Production method for colored nylon DTY glove special-used silk

A production method and special yarn technology, which are applied in the directions of melt spinning, adding pigments in spinning solution, mono-component polyamide rayon, etc., can solve the problems of unsuitable gloves, poor elasticity and shrinkage of colored nylon, and high cost , to achieve the effect of solving environmental pollution and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

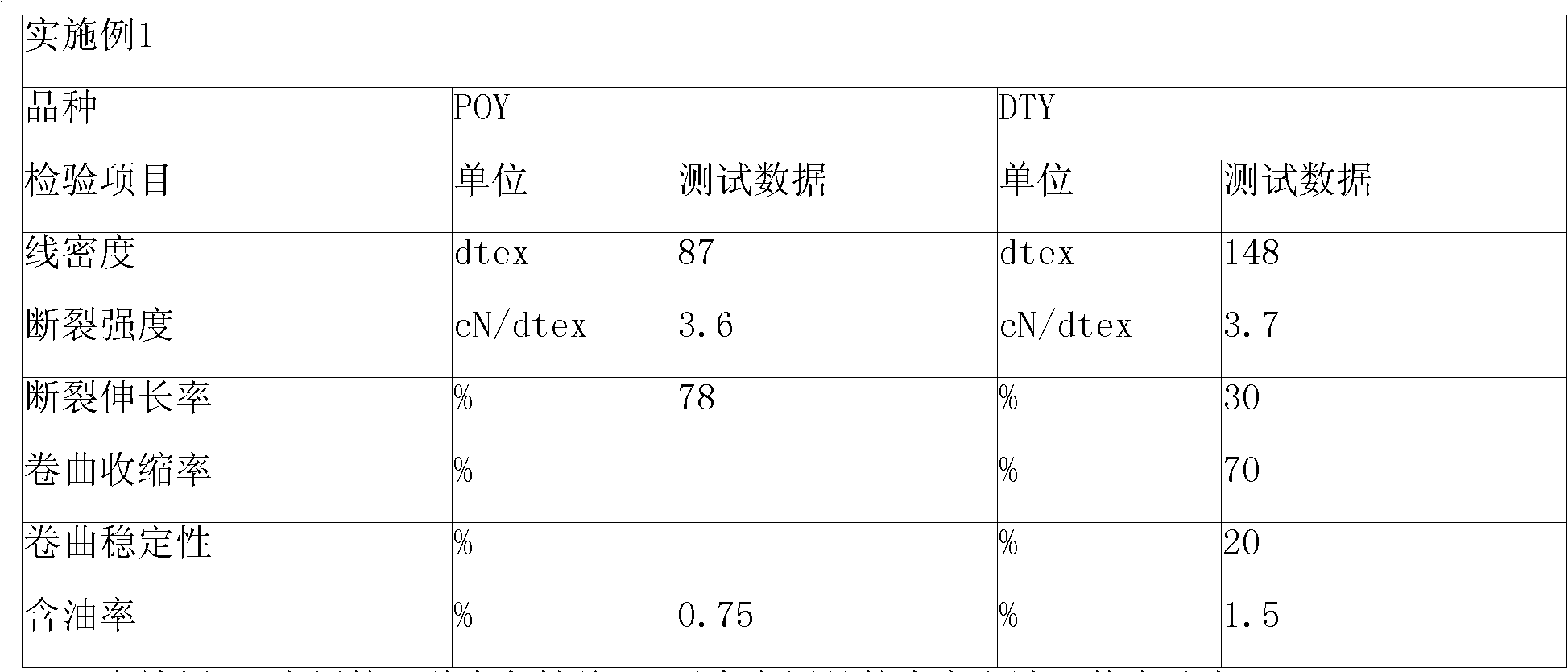

Embodiment 1

[0019] Example 1: In this example, a method for producing colored nylon DTY gloves special yarn, the steps are:

[0020] a. Dry the black masterbatch. The drying temperature of the masterbatch is 85°C and the drying time is 4.5 hours. Then add the masterbatch to the masterbatch machine, and then mix the masterbatch and nylon chips into the screw extruder. Extrusion and melting, the viscosity of the nylon chip is 2.45, and the added masterbatch accounts for 3.5% of the total mass after mixing;

[0021] b. Put the melted mixture into the spinning box for spinning. The temperature in the spinning box is 262°C and the spinning speed is 4250m / min. The thread is metered by a spinning metering pump, and then passed into the jet The silk components are spun, then cooled, oiled, and wound into POY;

[0022] c. Pass the POY into the texturing machine for texturing to form the original yarn, and then pass the original yarn through the roller for under-stretching, the stretching ratio is 1.26, ...

