Heavy-duty car direction converter bearing and its manufacturing technique

A heavy-duty vehicle and preparation technology, which is applied in the field of auto parts, can solve the problem that the meshing gap of worm gear and worm can no longer be adjusted, and achieve the effect of simple assembly and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

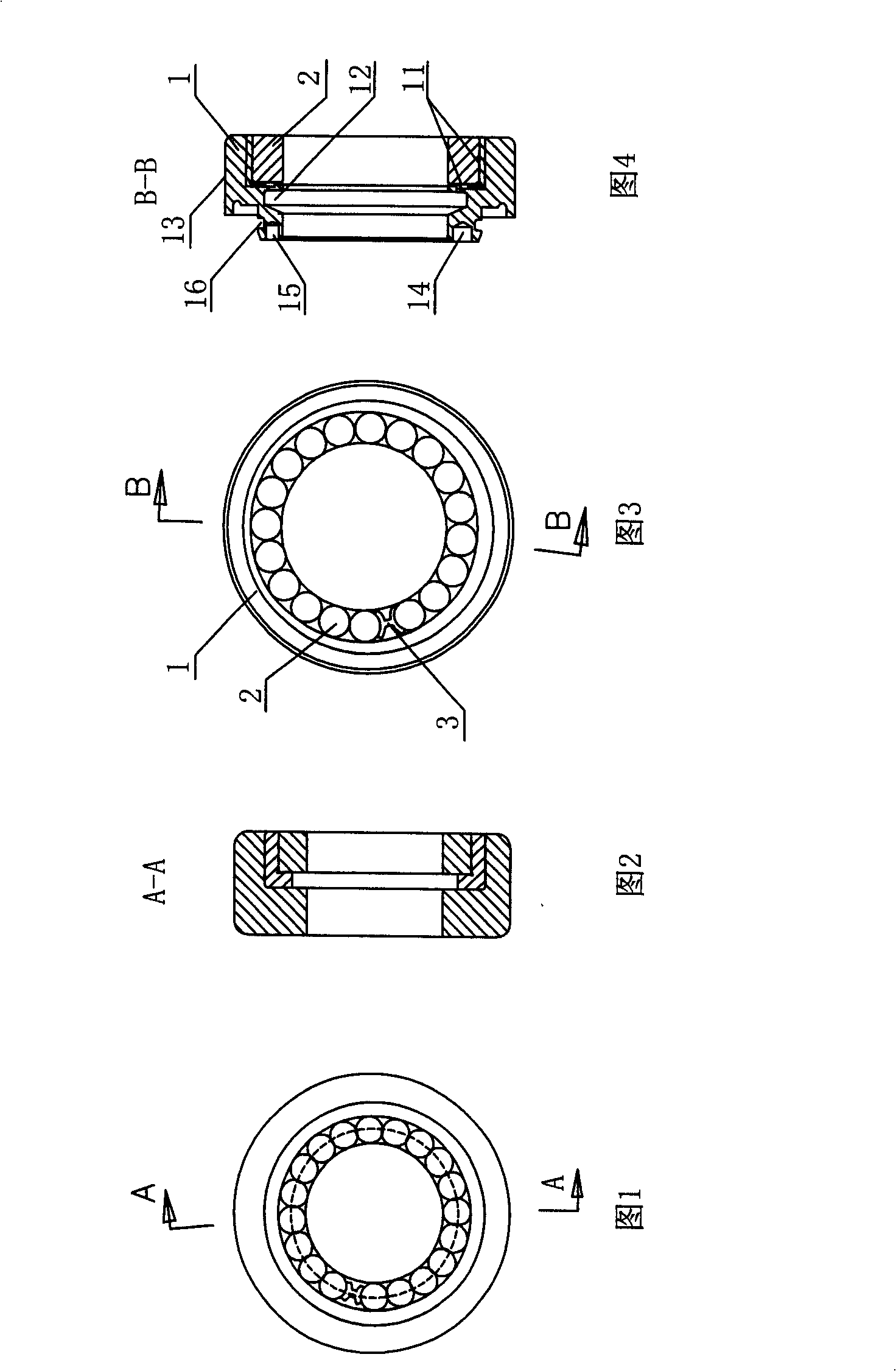

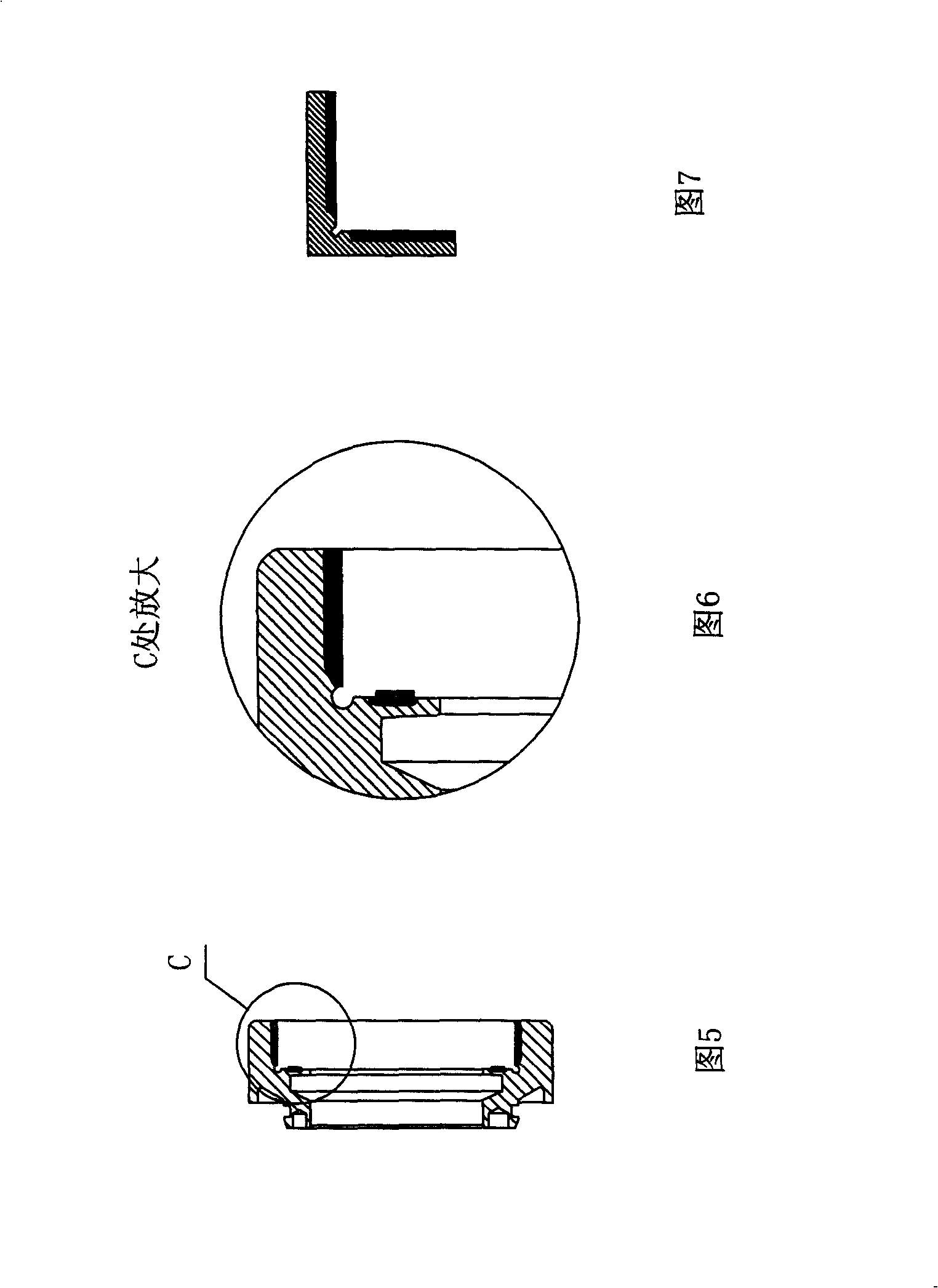

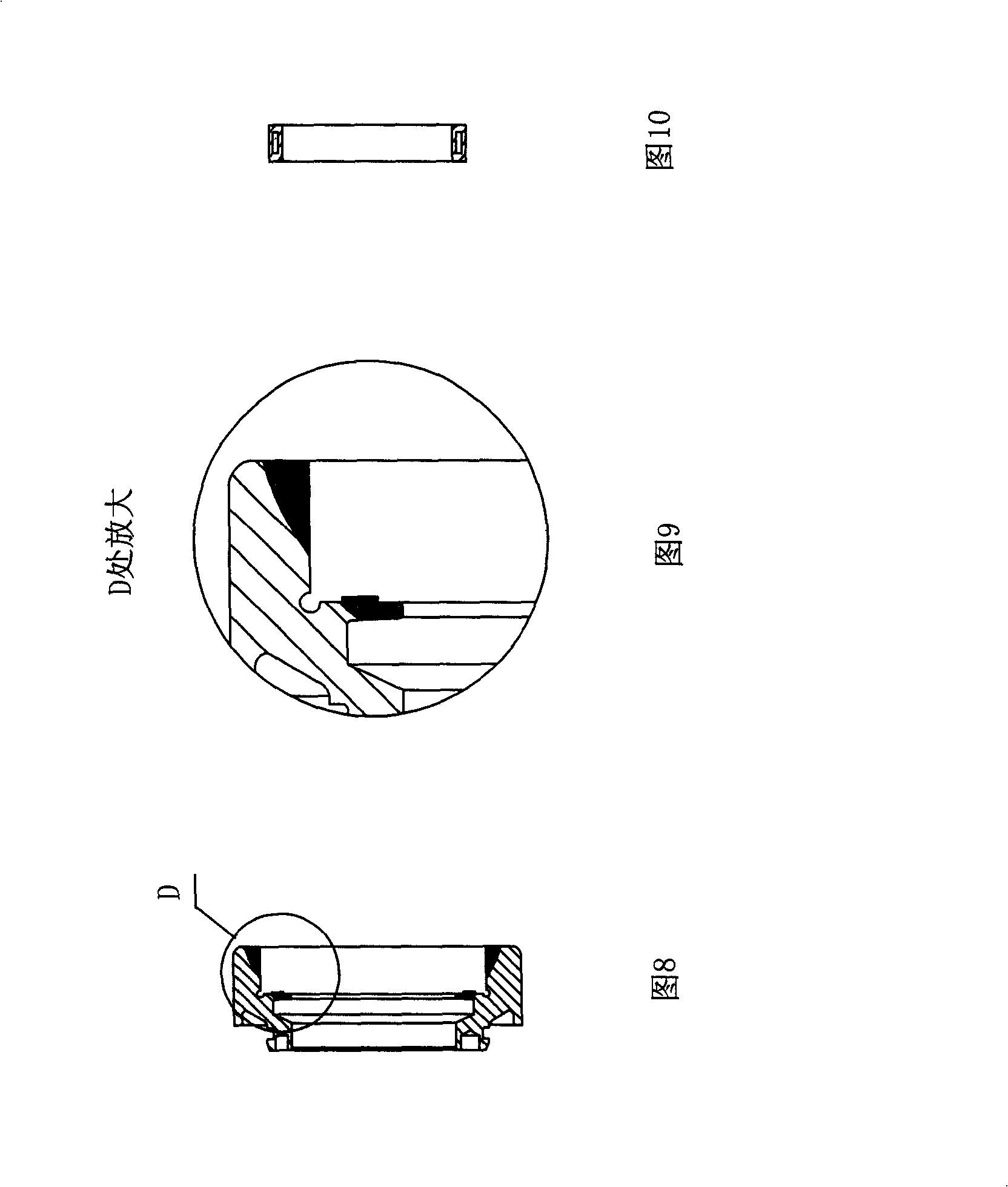

[0029] As shown in the accompanying drawing, a heavy-duty automobile steering gear bearing includes a bearing housing 1 and a roller 2. The opening on one side of the bearing housing 1 has a right-angled inner raceway 11, and the cylindrical rollers 2 are arranged in a ring on the inner raceway 11. After the rollers 2 are closely arranged, a clamping spacer 3 is provided in the gap between the head and tail rollers 2, and two pin holes are provided on the other end surface of the bearing housing 1, and the pin holes are on the same axis as the bearing. In the direction, at least one inner seal groove 12 is provided on the inner ring of the bearing housing 1 between the end face with the pin hole and the inner raceway 11. The outer ring 13 of the bearing housing 1 and the inner raceway 11 have an eccentric structure, and the eccentric direction is the same as that of the inner raceway 11. The axis of symmetry of the pin hole on the end face is in the same direction.

[0030] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com