Method for installing telescopic full-rotation auxiliary thruster

An installation method and thruster technology, applied in the directions of transportation and packaging, ship parts, ships, etc., can solve problems such as low installation accuracy, and achieve the effect of improving construction quality, meeting use requirements, and improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0021] A method for installing a telescopic azimuth auxiliary propeller, comprising the following steps:

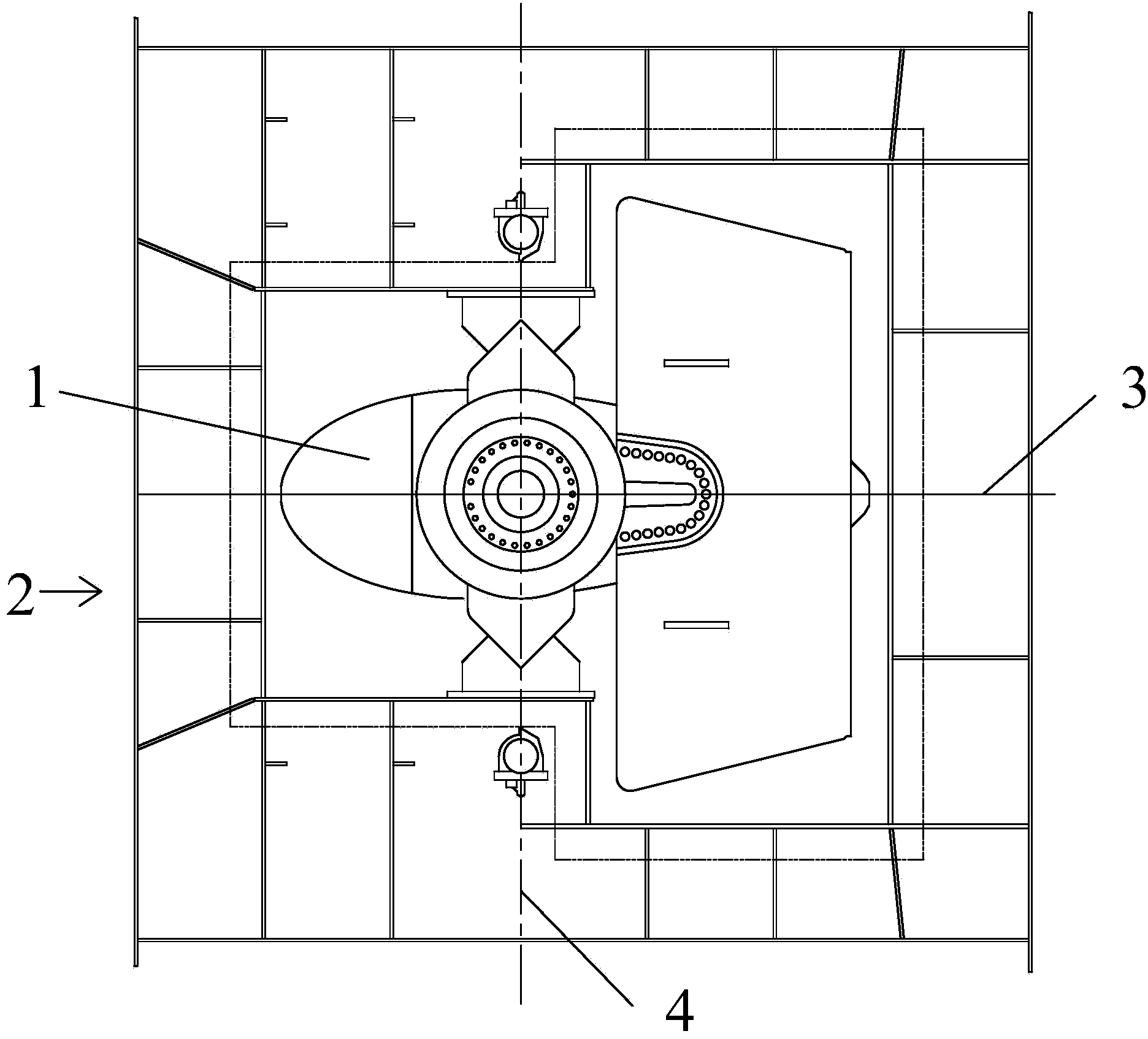

[0022] Step 1: If figure 1 As shown, the telescopic azimuth auxiliary thruster 1, also known as the telescopic rudder propeller, is installed on the section 2 of the hull 2410. Place the section 2 of the hull 2410 on a special bracket with a height of 3.5 meters and fix it firmly to prevent movement during equipment commissioning. The midship line 3 of the hull 2410 section 2 and the FR141 rib line 4 of the installation site are drawn through the equipment, and these two lines are used as the reference line for installation. Considering that the working length (longitudinal) of the telescopic rudder propeller is 2742mm, the obstacles at the installation site should be cleared to ensure that there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com