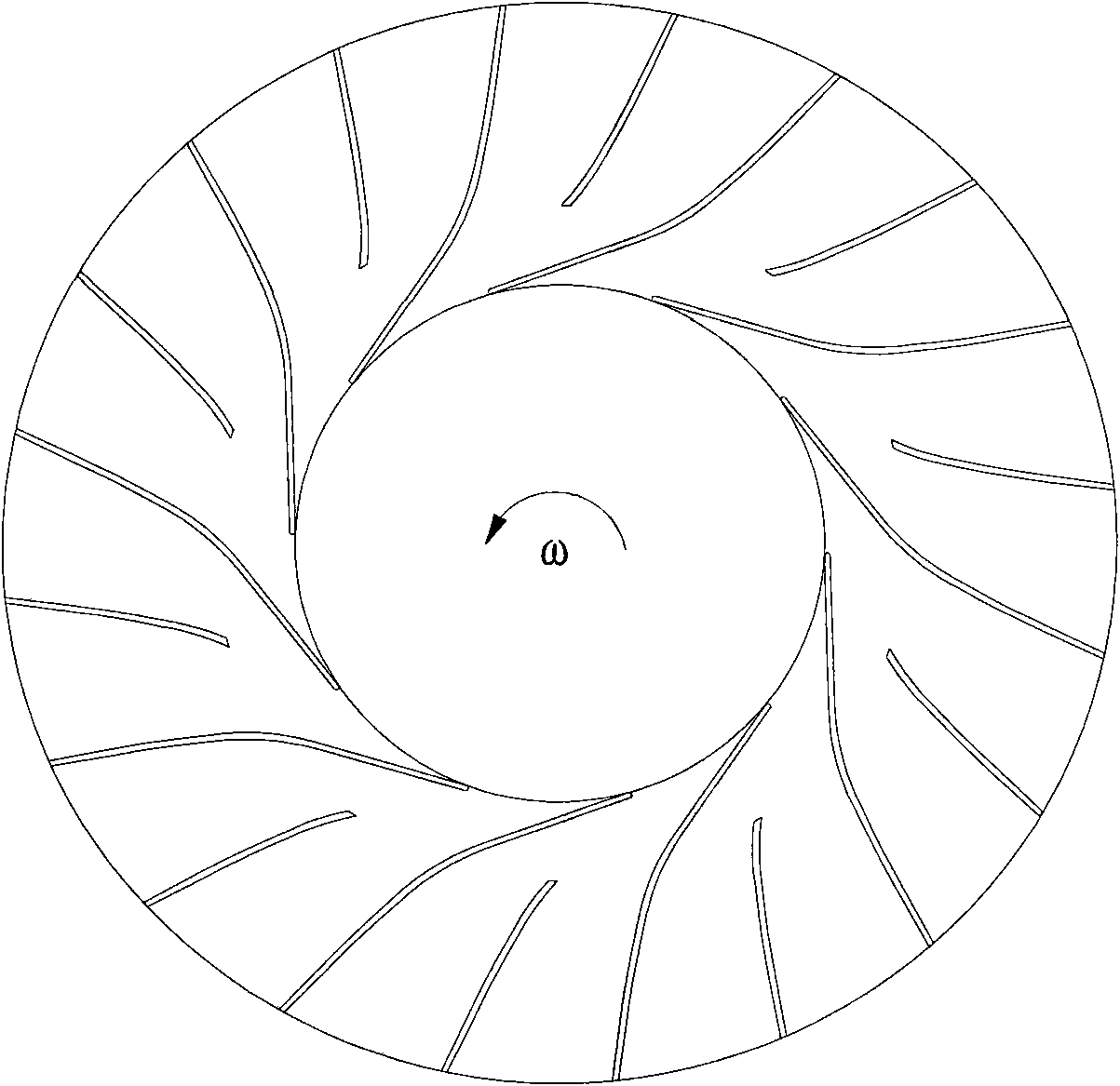

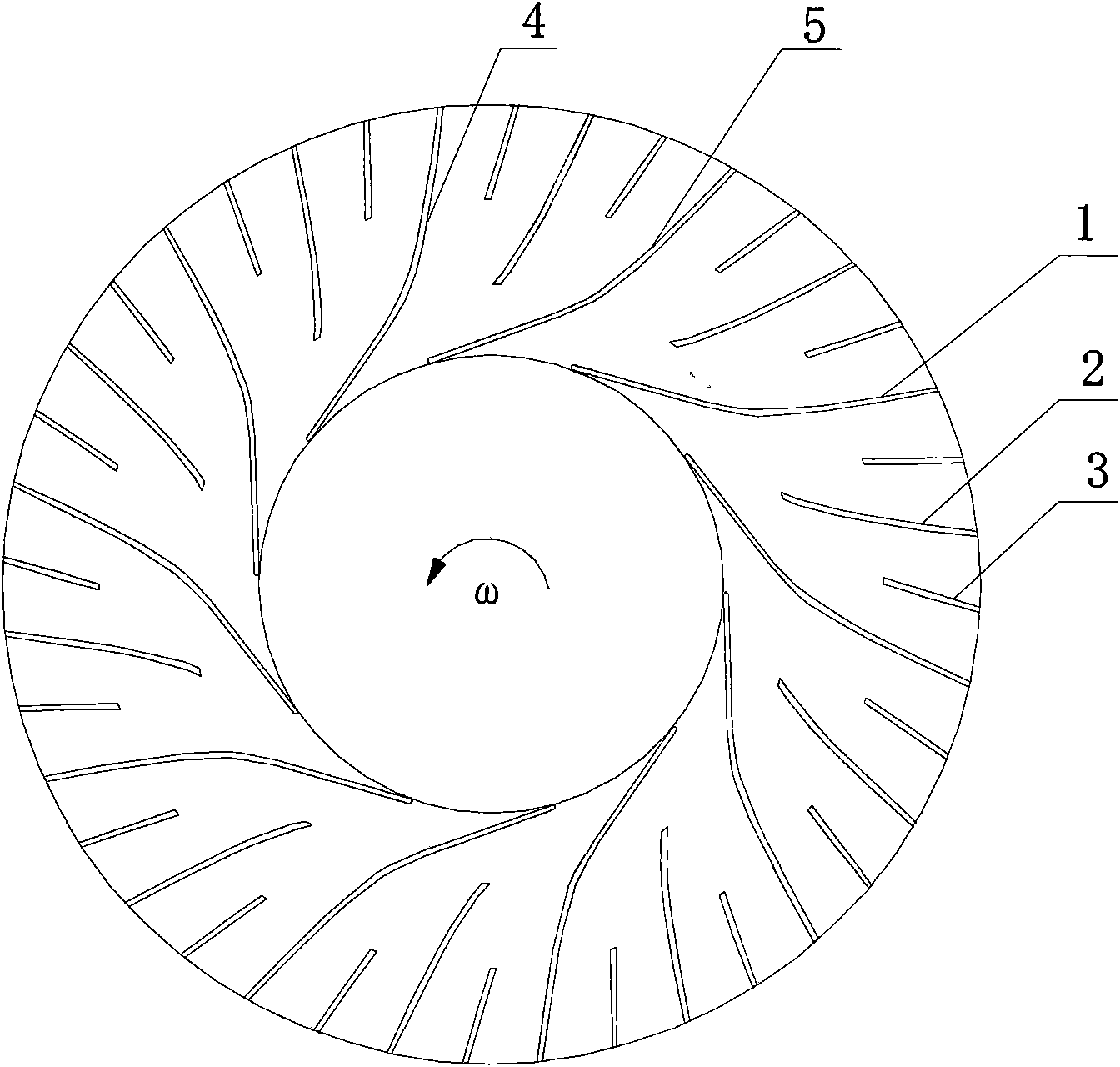

Secondary splitter blade type centrifugal impeller

A technology of splitter blades and centrifugal impellers, which is applied to non-variable pumps, parts of pumping devices for elastic fluids, machines/engines, etc., can solve problems such as weak boosting capacity and narrow stable operating range, and achieve Effects of improving flow conditions, increasing flow efficiency, and expanding stable operation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

