Double-acting piston compressor guided by a roller and driven by a gearwheel and racks

A double-acting piston and compressor technology, applied in piston pumps, engine control, combustion engines, etc., can solve the problems of increased ignition time, limitation, and inability to generate high torque, and achieve reduced mechanical friction loss, long-lasting operation, and reduced vertical height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

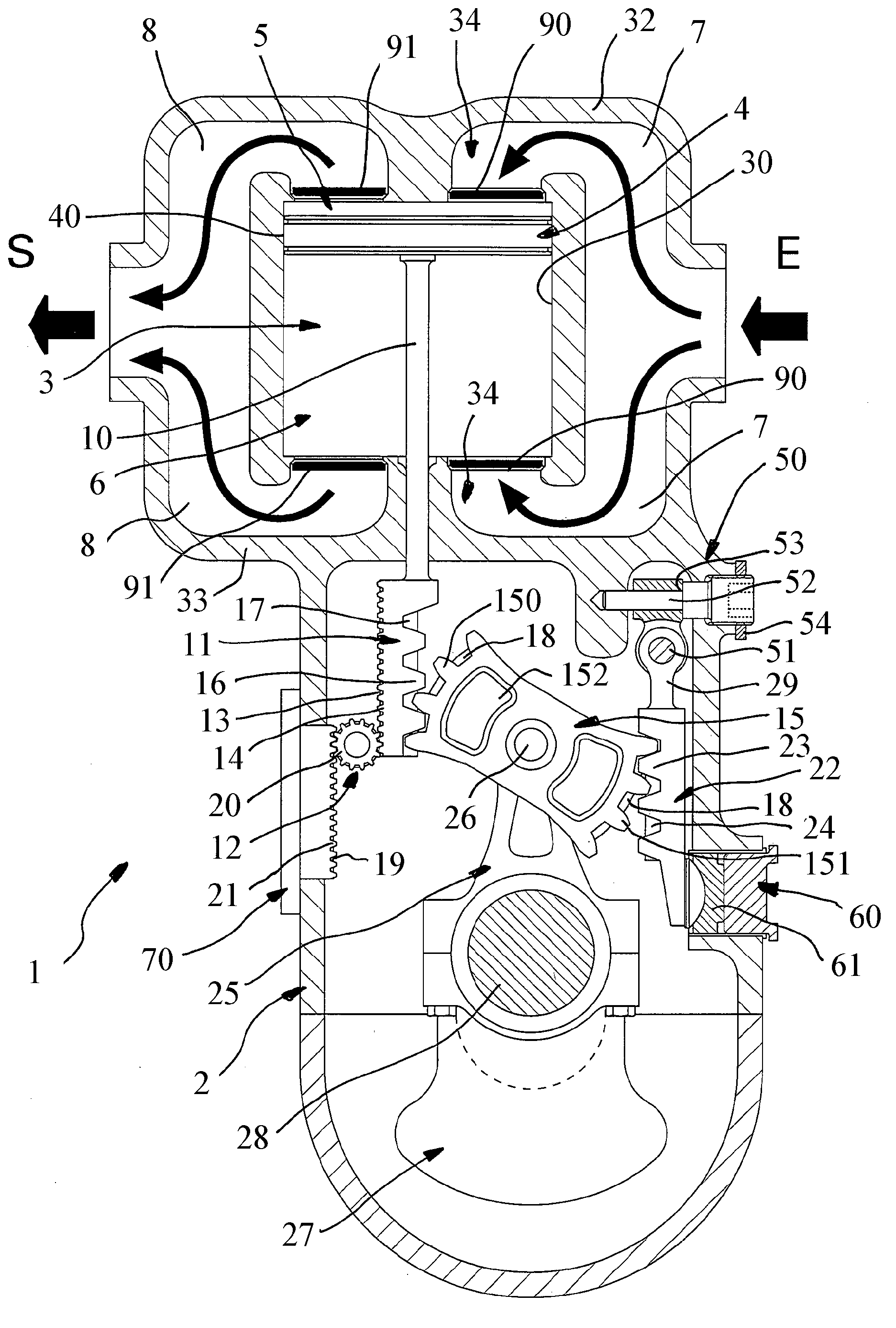

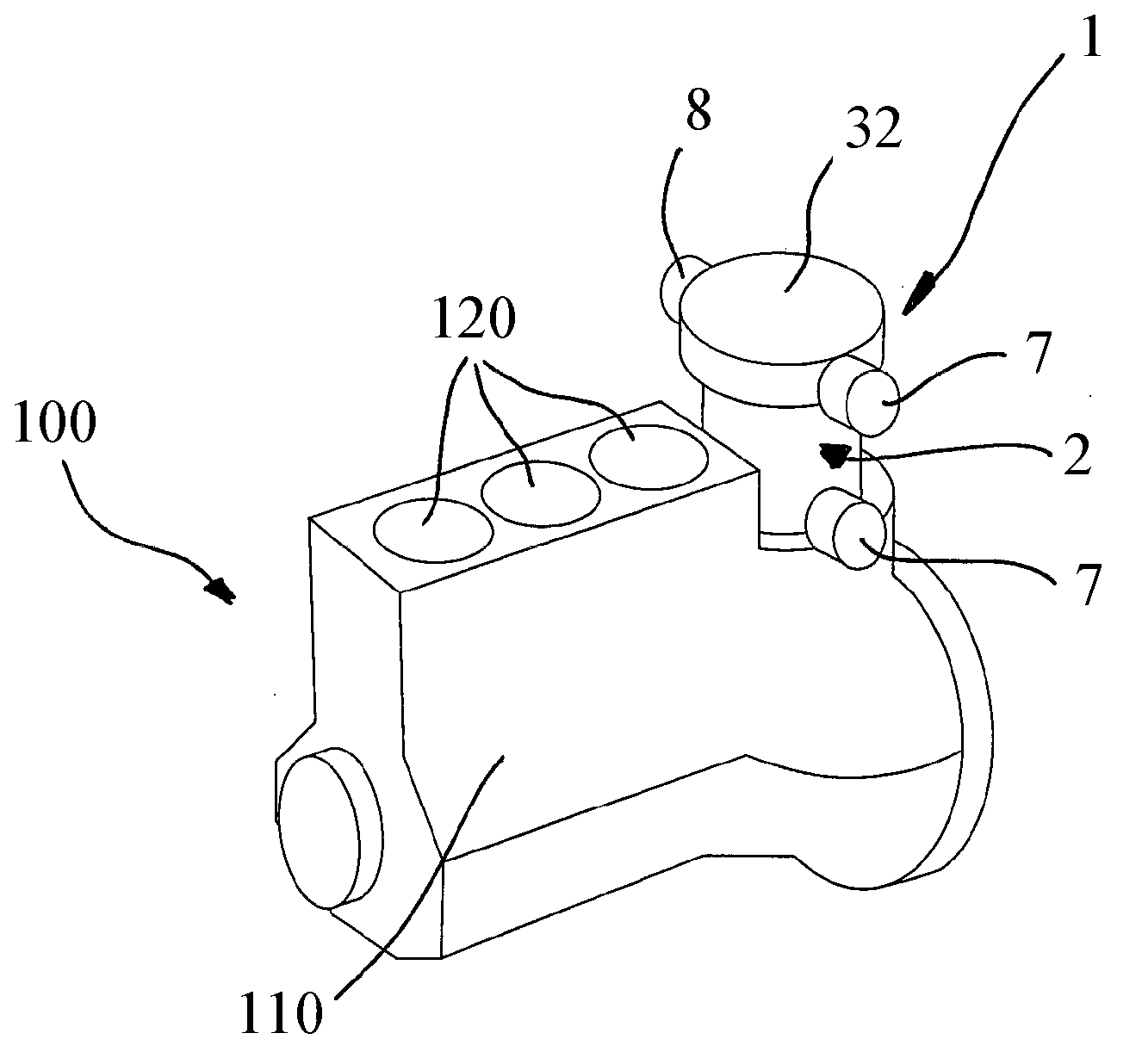

