Vibration-proof structure of series fan

A fan and anti-vibration technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pump devices, etc., can solve the problem of aging of internal electronic component contacts, great influence on noise value evaluation, and shortening of the system Life and other issues, to achieve the best efficacy and life, to avoid resonance effects and vibration noise, to avoid the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

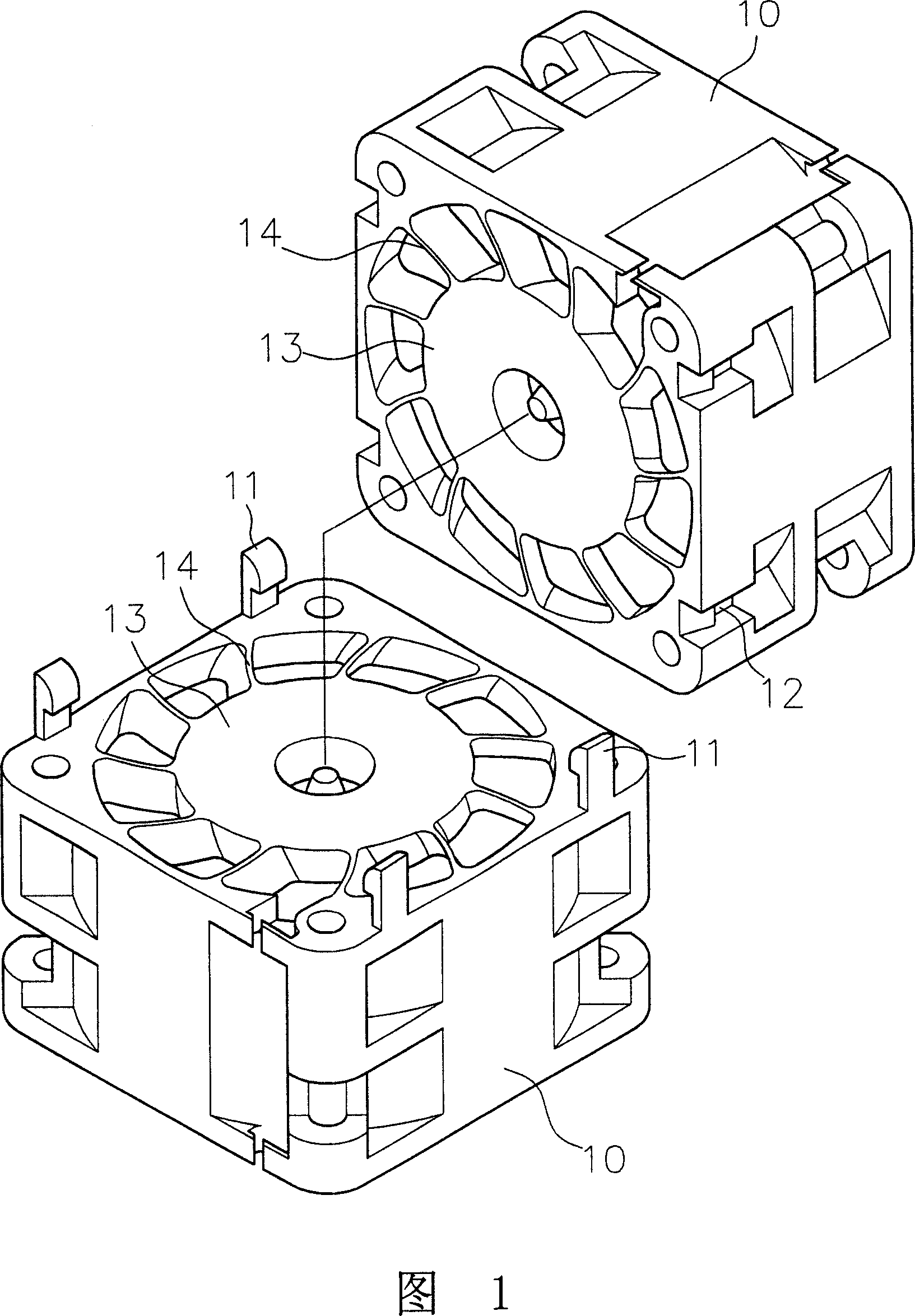

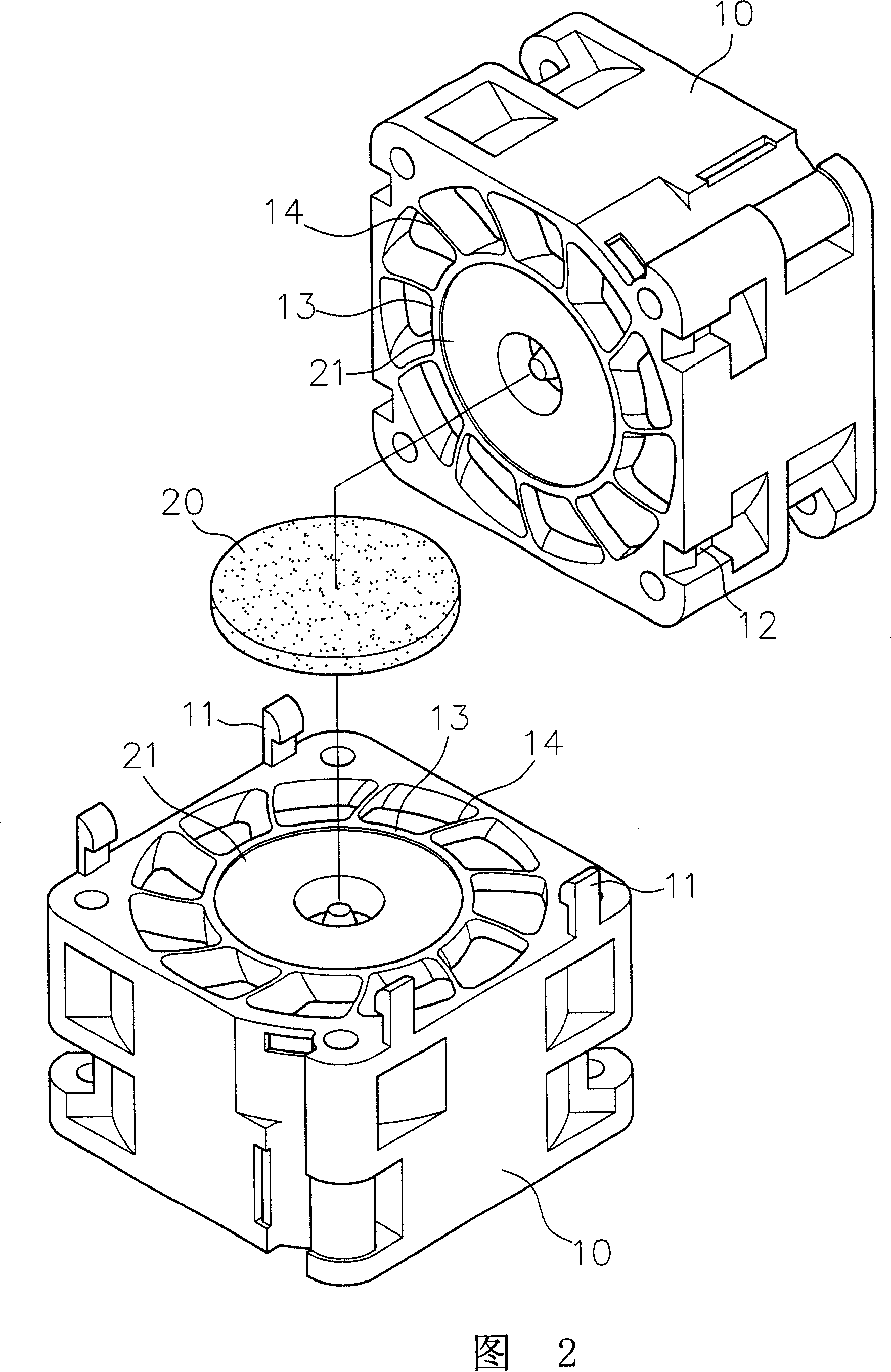

