updated data. The user browsing site also includes a WEB screen creation unit that, when an authenticated user requests to display a predetermined screen associated with one of the data IDs included in user and data tables, creates the screen by providing a link for the obtained screen image for transition to another screen corresponding to the screen image.

Owner:SOMPO JAPAN INSURANCE

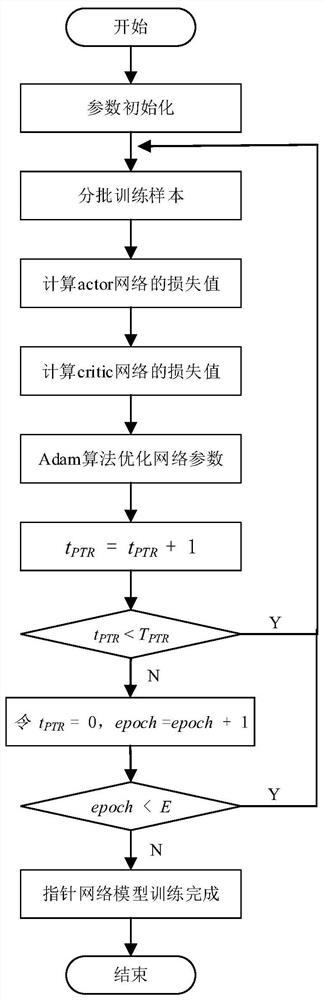

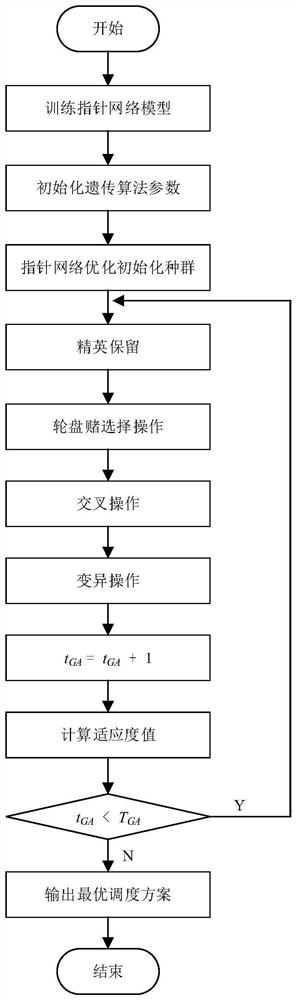

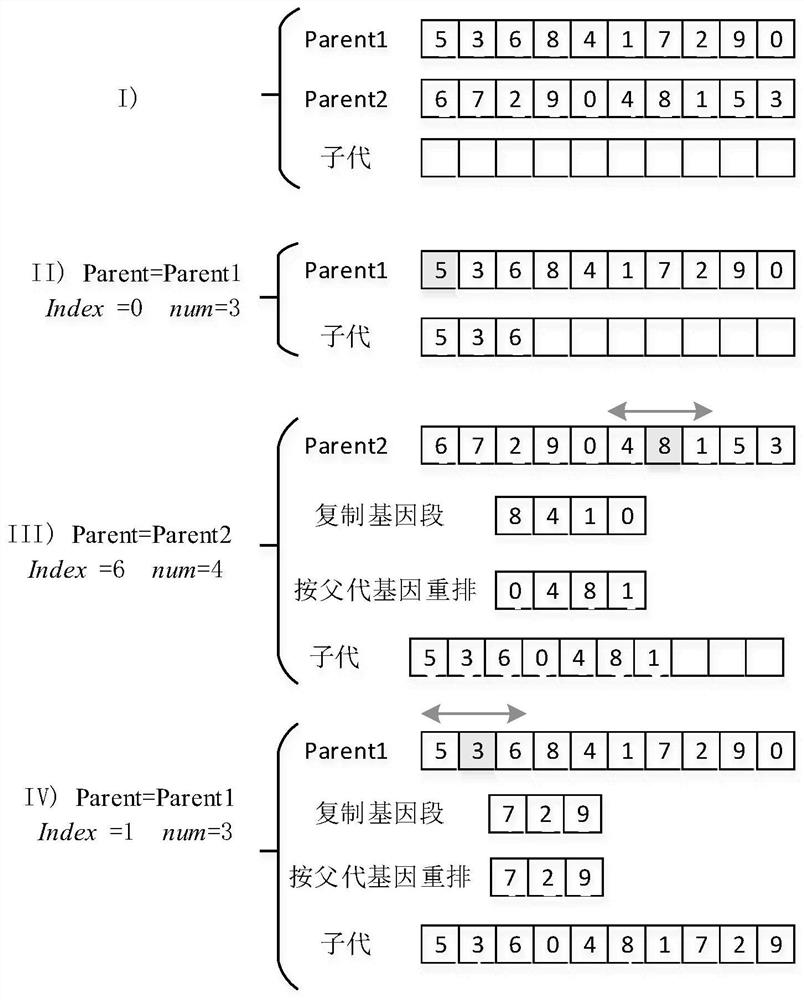

Batch scheduling optimization method based on deep reinforcement learning and genetic algorithm

ActiveCN112488315AQuality improvementImprove generalization abilityForecastingCharacter and pattern recognitionAlgorithmBatch machine

The invention belongs to the field of production and manufacturing scheduling, and discloses a batch scheduling optimization method based on deep reinforcement learning and a genetic algorithm, and the method comprises the steps: building a mathematic model of a difference workpiece batch scheduling problem; establishing a strategy model of the problem by adopting a pointer network; training a pointer network model by using an actor-critic algorithm; defining and initializing parameters of a genetic algorithm; optimizing the initial population of the genetic algorithm by using the trained pointer network; further optimizing the scheduling scheme by adopting a genetic algorithm; and the optimal scheme obtained by the genetic algorithm being used as a production scheme for processing workpieces by the batch processor. Compared with a traditional heuristic algorithm, the pointer network can obtain a better solution; in addition, in the crossover operation of the genetic algorithm, a novelcrossover mode is provided, and the performance of the scheme can be further improved by improving the optimization capability of the genetic algorithm on the basis of the scheduling scheme obtainedby the pointer network.

Owner:HEFEI UNIV OF TECH

Systems and methods for queuing an action in industrial automation systems

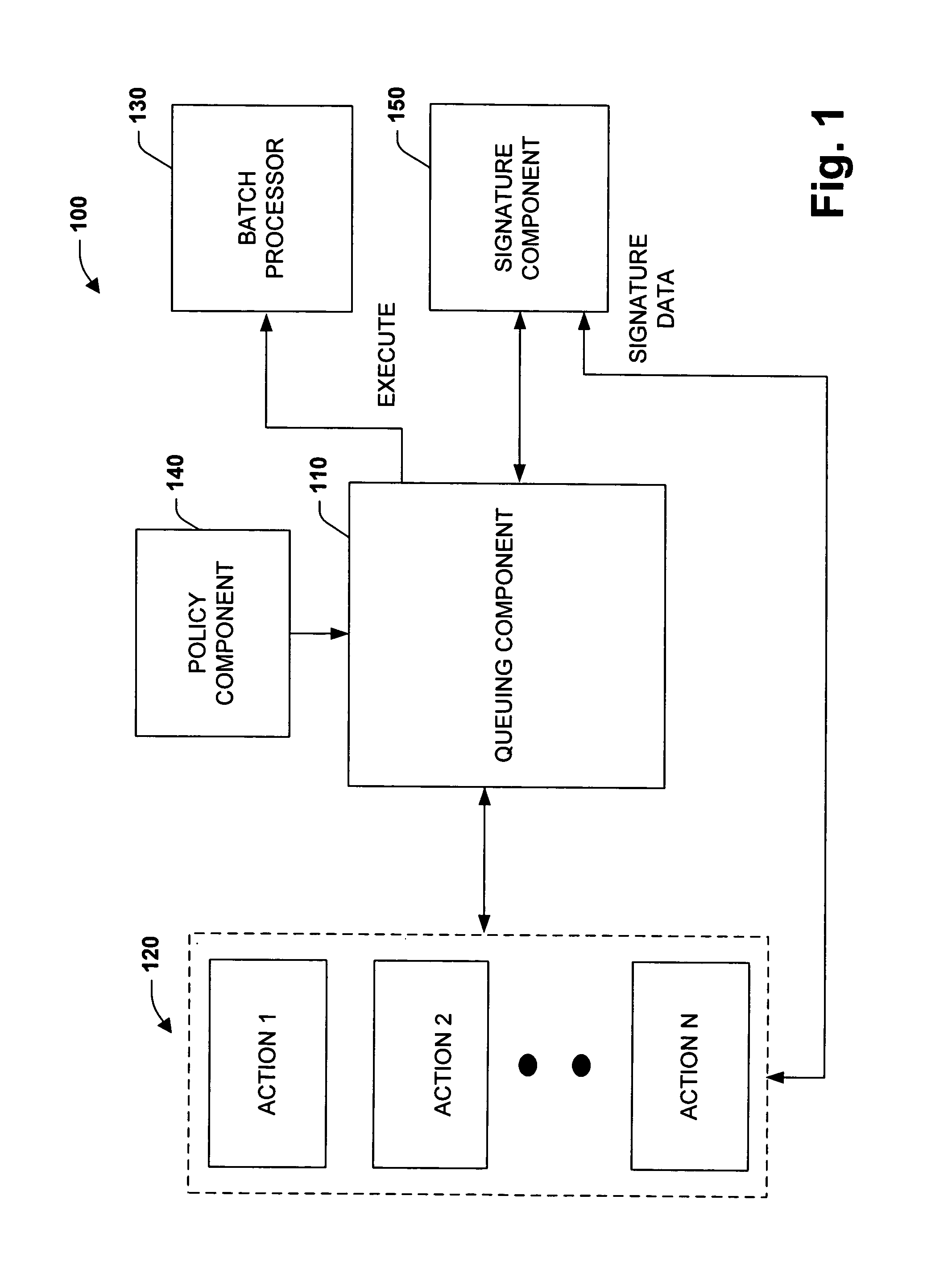

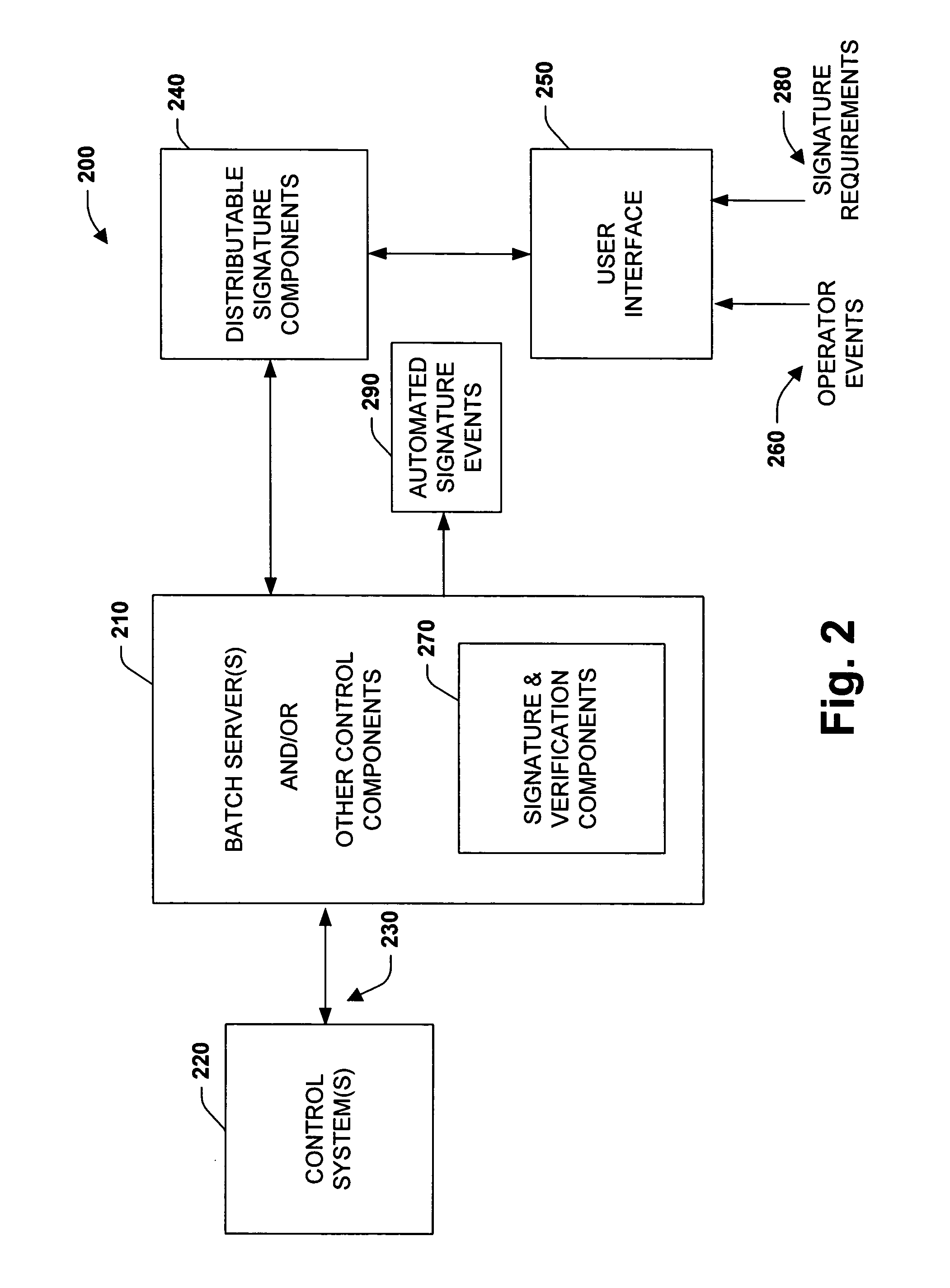

InactiveUS20110230991A1User identity/authority verificationSpecial data processing applicationsMultiple criteriaDistributed computing

