A Batch Scheduling Method Based on Product Family Sorting to Realize Minimum Total Completion Time

A technology of completion time and product family, which is applied in the field of batch scheduling based on product family sorting to achieve the goal of minimum total completion time, can solve problems that affect the time complexity of batch scheduling algorithms, increase the scale of scheduling problems, and increase the difficulty of solving problems, etc. Achieve the effects of reducing time complexity, realizing convenience, and meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further:

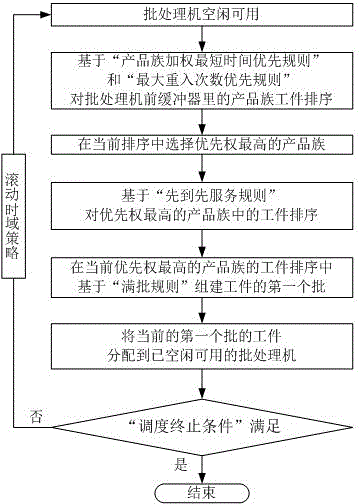

[0019] The batch scheduling method for realizing the minimum total completion time based on product family sorting provided by the present invention first takes different product families in the buffer in front of the re-entrant batch processor as the research objects, and then takes the workpieces in the product family with the highest priority as the research objects. The research object requires that the multi-product families processed on the batch processing equipment cannot be mixed into batches, and the products have different arrival times. Whenever the reentrant batch processing machine under study is idle and available, implement the minimum total completion time based on product family sorting The batch scheduling method of , completes the entire real-time scheduling specified by the rolling time-domain strategy.

[0020] refer to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com