Servo motor drive control device

A technology of servo motor and drive control, applied in the field of learning control, can solve problems such as difficult machining, and achieve the effect of reducing position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

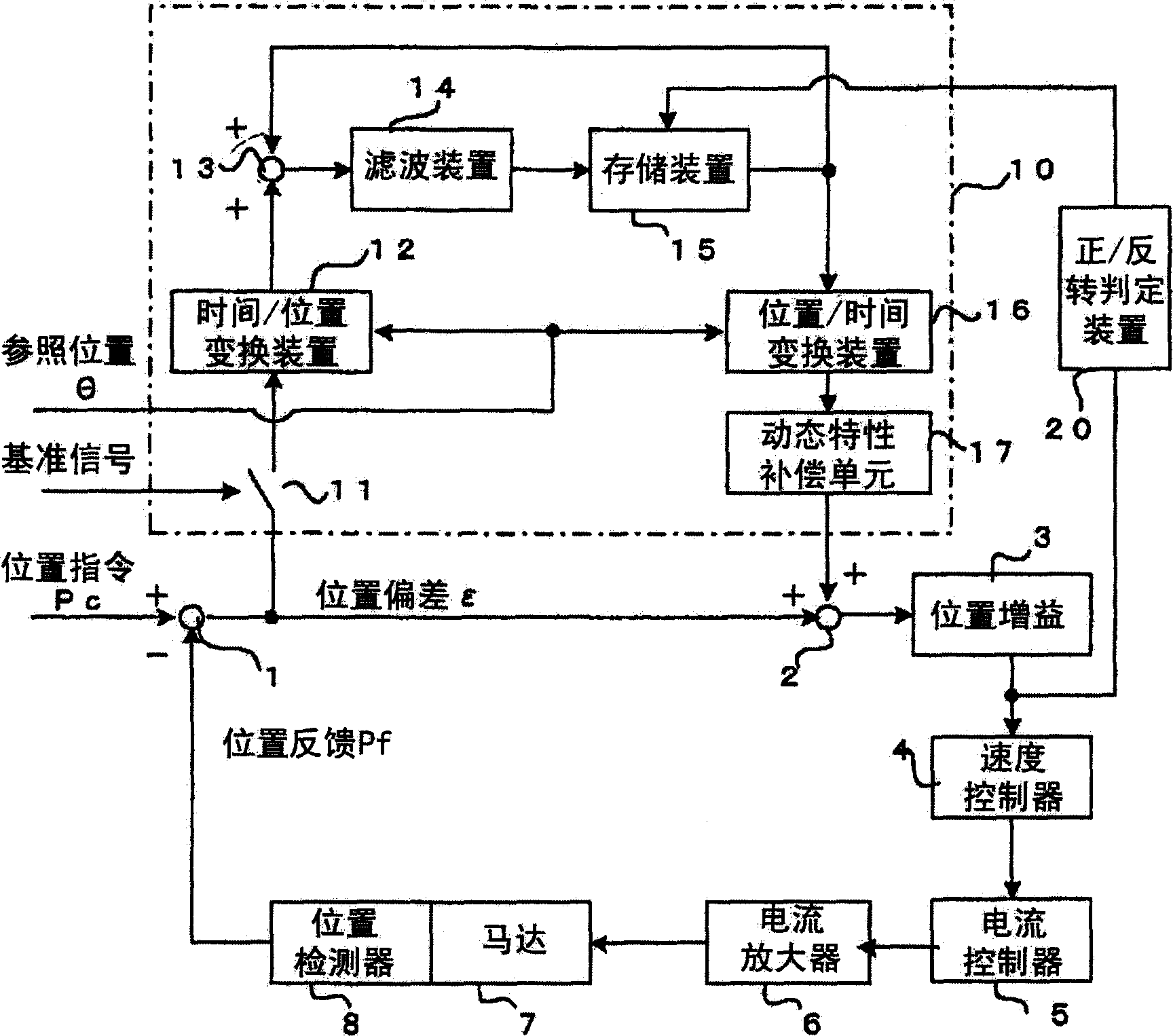

[0031] figure 1 It is a block diagram of main parts of the first embodiment of the present invention.

[0032] In the arithmetic unit 1, the position command Pc output from the upper control device such as a digital control device is subtracted from the servomotor mounted on the servomotor 7 to detect the position of the servomotor (or the position of the driven body driven by the servomotor). The feedback position Pf of the position detector 8 is used to obtain the position deviation ε. Then, the arithmetic unit 2 adds a correction amount from the learning control device 10 described later to the position deviation ε for correction, and multiplies the corrected position deviation by the position gain 3 to obtain a speed command. That is, position loop control processing is performed to obtain a speed command.

[0033]For this speed command, the speed loop control process is performed by the speed controller 4 (obtaining the speed deviation as the difference between the spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com