Fast evaluation method facing parallel batch processing machine dynamic scheduling

A batch scheduling and dynamic technology, applied in the direction of comprehensive factory control, comprehensive factory control, control/regulation system, etc., can solve the problems of reducing the number of evaluations, high computational cost, sufficient search, time infeasibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

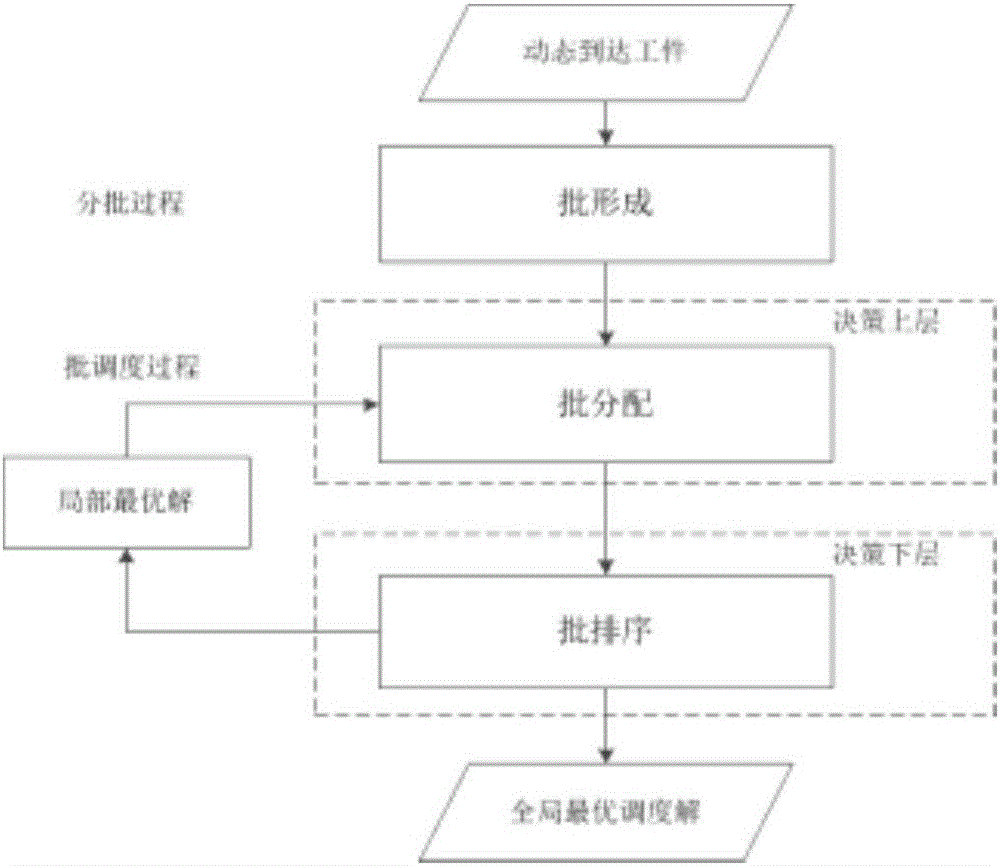

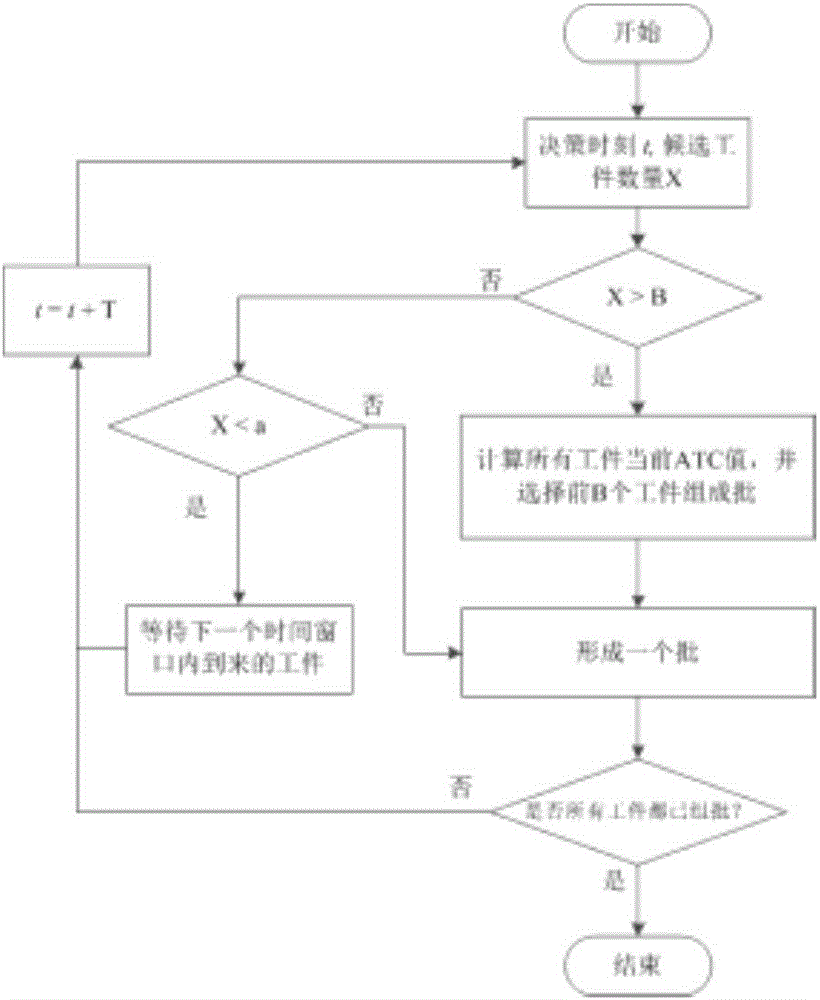

[0045] The following content will describe the present invention in detail in conjunction with the accompanying drawings.

[0046] 1. Problem model parameter setting;

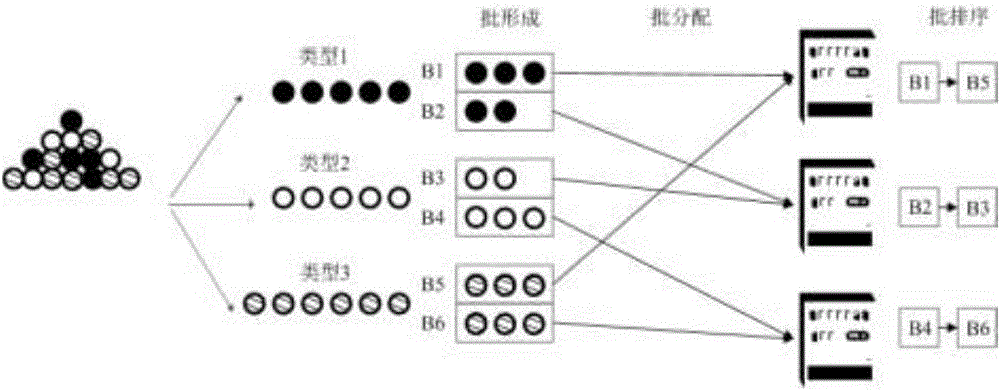

[0047] 1.1. Basic information attributes of the production line: workpiece type f; workpiece quantity n; equipment quantity m, and batch maximum capacity B.

[0048] 1.2. Workpiece dynamic feature attributes: workpiece arrival tightness control parameter η; workpiece processing time p, workpiece delay time d; workpiece weight w.

[0049] In the specific simulation experiment, the parameter settings are shown in the table below:

[0050]

[0051]

[0052] 2. Proxy model establishment and selection;

[0053] 2.1 According to the scale of the problem, we randomly sampled 400 sets of training data using the Latin square sampling method to build the model. After the training data is obtained, the data is evenly and randomly divided into 5 parts by cross-validation method, one of which is used as the test da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com