Cell cartridge with a composite intercell connecting net structure

A compound connection and interconnection technology, applied in the field of unit boxes, can solve the problems of reduced assembly productivity, inconvenient welding operation, excessive contact resistance, etc., to improve accuracy, eliminate poor welding problems, and improve structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

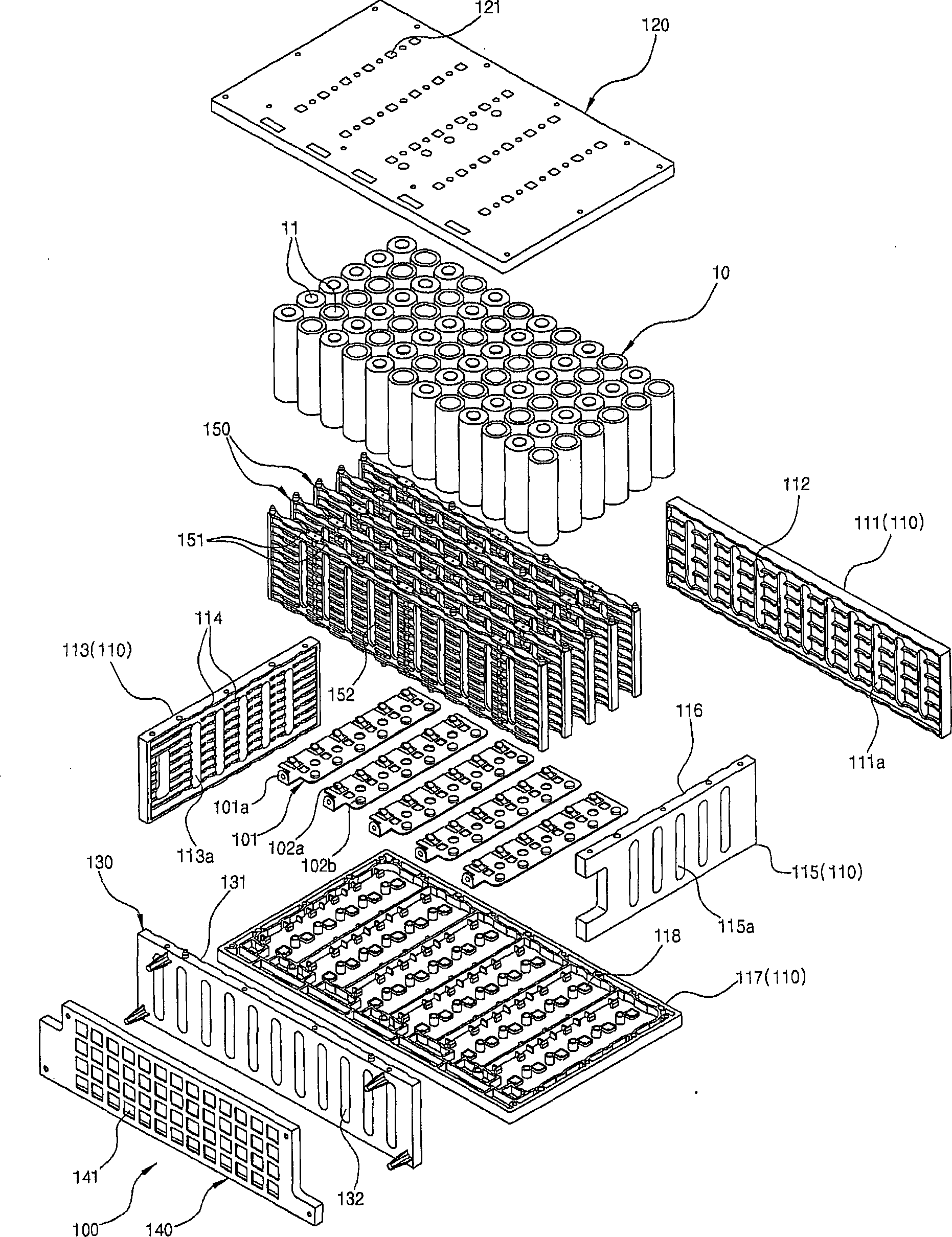

[0061] The features and advantages of the present invention will become clearer from the following detailed description based on the accompanying drawings. Regarding the terms or words used in this specification and the claims, they should be interpreted as being consistent with the technical idea of the present invention from the principle that the inventor properly defines the concept of the terms in order to explain his own invention in the best way. The meaning and concept of conformity. Hereinafter, in this specification, all units (cells) are collectively described with the term "battery" except for the unit case.

