Concrete batching plant

A mixing station and concrete technology, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the problems of many bending parts of pipelines, long time for dismantling pipes, high energy consumption of equipment, etc., to solve the problem of waiting time, Improve work efficiency and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the structure, features and other purposes of the present invention, the detailed description is as follows in conjunction with the attached preferred embodiments. The described preferred embodiments are only used to illustrate the technical solutions of the present invention, not to limit the present invention.

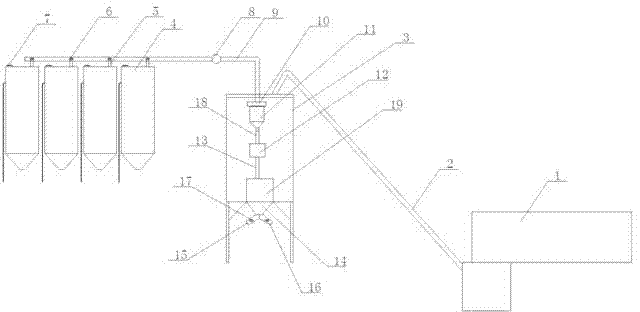

[0016] The specific embodiment of the present invention is as follows: as figure 1 As shown, a concrete mixing plant includes a batching machine 1, a hoist 2, a main building 3 of the mixing station, a powder bin 4 and a dust collection system; the dust collection system includes a powder bin connecting pipe 5, a main pipeline 9, a dust collector 10 and dust collection bin 11; the lower end of the powder bin connecting pipe 5 is connected to the top of the powder bin 4; the top of the powder bin connecting pipe 5 is connected to the main pipeline 9; the powder bin connecting pipe 5 and the connection of the main pipeline 9 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com