Weld joint tightness detecting device for ship under construction

A detection device and a technology for tightness, which can be applied in the direction of detecting the occurrence of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, etc. The effect of shipbuilding cycle, reasonable device structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and embodiments.

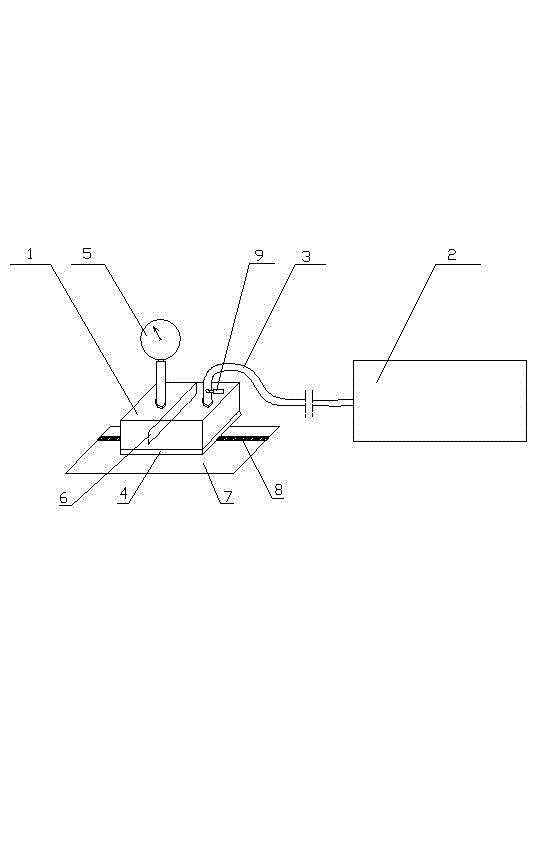

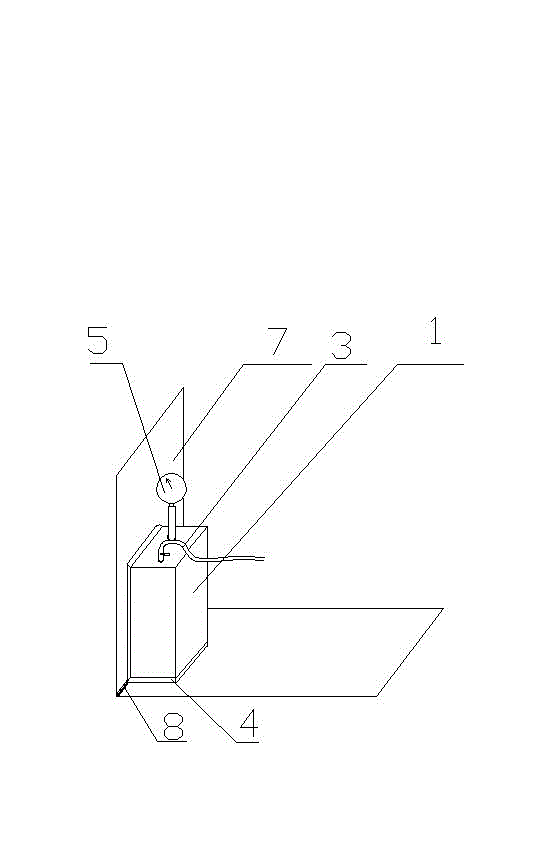

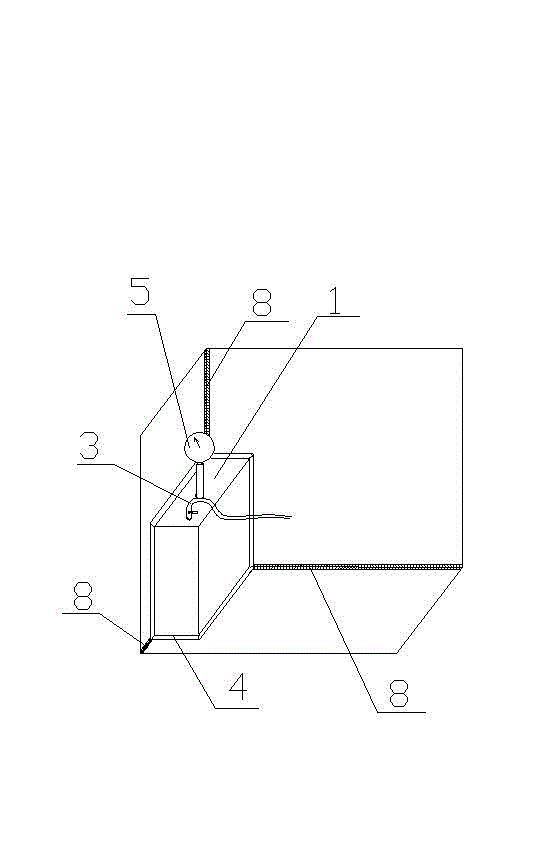

[0017] Such as figure 1 As shown, two steel plates are horizontally butt welded to form a welding surface 7 and a welding seam 8 on it.

[0018] In order to test the tightness of the weld 8, it is necessary to form a sealed space on the weld 8. By applying soapy water on the weld 8, the air pressure in the sealed space is reduced to a specified value. When the specified parameters are reached, soap bubbles will appear at the weld to show that the tightness of the weld is not up to standard.

[0019] Such as figure 1 As shown, the device provided by the present invention includes a weld covering box 1 and a vacuuming device 2. The weld covering box 1 and the vacuuming device 2 are connected by a pipeline 3, and the weld covering box 1 is covered on the weld 8. The welding seam cover box 1 and the welding surface 7 form a sealed space, and the vacuum device 2 is activated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com