Hybrid input spatial 3-DOF (degree-of-freedom) parallel mechanism

A technology of mixed input and degrees of freedom, which is applied in the fields of robotics and space mechanics, can solve the problems of large size of the mechanism and sacrifice of flexibility of the mechanism, so as to reduce the motion inertia, improve the processing and assembly accuracy of parts, and reduce the joints of the mechanism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

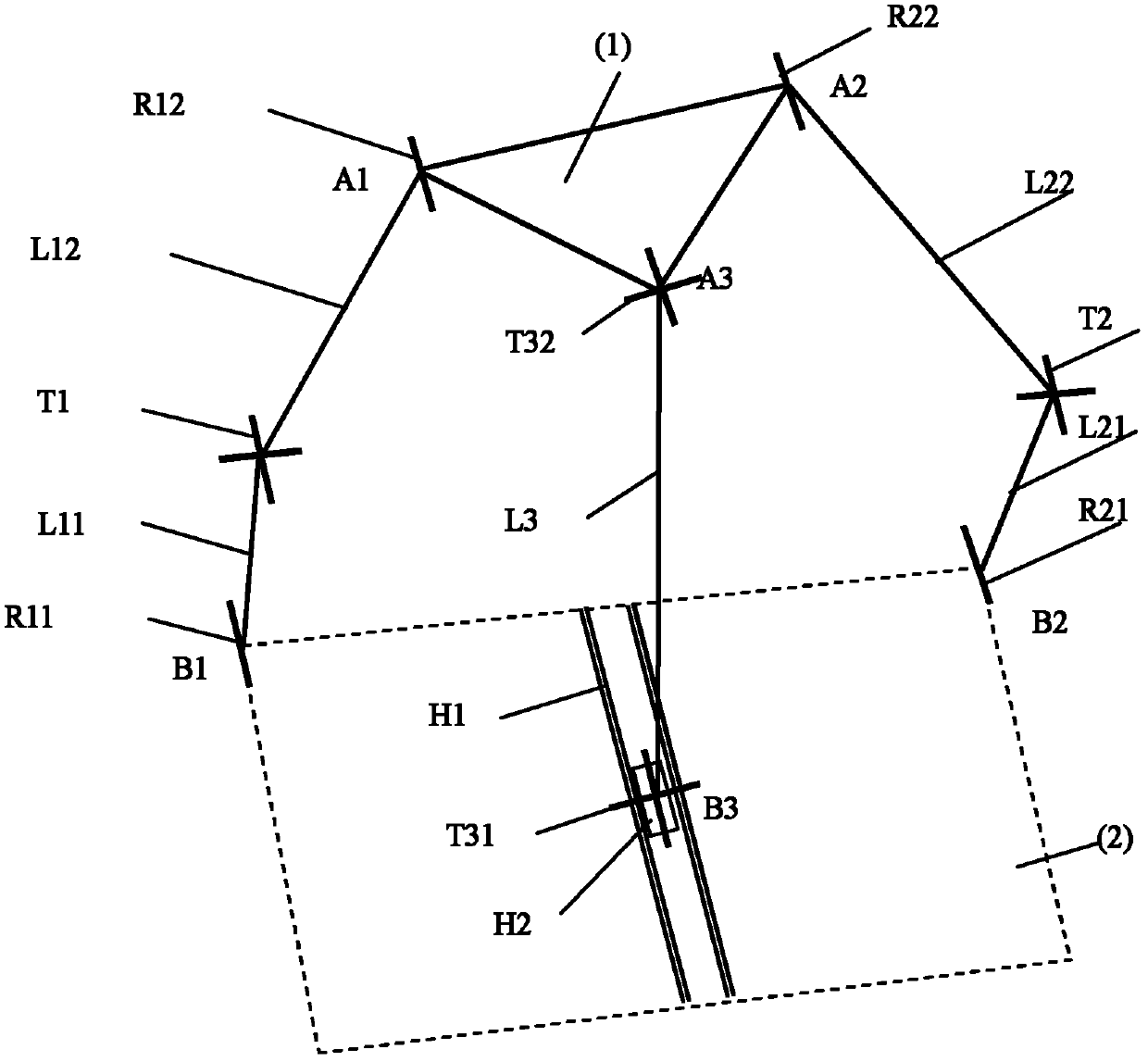

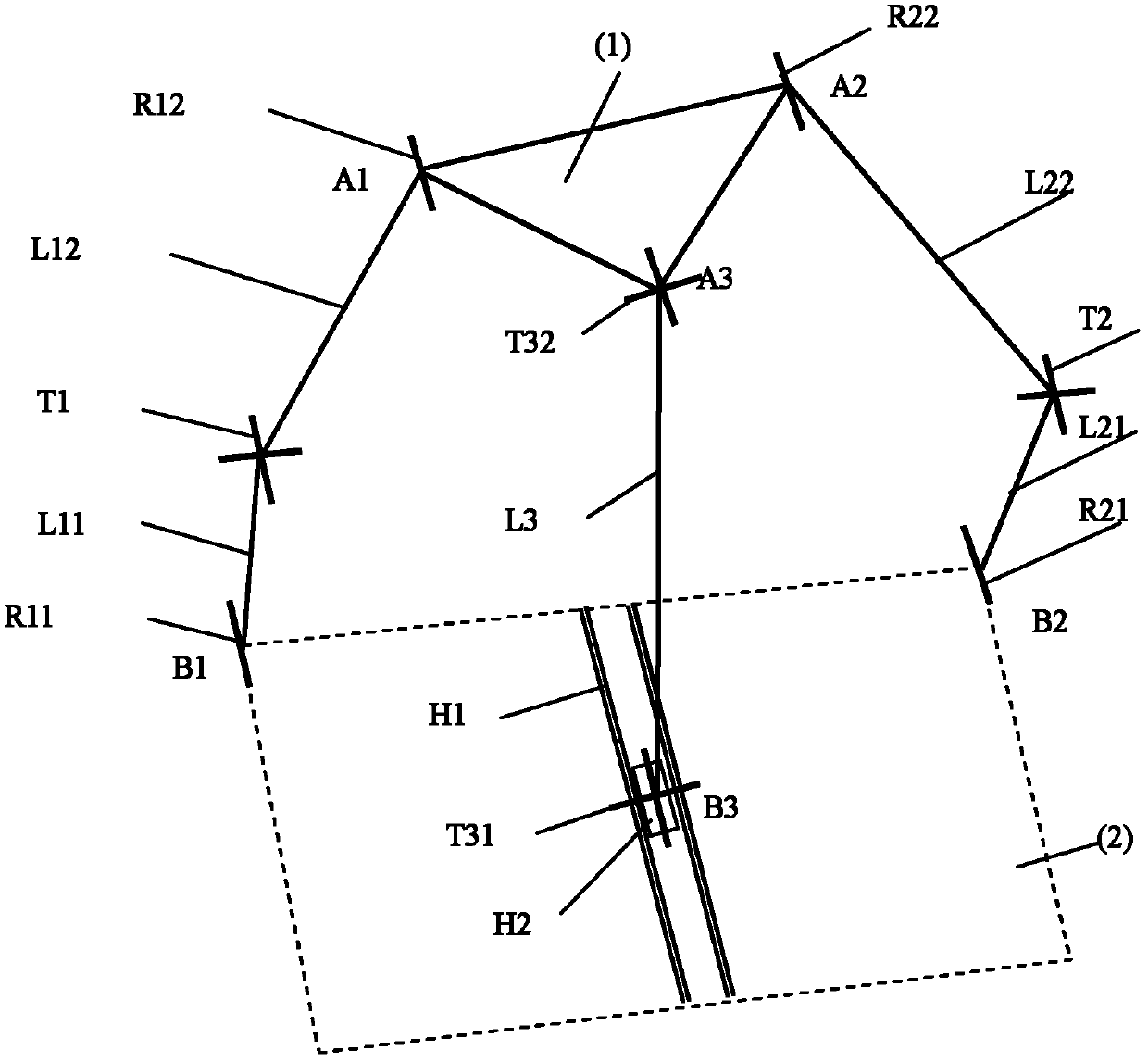

[0018] A space-parallel mechanism with one translation and two rotations is realized by using the driving method of mixed input, and the driving part of the mechanism is completely placed on the fixed platform, which greatly reduces the motion inertia of the whole mechanism. The mechanism is composed of a moving platform 1, a fixed platform 2 and three branch chains A1B1, A2B2, A3B3 connecting the above two platforms; the branch chains A1B1 and A2B2 are composed of rotating hinges R12, R22 and Hooke hinges T1 and T2 respectively from top to bottom. , rotating hinges R11, R21 and connecting rods L11, L12, L21, L22 between them; branch chain A3B3 consists of Hooke hinges T31, T31 from top to bottom, connecting rod L3 between them and sliding pair H2 Composition; of which:

[0019] Said connecting rods L12 and L22 have the same length, they are connected with the moving platform 1 through the rotating hinges R12 and R22 respectively, the connecting rod L3 is connected with the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com