Bus fan-belt transmission mechanism

A belt drive and fan technology, which is applied to transmissions, engine components, machines/engines, etc., can solve the problems of insufficient engagement between the fan belt and the two belt grooves, difficulty in ensuring flatness, and insufficient assembly accuracy, and achieve vibration attenuation. , Save assembly and post-adjustment time, and ensure the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

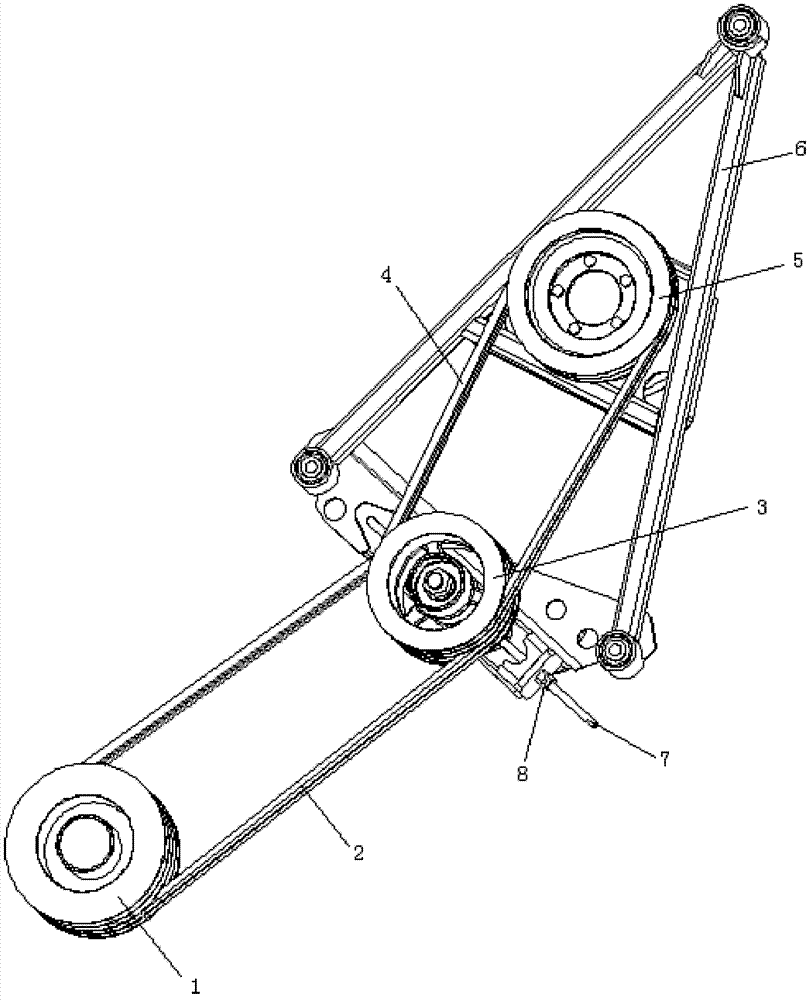

[0025] see figure 1 A passenger car fan belt drive mechanism of this embodiment includes a crankshaft pulley 1, a crankshaft belt 2, an intermediate pulley assembly 3, a fan belt 4, a fan pulley assembly 5, a tripod assembly 6 and an adjusting screw 7.

