Supporting method and device used for assembling ship broadside curved sections

A technology of curved surface segmentation and support devices, which is applied to ship parts, ship construction, ship design, etc., can solve problems such as time-consuming, labor-intensive and expensive, potential safety hazards, knocked-down support legs, etc., to avoid high-altitude operations, protect personnel and The effect of article security and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below we will further elaborate on a support method and device for the segmental assembly of ship side curved surface of the present invention in conjunction with the accompanying drawings and specific embodiments, in order to understand its structural composition and working mode more clearly. However, the protection scope of the patent for the present invention cannot be limited in this way.

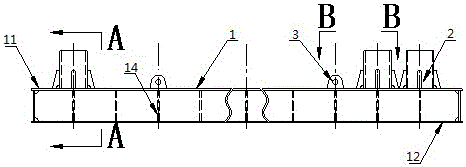

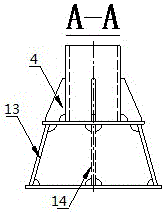

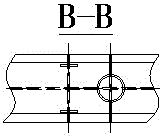

[0038] Such as figure 1 , figure 2 and image 3 As shown, a support device for the segmental assembly of the ship's side curved surface, the support device includes a base 1, support legs 2 and a hoisting horse 3, the base 1 is a strip-shaped frame structure, and the base 1 is composed of Steel plates are tailor-welded, and the cross-sectional shape of the base 1 includes trapezoid and rectangle, which can ensure that the base 1 has better pressure bearing capacity and better stability.

[0039] The base 1 includes an upper plate 11 and a lower plate 12, two side plates 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com