Controllable powder-feeding mechanism of power forming machine

A controllable and forming machine technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of collision between the punch and the powder feeding hopper, affecting the powder forming machine, increasing the height of the whole machine, etc., to achieve fast powder feeding, The powder feeding speed can be controlled to reduce the effect of conveying energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

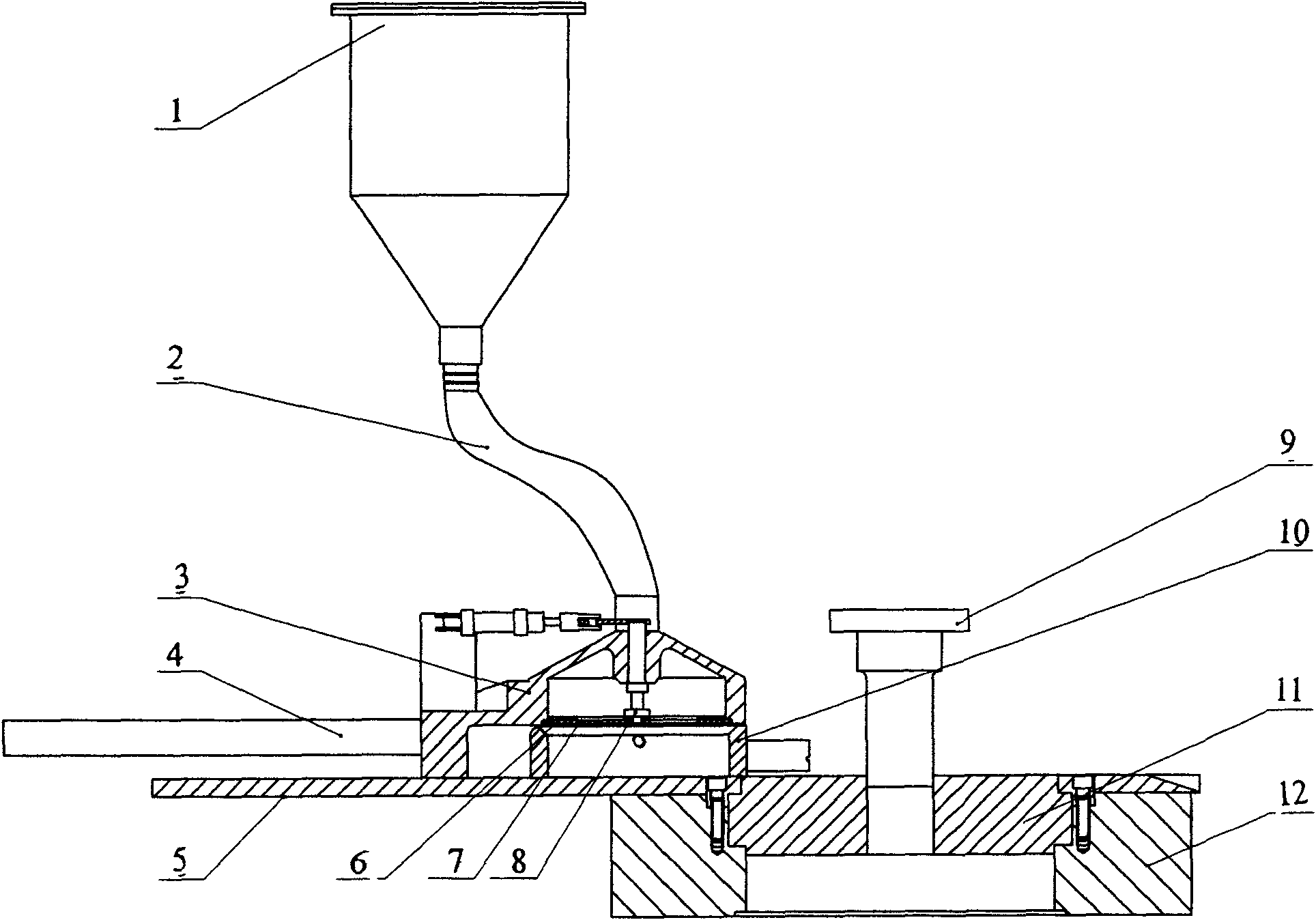

