Portable semi-automatic processing machine of plate with curved surface

A semi-automatic and portable technology, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high technical difficulty in the automatic processing system of large-scale curved steel plate water and fire forming, cannot be used on the construction site, and affects the shipbuilding cycle, etc., to achieve convenience Human movement, shortened shipbuilding cycle, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

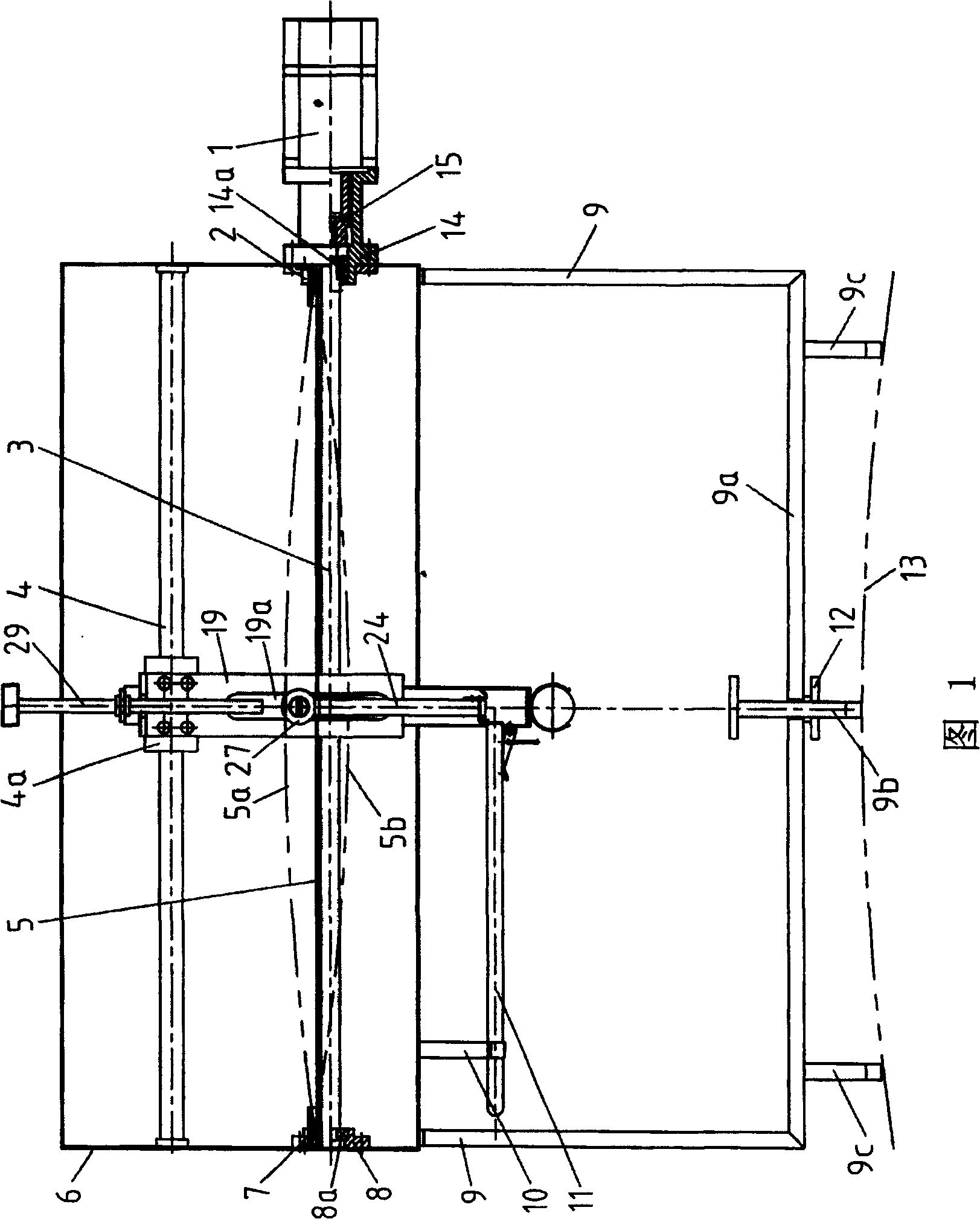

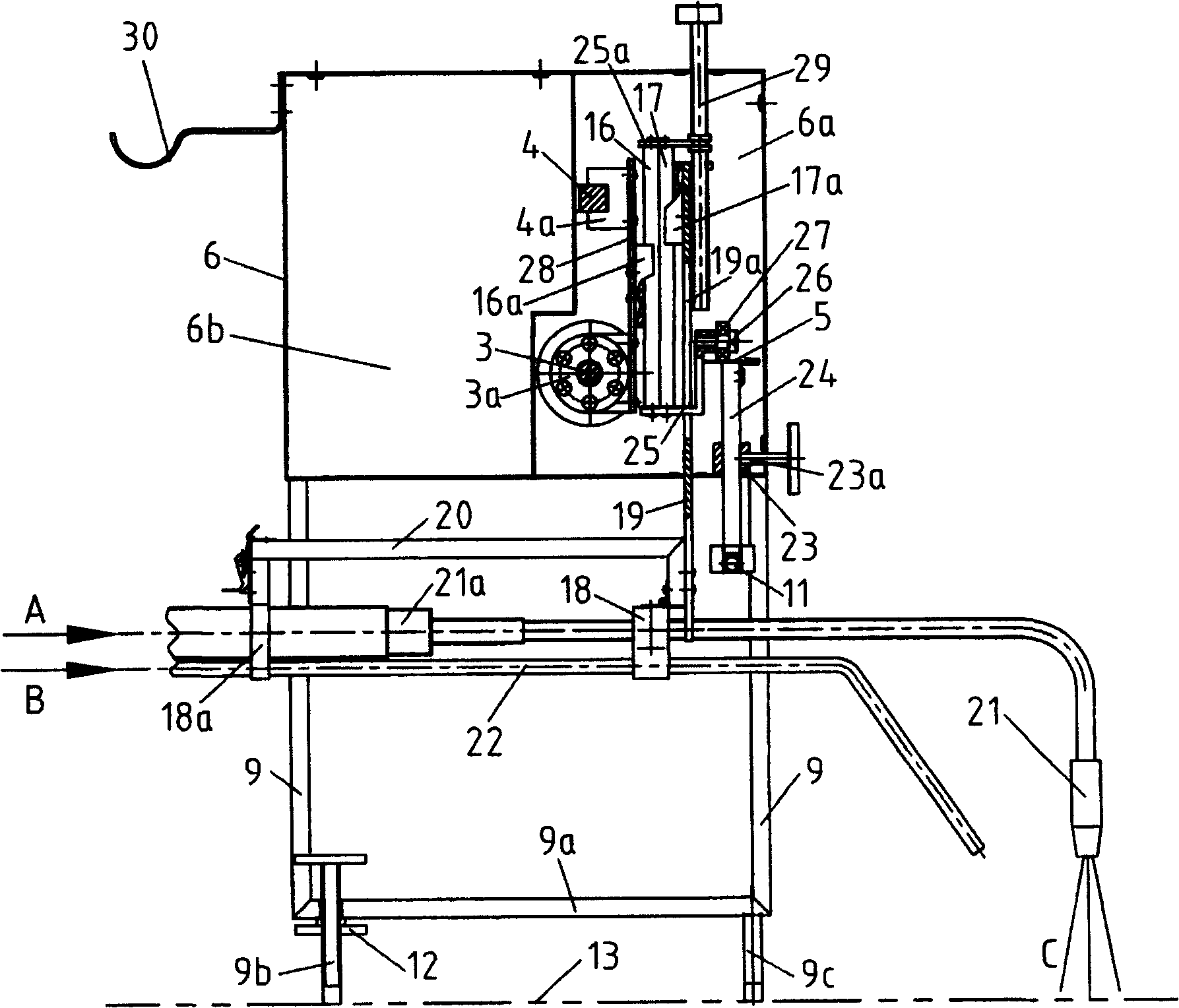

[0011] In the embodiment shown in Fig. 1, 2, this kind of portable semi-automatic processing machine for curved steel plate mainly includes a processing manipulator with flame heating and water cooling made up of welding torch 21 and cooling water pipe 22, a small I-axis positioning control box 6b and a mechanical transmission box 6a, the longitudinal height adjustment mechanism and the lateral travel mechanism of the processing manipulator are located in the mechanical transmission box 6a, and the box body 6 is welded together by four longitudinal members 9 and four cross members 9a There are two fixed outriggers 9c and one adjustable outrigger 9b under the frame, and the equipment can stand on the flat curved steel plate 13 by these three points of support, and can be used after the adjustable outrigger 9b is positioned. The locking nut 12 is locked.

[0012] The above-mentioned horizontal traveling mechanism of the processing manipulator is mainly a drive mechanism that dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com