Processing die of stirrer with aeration function

A technology for processing molds and agitators, which is applied in the field of processing molds with aerators with aeration function, can solve the problems of difficult processing of structural agitators, complex structure of agitators, and high maintenance costs, and achieves novel structure, convenient later demoulding, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

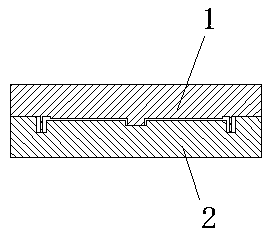

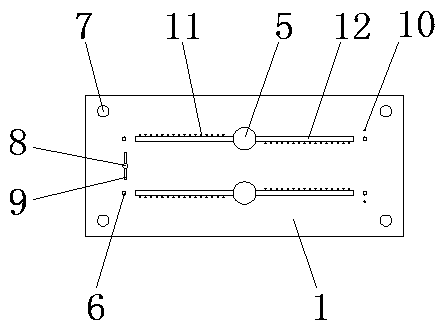

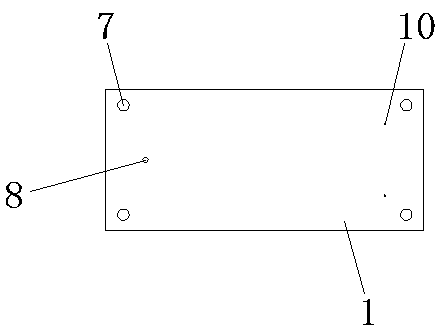

[0020] Such as Figure 1-6 As shown, a processing mold with an aeration function agitator, the mold is composed of an upper mold 1 and a lower mold 2, the four corners of the bottom surface of the upper mold 1 are provided with guide post holes 7, and the center of the bottom surface of the upper mold 1 is provided with two The upper mold cores that are mirror images of each other, each upper mold core is composed of a cylinder 5, a rectangular strip 12 and an air outlet mold core 11. The rectangular strip 12 is arranged on both sides of the cylinder 5, and the air outlet mold core 11 is arranged on the On the sides of the rectangular strips 12, the air jet cores 11 on the two rectangular strips 12 are arranged oppositely, and a pair of process cores 6 are respectively arranged on both sides of the two upper mold cores in the length direction, and the inner sides of the pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com