Reinforcing steel bar abut-joint device based on computer technology

A docking device, computer technology, applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of batch processing of steel bars, simple design structure, inconvenient use, etc., to improve efficiency, high degree of automation, Reduce the effect of assists

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

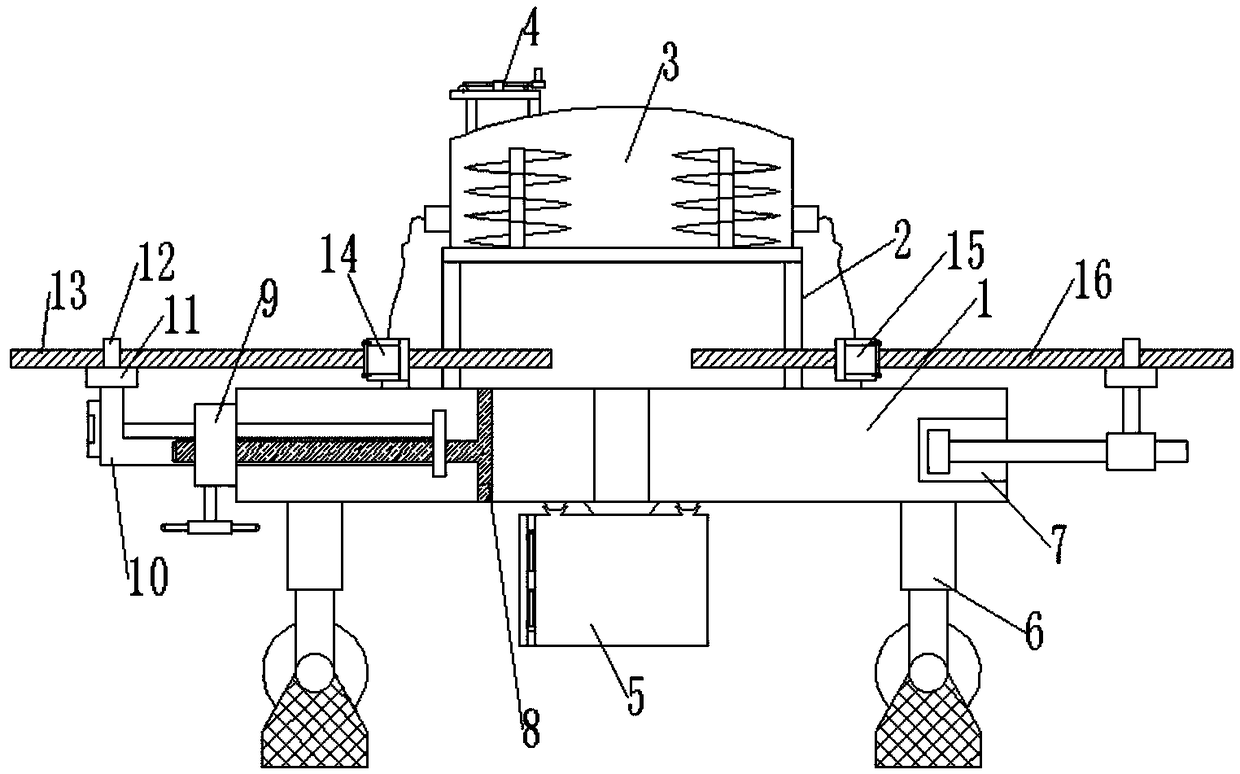

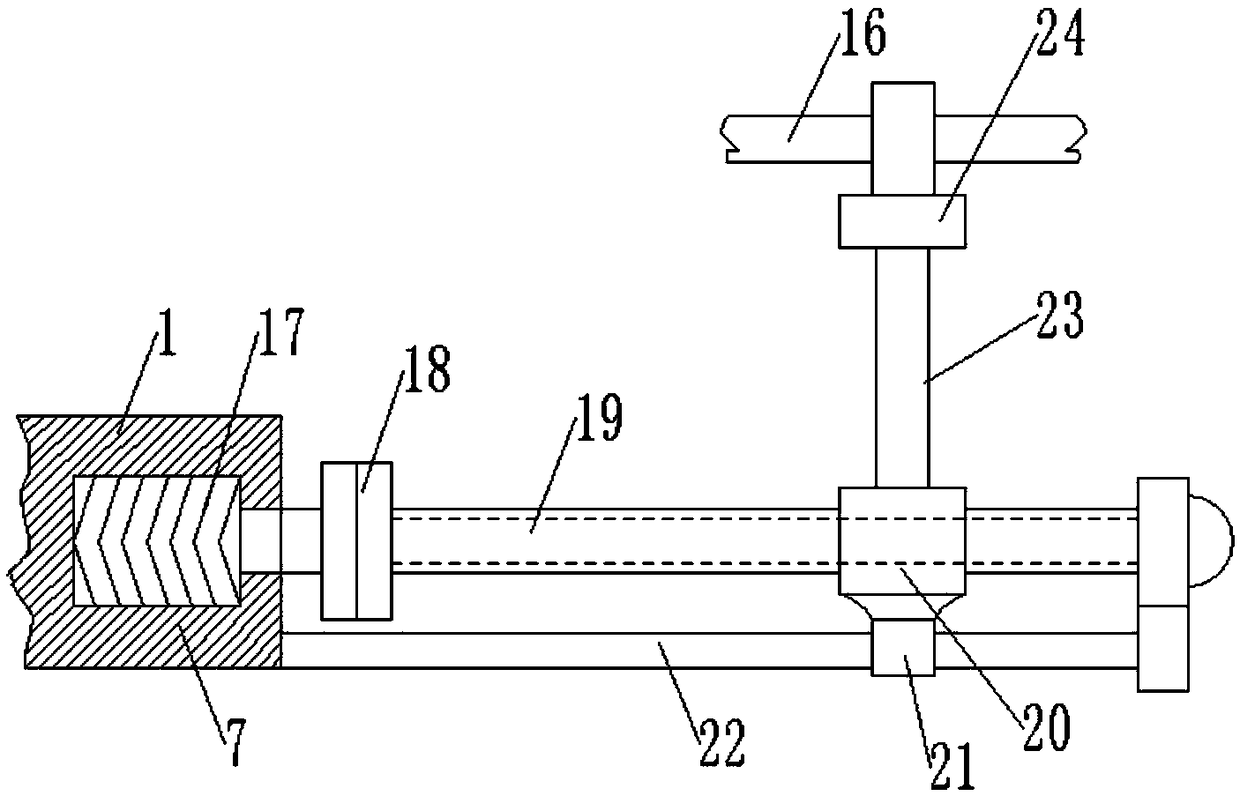

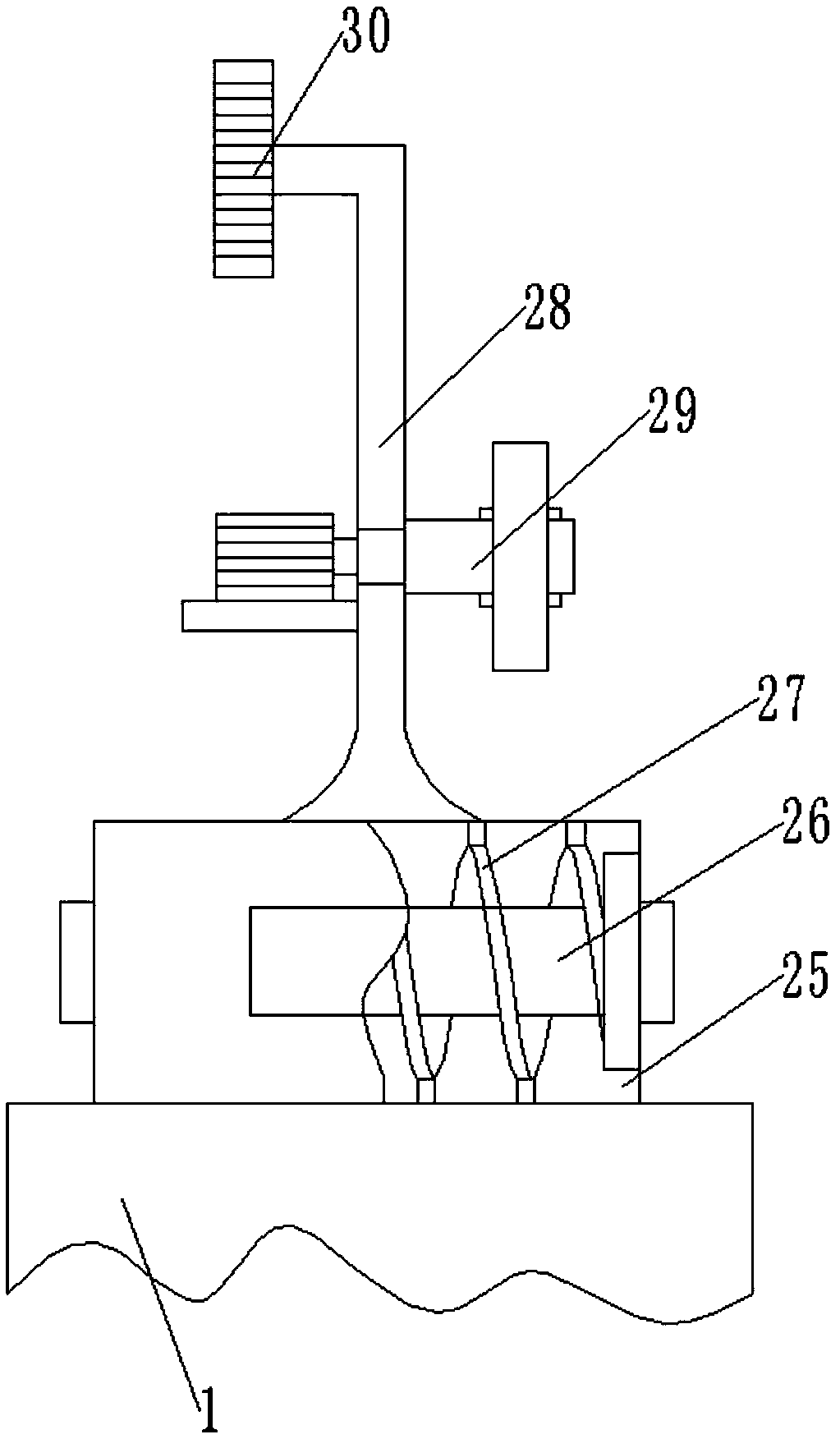

[0029] refer to Figure 1-6 , a steel bar butt joint device based on computer technology, comprising a fixed base 1, a fixed frame 2 is welded on the outer wall of the top of the fixed base 1, a transformer 3 is connected to the outer wall of the top of the fixed frame 2 by bolts, and the outer wall on one side of the top of the transformer 3 A switch 4 is connected to the top by a wire, and a discharge hole is arranged on the outer wall of the bottom of the fixed base 1, and a collection box 5 is arranged below the discharge hole, and hanging hooks are welded on the outer walls of both sides of the bottom of the fixed base 1. And collection box 5 is articulated on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com