Bottom template for ship frame and method for processing same

A processing method and frame technology, applied in the direction of metal processing equipment, ship construction, manufacturing tools, etc., to achieve the effect of improving product quality, increasing the total amount of shipbuilding, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

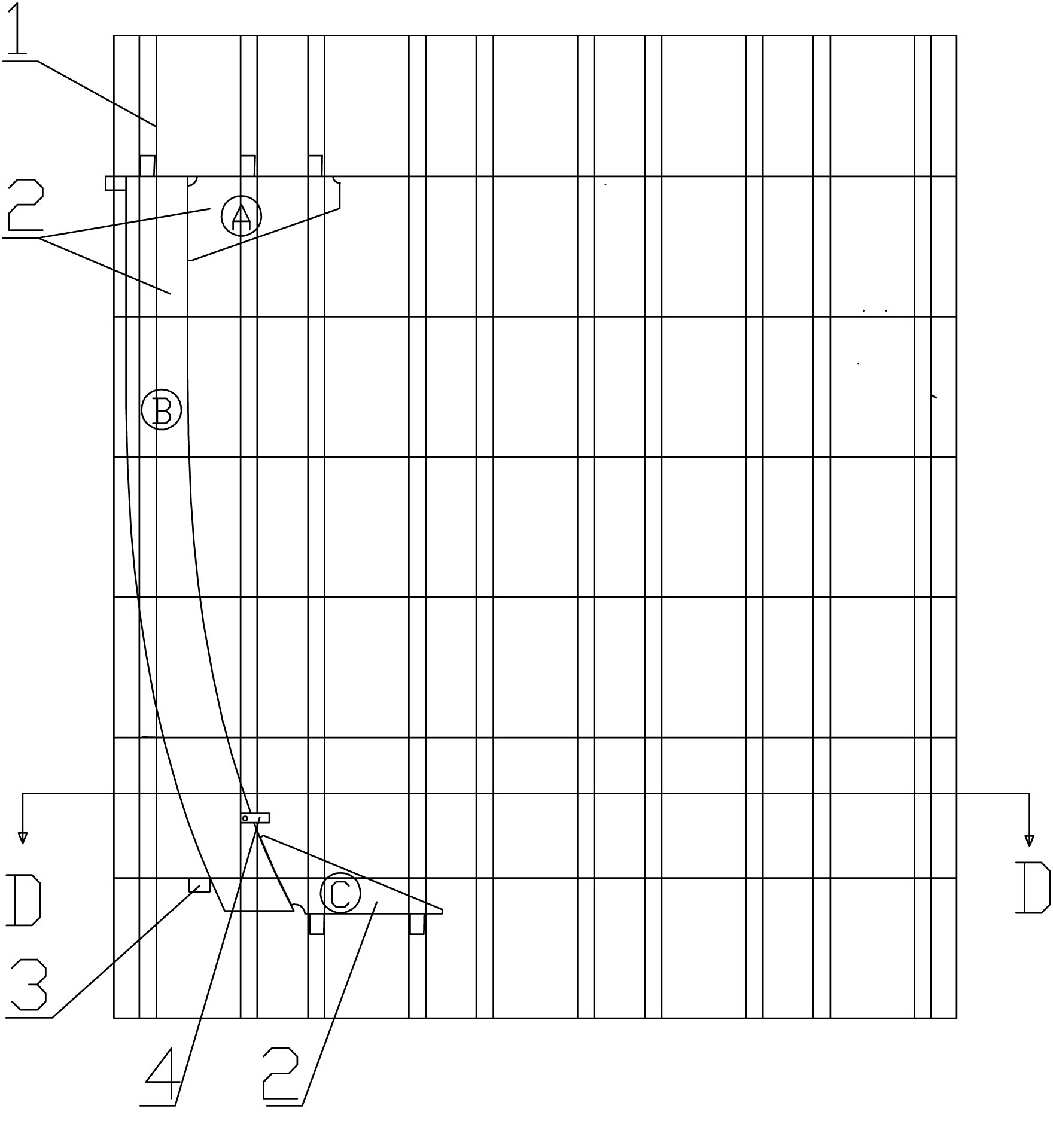

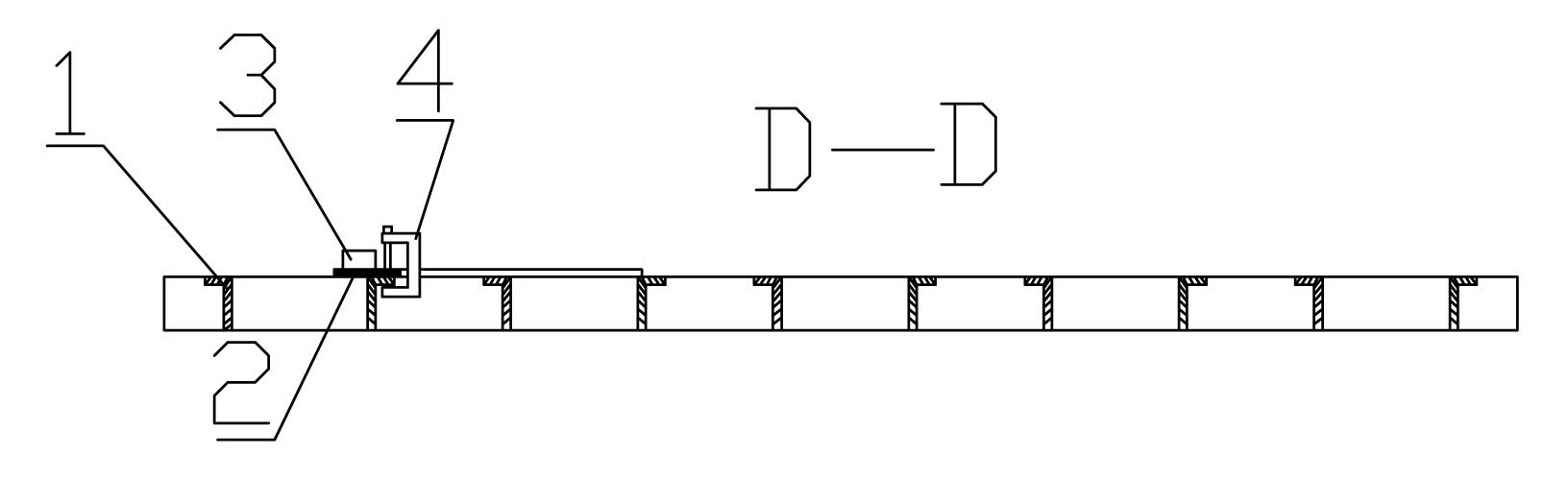

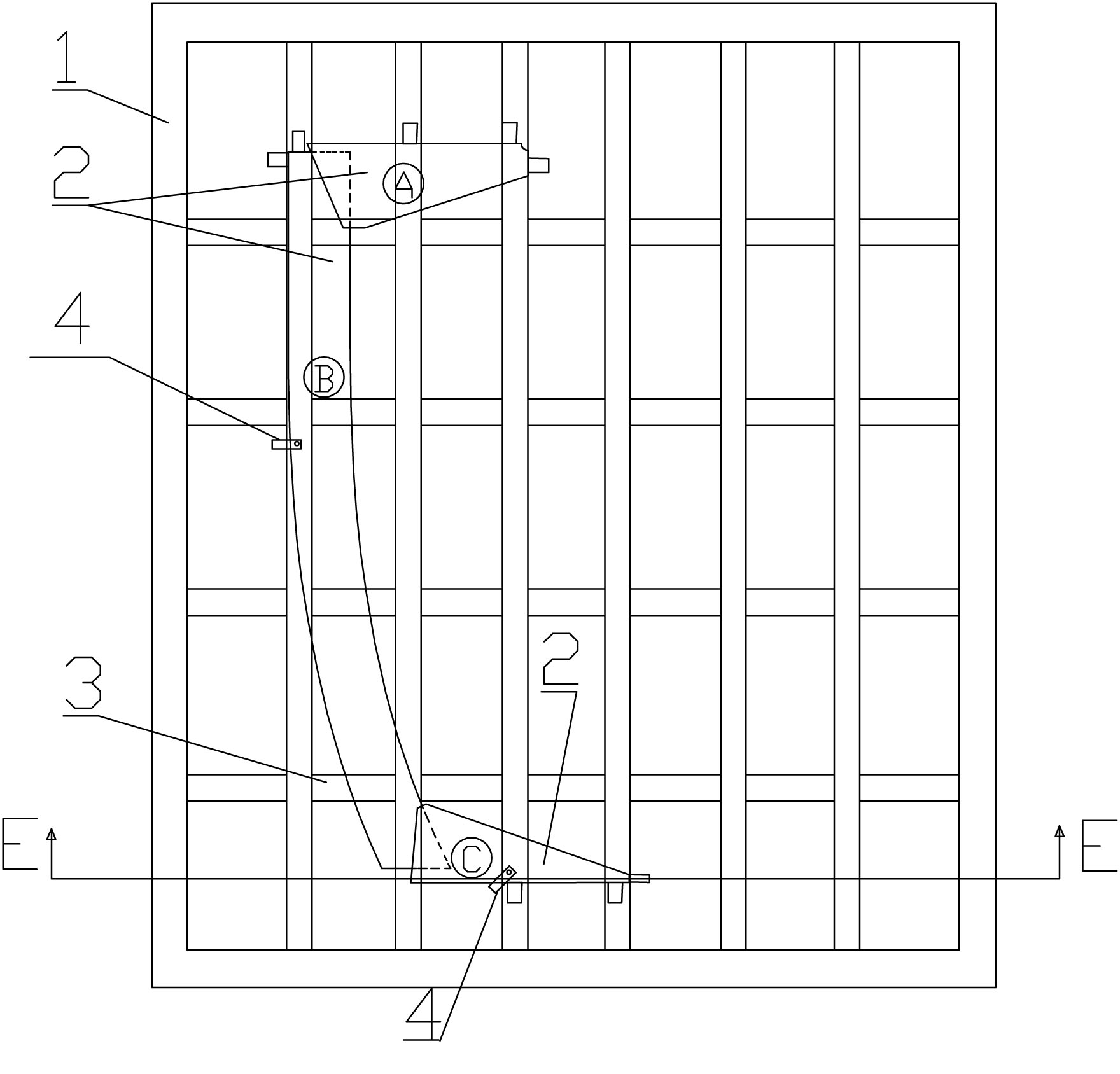

[0024] like figure 1 — Figure 4 Among them, a hull frame tire mold is welded into a tire frame 1 from profiles with an inverted "L" shape and a "[" shape in cross section. Selecting inverted "L" and "["-shaped profiles, welding into a frame is conducive to the clamping of various parts of workpiece 2, such as figure 1 Clamping of each part of A, B, and C. .

[0025] The tire frame 1 is also provided with a cushion block 5 . Through the adjustment of the spacer block 5, the welding seams of the various parts of the workpiece 2 are aligned. When the various parts in the workpiece 2 overlap each other, the spacer block 5 needs to be adjusted. For positioning, by adopting the tire frame type hull frame tire mold and the limit block 3 to cooperate with the spacer block 5 and the fixture 4, the positioning problem of the components when the workpiece is in the form of lap joint is solved.

[0026] The profiles in the tire frame are crisscrossed, and the interval between the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com