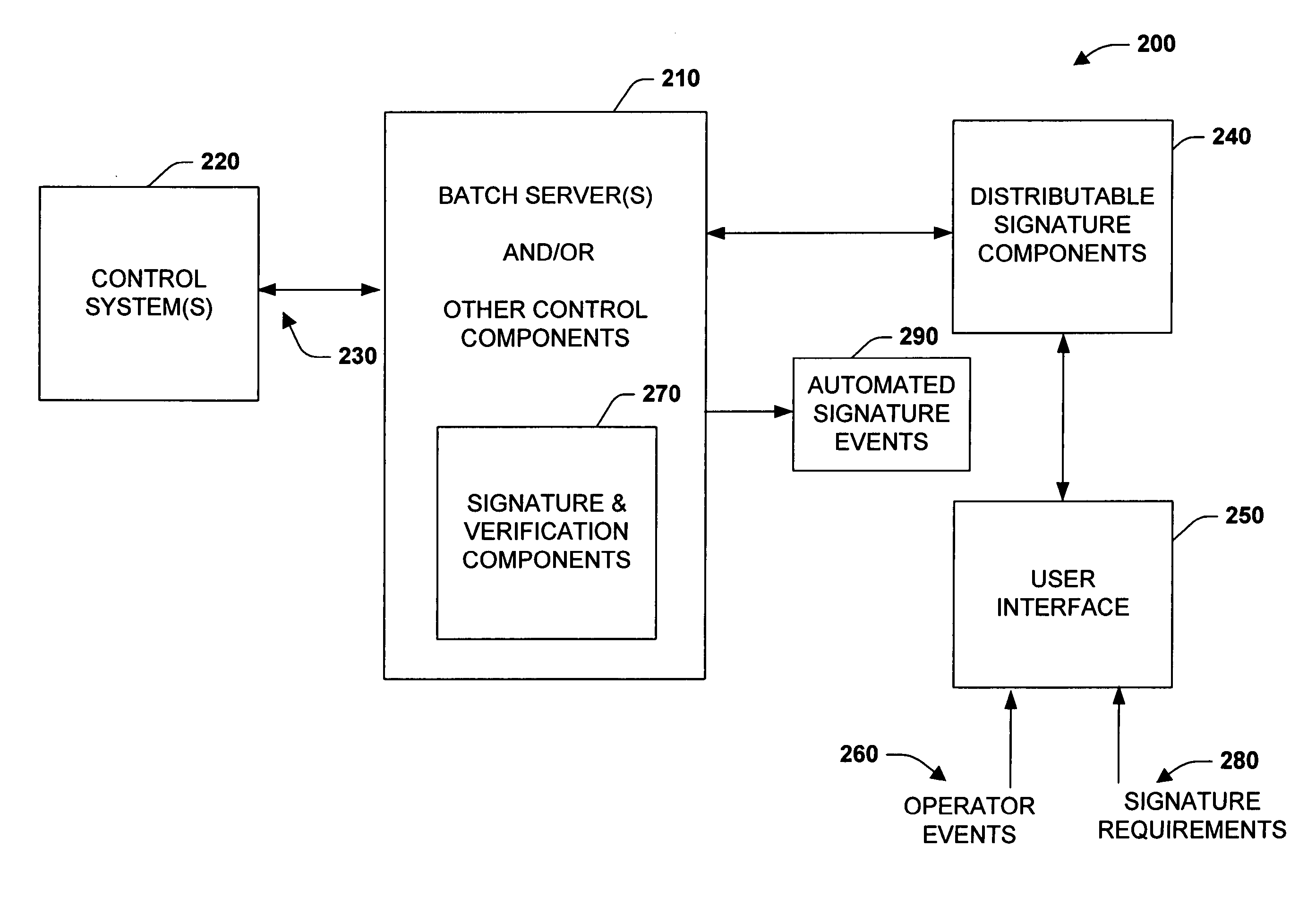

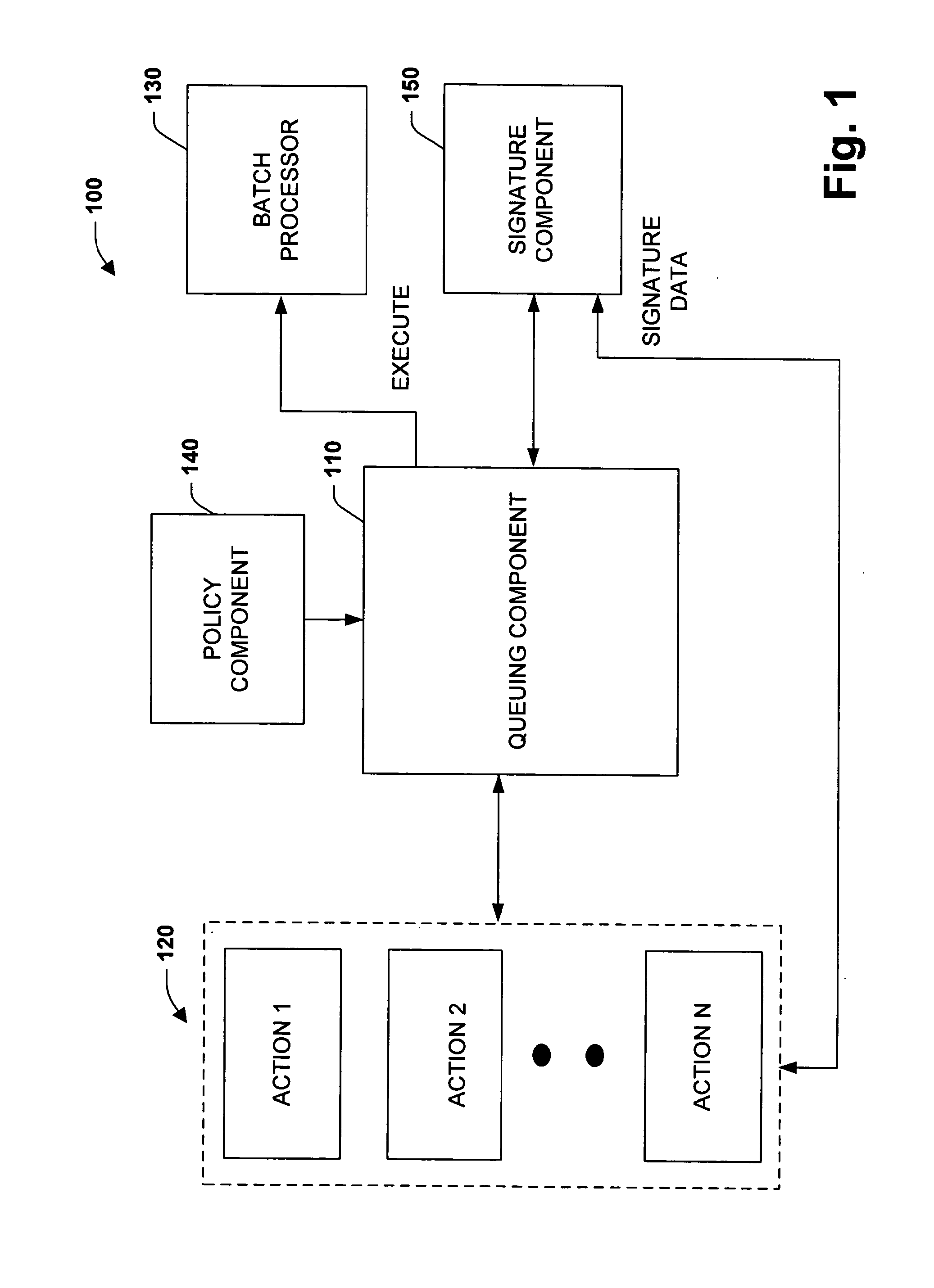

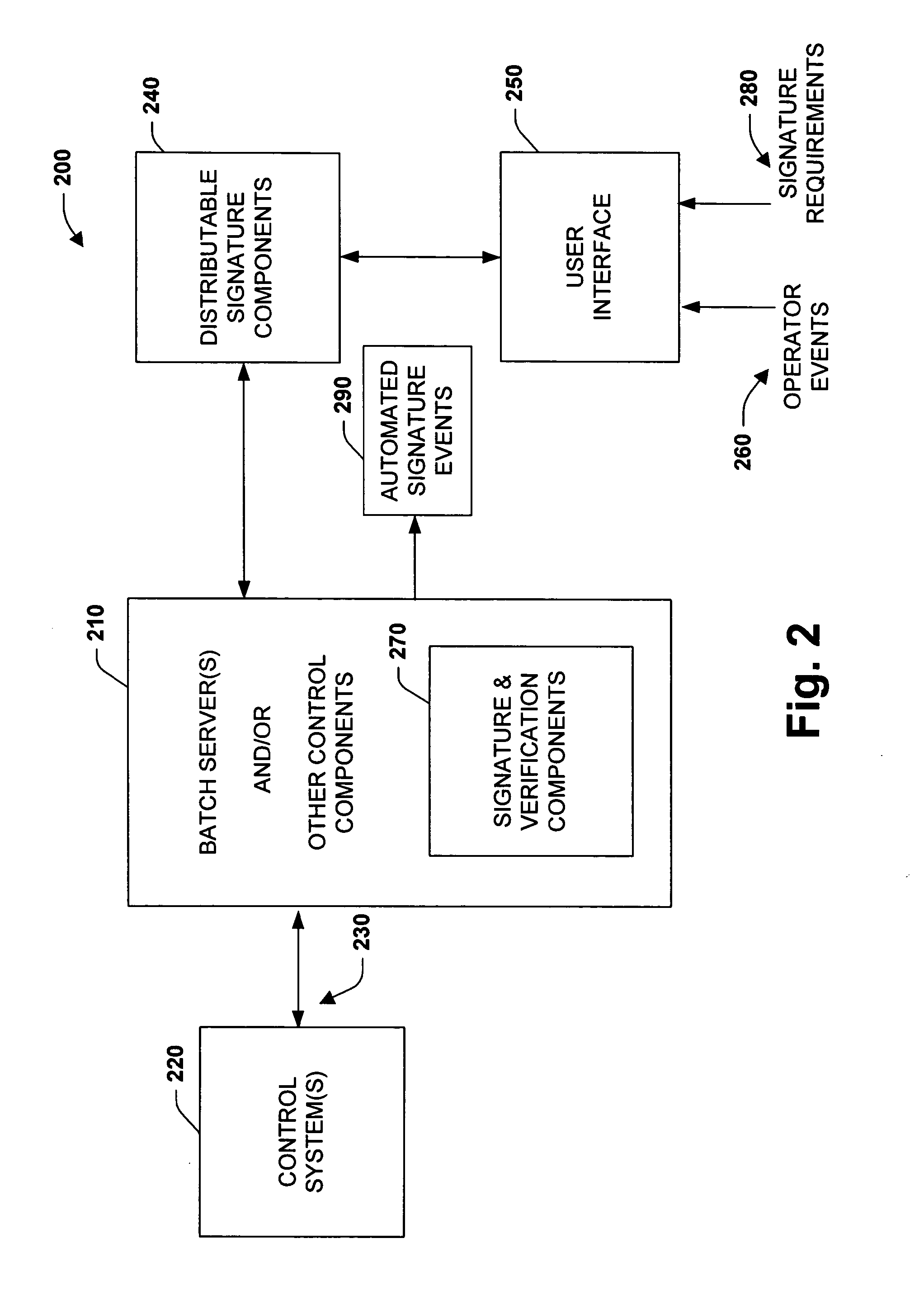

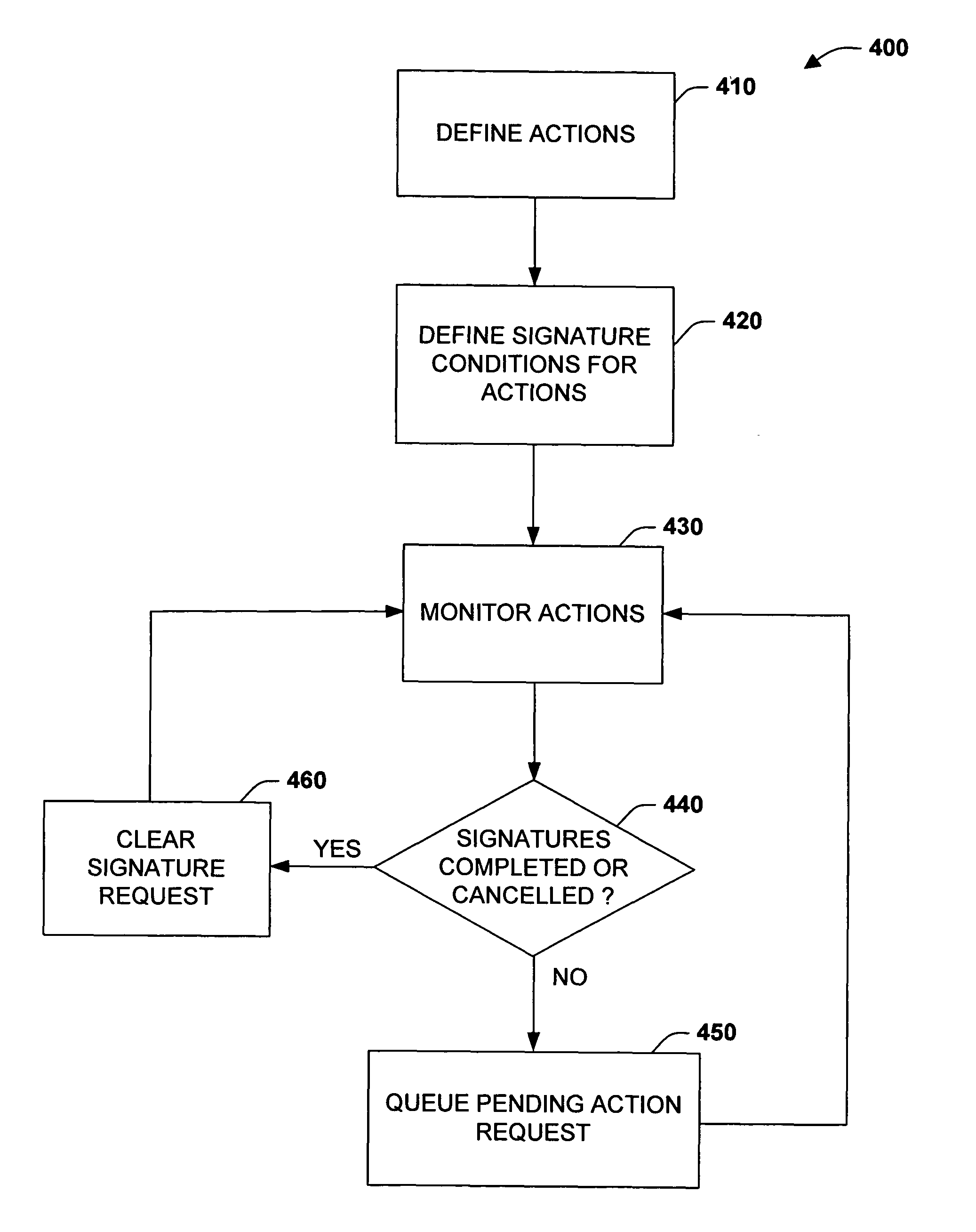

The subject invention relates to a system and methodology facilitating automated manufacturing processes in a regulated industrial controller environment, wherein operator commands are tied to one or more signature requirements before the requested commands take effect in a batch system. In one aspect, a system is provided for signature processing in an industrial control environment. The system includes a queuing component to hold a pending request for an action. A signature component then determines when an electronic signature is completed for the action, wherein a batch processor executes the action from the queuing component after the electronic signature is completed. A policy component can be provided to define one or more conditions for completing the electronic signature.

Owner:ROCKWELL AUTOMATION TECH

Systems and methods for queuing an action in industrial automation systems

ActiveUS7979706B1Well formedMemory loss protectionError detection/correctionMultiple criteriaDistributed computing

The subject invention relates to a system and methodology facilitating automated manufacturing processes in a regulated industrial controller environment, wherein operator commands are tied to one or more signature requirements before the requested commands take effect in a batch system. In one aspect, a system is provided for signature processing in an industrial control environment. The system includes a queuing component to hold a pending request for an action. A signature component then determines when an electronic signature is completed for the action, wherein a batch processor executes the action from the queuing component after the electronic signature is completed. A policy component can be provided to define one or more conditions for completing the electronic signature.

Owner:ROCKWELL AUTOMATION TECH

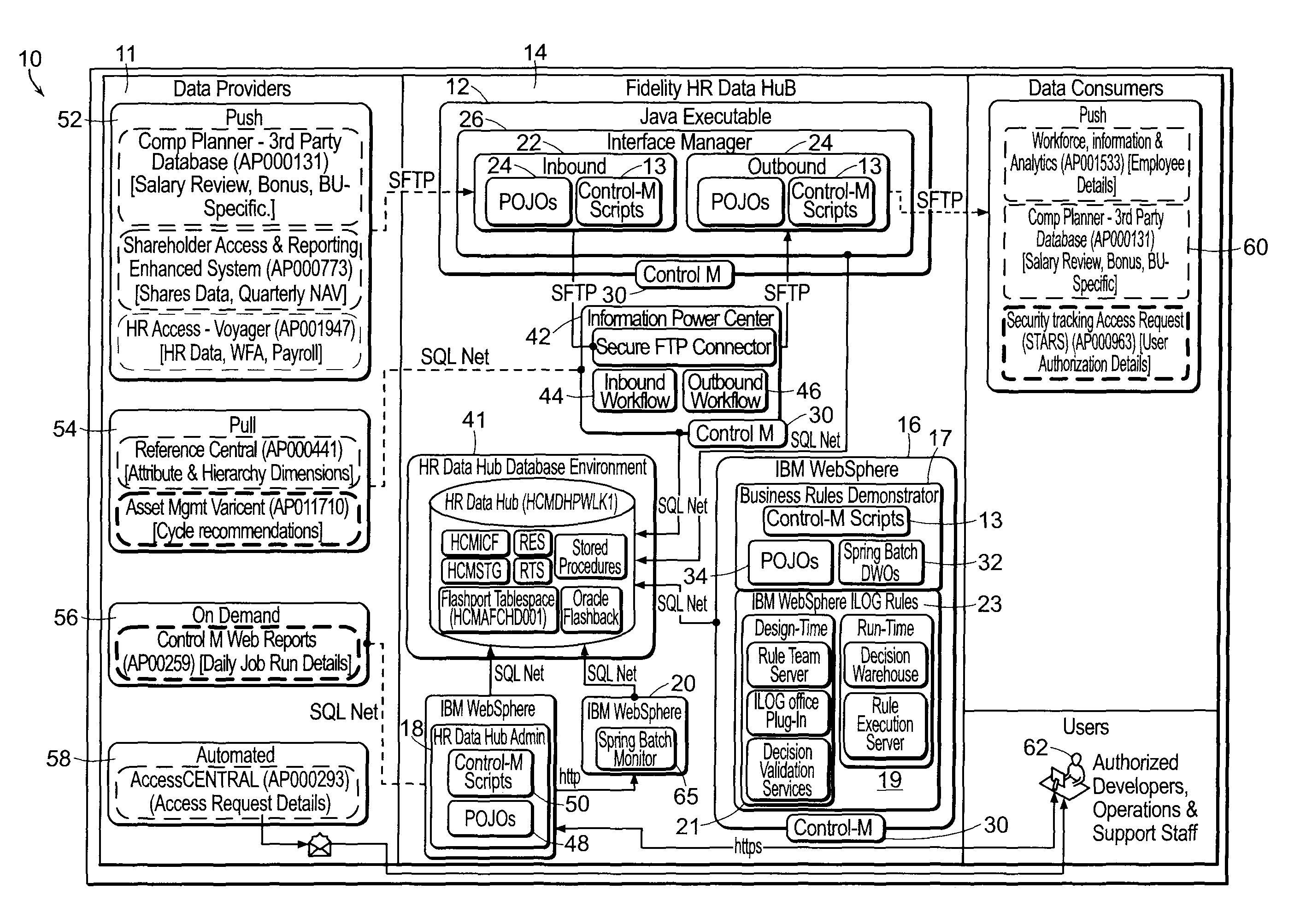

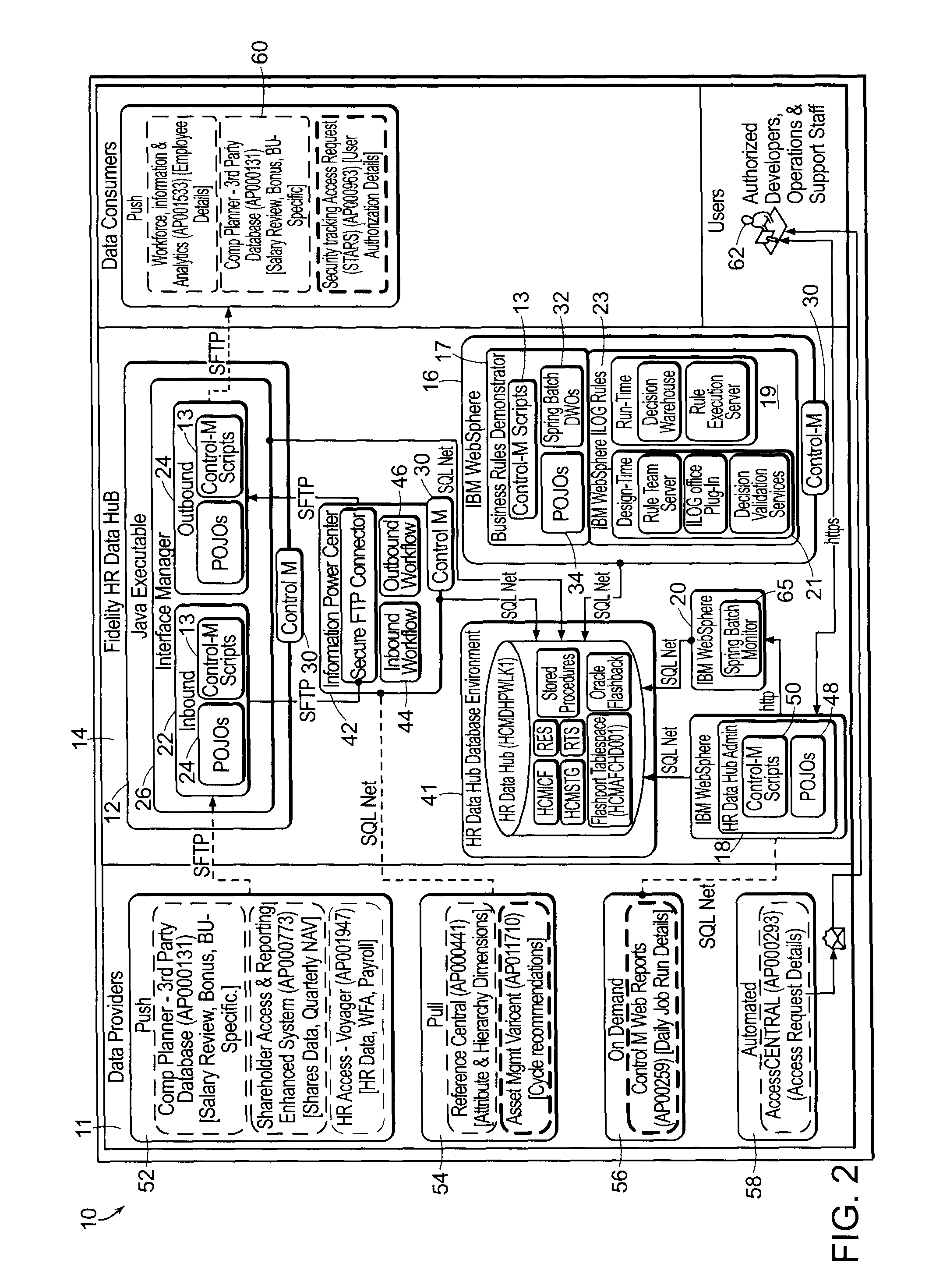

Business rules batch processor

A business rules batch processor is provided that includes a business rules manager that sends a plurality of pending requests to a rules database for processing. A business rules orchestrator receives statuses of the pending requests from the business rules manager. The business rules orchestrator manages the batch processing of the pending requests by assessing the rules database usage and job requirements of the pending requests.

