Shake and vibration reducing electricity generating ship under frame

A ship and underframe technology, applied in the field of ship anti-rolling and vibration reduction equipment, can solve the problems of engineering practical value limitation, inability to reduce cabin low-frequency swing, etc., achieve cost saving, weaken cabin vibration, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention. The expression of the structural position of each component such as up, down, top, bottom, etc. in the description is not absolute, but relative. These directional expressions are appropriate when the various components are arranged as shown in the drawings, but when the positions of the various components in the drawings are changed, these directional expressions are also changed accordingly.

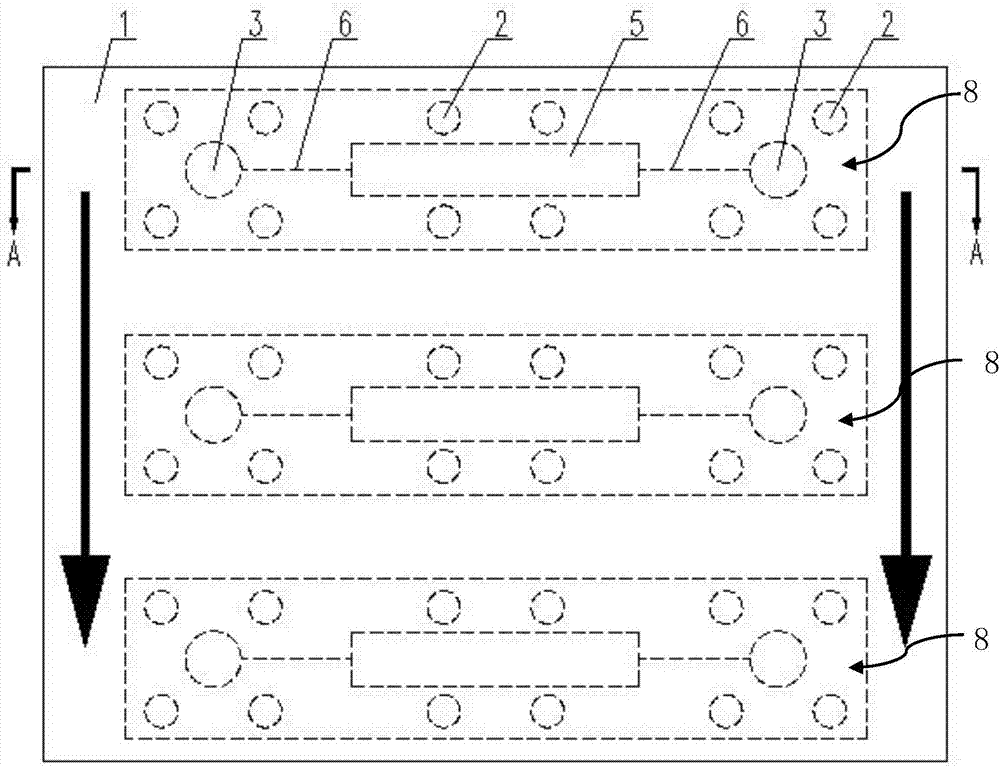

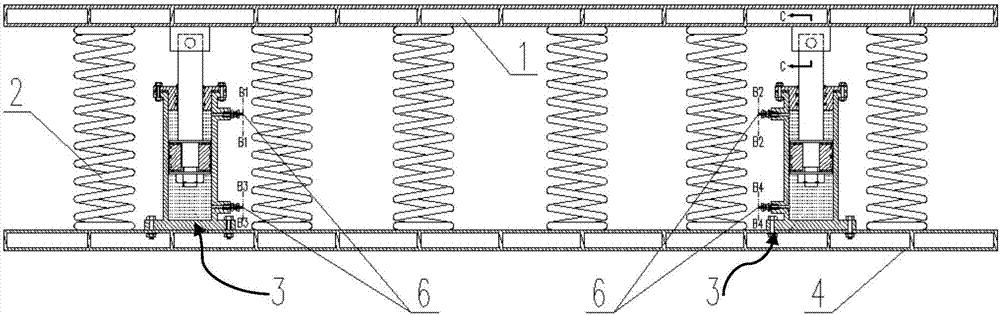

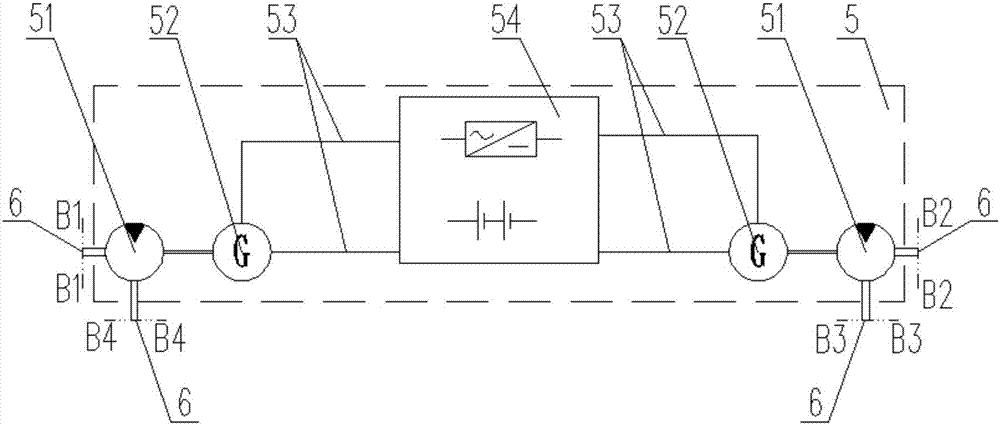

[0032] Such as figure 1 As shown, an anti-rolling and vibration-reducing underframe of a power generation ship includes an upper support frame 1 , a spring 2 , a lower support frame 4 and functional components 8 . The upper support frame 1 is fixed to the cabin of the ship, the lower support frame 4 is fixed to the plyw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com