Cable pipe sleeve suitable for cable structure system, multi-functional outer casing pipe containing cable pipe sleeve and cable structure

A technology of cable structure and outer casing, applied in the field of cable structure, can solve the problems of sleeve bearing capacity reduction, inability to route, increase cable-stayed cables, etc., to achieve the effect of convenient assembly and replacement, convenient assembly accuracy, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

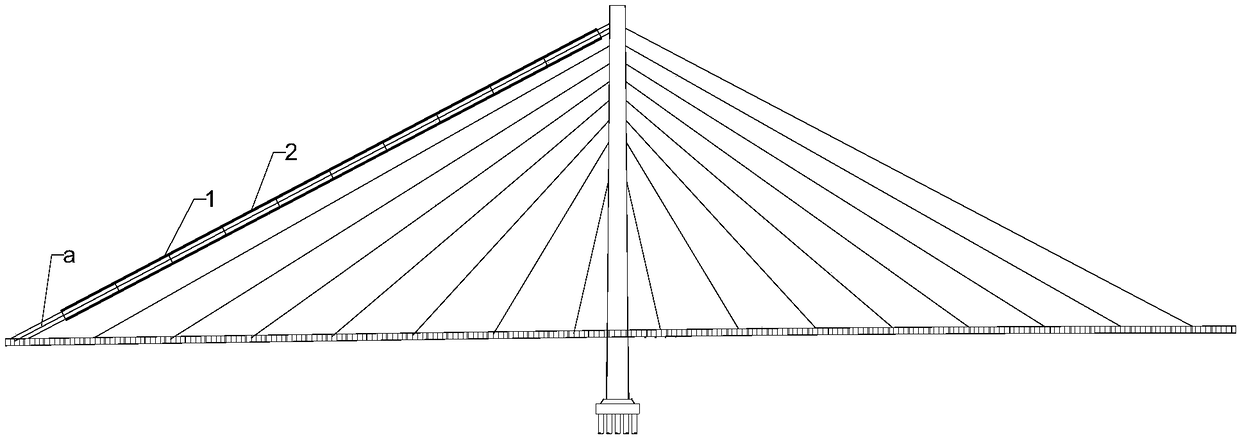

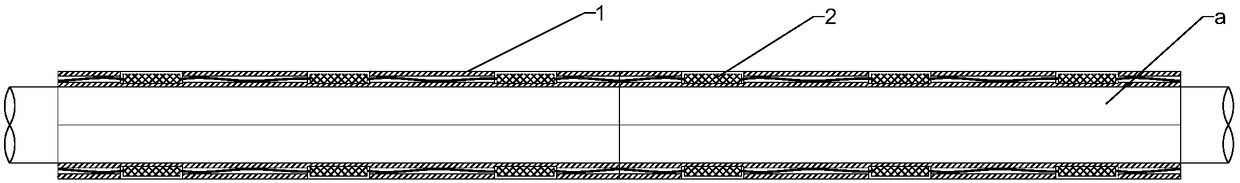

[0047] Such as Figure 1a and 1b As shown, the multi-purpose outer casing for the cable structure system includes a main body unit 1 and a functional unit 2 embedded in the main body unit 1. The casing is gradually lifted along the cable body and tightly wrapped on the surface of the cable unit a, and the two ends are sealed to form a closed space.

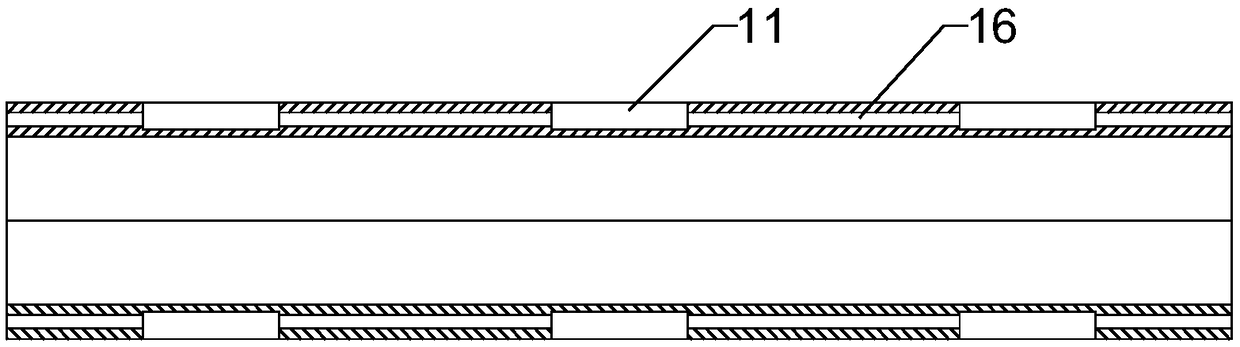

[0048] Such as Figure 1a and 1b , Figure 2a and 2b As shown, the main unit is a segmented Haval tube with a thickness of 5 cm. The tube wall is provided with a mounting groove 11 and a protective cover 12 for the mounting groove. The tube wall is provided with 4 long weight-reducing holes 13. Guide groove 14. Segmented and segmented Haval tube, the length of each segment is equal to 3.6m, and the number of longitudinal segments in each segment is 2 pieces, with dovetail groove 15 structural connection between each piece and pre-embedded resistance wire 18 at the longitudinal seam and then hot-melted The form of welding is f...

Embodiment 2

[0060] Such as Figure 10a and 10b As shown, the main unit is a segmented Haval tube with a thickness of 3cm. There is a long weight-reducing hole 13, and there is a guide groove 14 on the inner side of the pipe wall; the number of pieces in each section of the main unit is 3 pieces, which are in the form of a concave-convex platform connection; Helically arranged; the number of size levels of the guide groove 14 matches the guide bar b on the outer wall of the cable structure a to which the main unit 1 is attached, and the number of guide bars in the cross section is 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com