Owner:FMR CORP

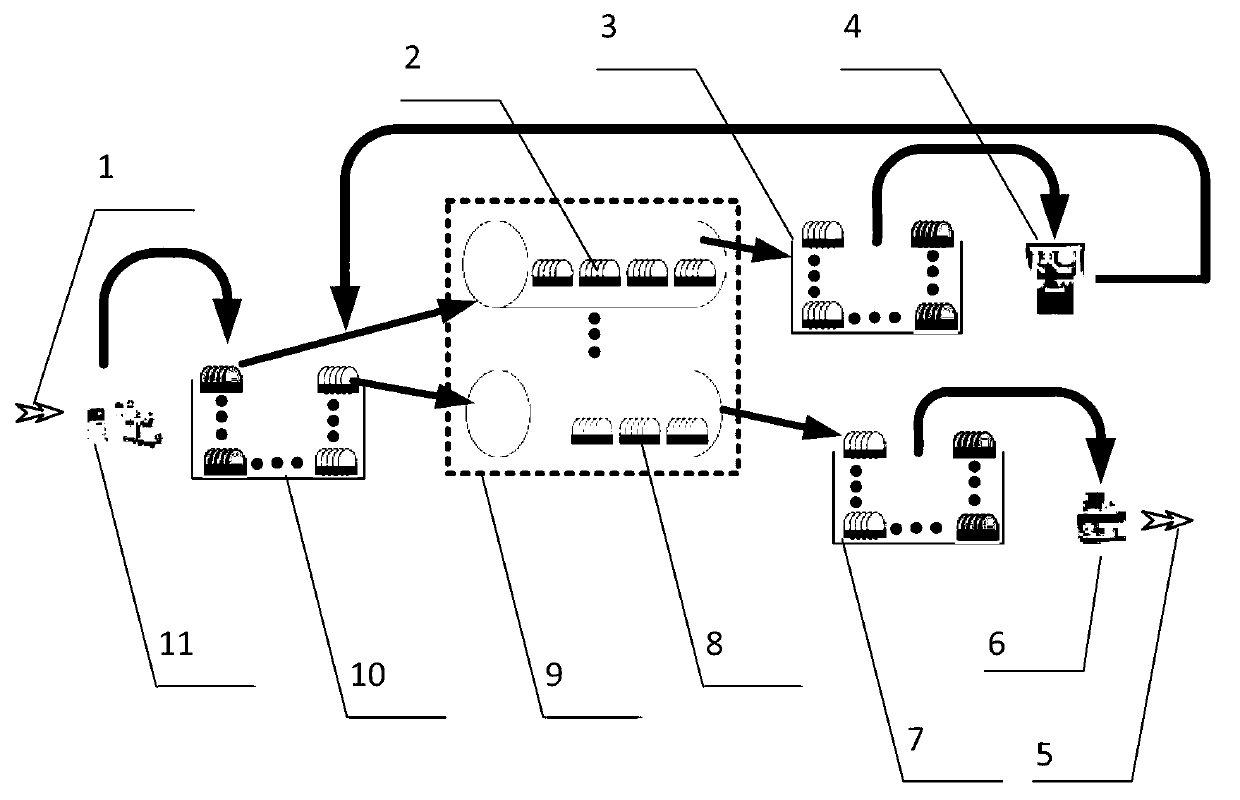

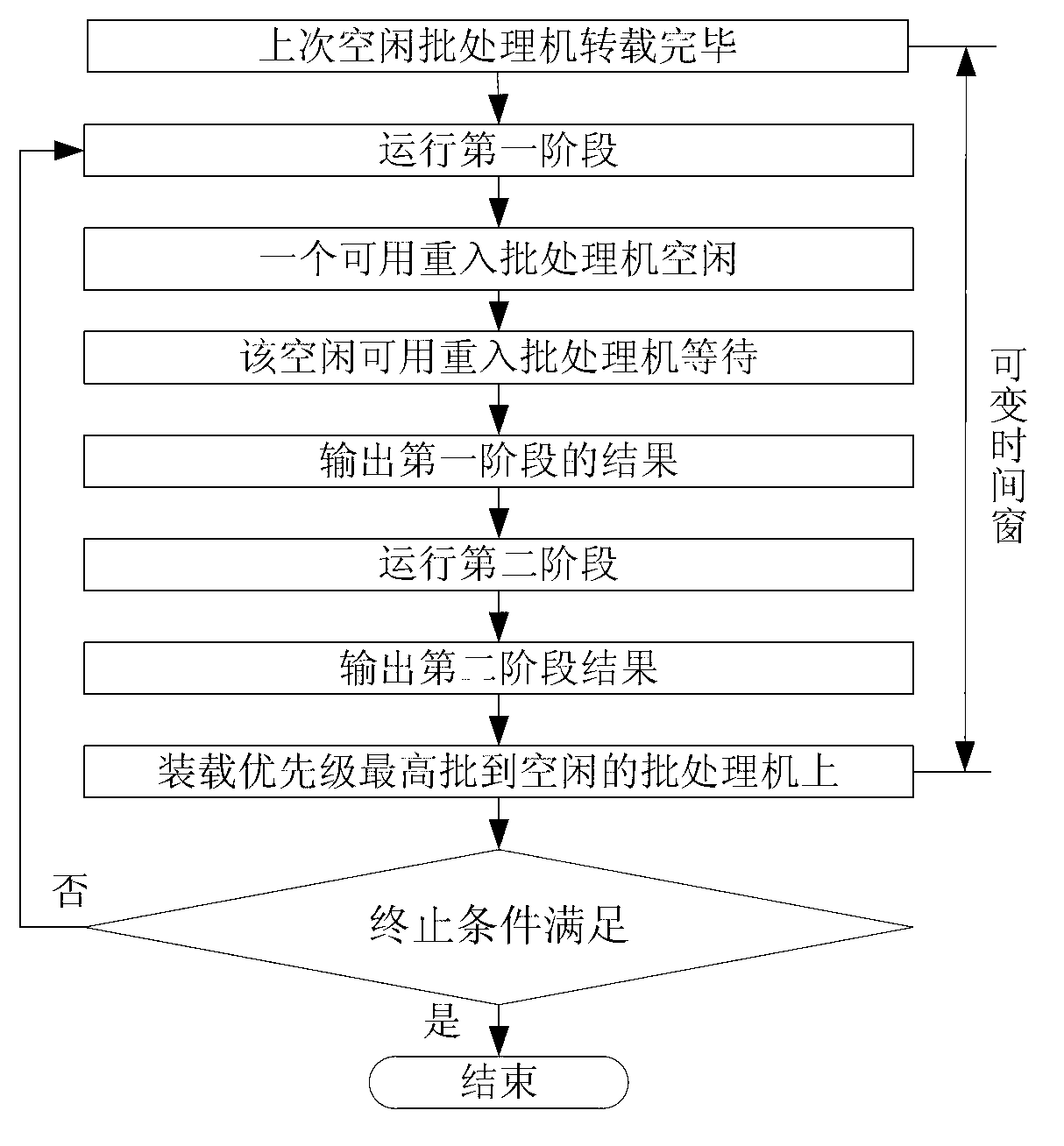

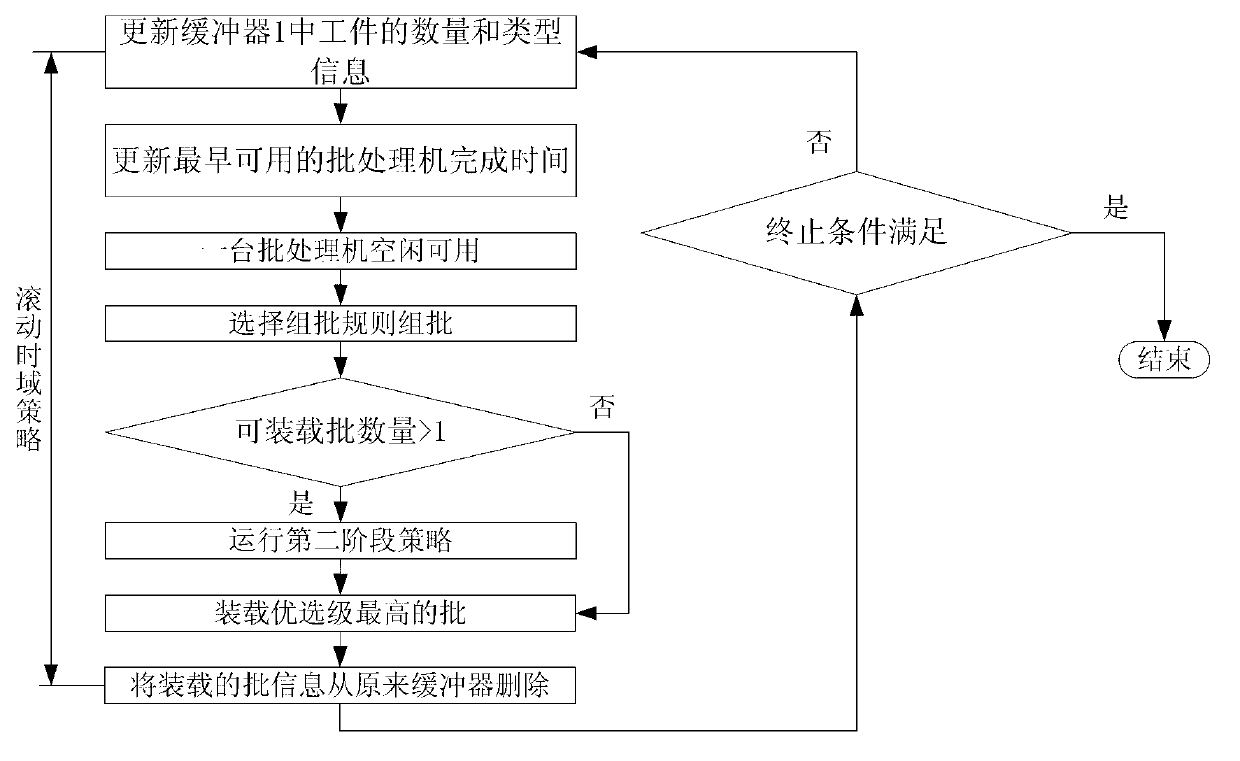

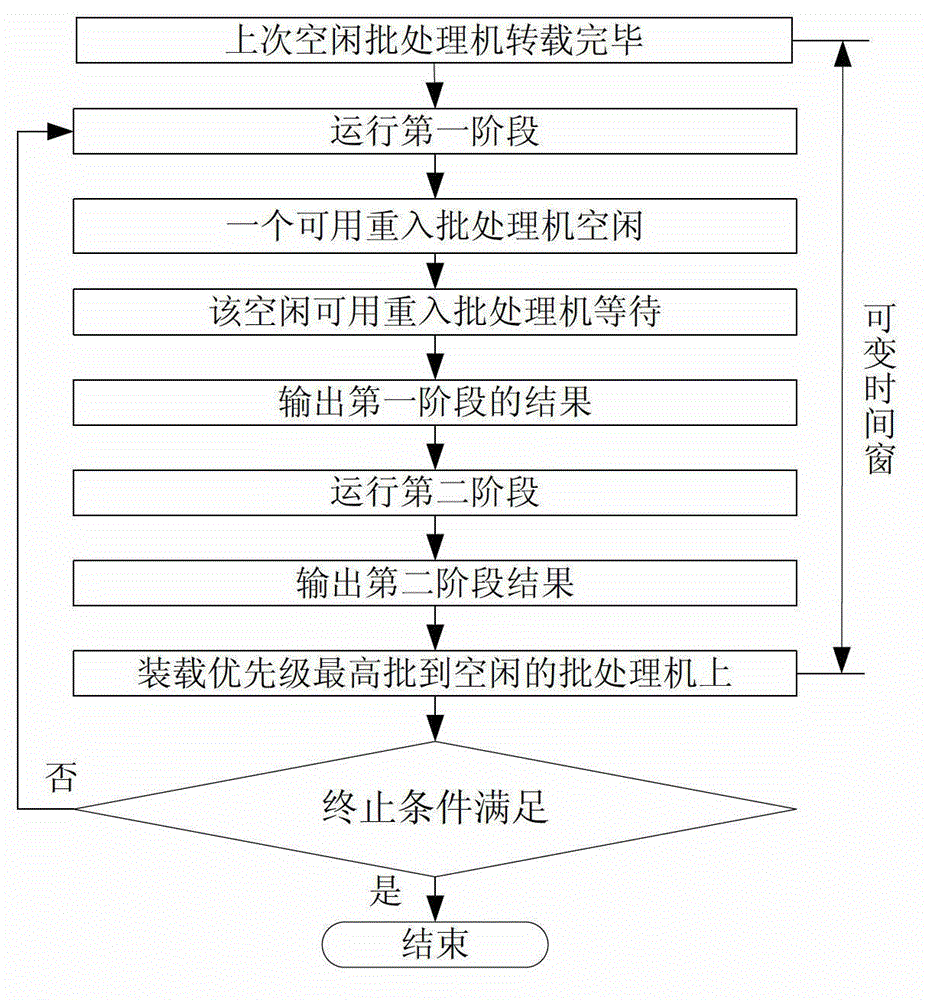

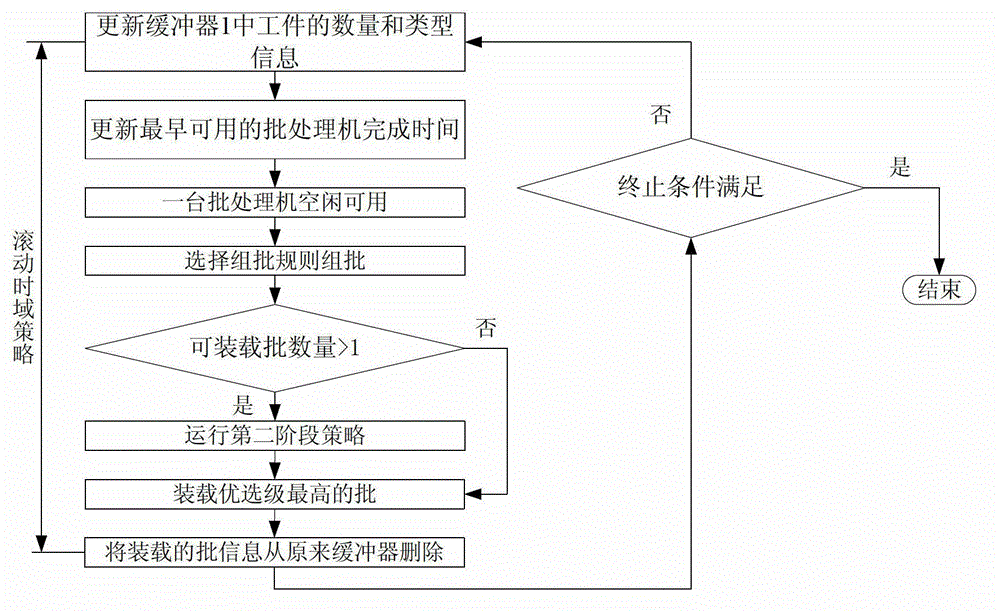

Method used for implementing two-stage mixing optimized batch processing scheduling and based on variable time window

InactiveCN103105837AMeet the dynamic real-time scheduling characteristicsTotal factory controlProgramme total factory controlDecompositionMathematical model

The invention provides a method used for implementing two-stage mixing optimized batch processing scheduling and based on a variable time window. According to the method, a decomposition rule of a complex problem is used, an aim of smallest total weighting delaying time is achieved, and two-stage mixing control is implemented. A first stage comprises the steps of based on a multi-rule combined self-adaptive principle, establishing a real-time control platform, adopting a variable time window rolling time domain method to obtain real-time parameters of patch combination and the like. A second stage comprises the steps of based on a flabby method, establishing a flabby linear integer mathematical model, obtaining a solution through a combined engineer of .NET and ILOG CPLEX commercialized software, and obtaining optimized order of batch sequencing. According to the two stages, lot grouping and sequencing for lot grouping in the batch scheduling problem are respectively solved, a multi-entrance property of a batch processor is considered, and according to the variable time window rolling time domain method, a dynamic state real-time scheduling property of machined work piece batches is met. According to the method used for implementing the two-stage mixing optimized batch processing scheduling and based on the variable time window, scheduling accuracy and operating time of a central processing unit (CPU) are considered in a comprehensive mode, real-time optical scheduling of a reentrant next batch processor can be achieved, and the method is beneficial to being popularized and applied in semiconductor field and the like.