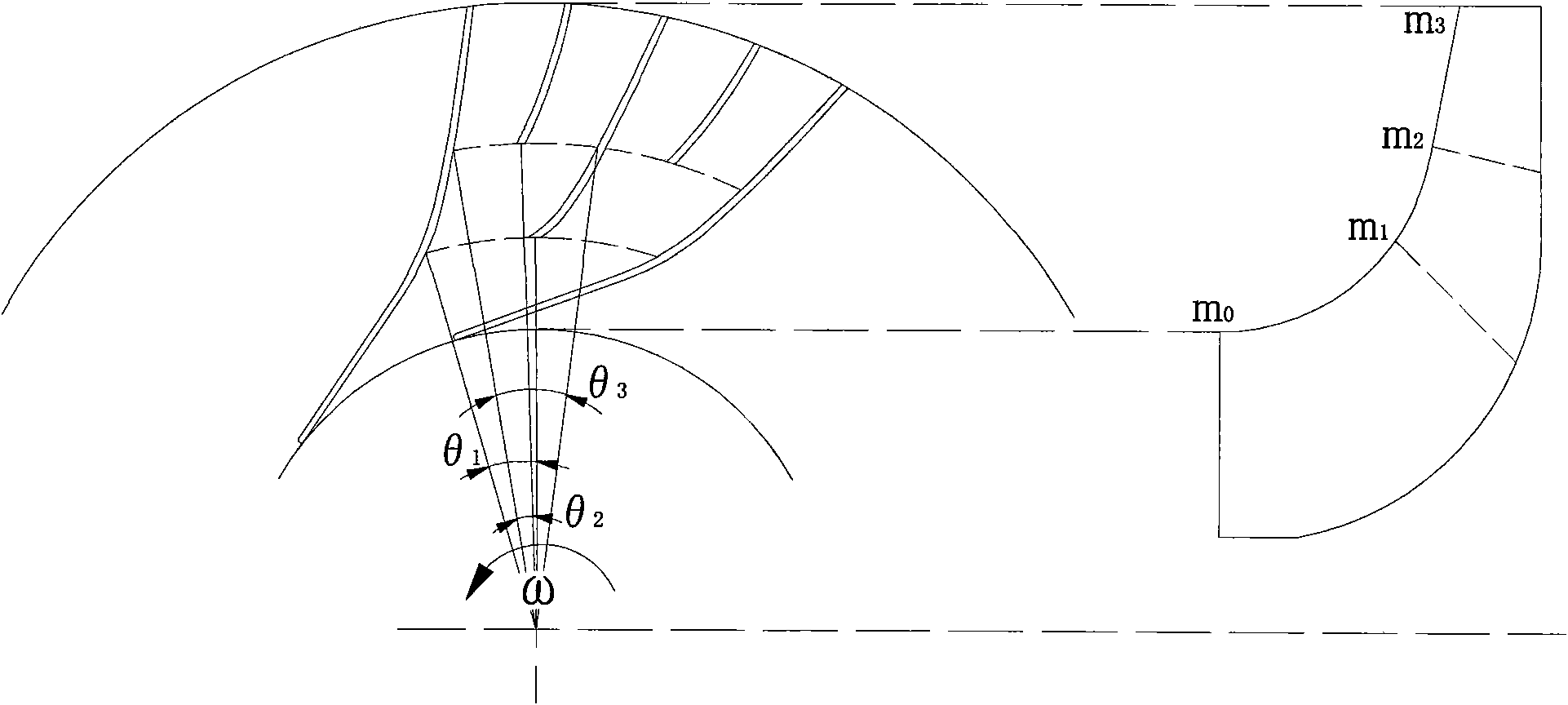

[0024] Example 1: When the first splitter vane meridian relative to the inlet position m 1 =0.1, the meridional direction of the second splitter vane relative to the inlet position m 2 =0.5, the circumferential relative inlet position of the first splitter vane θ 1 =0.5, the circumferential relative inlet position of the second splitter vane θ 2 0.5 on the wheel side and 0.5 on the wheel cover side;

Embodiment 2

[0025] Embodiment 2: When the meridional direction of the first splitter blade is relative to the inlet position m 1 =0.2, the meridional direction of the second splitter vane relative to the inlet position m 2 =0.6, the circumferential relative inlet position of the first splitter vane θ 1 =0.45, the position of the second splitter blade relative to the inlet in the circumferential direction θ 2 0.45 on the wheel side and 0.55 on the wheel cover side;

Embodiment 3

[0026] Embodiment 3: When the meridional direction of the first splitter blade is relative to the inlet position m 1 =0.3, the meridional direction of the second splitter vane relative to the inlet position m 2 =0.7, the circumferential relative inlet position of the first splitter vane θ 1 =0.4, the position of the second splitter blade relative to the inlet in the circumferential direction θ 2 0.4 on the wheel side and 0.6 on the wheel cap side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com