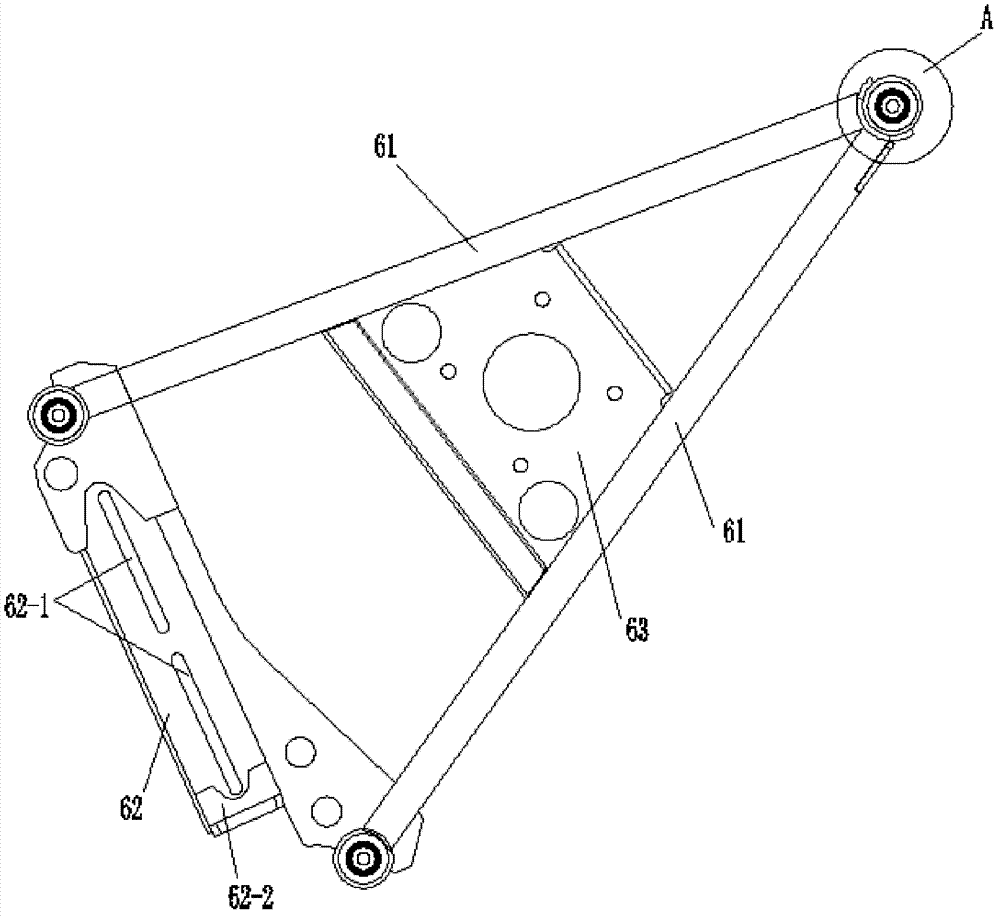

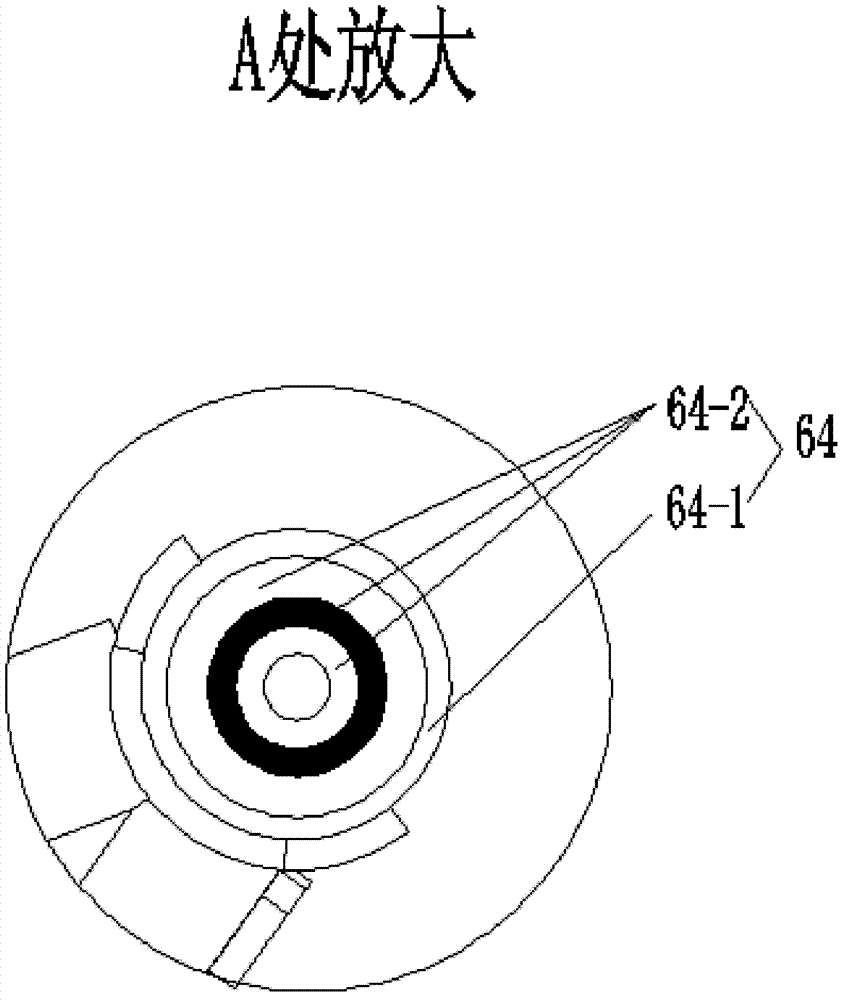

[0026] The intermediate pulley 31 of the intermediate pulley assembly 3 is a double-layer pulley; the crankshaft belt 2 surrounds one layer of the crankshaft pulley 1 and the intermediate pulley 31; the fan belt 4 surrounds the other layer of the intermediate pulley 31 and the fan pulley assembly 5. The tripod assembly 6 is installed on the gantry frame structure of the passenger car underframe, and includes two inclined beams 61, a middle pulley mounting bracket 62, a fan pulley mounting bracket 63 and three top angle assemblies 64; two inclined beams 61 are The rectangular tube, the middle pulley mounting bracket 62 and the fan pulley mounting bracket 63 are stamped parts. The middle pulley mounting bracket 62 is the bottom sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com