Owner:SHANGHAI JIAO TONG UNIV

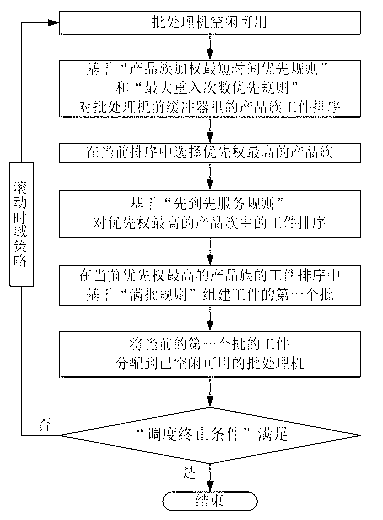

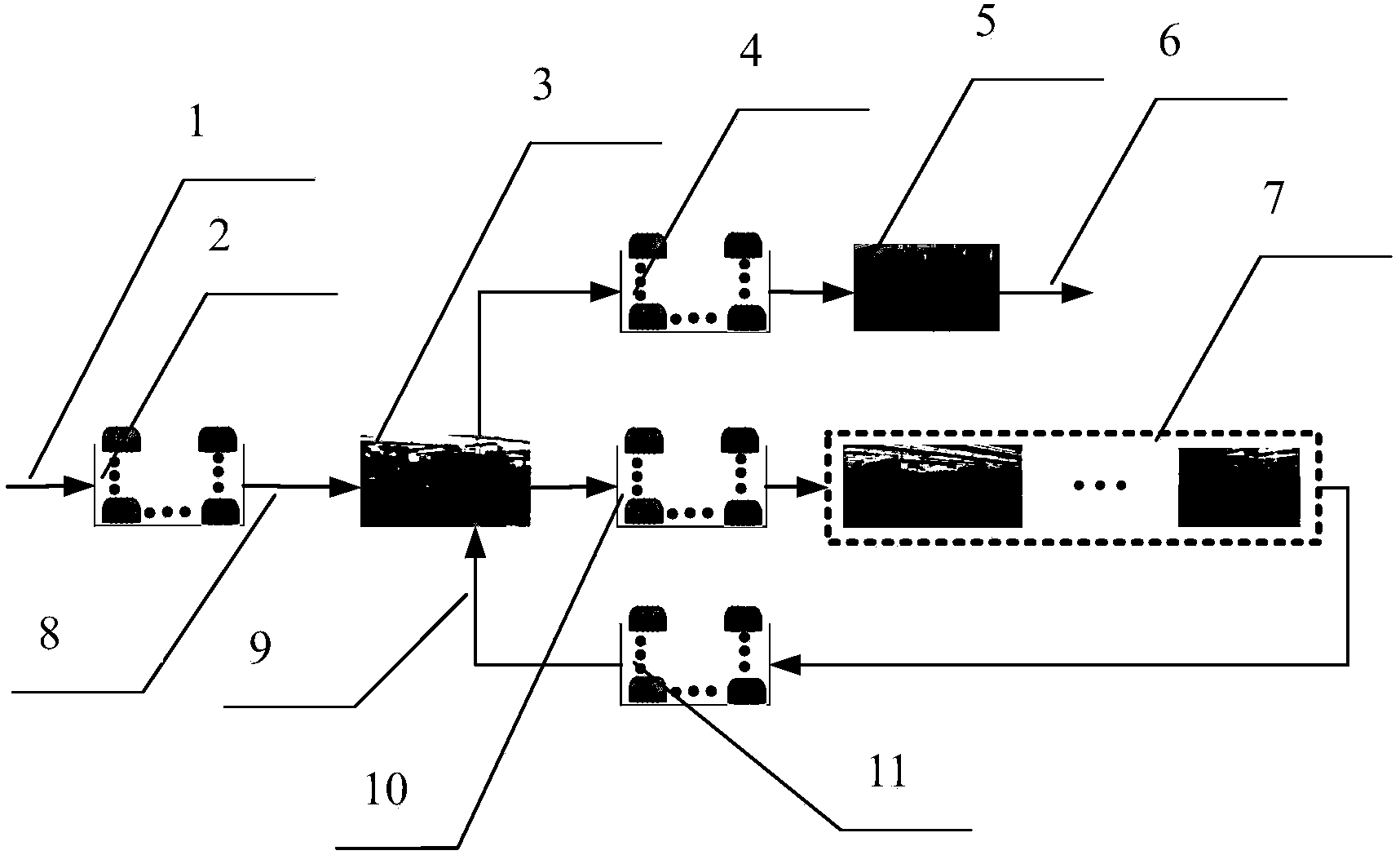

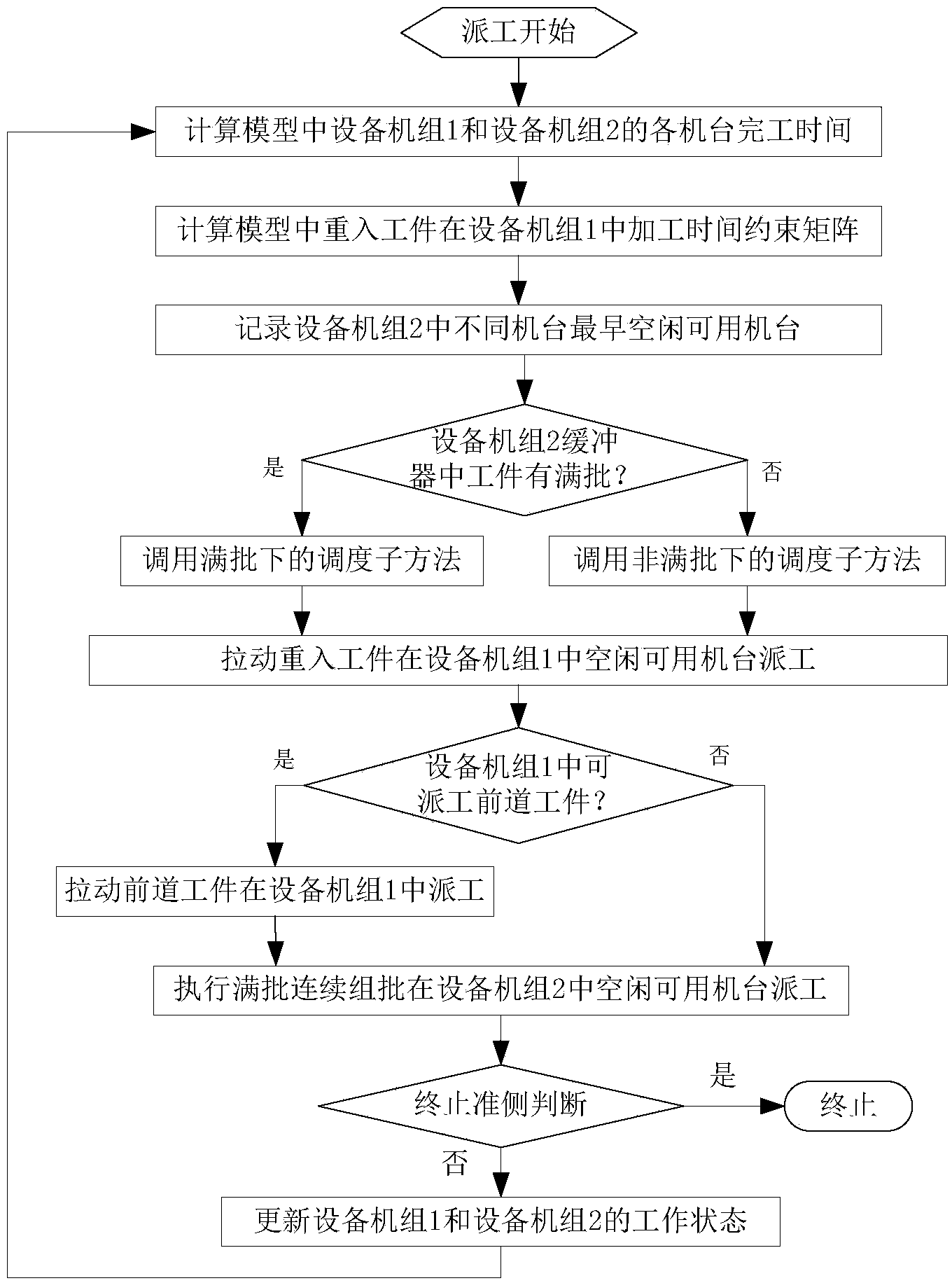

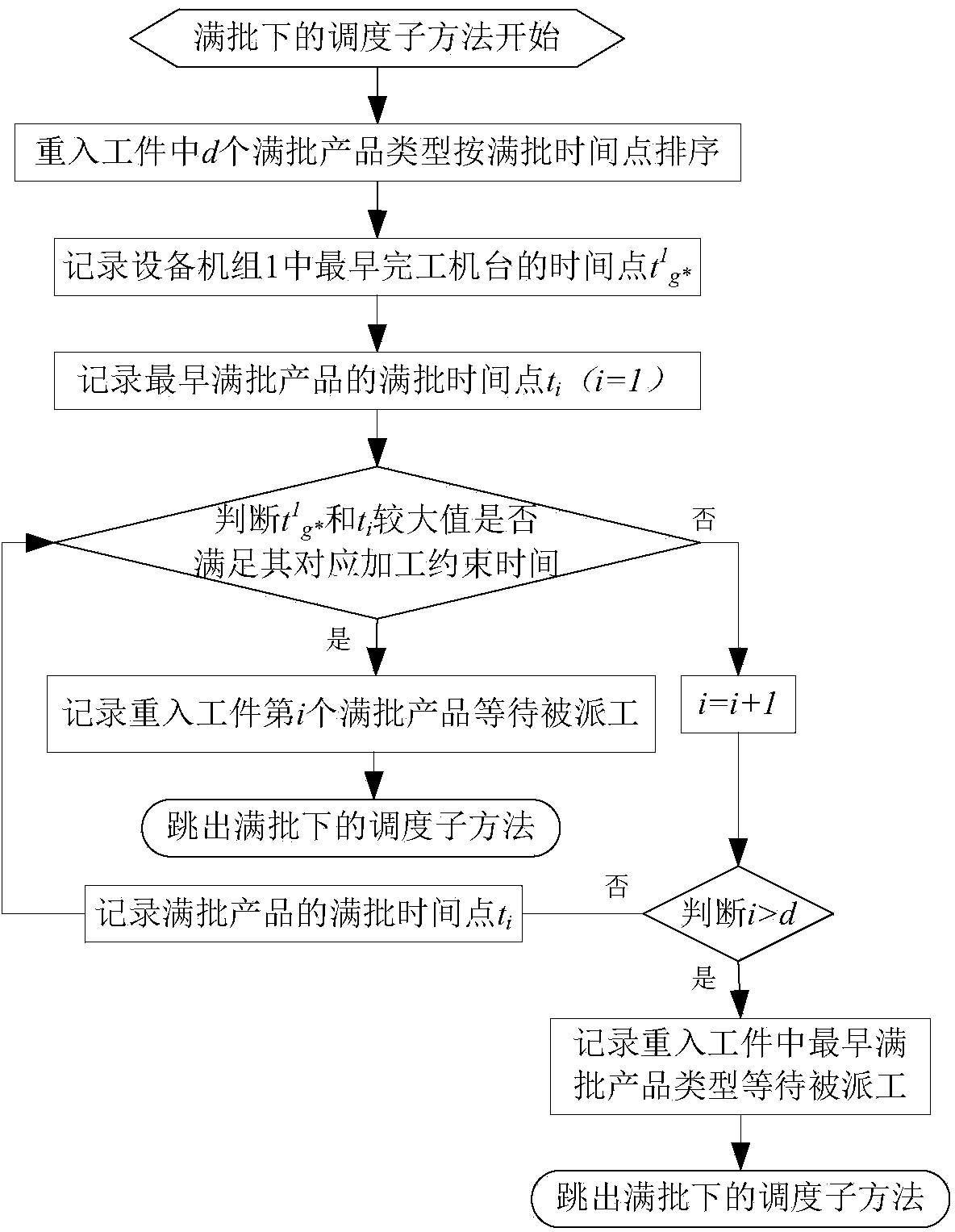

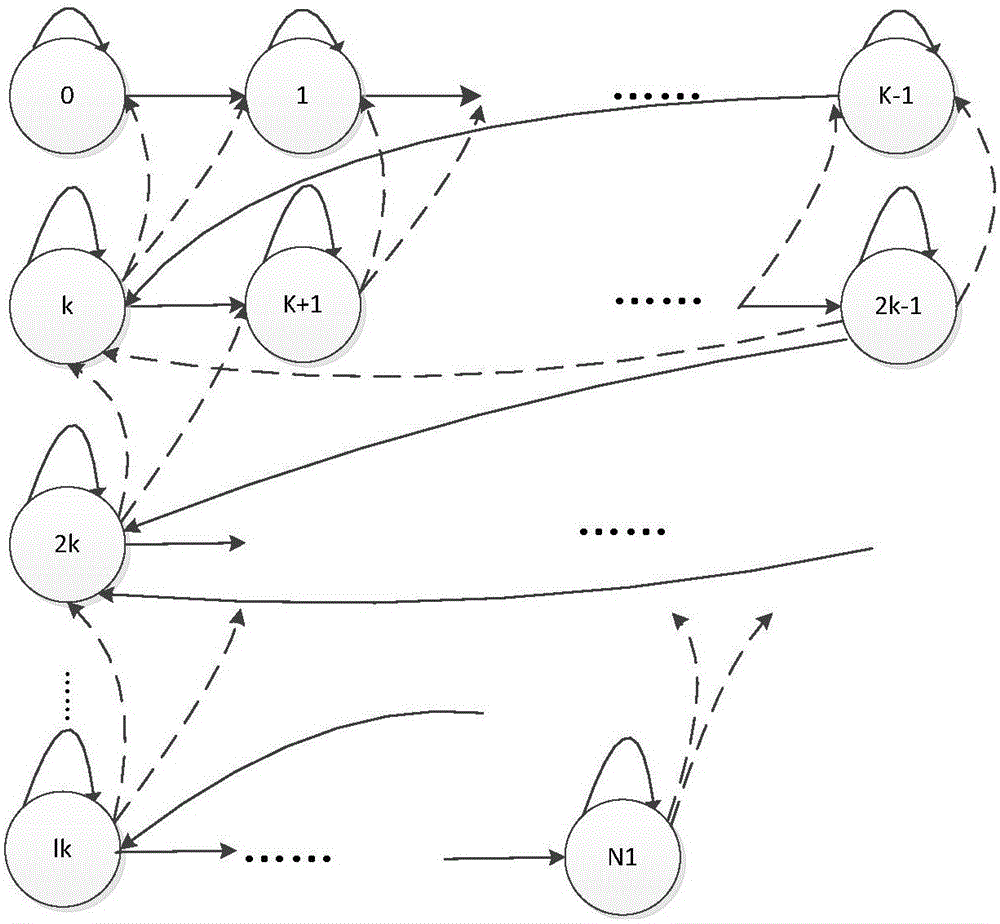

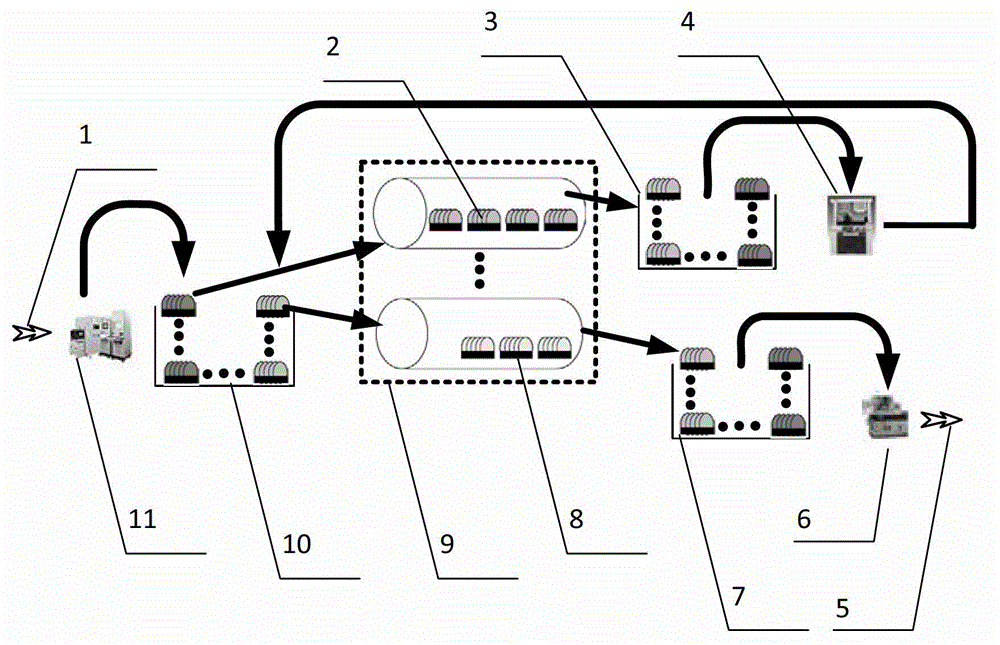

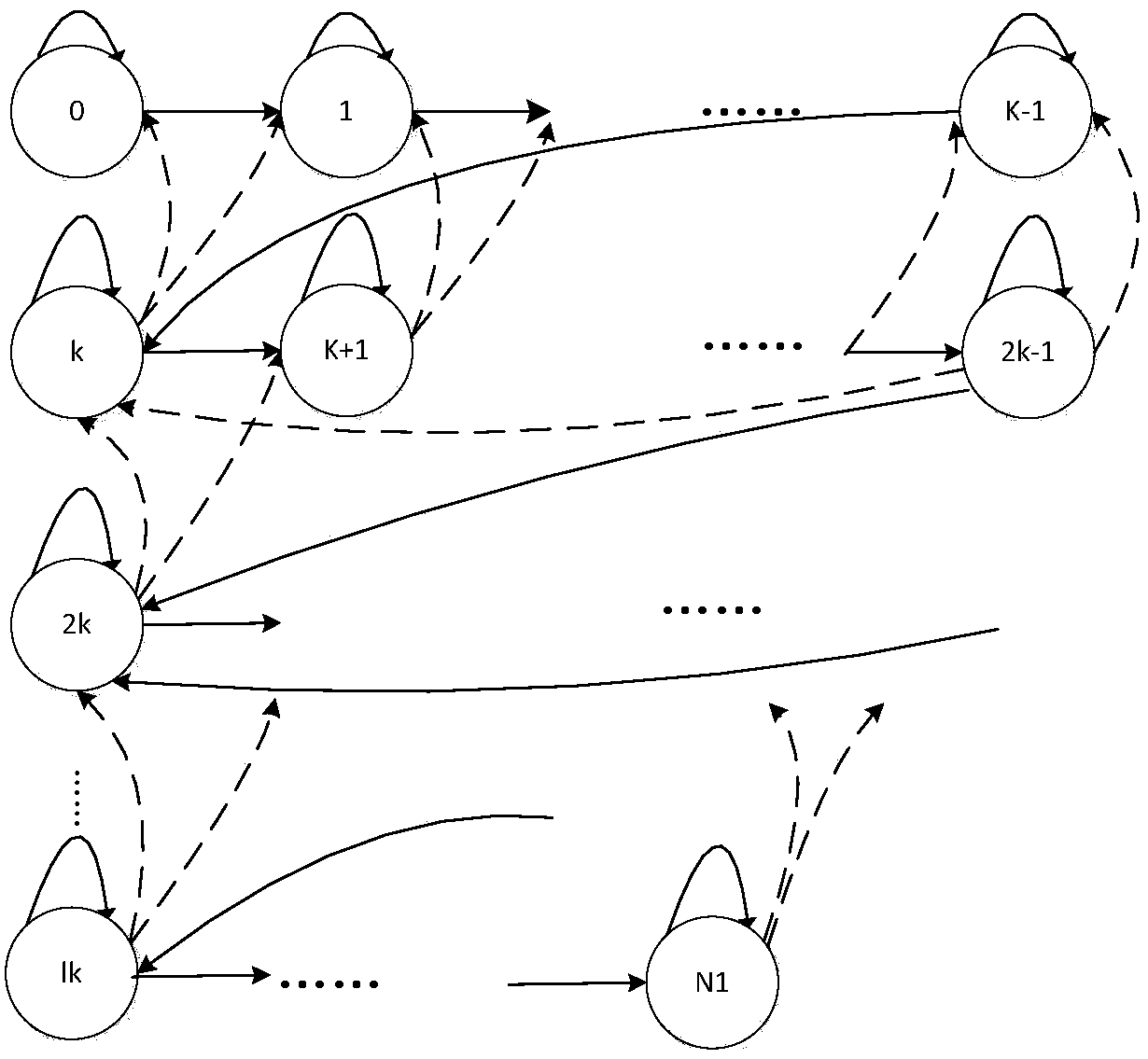

Dispatching control method for batch processor of reentrant manufacturing system

InactiveCN103927689AIn line with the actual situation of the production siteGood collaborative manufacturingData processing applicationsManufacturing computing systemsBatch operationSemiconductor chip

The invention provides a dispatching control method for a batch processor of a reentrant manufacturing system. The dispatching control method comprises a primary dispatching control method based on the pull rule, a subsidiary dispatching control method based on the pull rule under a full-batch circumstance and a subsidiary dispatching control method based on the pull rule under a non-full-batch circumstance. The actual requirement that a product maximum dead time limit exist between different equipment units is considered, continuous full-batch operation of the batch processor serves as the pull requirement, dispatching and lot grouping of workpieces of a previous process and reentrant workpieces are pulled, whether the full-batch requirement of the reentrant workpieces is met within a machining constraint time serves as a judgment condition, and the subsidiary dispatching control method based on the pull rule under the full-batch circumstance or the subsidiary dispatching control method based on the pull rule under the non-full-batch circumstance is called. According to the dispatching control method, good collaborative manufacturing between different equipment units is realized according to the pull rule, and the production dispatching requirement of the reentrant manufacturing system can be met. The dispatching control method is simple in conception, convenient to implement, and beneficial to popularization of reentrant manufacturing industries such as semiconductor chip manufacturing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

