Multi-objective workpiece scheduling algorithm based on ant colony algorithm

A scheduling method and workpiece technology, applied in the direction of total factory control, total factory control, control/regulation system, etc., can solve problems such as insufficient quality, simple model, and weak energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

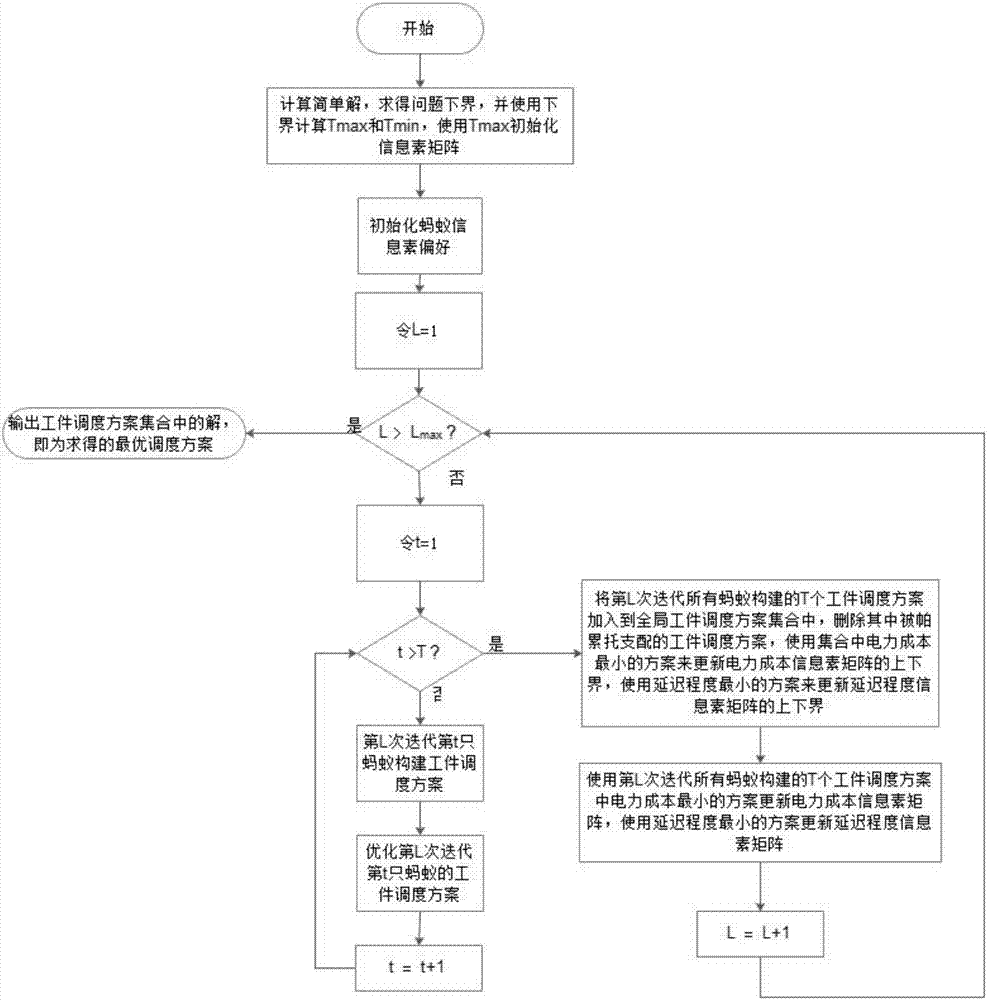

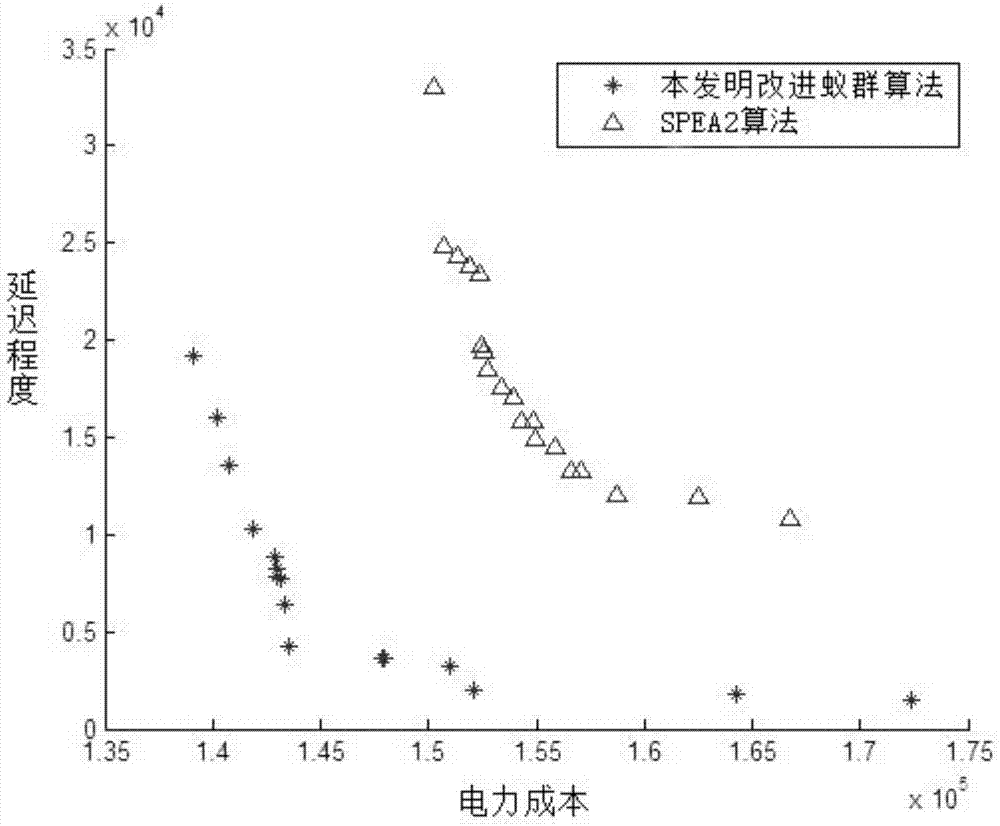

Method used

Image

Examples

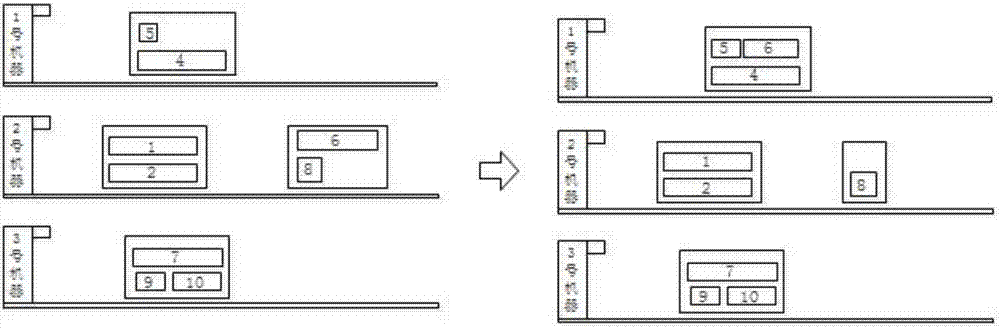

Embodiment Construction

[0134] In this embodiment, a workpiece scheduling method based on an ant colony optimization algorithm is applied to a scheduling scheme in which n workpieces are scheduled to be processed in batches on K same batch processing machines under the production conditions of time-of-use electricity price, The scheduling scheme is based on the optimization goal of electricity cost A and delay degree B; the time-of-use electricity price is a step function about time, 0 time is the starting point of high electricity price, and the length of high electricity price period is U H , the electricity price during the high electricity price period is C H , the length of the low electricity price period is U L , the low electricity price is C L , the end moment of each high electricity price period is the start moment of the low electricity price period, and the end moment of each low electricity price period is the start moment of the high electricity price period;

[0135] Record the size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com