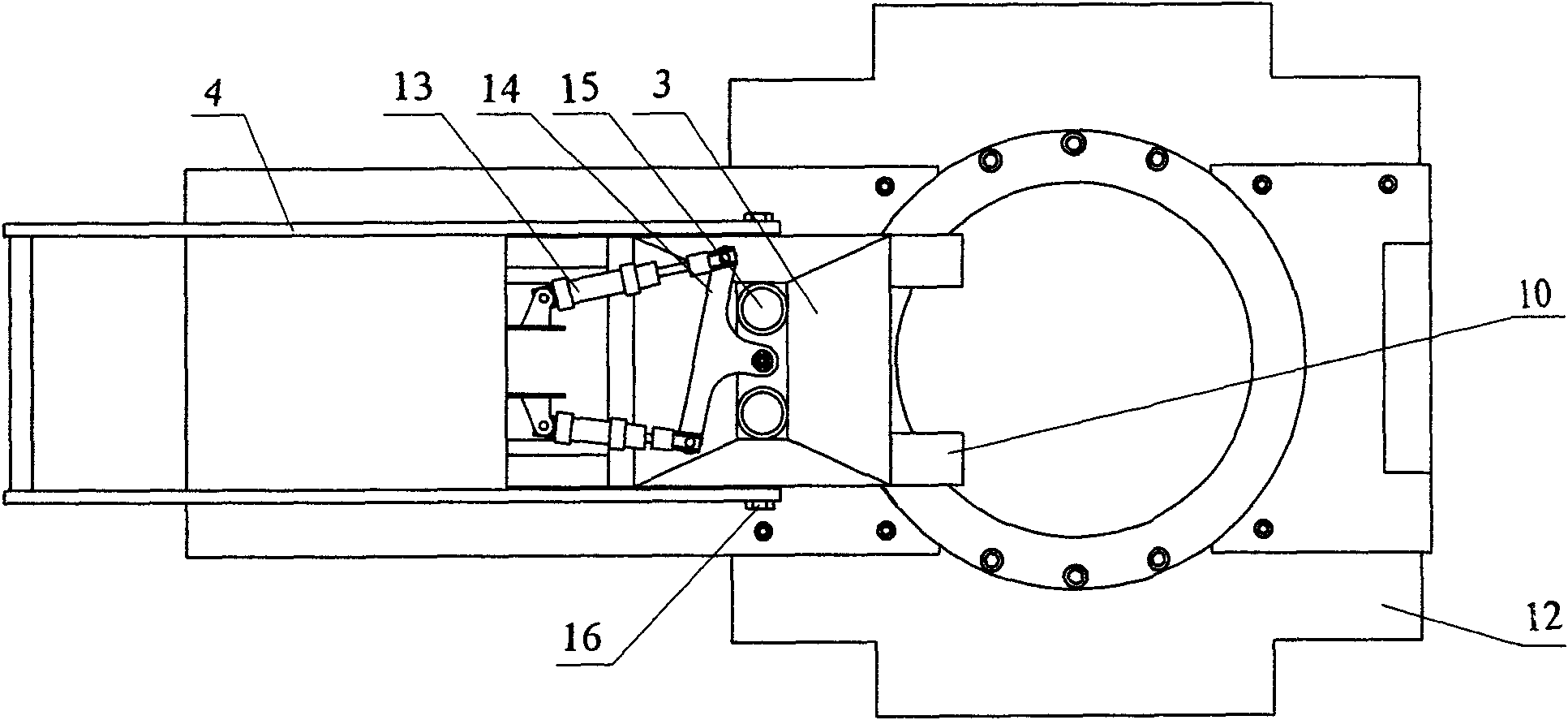

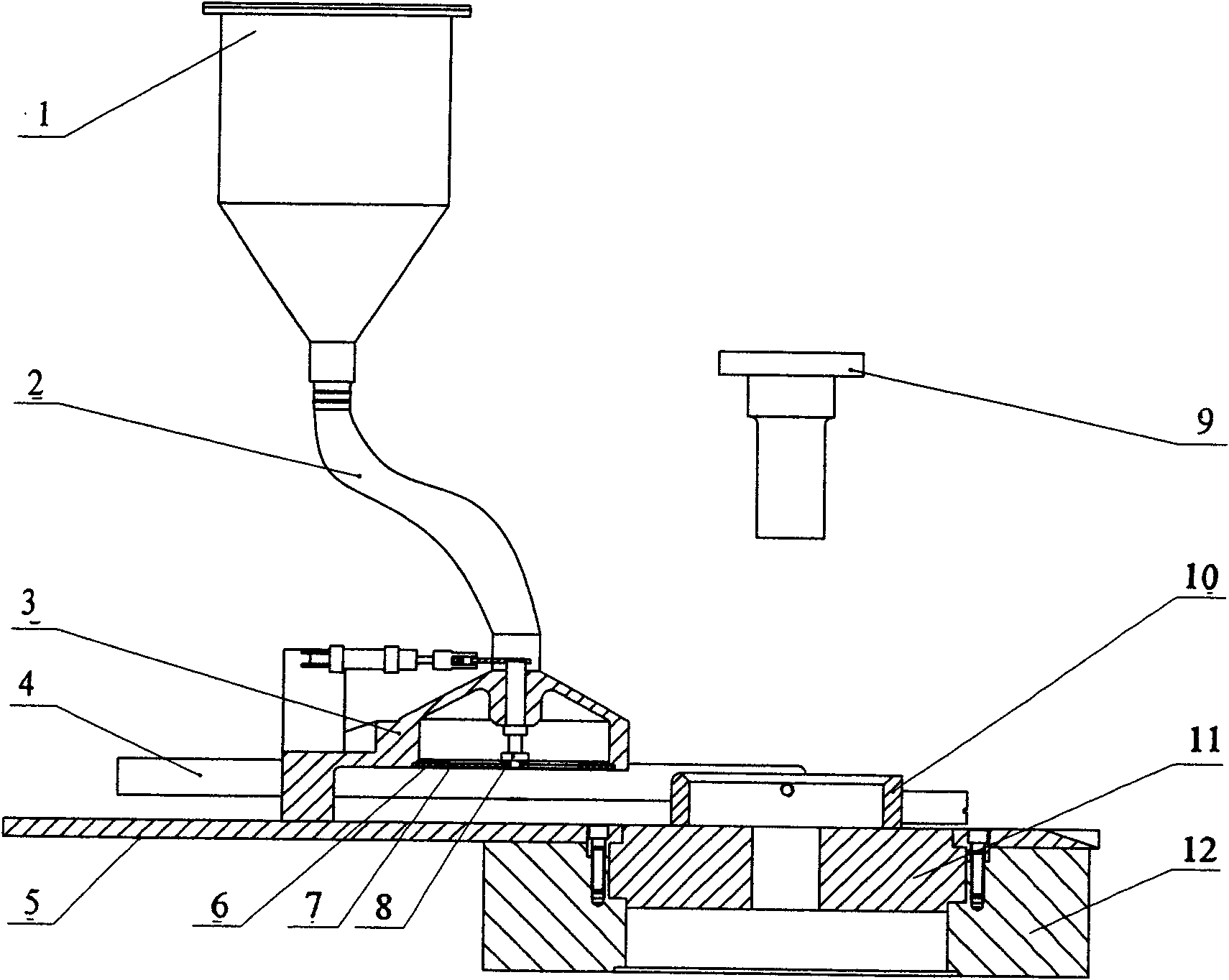

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The powder feeding plate 5 is fixed on the female template 12 with screws, and the upper punch 9 on the powder molding machine cooperates with the female mold 11, which are all prior art parts.

[0018] The upper hopper 3 is an integral part, one side is stepped, the other side is a cantilever chamber, and there is more than one feeding port in the middle of the upper surface. There are two symmetrical feeding ports 15 on the upper hopper, and the inner wall of the cantilever chamber has two inlets. There is a boss with a through hole between the feed openings, and the rotating shaft 8 passes through the through hole on the boss in the middle of the upper hopper and is installed on the upper hopper 3 .

[0019] The driving mechanism can be different power sources such as cylinder promotion or mechanical transmission, and the existing driving mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com