Batching machine with selvage flatting function

A cloth rolling machine, functional technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problem that the two ends of the cloth roll are not even enough to achieve a satisfactory level, the labor intensity of the workers is high, and the labor force waste of resources etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

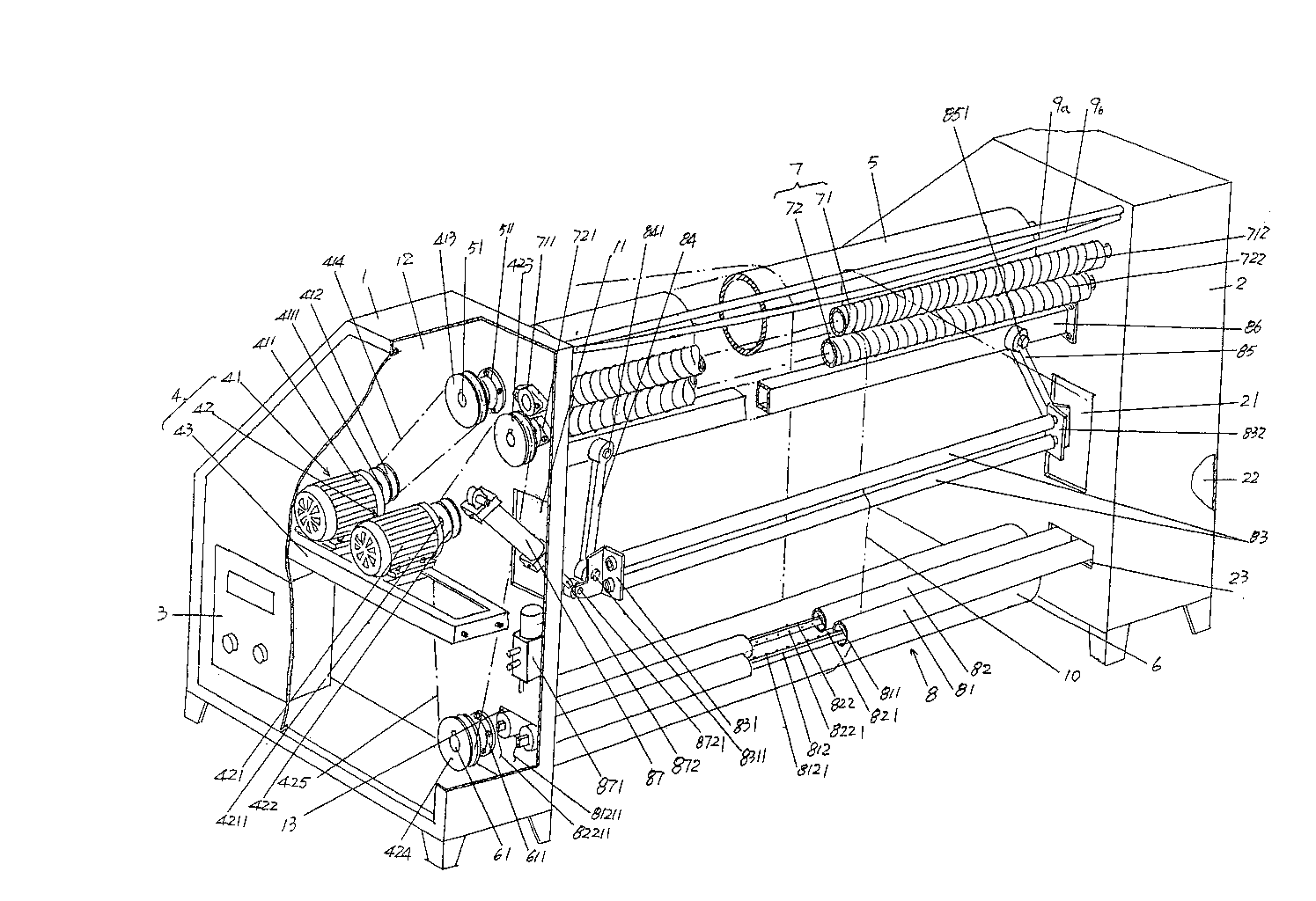

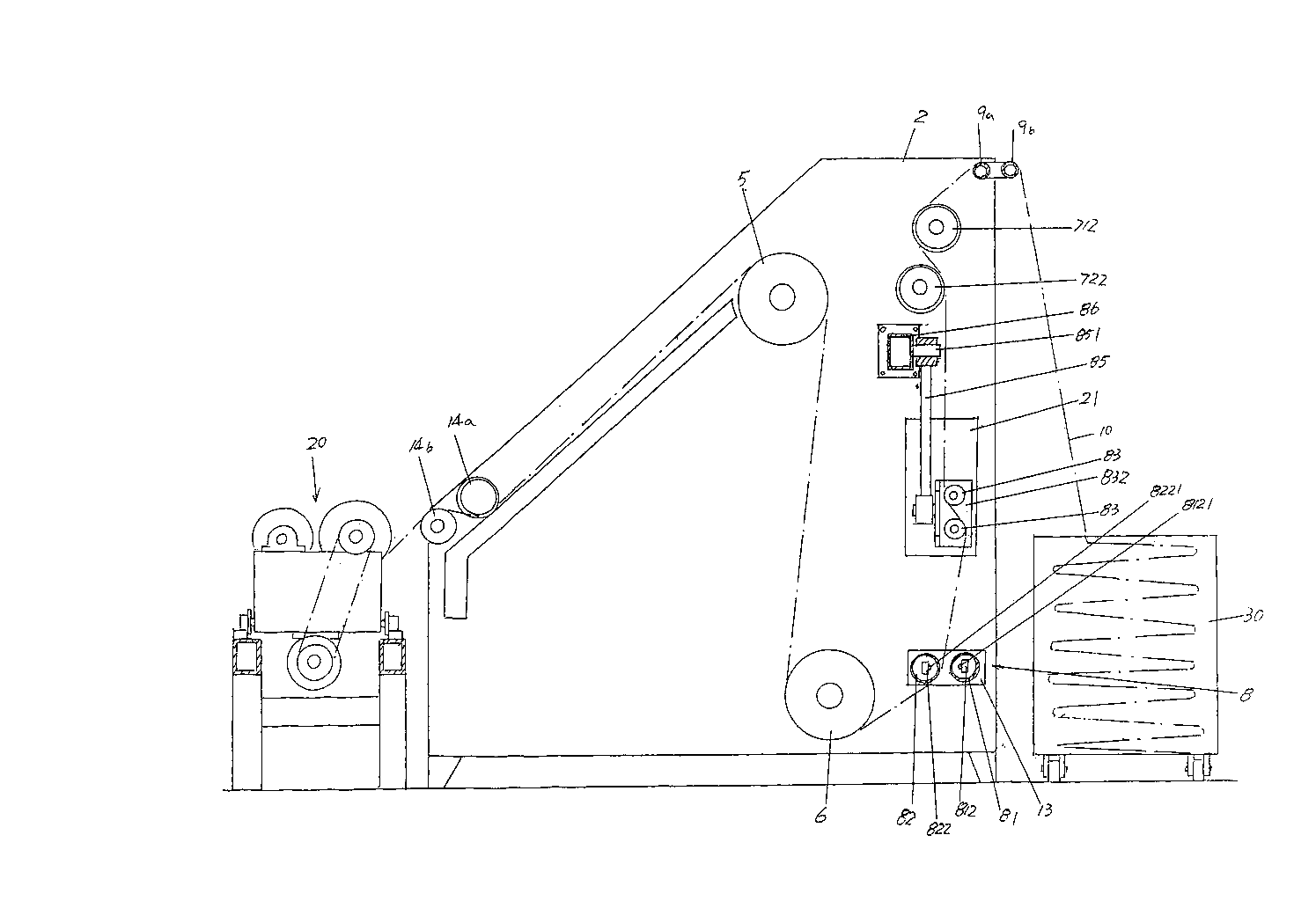

[0023] See figure 1 , a first rack wall panel 1 and a second rack wall panel 2 are given, the first and second rack wall panels 1, 2 are arranged facing each other and connected together in the state of use, the first 1. The specific structures of the second rack wall panels 1 and 2 are substantially the same, and each is formed with a wall panel cavity, that is, the first frame wall panel 1 forms a first wall panel cavity 12, and the second frame wall The panel 2 forms a second panel cavity 22 . On the wall body on the side of the first frame wallboard 1 towards the second frame wallboard 2, there is a first relief chamber 11 communicated with the first wallboard cavity 12; and on the second frame wallboard 2 A second relief chamber 21 communicating with the second wallboard cavity 22 is provided on the wall facing the side of the first frame wallboard 1, and the first and second relief chambers 11 and 21 correspond to each other.

[0024]Provided is an electrical control b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com