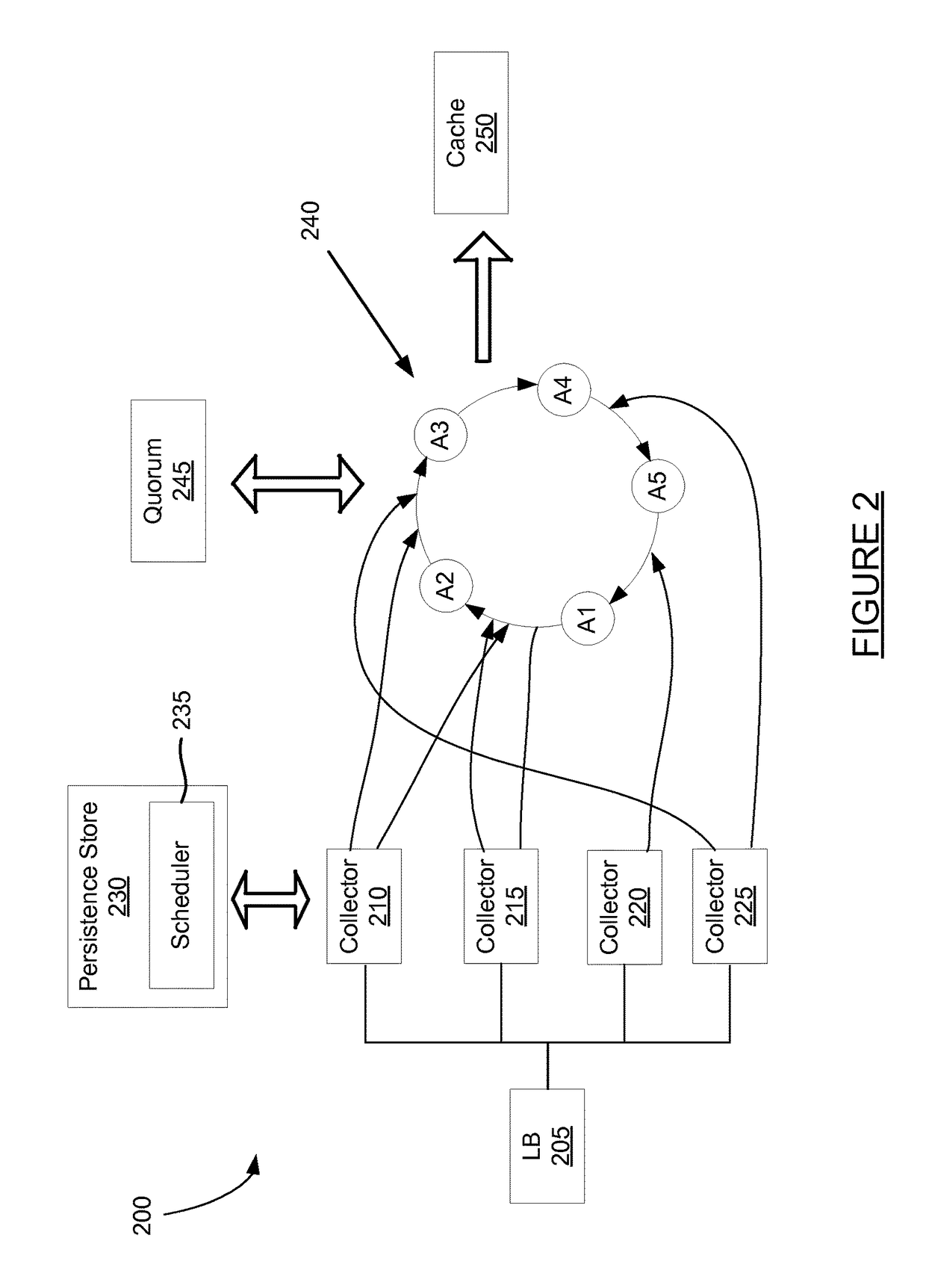

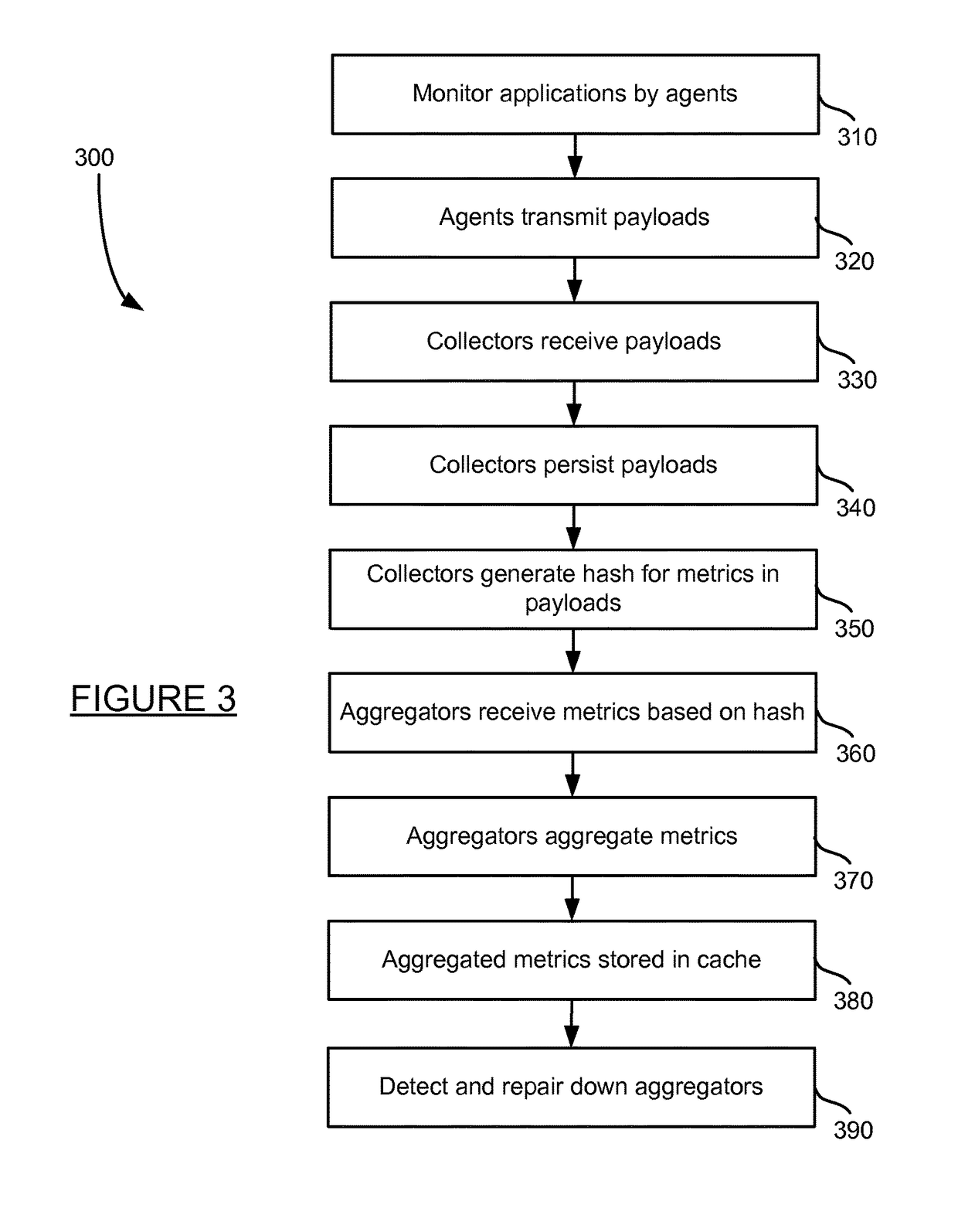

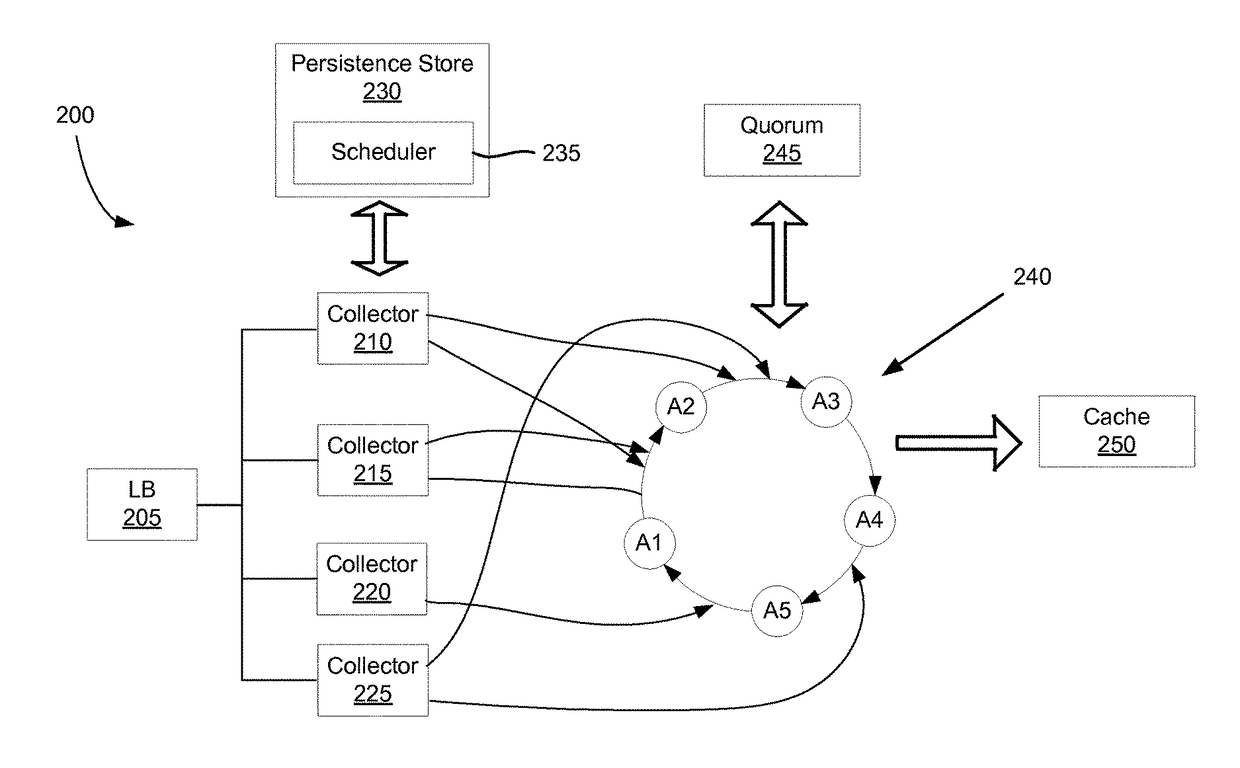

Quorum based aggregator detection and repair

Owner:CISCO TECH INC

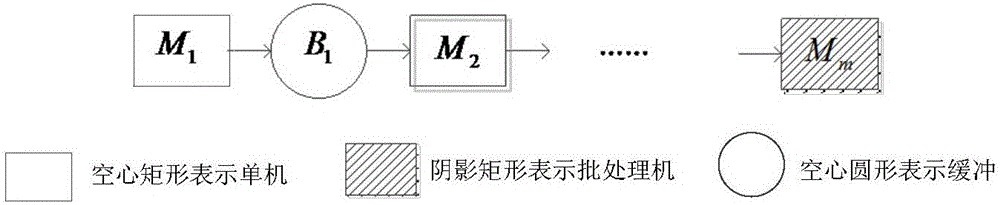

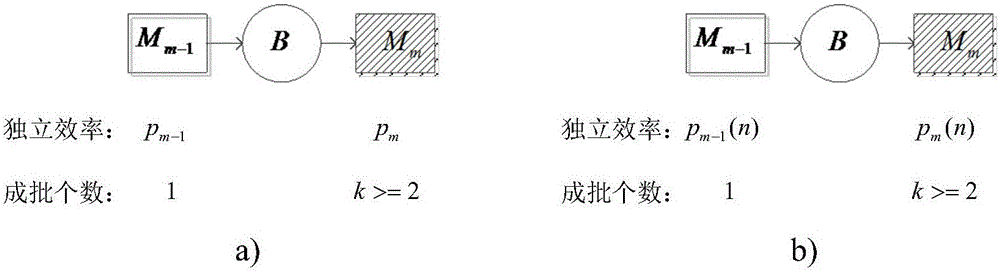

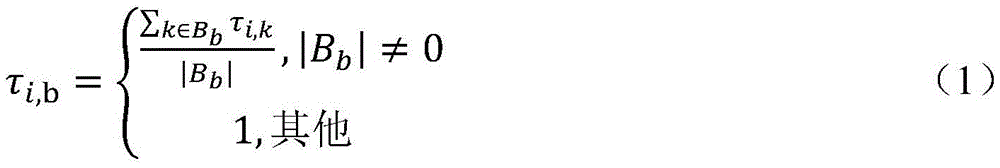

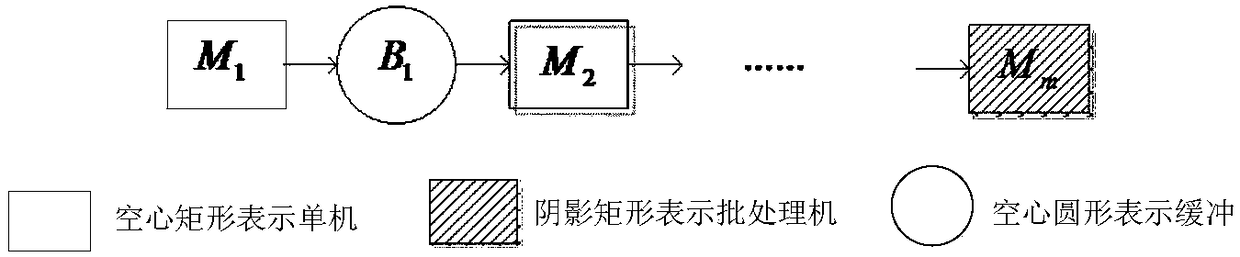

Batch processing pipeline performance evaluation method

ActiveCN105956295AVerify validityDesign optimisation/simulationResourcesProduction rateMulti machine

The invention provides a batch processing pipeline performance evaluation method. The method is used for evaluating batch processing pipeline average output and each buffer zone level and like indexes; the main existing problem of the batch processing pipeline performance evaluation problem is as follows: the solution of single machine+ batch processor two-machine precise model and the establishment of a batch processor pipeline decomposition equation. The specific process of the invention is as follows: 1, obtaining the precise solution of the two machine models of single machine+ batch processor and single machine+ single machine; 2, decomposing the pipeline containing multi-machine into a plurality of building blocks containing two-machine single-buffer, and establishing the decomposition equations aiming at the building blocks; 3, solving the equations through an iterative method (PDDX method), and finally obtaining the performance index of the pipeline: production yield and number of work in process; 4, performing numerical contrast through summation simulation result to verify the rationality of the method provided by the invention.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

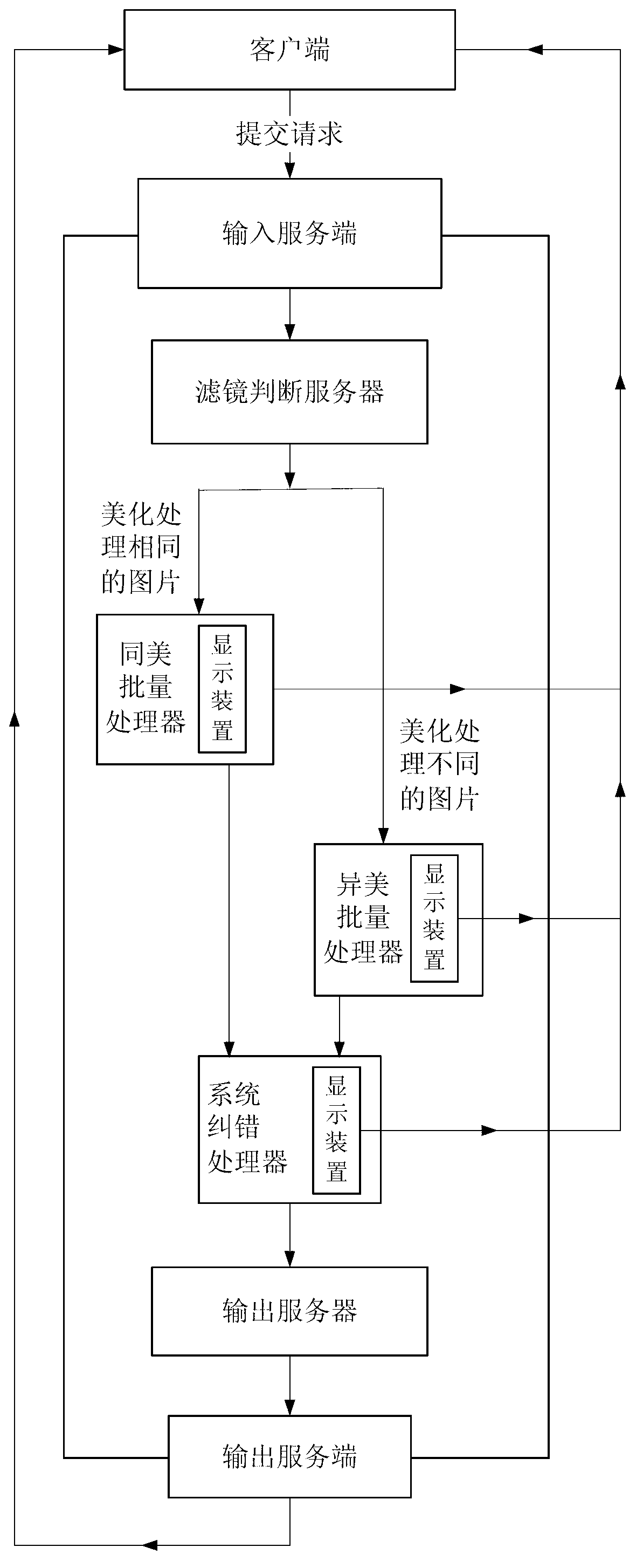

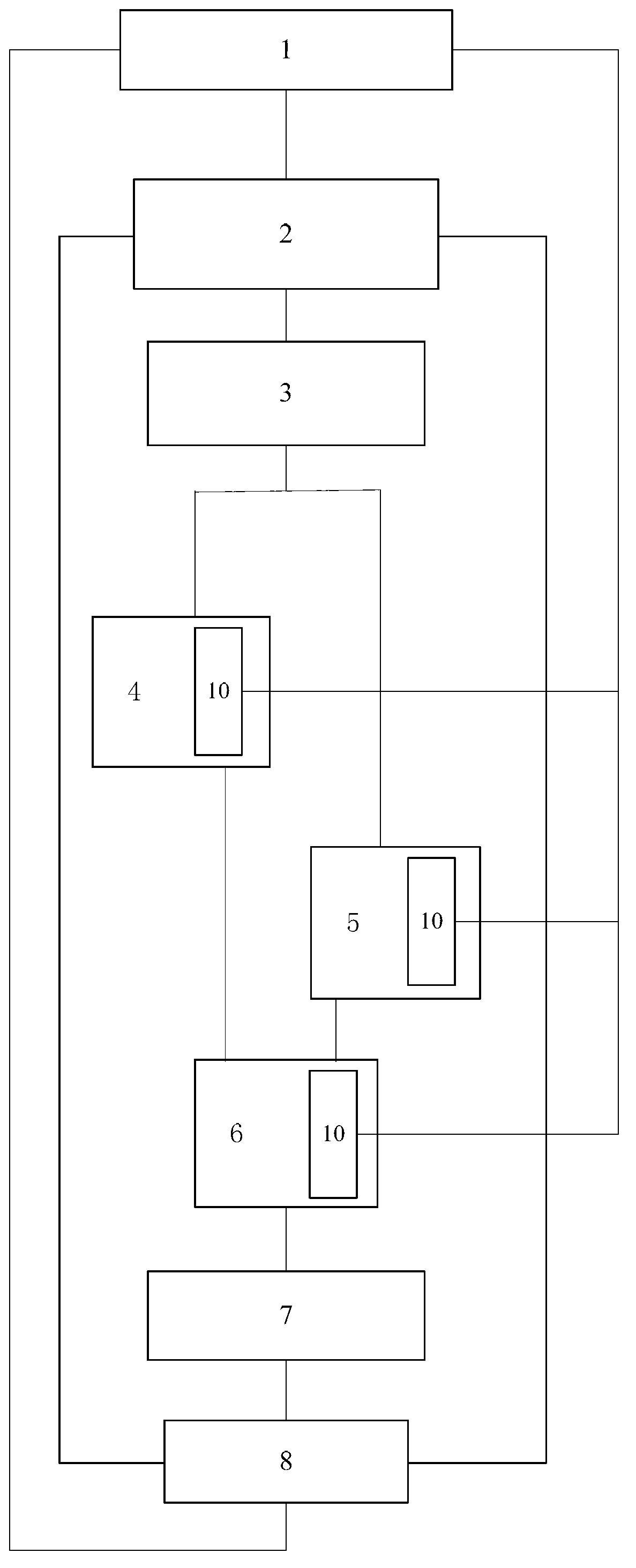

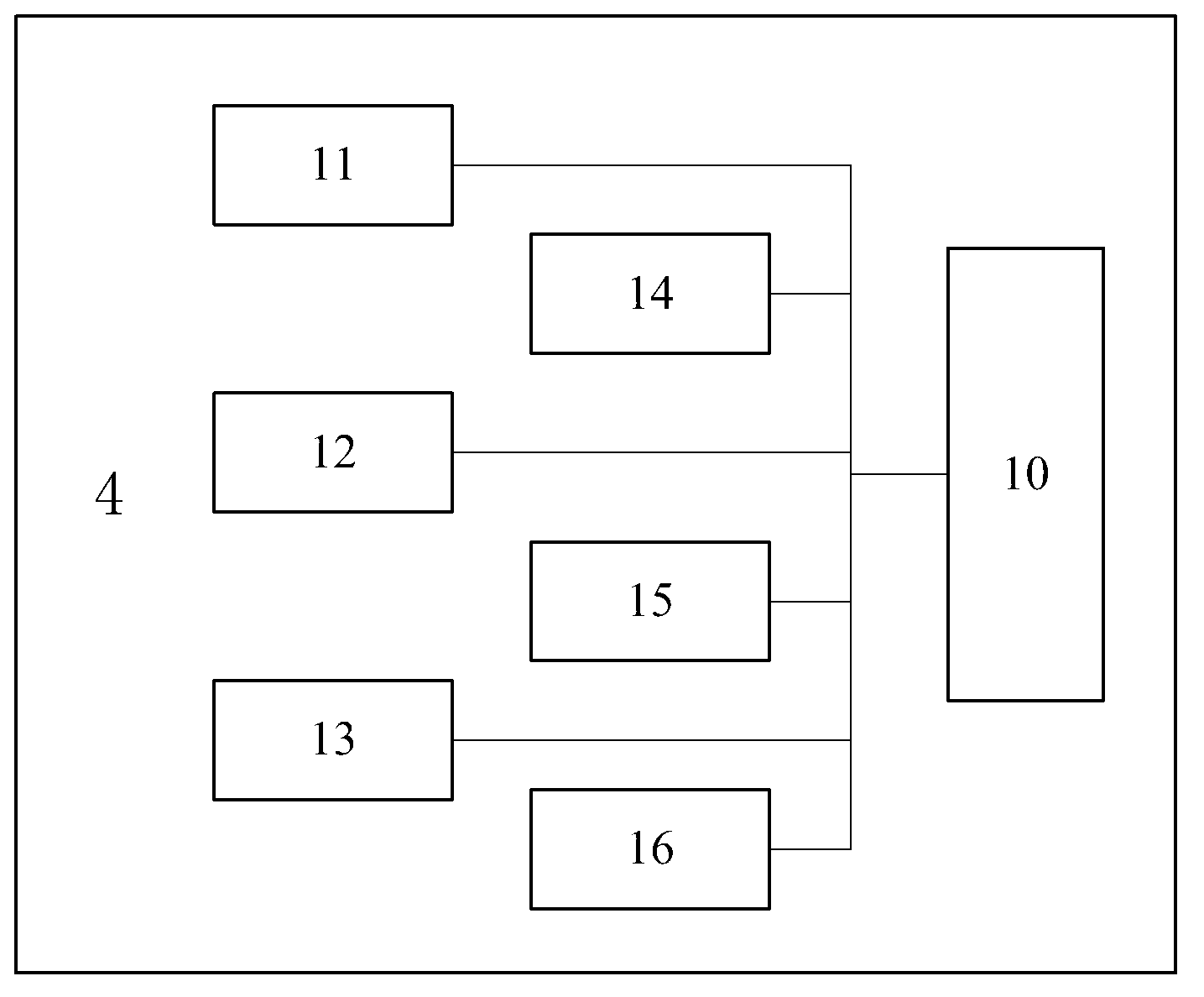

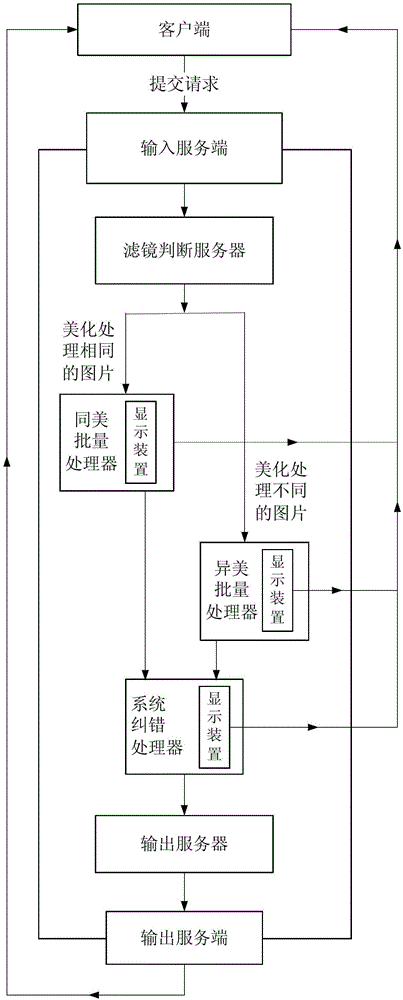

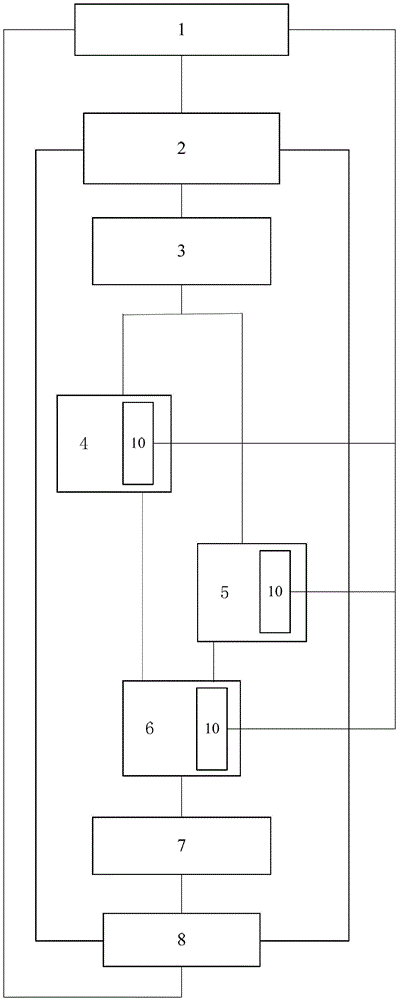

Method and device of beautifying pictures in batch

ActiveCN103226803AShorten the timeSave energyImage data processing detailsConducting systemSystem error

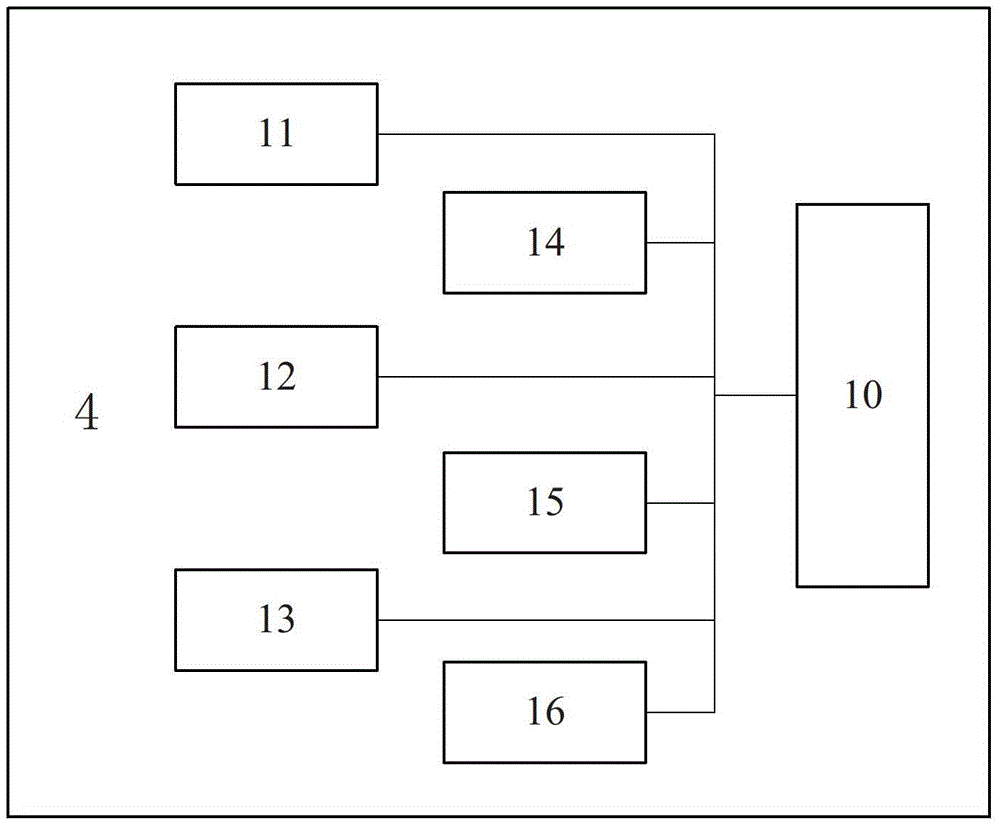

The invention relates to the technical field of picture processing and particularly discloses a method and a device of beautifying pictures in batch. The method comprises the steps that a client submits a request of the pictures to be beautified, an input service end receives and transmits the request to a filter judgment server, the filter judgment server judges the request and transmits a request of beautifying the identical pictures and a request of beautifying the different pictures to an identical beautification batch processor and a different beautification batch processor, the identical beautification batch processor and the different beautification batch processor conduct batch processing and generate processed results; a system correction processor receives the processed results and conducts system error correction and modification; an output server transmits the processed results to an output service end after the correction and modification, and the output service end receives and outputs the processed results to the client. The method and device save a great deal of time and energy for a user, is easy, simple and quick to operate, avoid errors caused by artificial beautification, and improve the working efficiency.

Owner:4399 NETWORK

High-efficiency order batch-processing method of tobacco industry orders

The invention discloses a high-efficiency order batch-processing method of tobacco industry orders, belonging to the field of order processing methods. The high-efficiency order batch-processing method comprises the steps: sending messages to an order processing application queue by order foreground applications in turn, after the order processing application receives a request of submitting orders, packing order information into one message, placing the message in an order queue, and then returning to user prompt information; timing-starting processing the orders by a background, executing a plurality of threads, firstly generating a batch by a timer, namely, packing a plurality of orders into an order group, then transmitting the order group into an order batch processor, and summating order combined goods by the order batch processor for reserving inventory. Compared with the prior art, the high-efficiency order batch-processing method of tobacco industry orders, disclosed by the invention, is capable of effectively increasing transaction processing capacity per second of order processing, and has good popularization and application values.