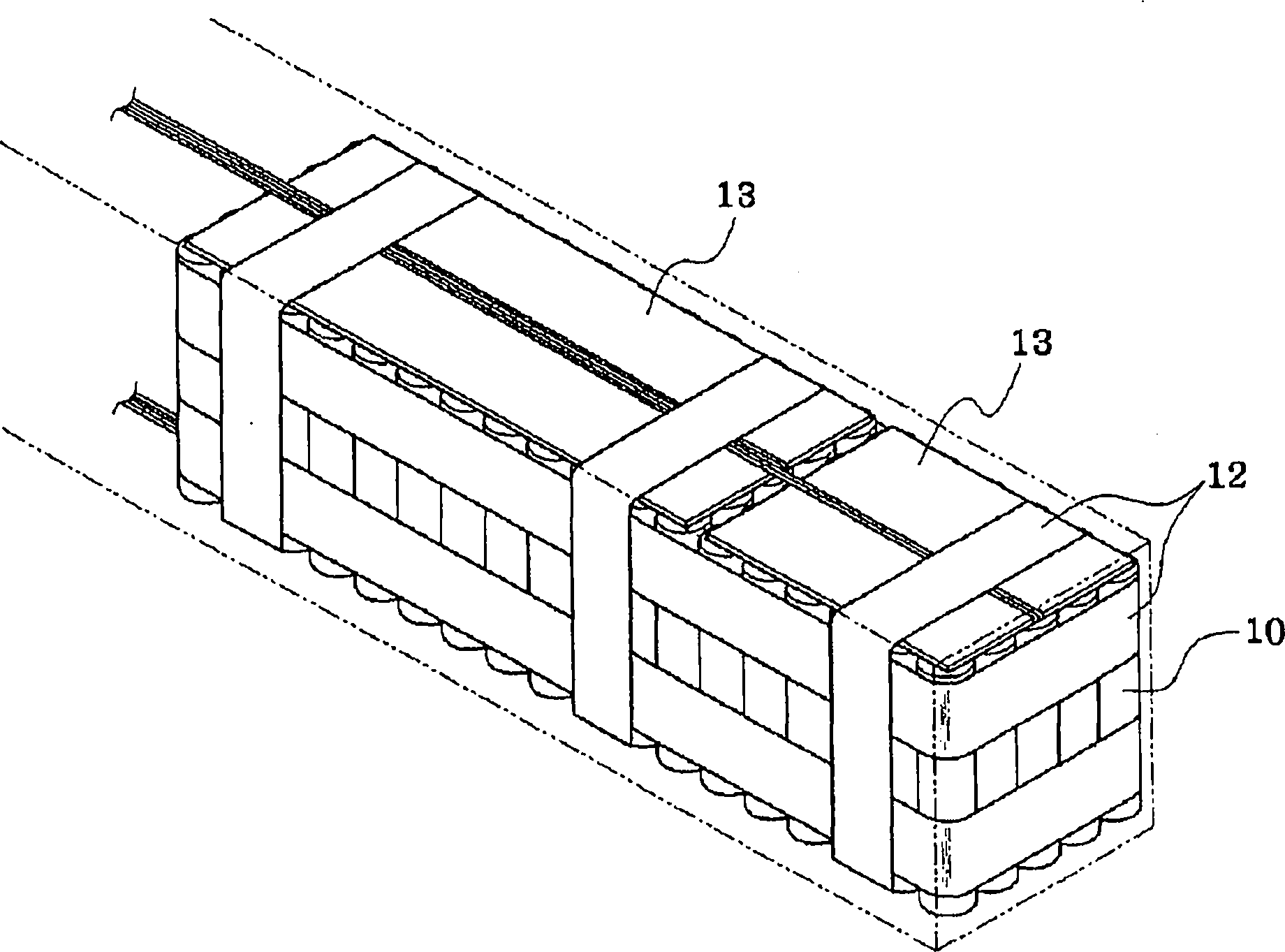

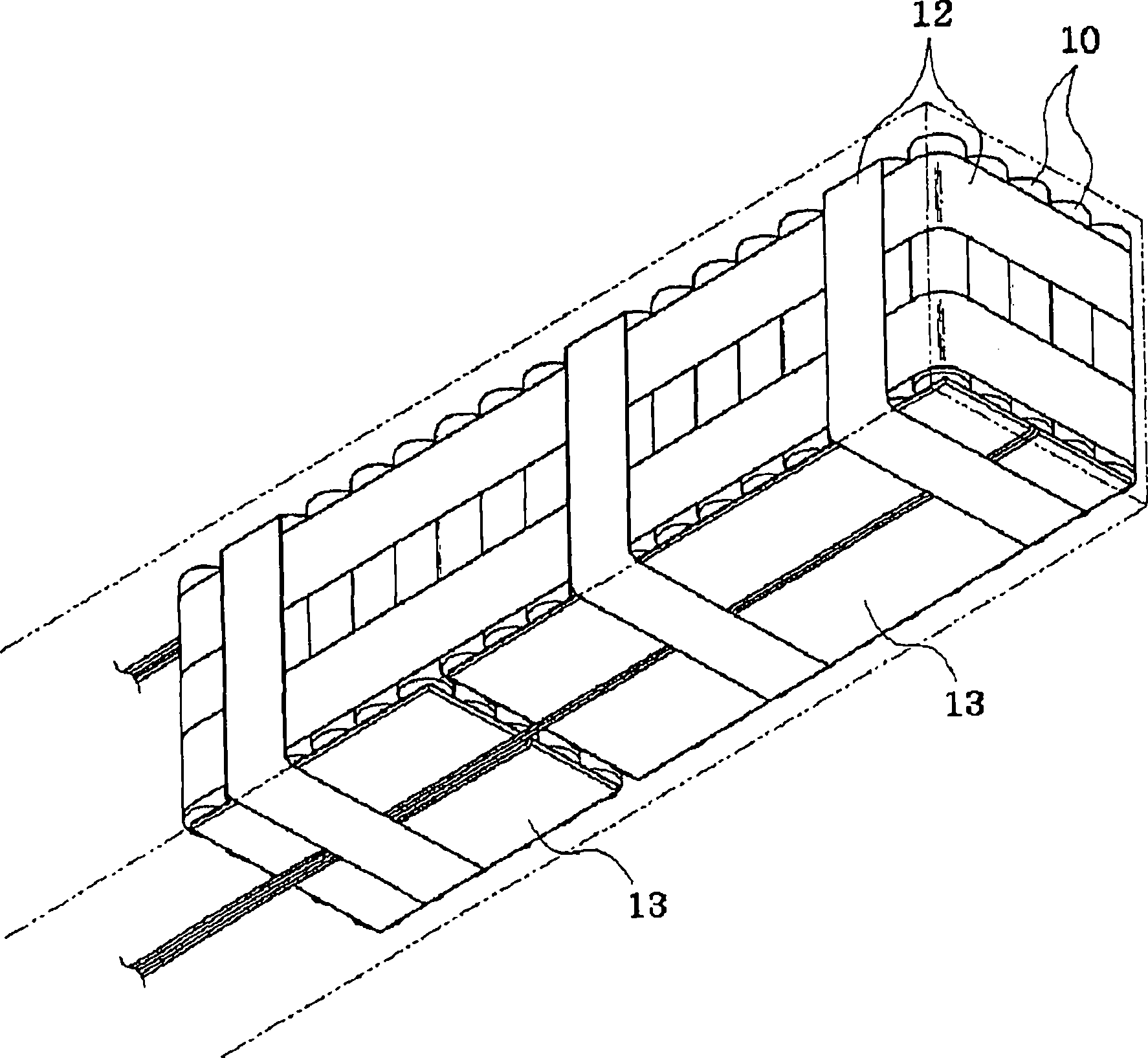

[0062] The present invention relates to a unit box (cell cartridge) composed of a compound connection network between units (batteries), and relates to the structure of a compound connection network structure between units assembled in a casing in a series-parallel compound connection mode and modularized box.

[0063] In the unit case of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com