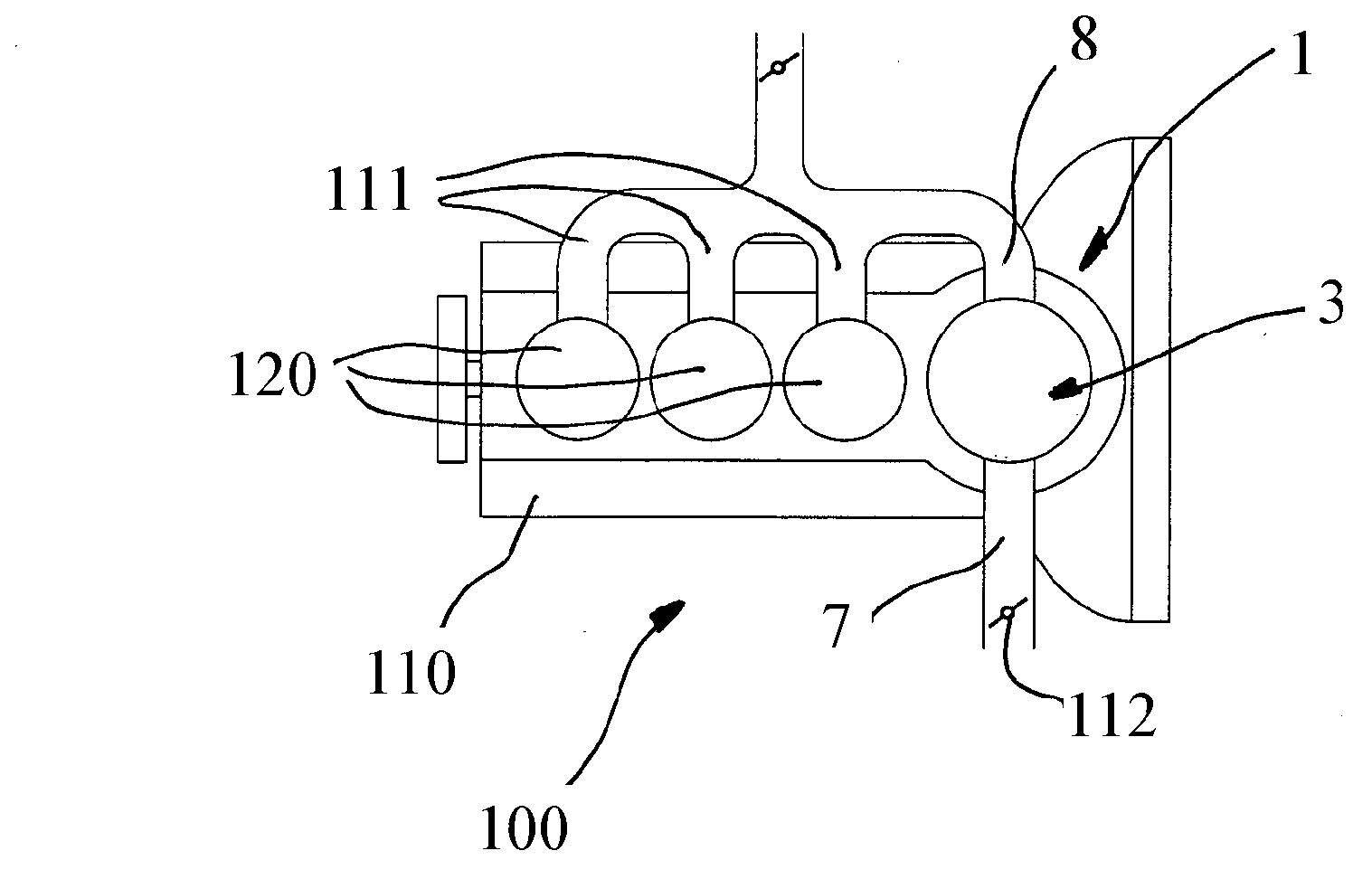

[0129] figure 1 Depicted is a double-acting piston compressor 1 comprising a compressor housing 2 providing at least one cylinder 3 within which a double-acting piston 4 moves.

[0130] Said cylinder 3 is closed at each end by a cylinder head 32, 33 respectively so that said cylinder 3 and said piston 4 jointly define an upper chamber 5 and a lower chamber 6, said chambers each being provided with at least one inlet duct 7 and at least one output conduit 8 , wherein said conduits each comprise at least one valve 90 , 91 .

[0131] According to other embodiments, each valve 90 , 91 may be replaced by a poppet valve, a slide valve or any other device allowing the cyclic opening and closing of the inlet conduit 7 and outlet conduit 8 .

[0132] Said valves 90, 91 comprise dampers and / or restrictors comprising, for example, elastic connections between the valve bodies and bearing surfaces of said valves, the valve throttles passing through The bearing surface rests on the seat o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com