Owner:INSPUR SOFTWARE CO LTD

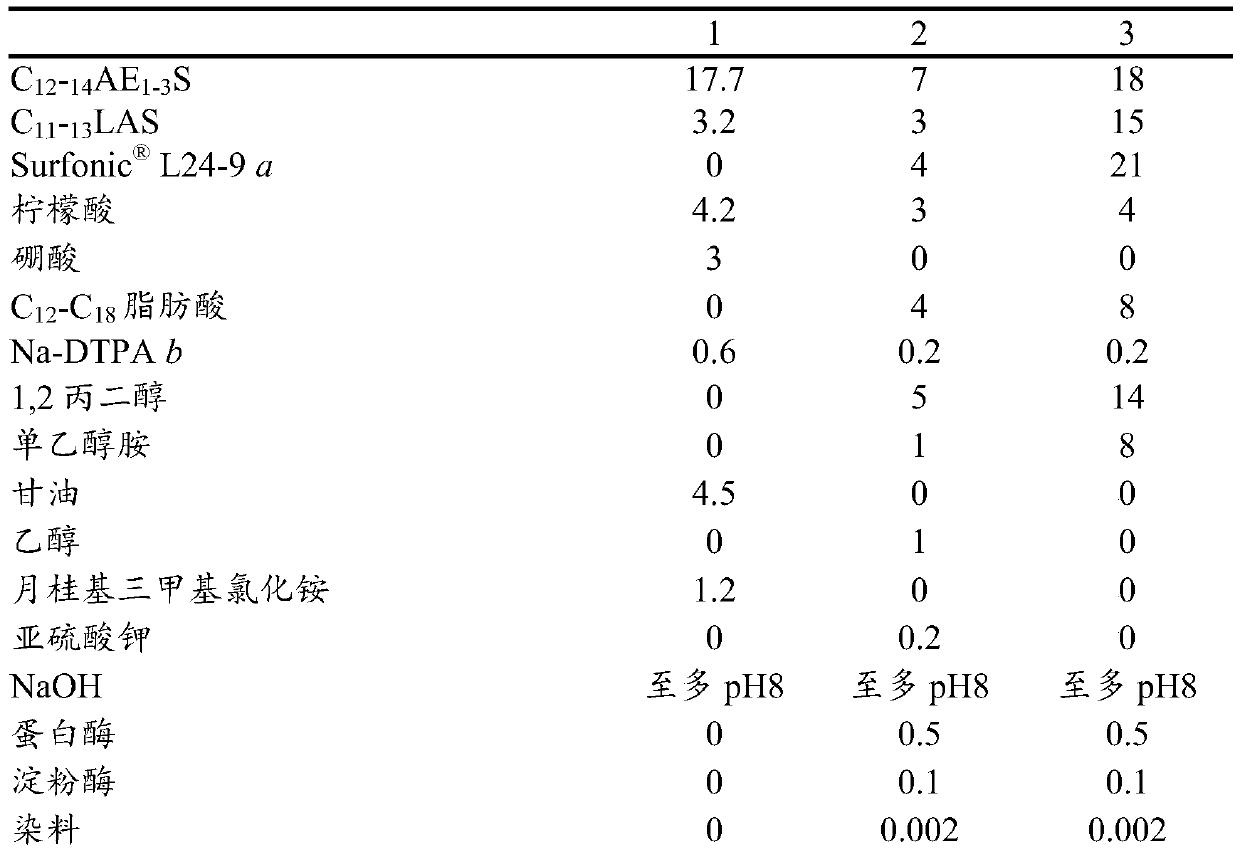

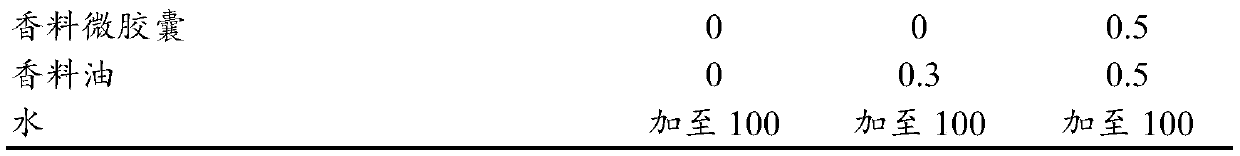

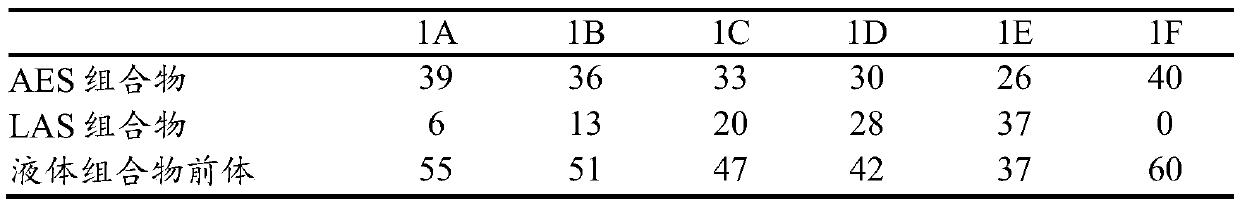

Process of making liquid cleaning composition

ActiveCN105518117AIncrease production capacityAnionic surface-active compoundsDetergent mixture composition preparationSURFACTANT BLENDBatch processor

In a process of making a liquid cleaning composition, adding a gel breaker upstream of an anionic surfactant addition in the recirculatory loop of a recirculatory batch processor mitigates the viscous hexagonal phase whilst providing maximum flexibility in formulating various ingredients in the composition.

Owner:PROCTER & GAMBLE CO

Business rules batch processor

A business rules batch processor is provided that includes a business rules manager that sends a plurality of pending requests to a rules database for processing. A business rules orchestrator receives statuses of the pending requests from the business rules manager. The business rules orchestrator manages the batch processing of the pending requests by assessing the rules database usage and job requirements of the pending requests.

Owner:FMR CORP

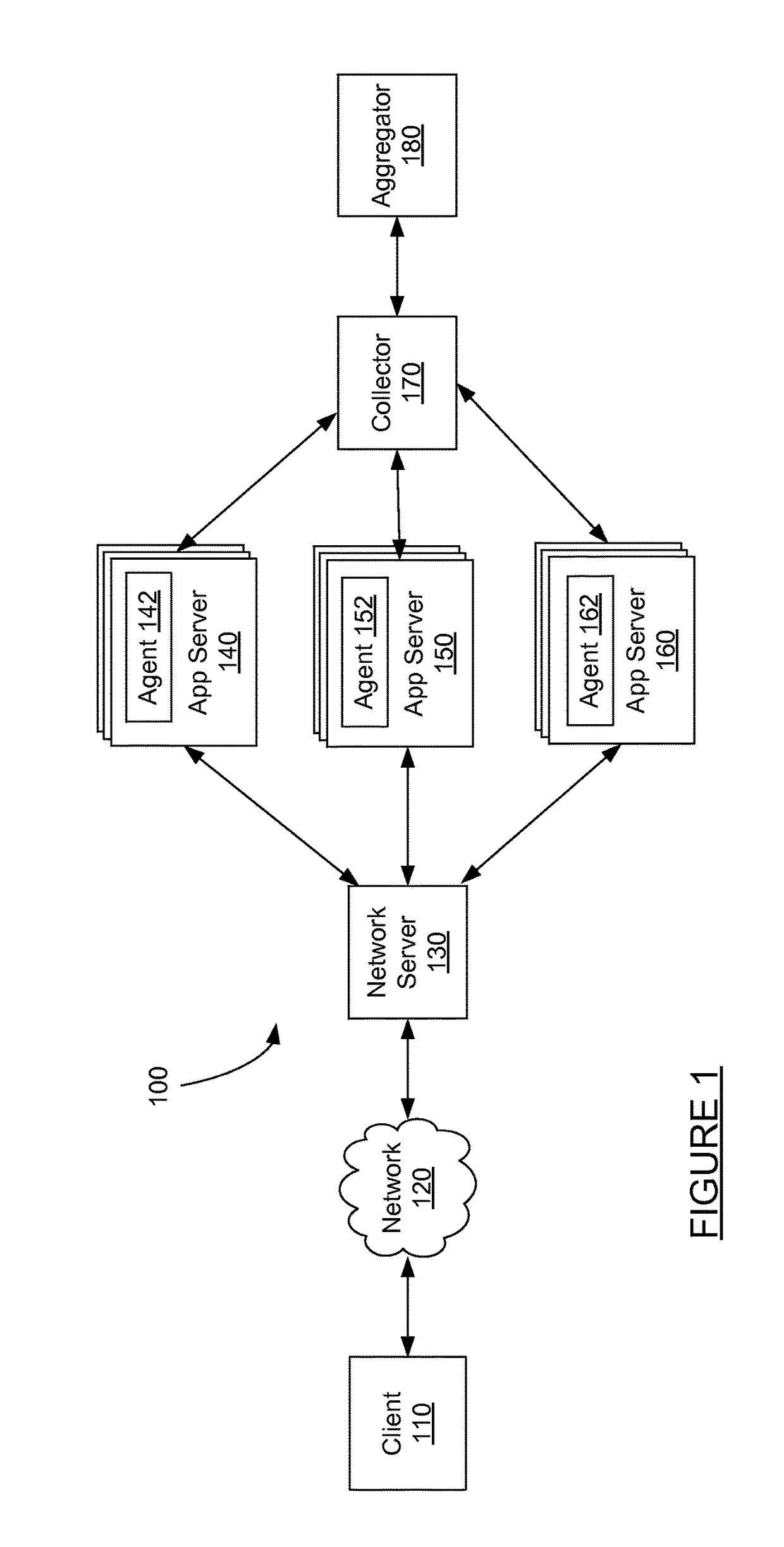

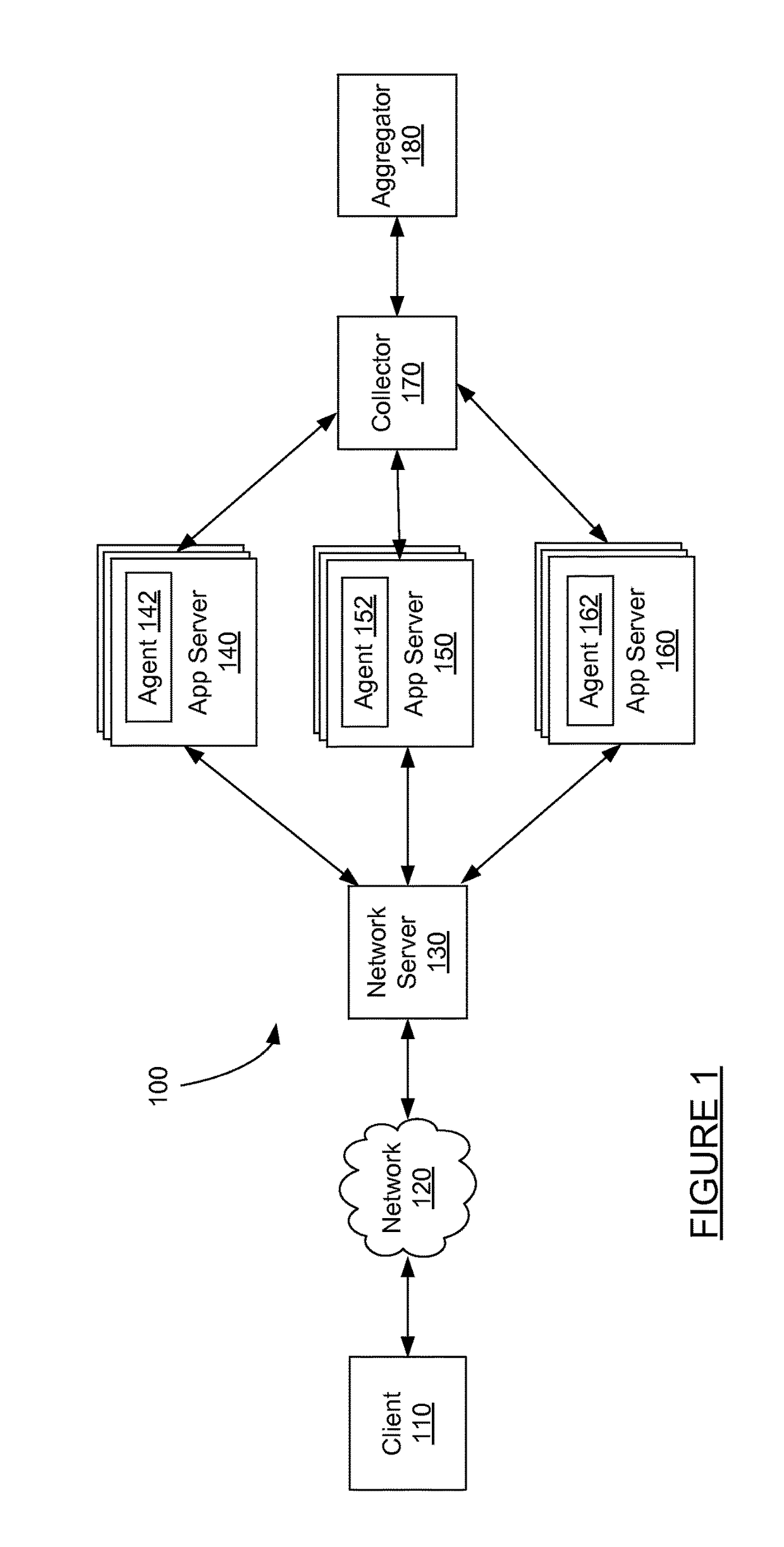

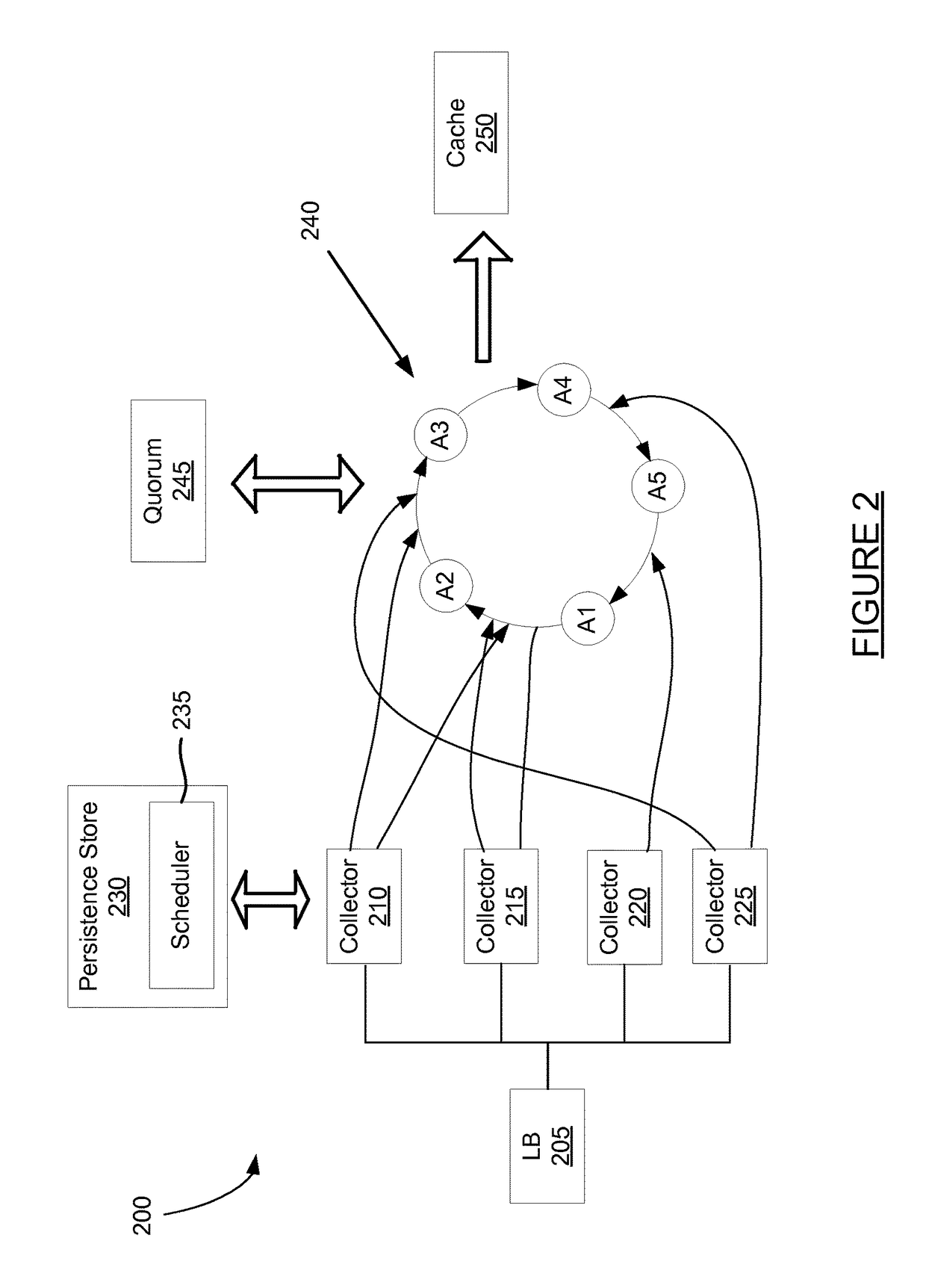

Quorum based aggregator detection and repair

InactiveUS20170123942A1Hardware monitoringRedundant hardware error correctionTime rangeTask completion

The present system uses quorum based aggregator failure detection in which a failed aggregator is detected and configured. Rather than repair and roll-up of all metrics for a period of time associated with the failed aggregator, only the specific metrics that were to be processed by the failed aggregator are repaired. Once the failed aggregator is identified, the time range for the downed aggregator and keys processed by the aggregator are identified. Keys for replica aggregators associated with the identified time ranges and key values are then pulled, provided to a batch processor, and processed. At cluster roll-up task completion, a time rollup task for cluster rollup is then started.

