A Cross-job Unit Scheduling Method with Batch Processor

A scheduling method and processor technology, which are applied to the scheduling of manufacturing systems and the field of cross-operation unit scheduling with batch processing machines, which can solve problems such as unpublished results and complex batch scheduling problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Preferred embodiments of the present invention will be specifically described below.

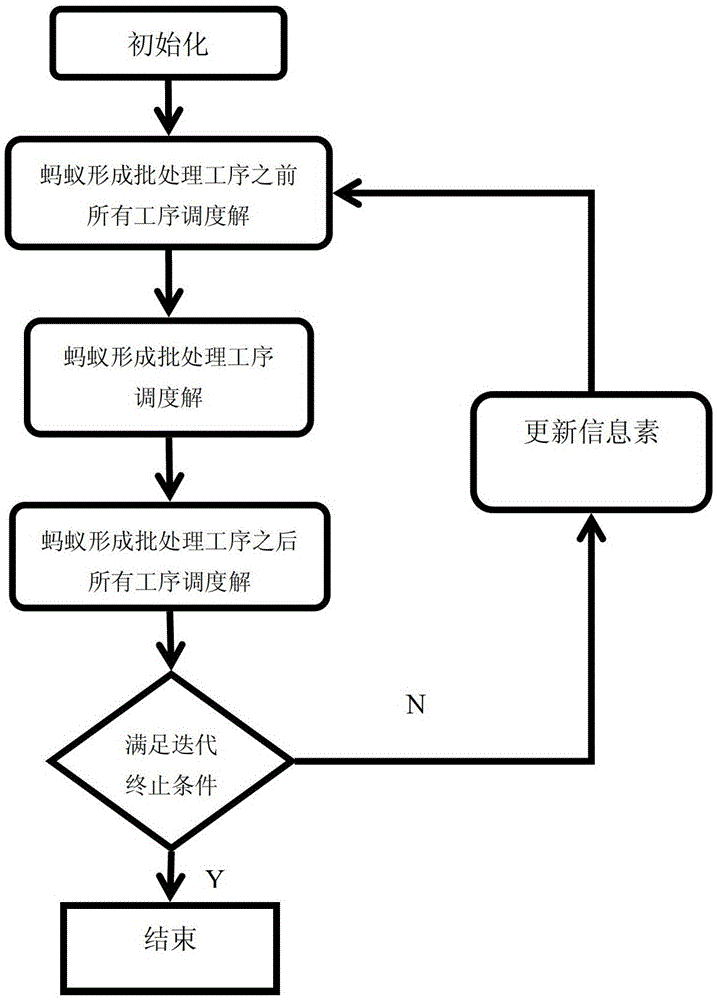

[0110] This embodiment implements the cross-job unit scheduling algorithm with batch processors based on ant colony optimization algorithm proposed by the present invention according to the execution steps in the summary of the invention, such as figure 1 shown.

[0111] Carry out following experiment simulation to present embodiment:

[0112] The unit manufacturing system used for simulation of the present invention is set up as follows: 20 non-batch processing machines and 1 batch processing machine are respectively set up, and the unit division of each machine is shown in Table 2. Non-batch machines use 1 to 20 indexes, and batch machines use 21 indexes.

[0113] Table 2 Unit division

[0114]

[0115] Note: The optional machine index M1-20 in the table indicates a non-batch machine, and B21 indicates a batch machine.

[0116] The manufacturing process route of parts is flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com