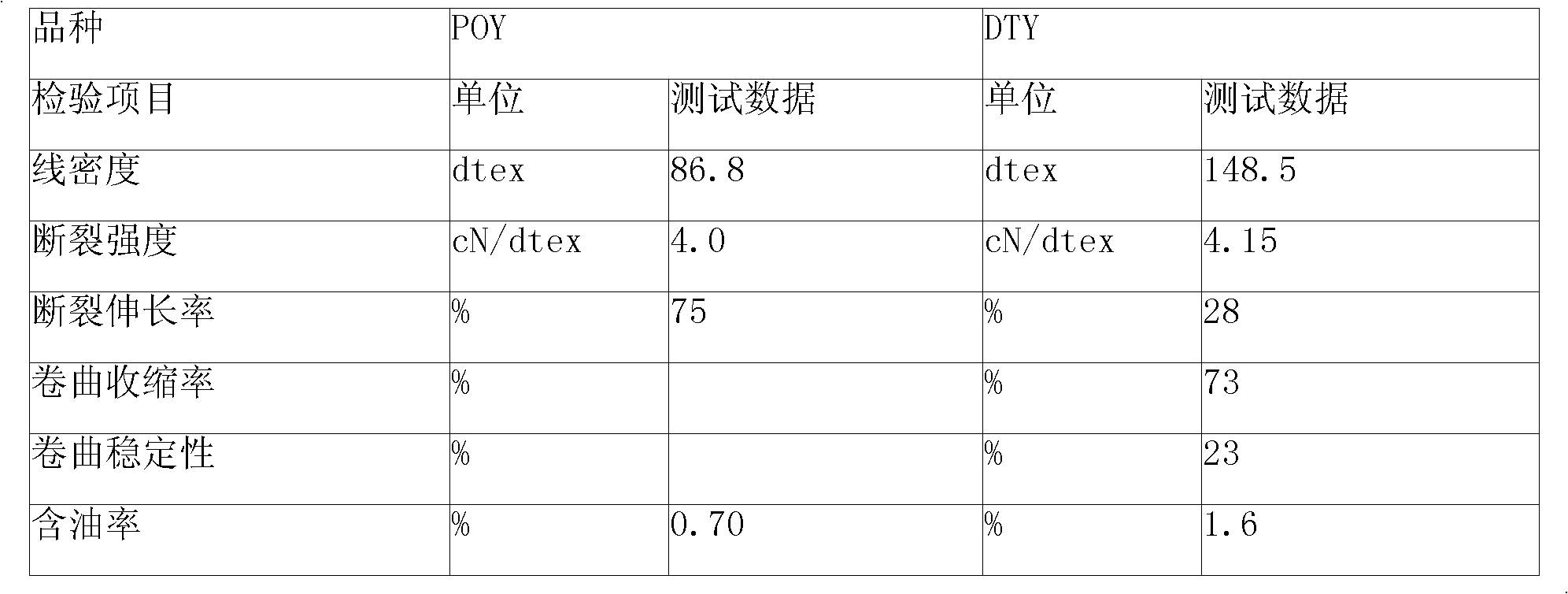

Embodiment 2

[0025] Example 2: The production method of a colored nylon DTY glove special yarn of this example, the steps are:

[0026] a. Dry the gray masterbatch. The drying temperature of the masterbatch is 90℃ and the drying time is 5 hours. Then it is added to the masterbatch machine, and then the masterbatch and nylon chips are mixed and put into the screw extruder. Extrusion and melting, the viscosity of the nylon chip is 2.45, and the added masterbatch accounts for 4% of the total mass after mixing;

[0027] b. Put the melted mixture into the spinning box for spinning. The temperature in the spinning box is 258°C and the spinning speed is 4300m / min. The thread is measured by a spinning metering pump, and then it is fed into the jet The silk components are spun, then cooled, oiled, and wound into POY;

[0028] c. Pass the POY into the texturing machine for texturing to form the original yarn, and then pass the original yarn through the roller for under-stretching, the stretching ratio is ...

Embodiment 3

[0032] Example 3: The production method of a colored nylon DTY glove special yarn of this example, the steps are:

[0033] a. Dry the bleached masterbatch. The drying temperature of the masterbatch is 90℃ and the drying time is 7 hours. Then it is added to the masterbatch machine, and then the masterbatch and nylon chips are mixed and put into the screw extruder. Extrusion and melting are carried out inside, the viscosity of the nylon chip is 2.42, and the added masterbatch accounts for 2.5% of the total mass after mixing;

[0034] b. Put the melted mixture into the spinning box for spinning. The temperature in the spinning box is 257°C, and the spinning speed is 4300m / min. The thread is measured by a spinning metering pump, and then it is fed into the jet The silk components are spun, then cooled, oiled, and wound into POY;

[0035] c. Pass the POY into the texturing machine for texturing to form the original yarn, and then pass the original yarn through the roller for under-stretc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com