Owner:CISCO TECH INC

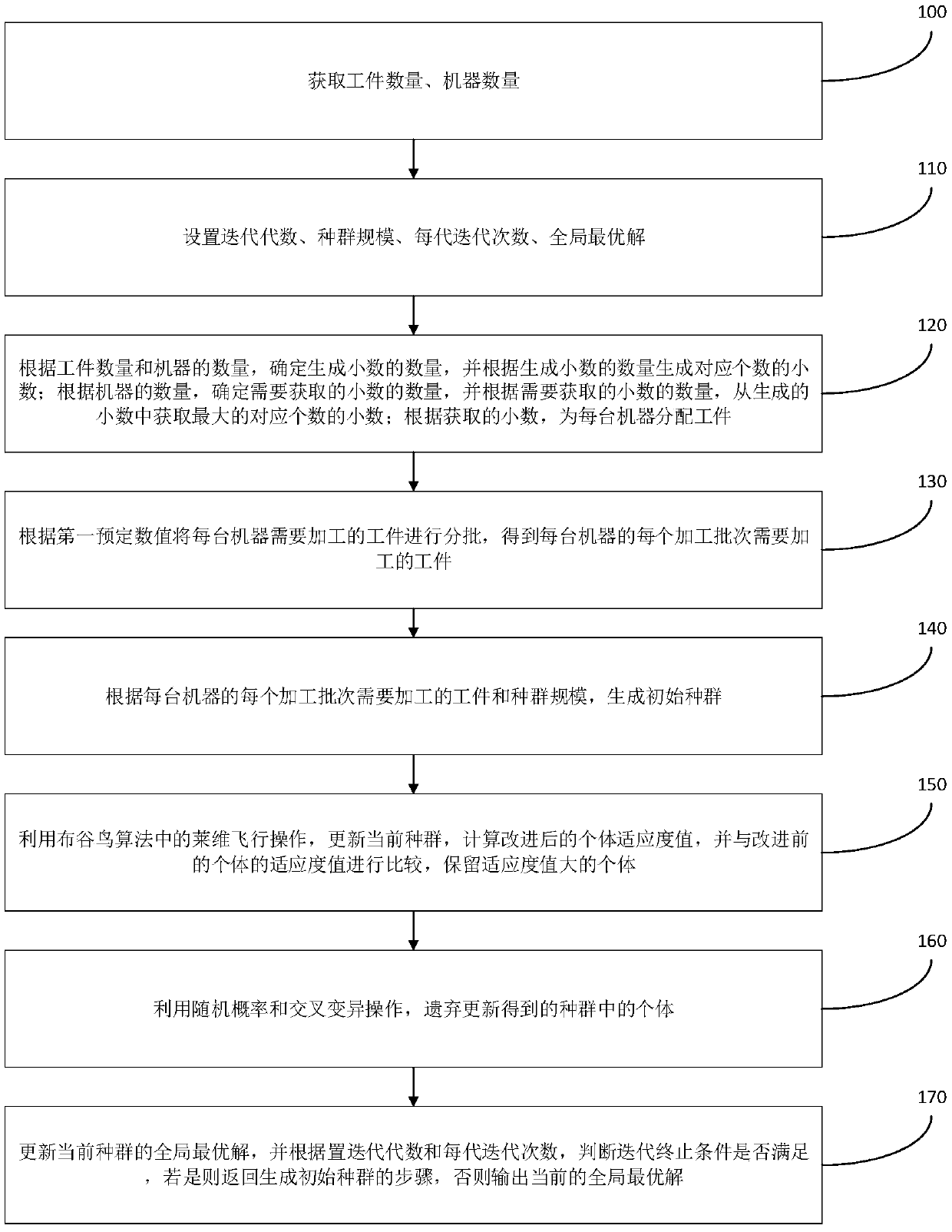

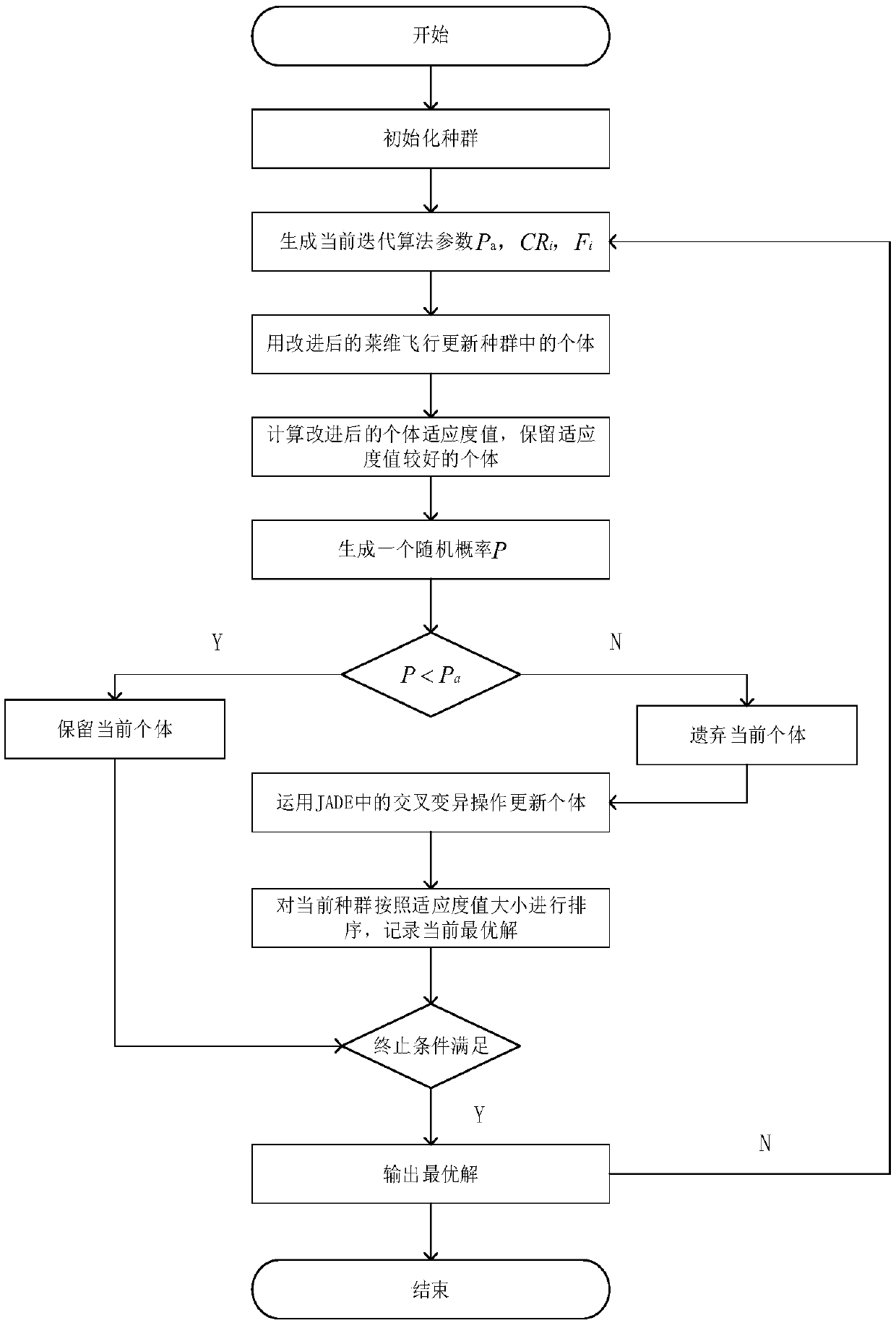

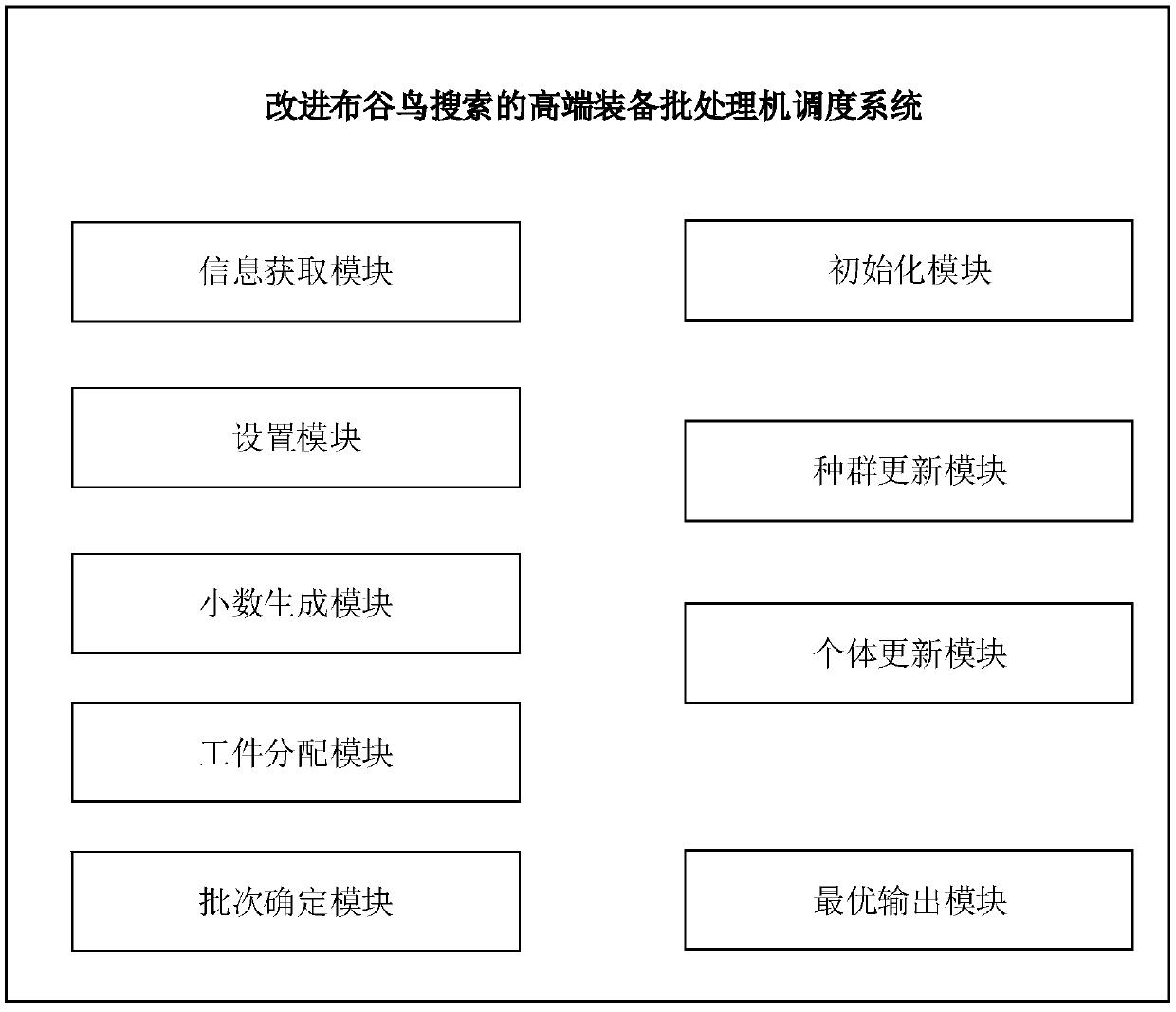

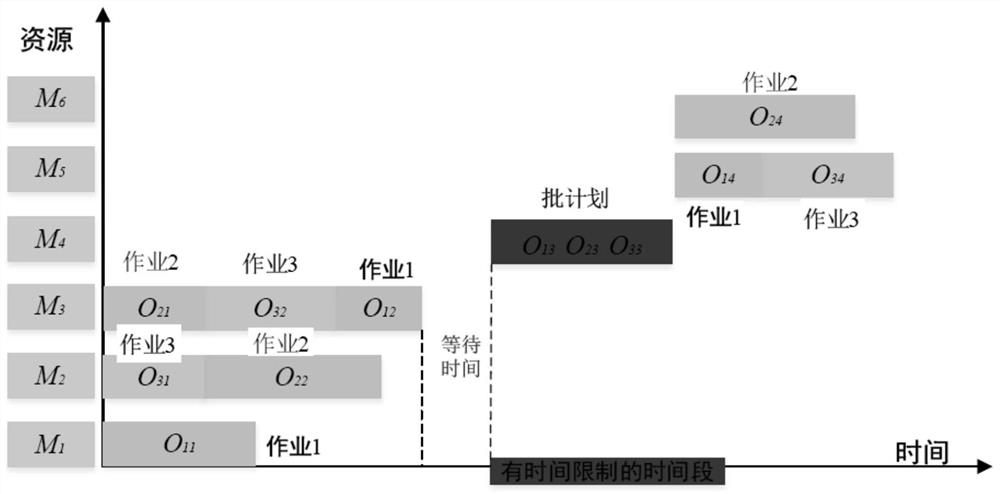

High-end equipment batch processor scheduling method and system for improving cuckoo search

ActiveCN109102211AMinimize manufacturing spanSolve the batch scheduling problem of parallel machinesArtificial lifeResourcesComputer scienceGlobal optimal

The embodiment of the invention provides a high-end equipment batch processor scheduling method and system for improving cuckoo search. Start with the number of artifacts, the number of machines and the first predetermined value assign workpieces to each machine, then, the initial population is generated, and the current population is updated by using the Levy flight operation of the cuckoo algorithm, and the improved individual fitness value is calculated and compared with the fitness value of the unimproved individual, so that the individual with large fitness value is reserved; and finally,the improved individual fitness value is calculated and compared with the improved individual fitness value; by using random probability and cross mutation operation, the individuals in the updated population are discarded, and finally, the global optimal solution is output. The technical scheme determines that each job will be assigned to a specific machine, and the batch mode and the batch processing order of the jobs on the machine can minimize the manufacturing span, improve the production efficiency, and solve the parallel machine batch scheduling problem under the condition of learningeffect.

Owner:HEFEI UNIV OF TECH

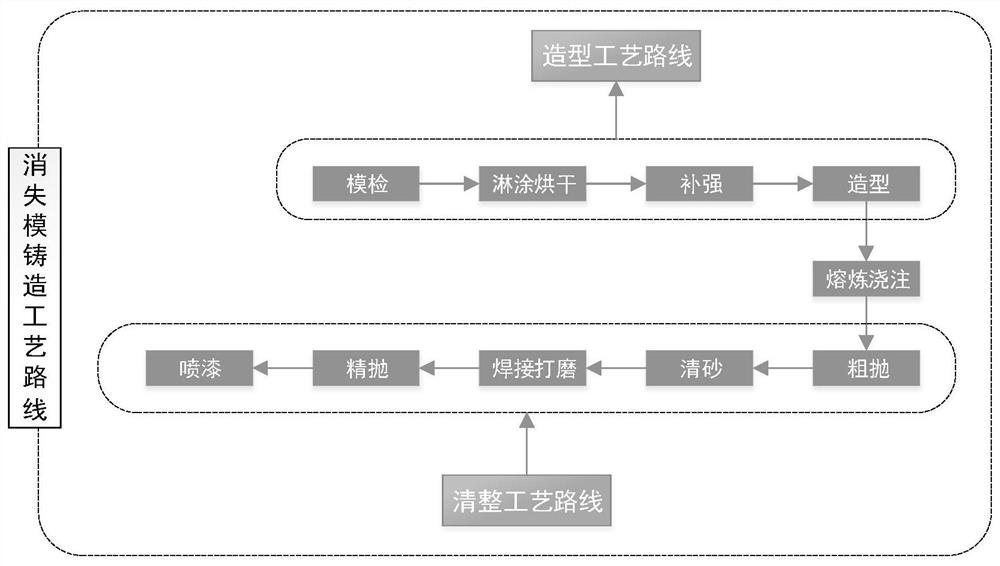

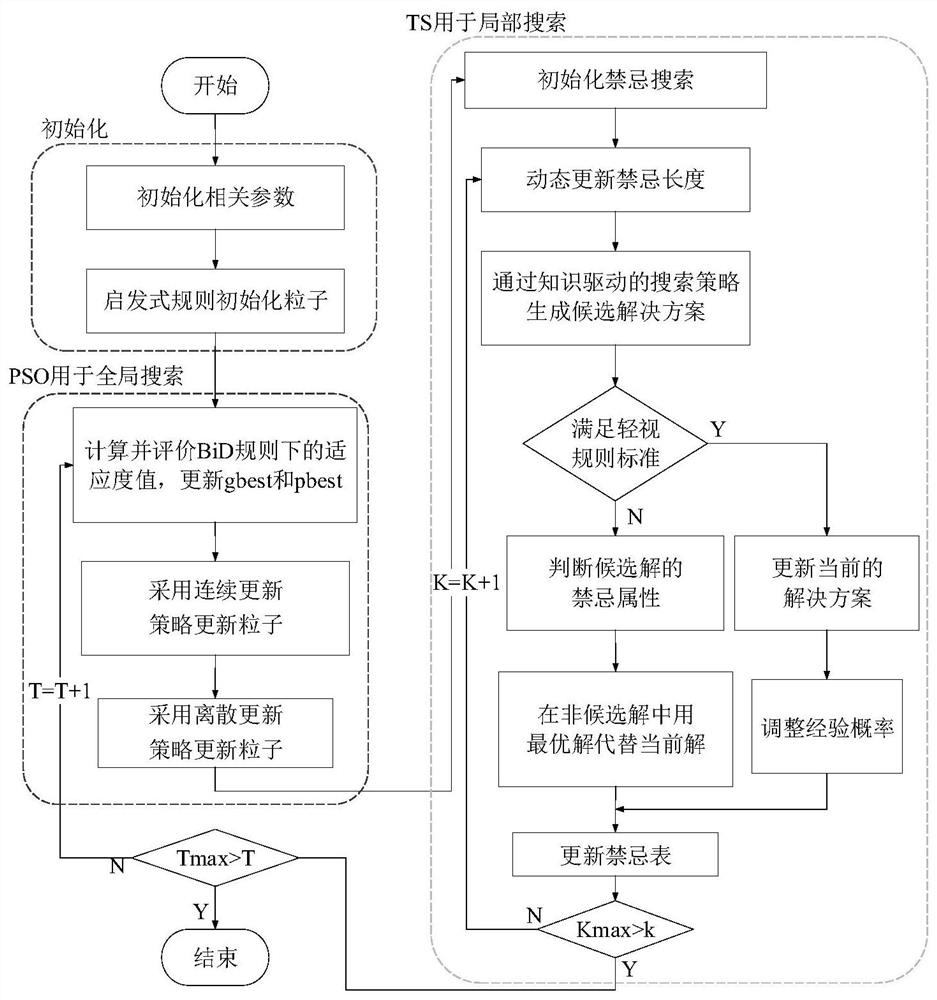

Knowledge-driven flexible discrete manufacturing production scheduling optimization method

ActiveCN113467399ASolve scheduling problemsImprove local search capabilitiesManufacturing computing systemsProgramme total factory controlLocal search (optimization)Completion time

The invention relates to a knowledge-driven flexible discrete manufacturing production scheduling optimization method. A flexible job shop scheduling problem of a batch processor in an evanescent mode casting environment is researched, and a flexible casting job shop scheduling model based on a completion time criterion is established. In combination with the characteristics of casting production, the time execution window is applied to the model. And the model is solved by adopting a hybrid particle swarm optimization (HPSO) algorithm. In the algorithm, a block integration decoding rule is provided to solve the scheduling integration problem. And global search is carried out on the particle swarm optimization algorithm by adopting a discrete type search strategy and a continuous type search strategy. On the basis, a neighborhood tabu search algorithm based on knowledge driving is adopted for local search. A simulation experiment is carried out to verify the feasibility of the optimized model, and the optimized model is applied to lost foam casting. Experimental results show that the algorithm has higher efficiency and robustness than the existing algorithm.

Owner:WUHAN UNIV OF TECH

Method used for implementing two-stage mixing optimized batch processing scheduling and based on variable time window

InactiveCN103105837BMeet the dynamic real-time scheduling characteristicsTotal factory controlProgramme total factory controlMathematical modelDecomposition

The invention provides a method used for implementing two-stage mixing optimized batch processing scheduling and based on a variable time window. According to the method, a decomposition rule of a complex problem is used, an aim of smallest total weighting delaying time is achieved, and two-stage mixing control is implemented. A first stage comprises the steps of based on a multi-rule combined self-adaptive principle, establishing a real-time control platform, adopting a variable time window rolling time domain method to obtain real-time parameters of patch combination and the like. A second stage comprises the steps of based on a flabby method, establishing a flabby linear integer mathematical model, obtaining a solution through a combined engineer of .NET and ILOG CPLEX commercialized software, and obtaining optimized order of batch sequencing. According to the two stages, lot grouping and sequencing for lot grouping in the batch scheduling problem are respectively solved, a multi-entrance property of a batch processor is considered, and according to the variable time window rolling time domain method, a dynamic state real-time scheduling property of machined work piece batches is met. According to the method used for implementing the two-stage mixing optimized batch processing scheduling and based on the variable time window, scheduling accuracy and operating time of a central processing unit (CPU) are considered in a comprehensive mode, real-time optical scheduling of a reentrant next batch processor can be achieved, and the method is beneficial to being popularized and applied in semiconductor field and the like.

Owner:SHANGHAI JIAOTONG UNIV

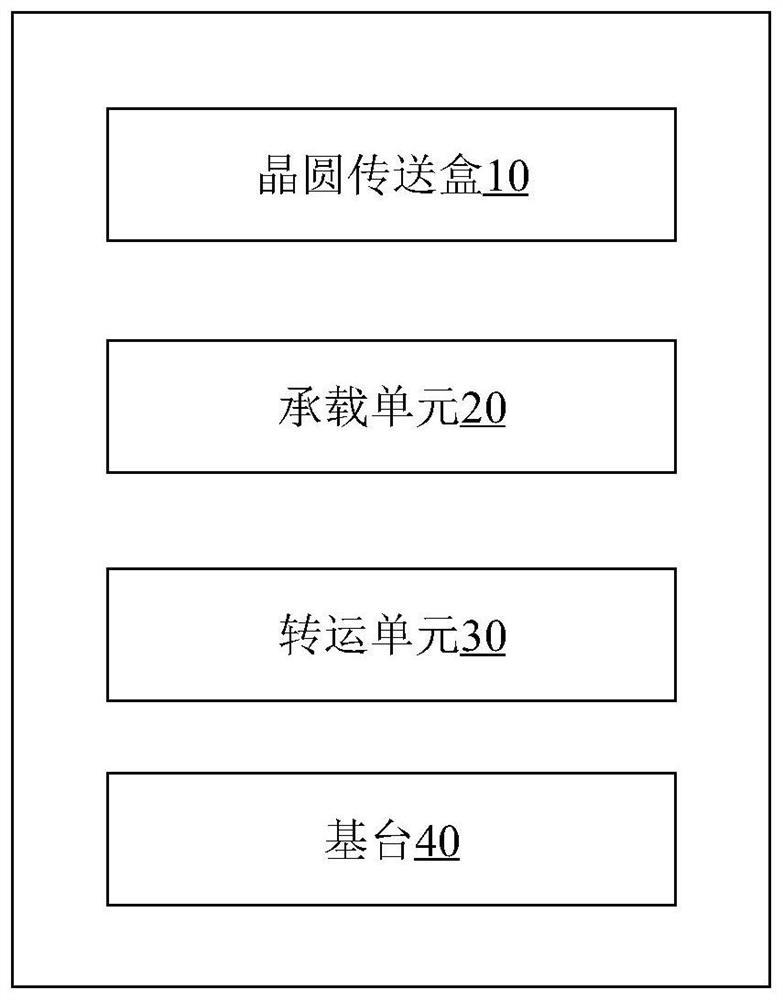

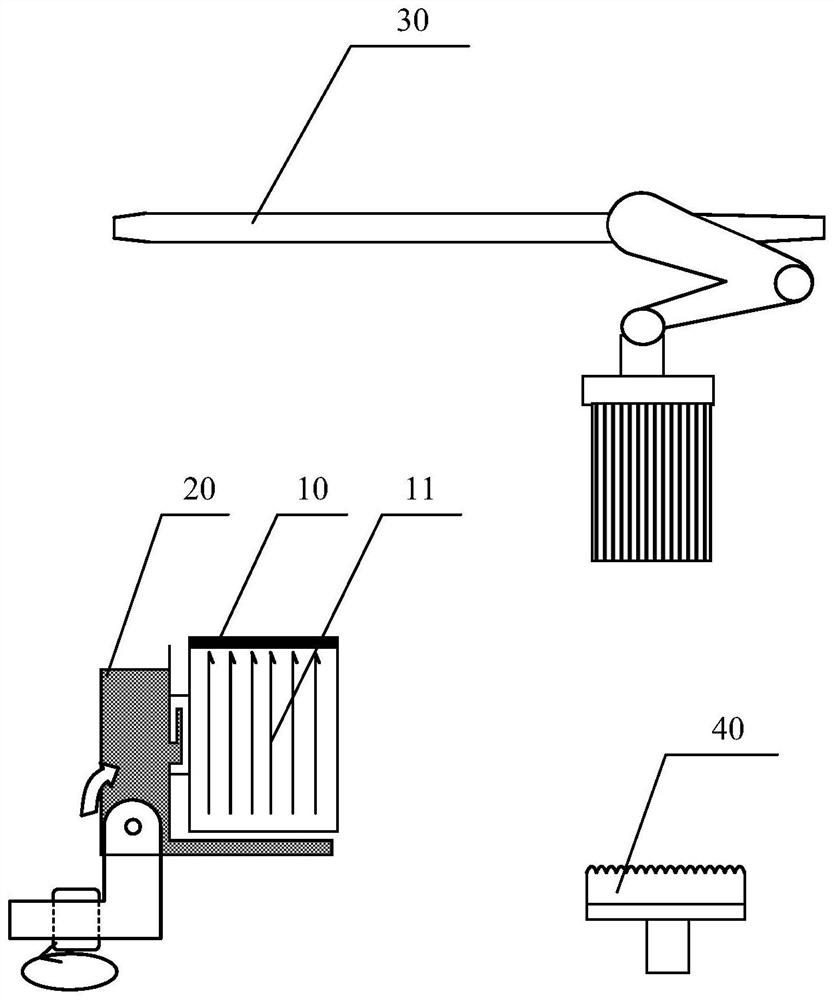

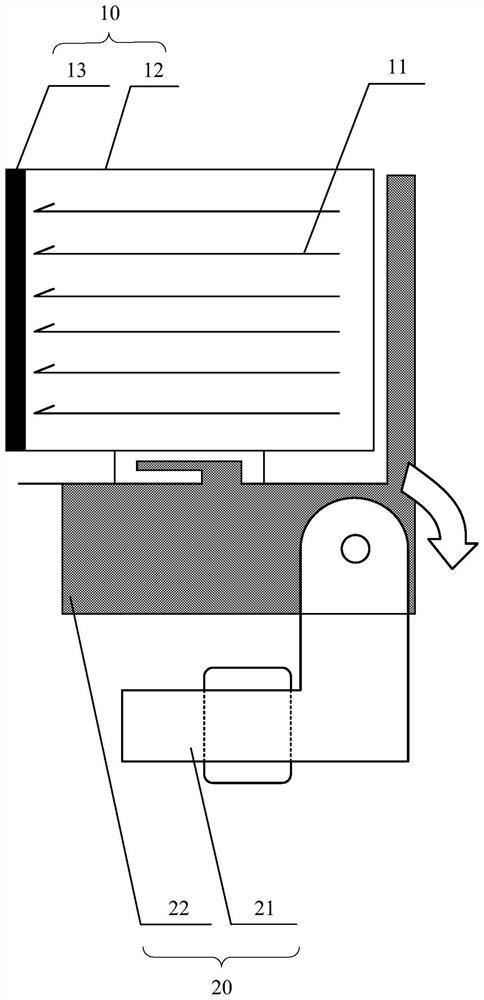

Wafer conveying system and wafer conveying method

PendingCN114446847AGuaranteed transmission securityFlip fastSemiconductor/solid-state device manufacturingConveyor partsWaferProcess engineering

The invention discloses a wafer transfer system and a wafer transfer method. According to the embodiment of the invention, the wafer conveying system comprises a wafer conveying box used for placing a wafer to be conveyed; the bearing unit is used for being connected with the wafer conveying box so as to bear the wafer conveying box; the transfer unit is used for obtaining the wafers to be conveyed from the wafer conveying box and transferring the wafers to the base station; and the base station is used for receiving the wafer to be conveyed. According to the wafer conveying system and the wafer conveying method provided by the embodiment of the invention, the productivity per hour and the processing effect of the wet-process batch processor are improved.

