Automatic assembly machine for cranked link chain single link

A technology of assembly machine and bending plate chain, applied in the direction of assembly machine, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly accuracy, high safety hazards, and high assembly cost, and achieve high assembly efficiency, mechanization, and assembly accuracy. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

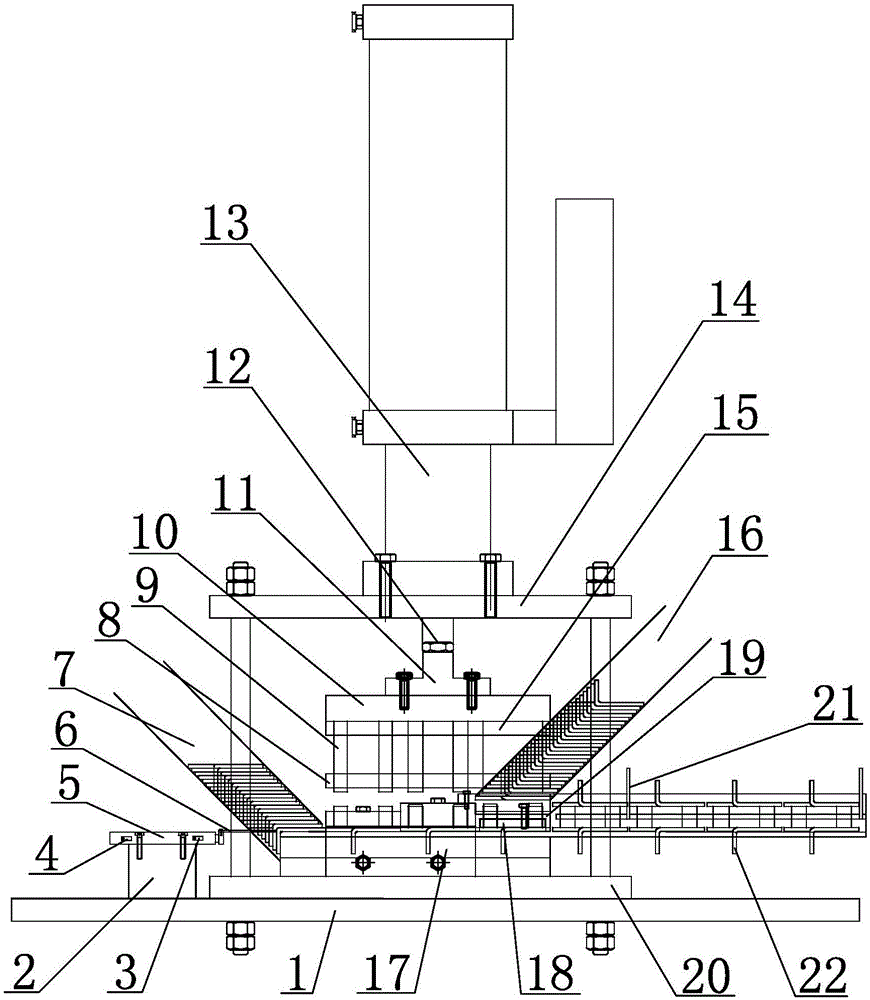

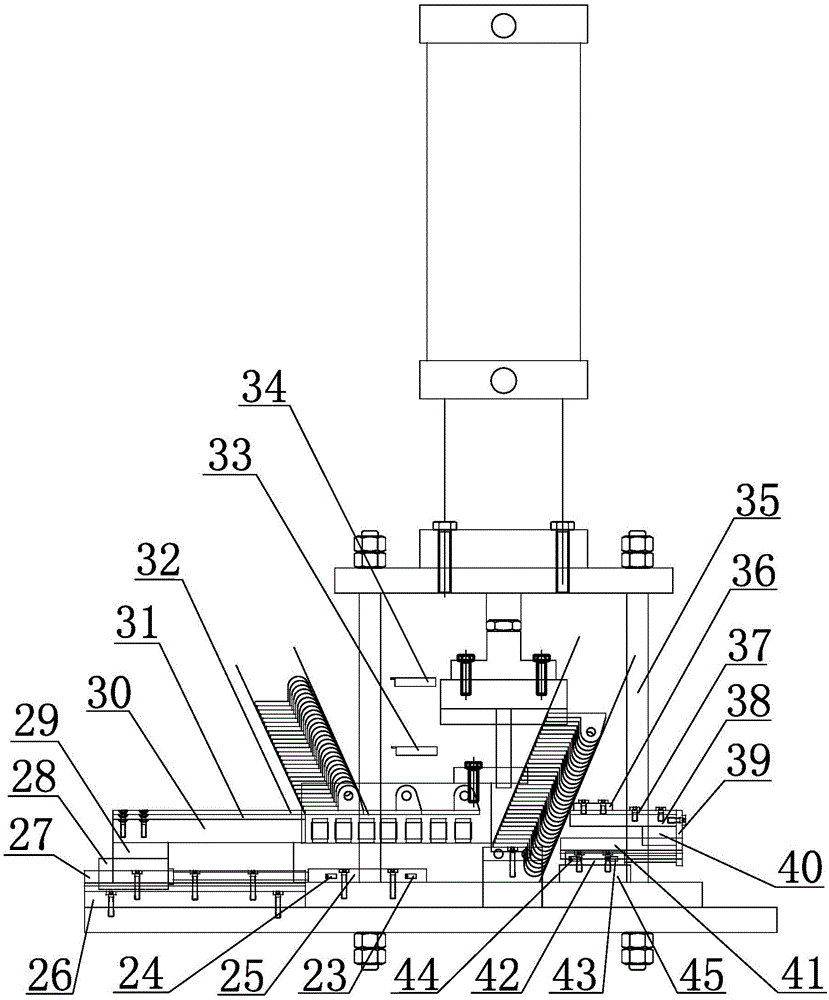

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 and figure 2 The single-section automatic assembly machine for bent plate chains shown includes a frame 1 and a transfer mechanism, a feeding mechanism, a positioning mechanism and a press-fitting mechanism arranged on the frame 1. A bottom plate 20 is fixed in the center of the frame 1. The base plate 20 is fixed with a working table, the right end of the working table is connected with a single-section delivery frame 21 for finished products, and the four corners of the base plate 1 are also connected with gas cylinders through four vertically arranged fixed table support columns 35. The hydraulic pressurized cylinder fixes the platen 14, and the transfer mechanism includes a left-curved chain plate delivery cylinder 5, a left-curved chain plate push plate 6 and a left-curved chain plate sheet tube 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com