Optimal scheduling method of parallel batch processing machines

A technology for optimizing scheduling and processing equipment, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems that cannot meet the diversified batch processing forms of production enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

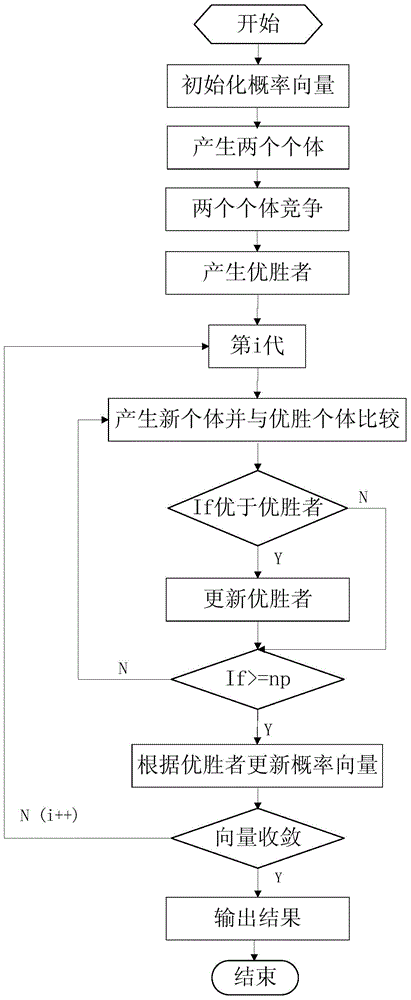

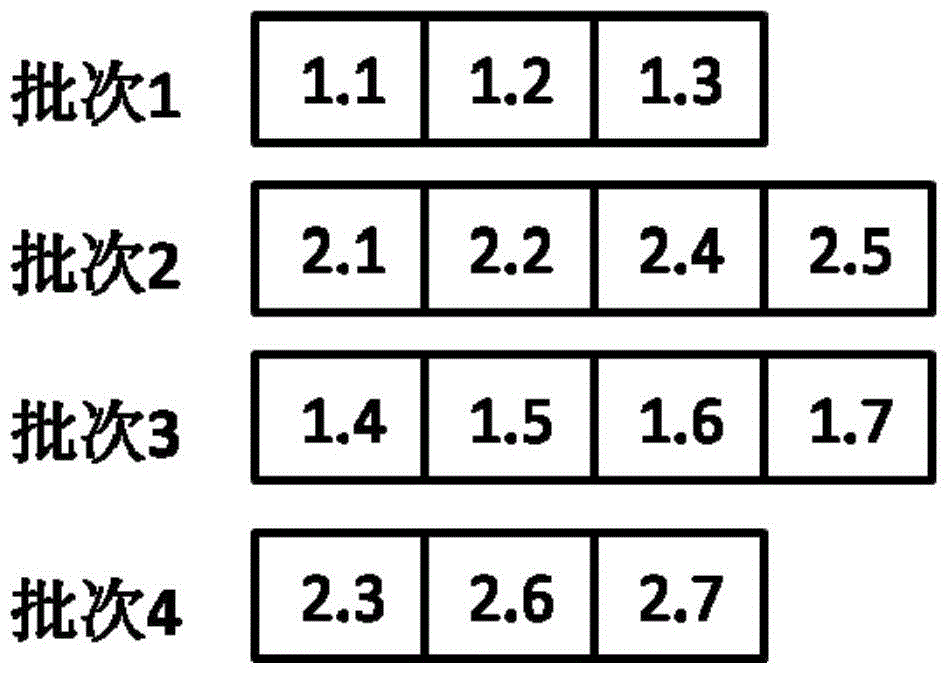

[0051] The improved compact genetic algorithm flowchart used by the present invention is as attached figure 1 shown. Taking the curing process in the semiconductor back-end manufacturing process as an example to illustrate, figure 2 is the initial sampling probability model diagram, image 3 is the workpiece batch diagram obtained for using the present invention, Figure 4 is the workpiece batch graph obtained based on the first-come-first-served processing rule.

[0052] The implementation process of the present invention will be explained below in conjunction with technical solution examples and accompanying drawings.

[0053] Table 1 describes data such as the processing time at the end of the previous process and the processing time of the curing process, Lot type, minimum batch size and maximum batch size of processing equipment in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com