Owner:YANGTZE MEMORY TECH CO LTD

A method and device for beautifying pictures in batches

The invention relates to the technical field of picture processing and particularly discloses a method and a device of beautifying pictures in batch. The method comprises the steps that a client submits a request of the pictures to be beautified, an input service end receives and transmits the request to a filter judgment server, the filter judgment server judges the request and transmits a request of beautifying the identical pictures and a request of beautifying the different pictures to an identical beautification batch processor and a different beautification batch processor, the identical beautification batch processor and the different beautification batch processor conduct batch processing and generate processed results; a system correction processor receives the processed results and conducts system error correction and modification; an output server transmits the processed results to an output service end after the correction and modification, and the output service end receives and outputs the processed results to the client. The method and device save a great deal of time and energy for a user, is easy, simple and quick to operate, avoid errors caused by artificial beautification, and improve the working efficiency.

Owner:4399 NETWORK

A Multi-objective Workpiece Scheduling Algorithm Based on Ant Colony Algorithm

ActiveCN106970604BEvenly distributedRich demandEnergy industryTotal factory controlElectricity priceBusiness enterprise

Owner:ANHUI UNIVERSITY

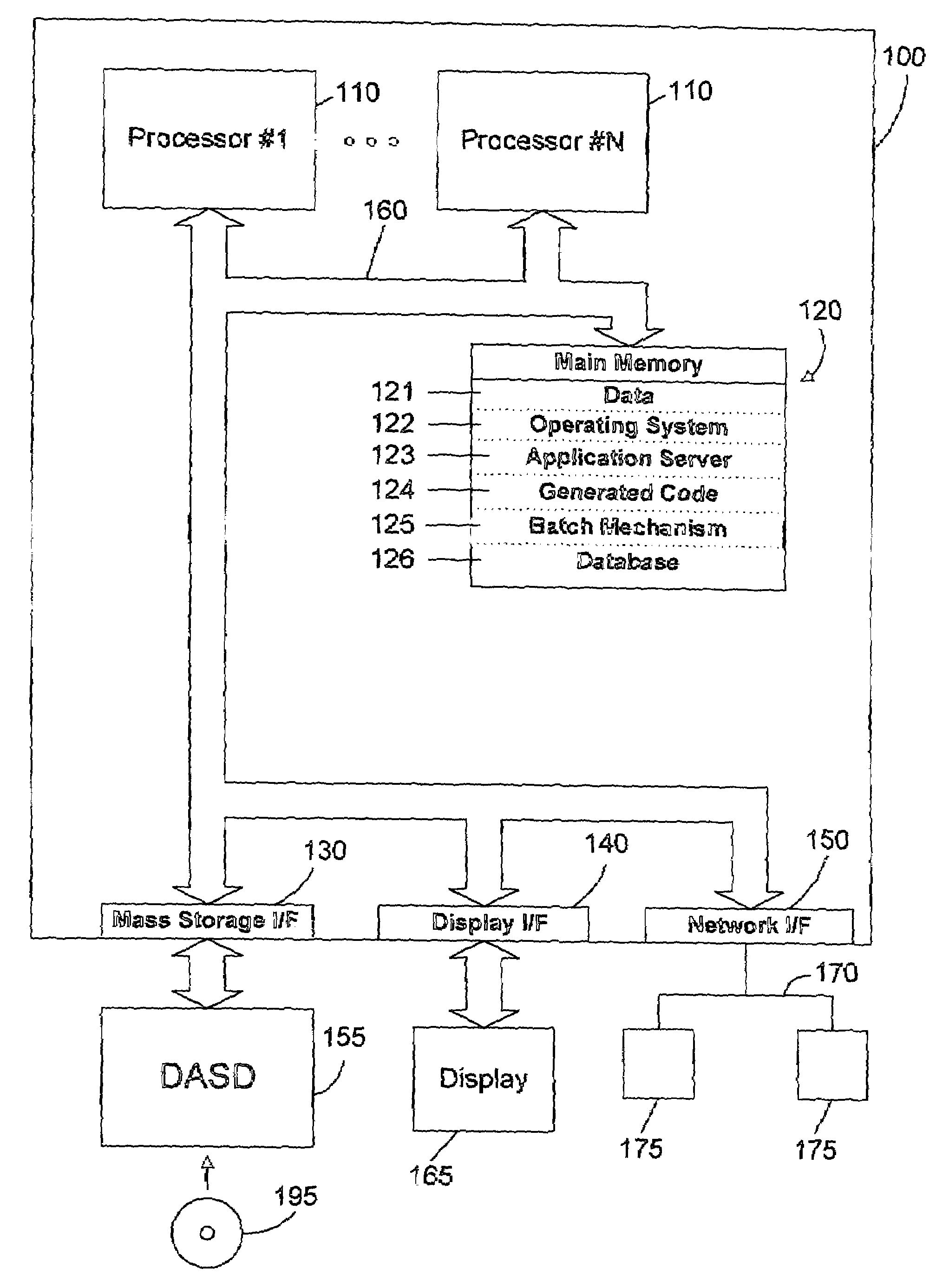

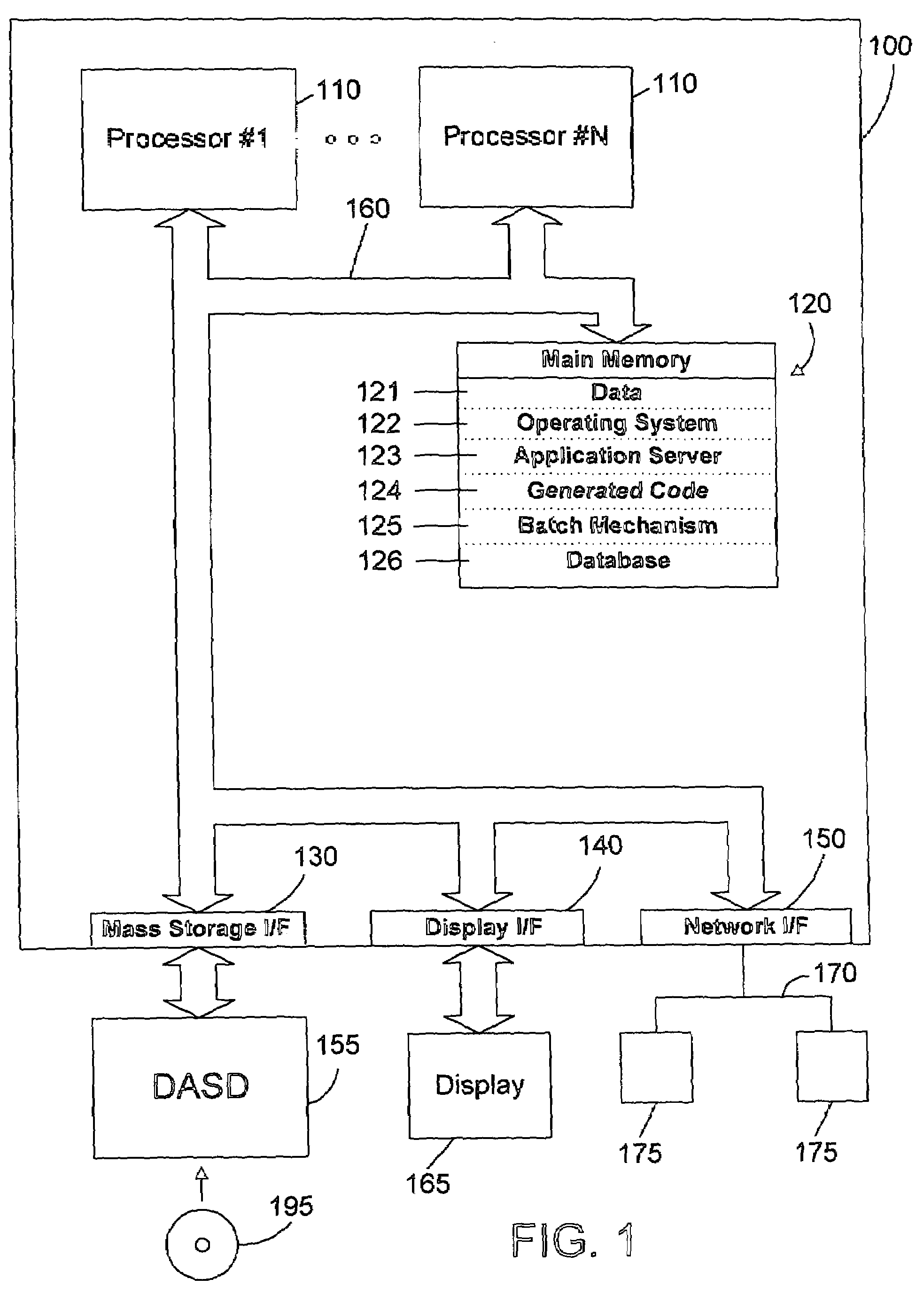

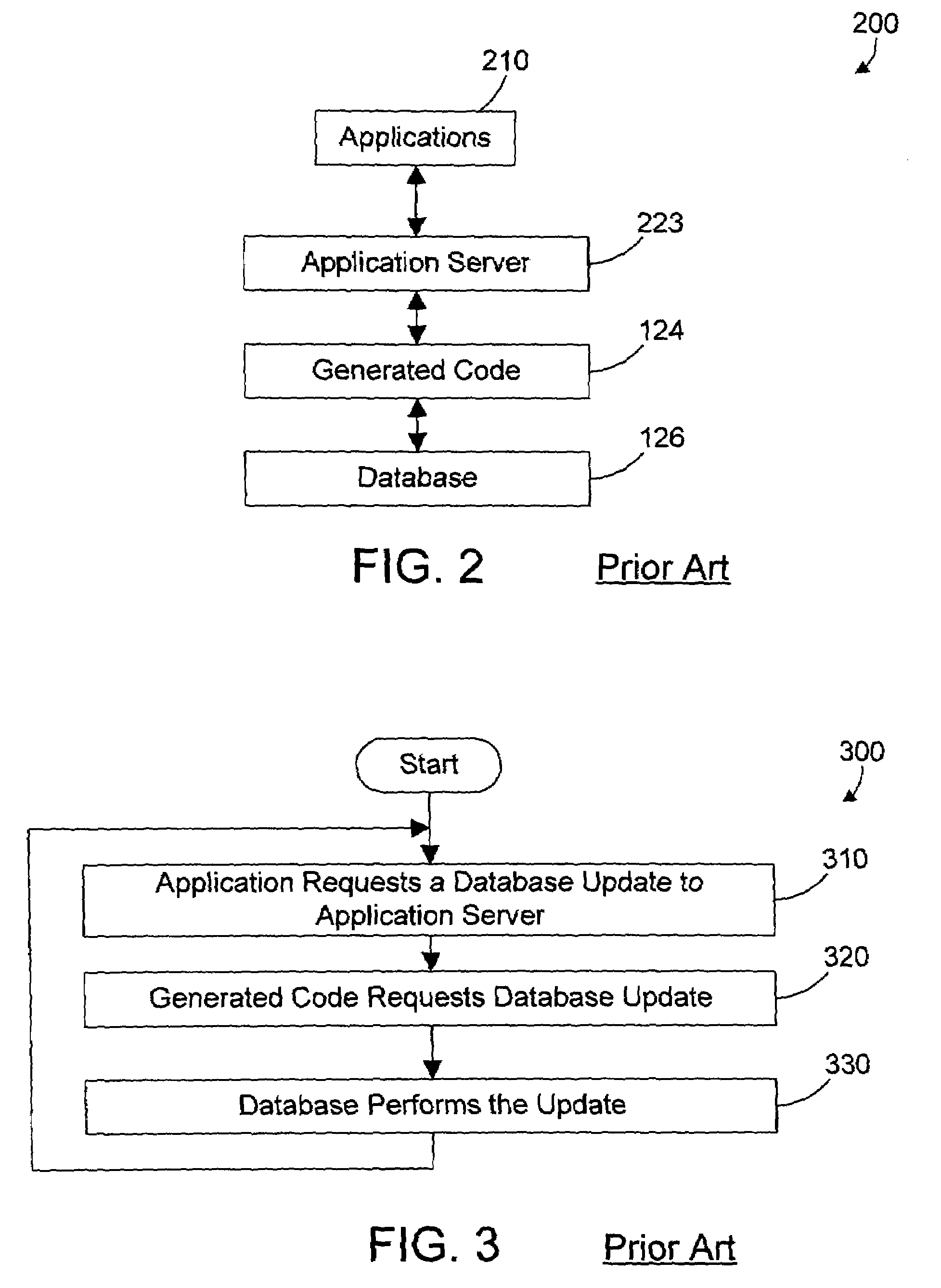

Apparatus and method for enabling database batch updates without modifying generated code

InactiveUS7225205B2Digital data information retrievalSpecial data processing applicationsApplication serverApplication software

An apparatus and method enable batch processing of database updates without modifying generated code, i.e., without redeployment of the application server or application. A batch mechanism intercepts calls from the generated code, compiles updates into batches, and processes the updates to the database in batches. In this manner the batch mechanism takes advantage of the batch processing capabilities of the database without modifying the generated code.

Owner:INT BUSINESS MASCH CORP

A Cross-job Unit Scheduling Method with Batch Processor

InactiveCN102938102BSolve the cross-unit scheduling problemGuaranteed operating efficiencyResourcesCell schedulingBatch machine

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Process of making a liquid cleaning composition

InactiveUS9758745B2Increase capacityEfficient processingOrganic detergent compounding agentsAnionic surface-active compoundsSURFACTANT BLENDBatch processor

In a process of making a liquid cleaning composition, adding a gel breaker upstream of an anionic surfactant addition in the recirculatory loop of a recirculatory batch processor mitigates the viscous hexagonal phase whilst providing maximum flexibility in formulating various ingredients in the composition.

Owner:THE PROCTER & GAMBLE COMPANY

Batch Pipeline Performance Evaluation Method

ActiveCN105956295BVerify validityDesign optimisation/simulationResourcesProduction rateMulti machine

The invention provides a batch processing pipeline performance evaluation method. The method is used for evaluating batch processing pipeline average output and each buffer zone level and like indexes; the main existing problem of the batch processing pipeline performance evaluation problem is as follows: the solution of single machine+ batch processor two-machine precise model and the establishment of a batch processor pipeline decomposition equation. The specific process of the invention is as follows: 1, obtaining the precise solution of the two machine models of single machine+ batch processor and single machine+ single machine; 2, decomposing the pipeline containing multi-machine into a plurality of building blocks containing two-machine single-buffer, and establishing the decomposition equations aiming at the building blocks; 3, solving the equations through an iterative method (PDDX method), and finally obtaining the performance index of the pipeline: production yield and number of work in process; 4, performing numerical contrast through summation simulation result to verify the rationality of the method provided by the invention.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

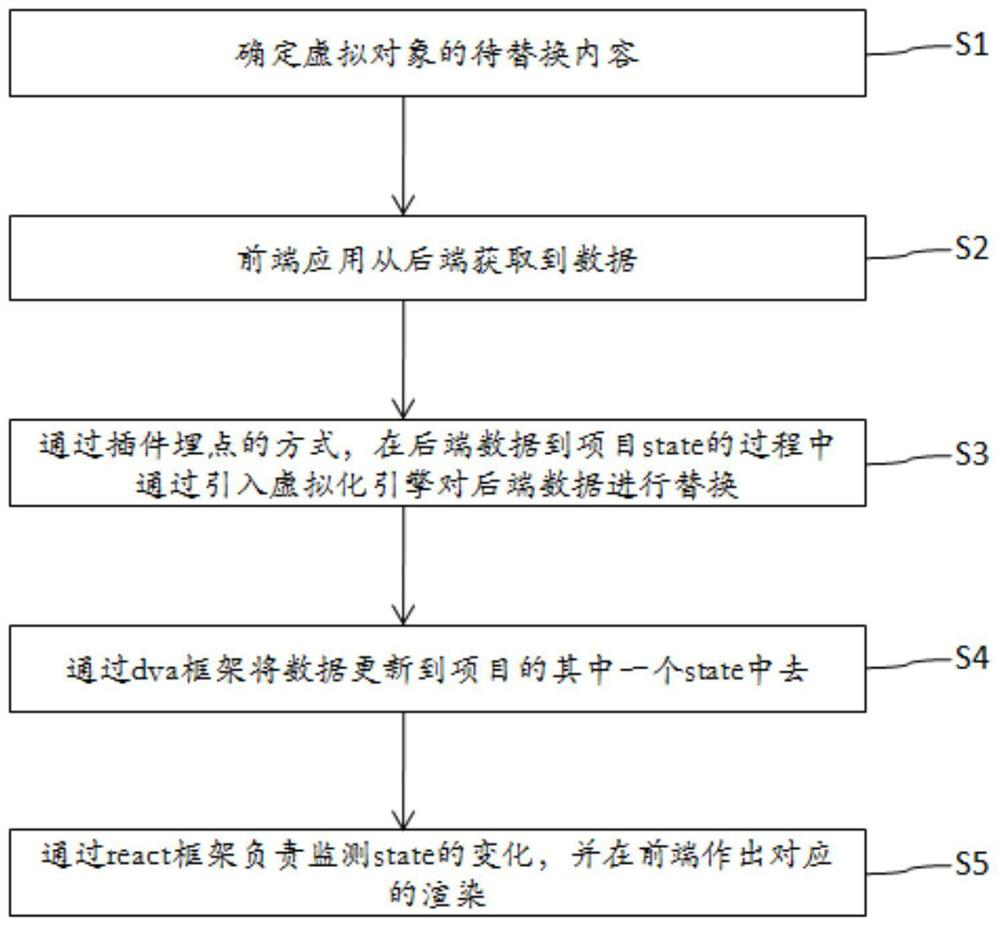

Front-end display data virtual replacement method

PendingCN112527439AEasy enable/disableFlexible deploymentExecution for user interfacesSoftware simulation/interpretation/emulationVirtualizationClient-side

The invention discloses a front-end display data virtual replacement method. The method comprises the steps of S1, determining to-be-replaced content of a virtual object; S2, by a front-end application, obtaining data from a rear end; S3, replacing the rear-end data by introducing a virtualization engine in a process from the rear-end data to the project state in a plug-in point burying manner; S4, updating the data to one state of the project through a dva framework; and S5, monitoring the change of the state through a react framework, and performing corresponding rendering at the front end.The virtualization engine replaces the back-end data in the modes of basic processor replacement, array batch processor replacement and user-defined processor replacement. The virtualization engine isarranged in a client side in a completely working browser, and a virtual mode can be conveniently started / stopped by configuring the content in a local storage of the browser.

Owner:上海数依数据科技有限公司

A Batch Scheduling Method Based on Product Family Sorting to Realize Minimum Total Completion Time

Owner:ANHUI POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com