On-sea alignment and assembly method for huge blocks of hull

A giant, total section technology, applied in ship parts, ship construction, ship design, etc., can solve the problems of too many, unable to load, and the size of the giant total section of the hull is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

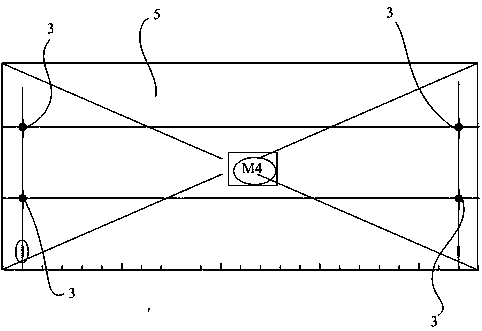

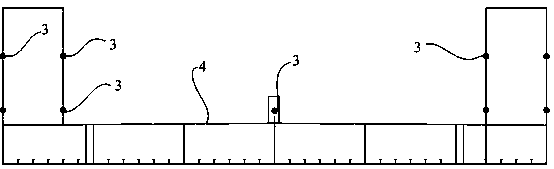

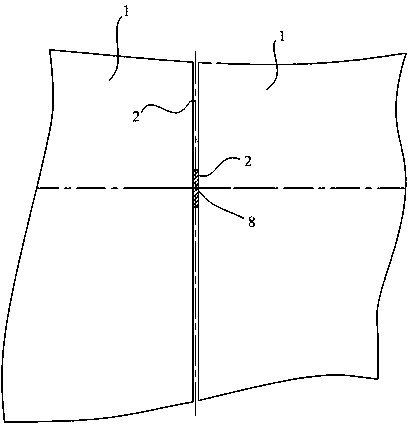

[0035] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The present invention proposes an embodiment of a method for aligning and closing the giant general section of the hull at sea. Refer to Figure 1-Figure 13 As shown, it includes the following steps: Step 1: Simulation of each giant general section 1: After the processing of each giant general section 1 is completed, each giant general section 1 is modeled through software, and each giant general section 1 is simulated through the model Loading and data analysis, the simulated loading of the giant total section 1 can be realized through CAD or some commonly used 3D software, such as PROE, etc., and the margin and compensation amount of the giant total section 1 are determined according to the simulated loading analysis results to ensure that the giant total section 1 The gap between the closed welds 2 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com