Pintle chain automatic assembly machine

An assembly machine and pin-joint chain technology, applied in the direction of metal chains, etc., can solve the problems of low assembly accuracy, low production efficiency, and large safety hazards, and achieve the effects of high assembly efficiency, low cost, and good assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

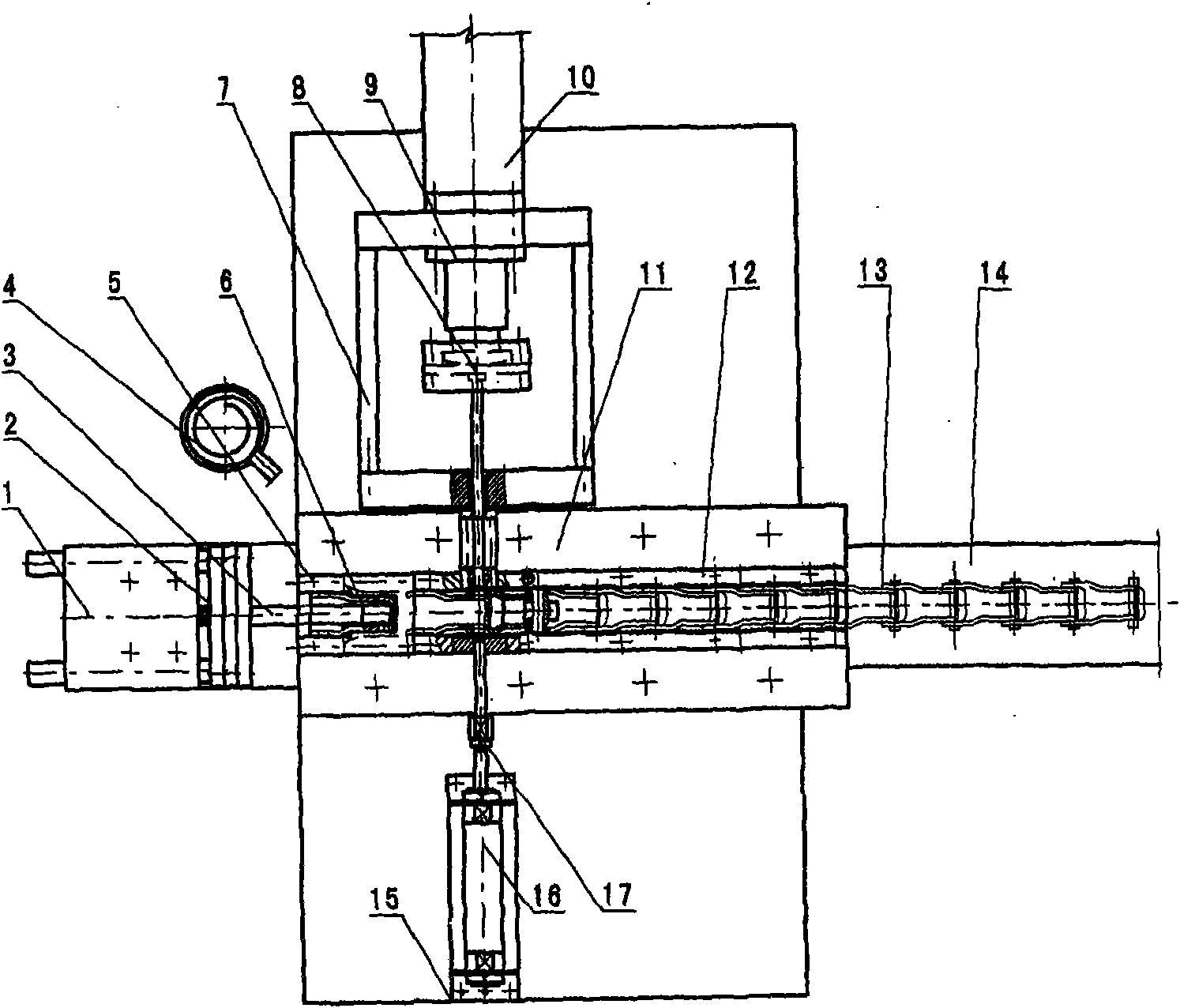

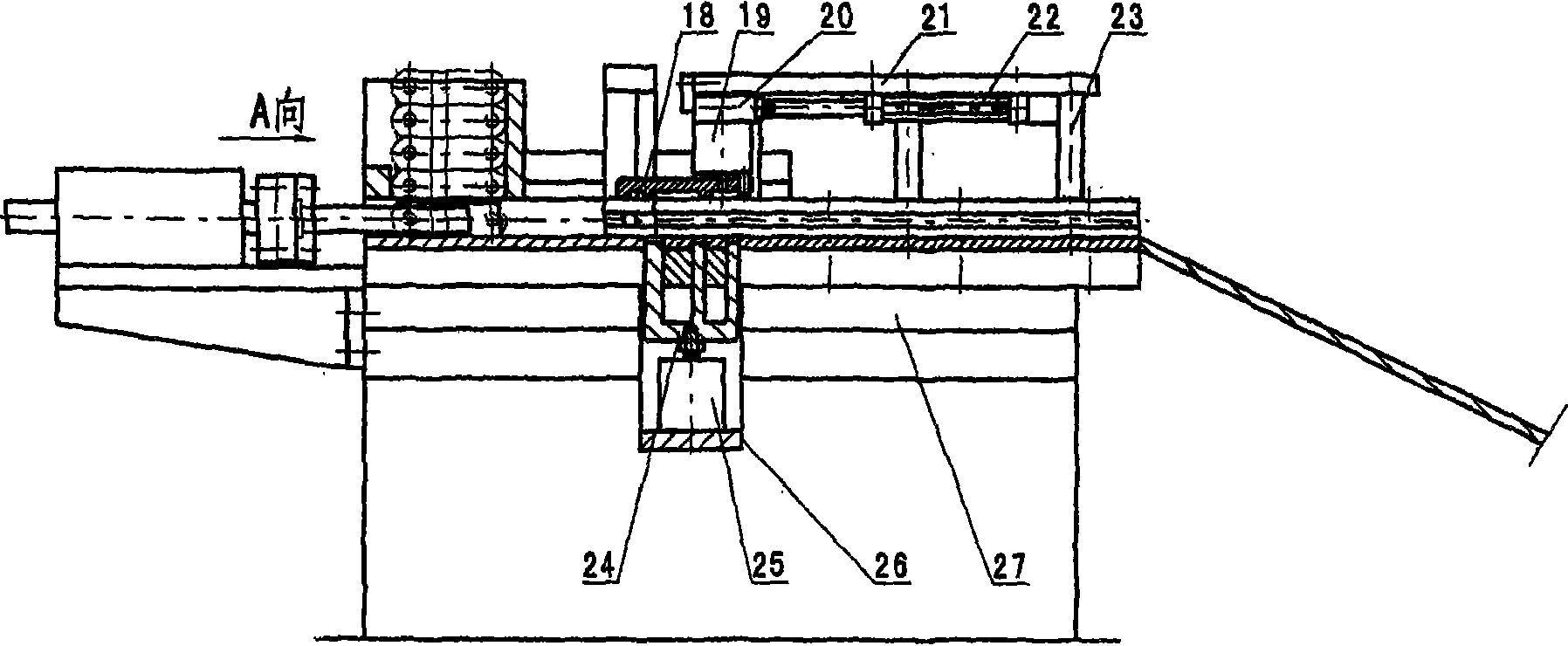

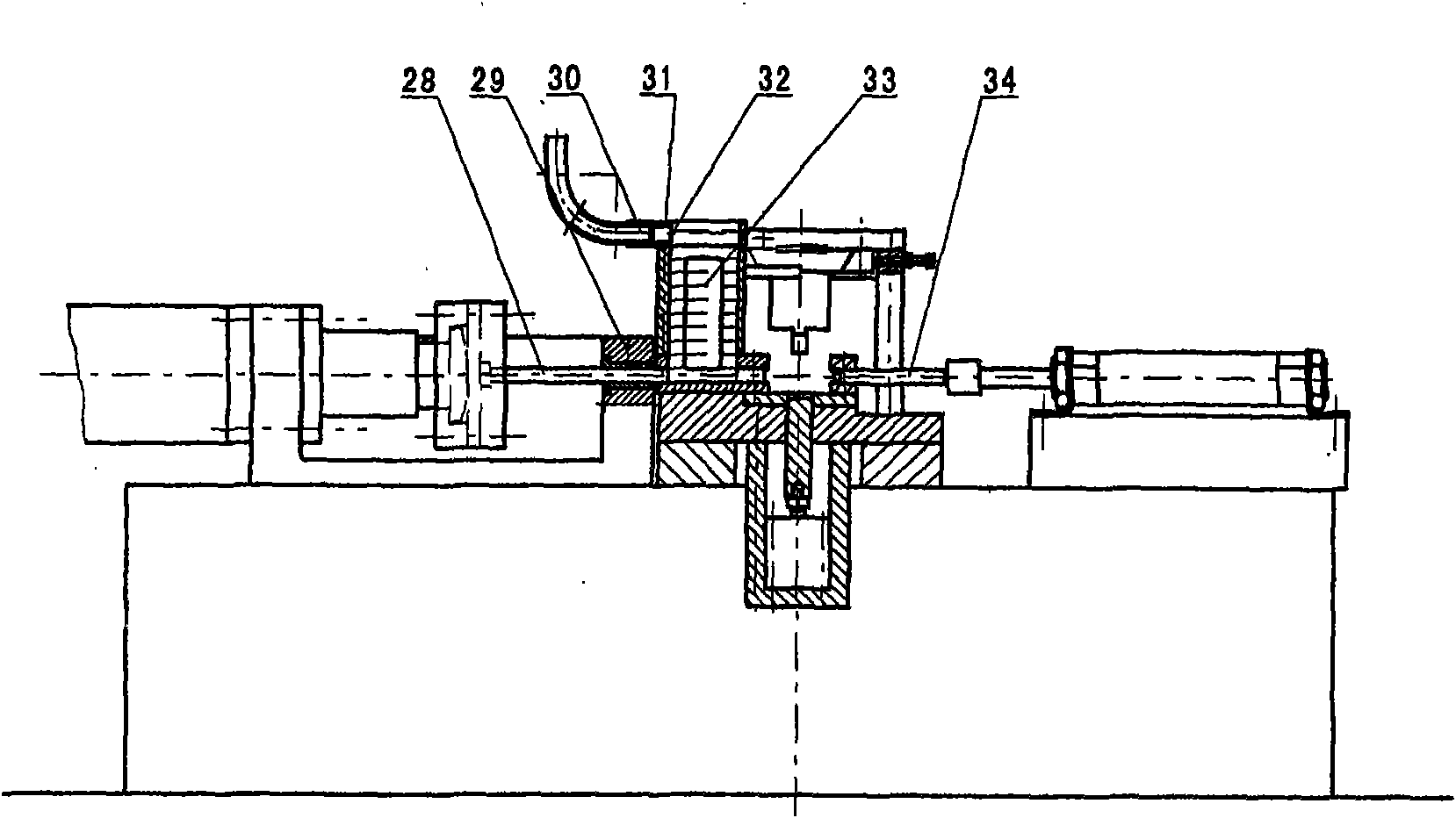

[0009] Such as figure 1 , 2 , As shown in 3, a pin-joint chain automatic assembly machine is composed of a chain plate feeding mechanism, a chain plate positioning mechanism, a chain pin feeding and pin threading mechanism, a chain link transfer mechanism and a frame, a discharge plate and PLC automatic control The Pin Chain Assembly Machine.

[0010] The chain plate feeding mechanism is composed of a double-column feeding cylinder arranged on the front side of the frame 27, a feeding rod and a chain feeding plate. The cylinder rod of the double-column feeding cylinder 1 is connected with the feeding rod 3 through the cylinder connection seat 2 . Feeding chain plate closes 5 and is installed on the top of the parallel track 12 that is formed by the left and right parallel track fixed seat 11 that is provided with on the frame platen, and its below offers the through groove that is parallel with parallel track. The chain plate 6 in the chain plate is pushed forward steadily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com