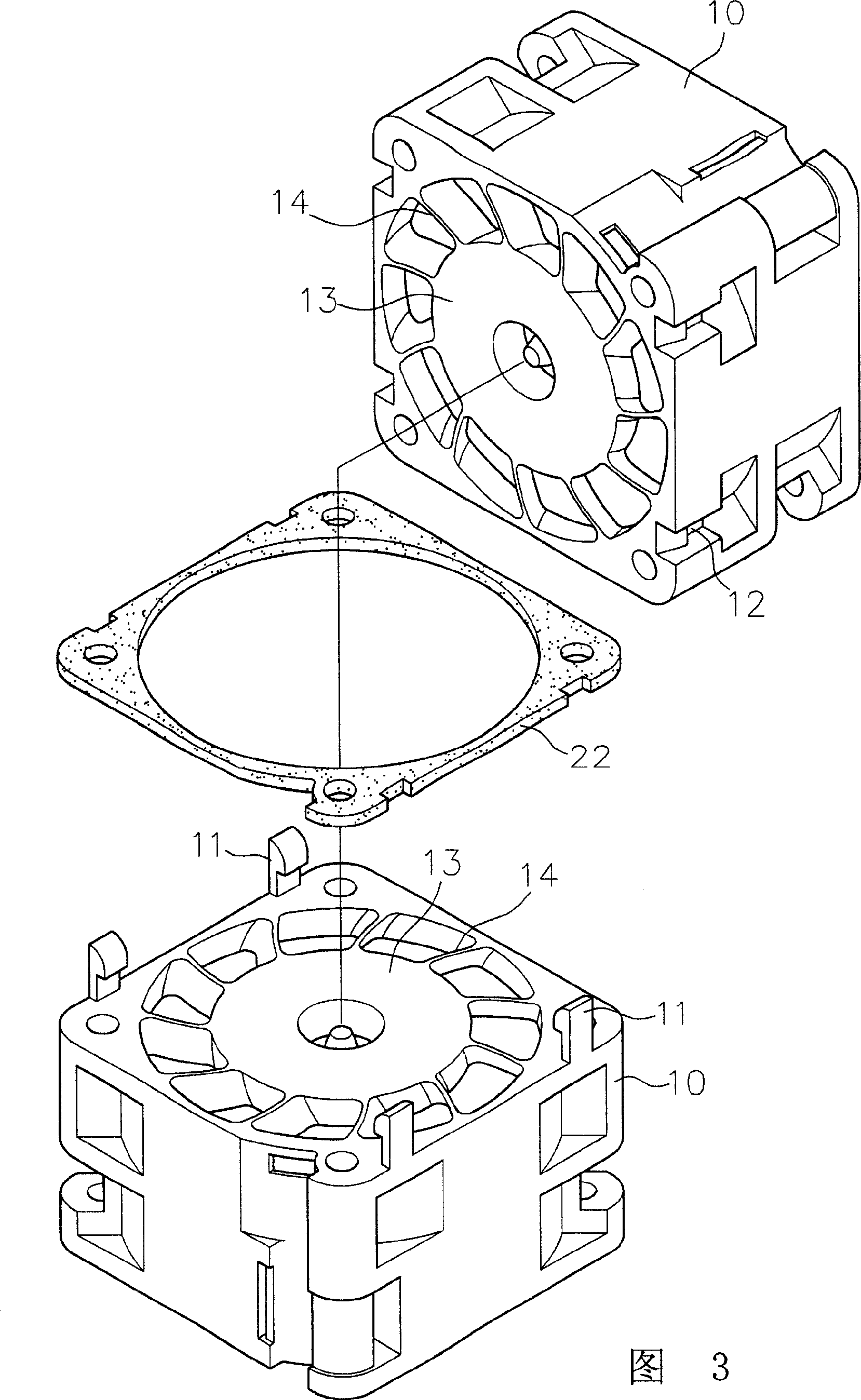

[0022] The invention relates to a vibration isolation structure of a serial fan, wherein the serial fan is composed of at least two fans connected in series, and a vibration isolation component is arranged at the junction of each adjacent fan frame, and the vibration isolation component itself is used for buffering and Absorb vibration characteristics, isolate and reduce the vibration fundamental frequency of series fans.

[0023] In the following, two embodiments in which the present invention is actually applied in series with dual fans are listed and described with reference to the accompanying drawings.

[0024] As shown in Figure 2, the serial fan implemented in the present invention includes at least two fan frames 10, and the two fan frames 10 are respectively provided with corresponding buckle parts 11 and buckle grooves 12, so that the two fan frames 10 can be connected in series. switch combination.

[0025] The inside of the fan frame 10 is a hollow accommodation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com