Built-in part array assembling machine and production method of motor stator using same

A built-in, assembly machine technology, applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve the problems of poor quality stability, poor assembly accuracy, and high assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

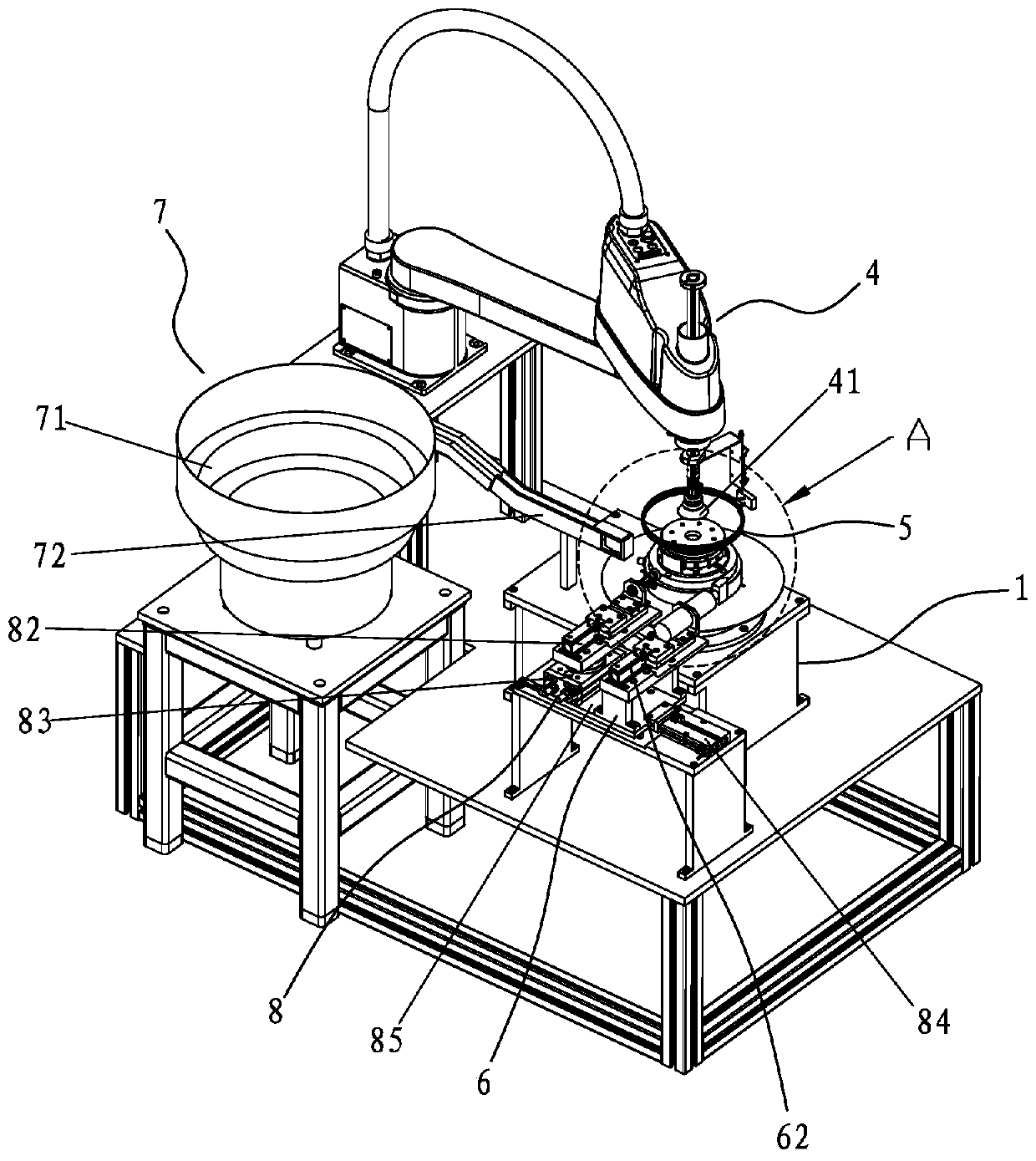

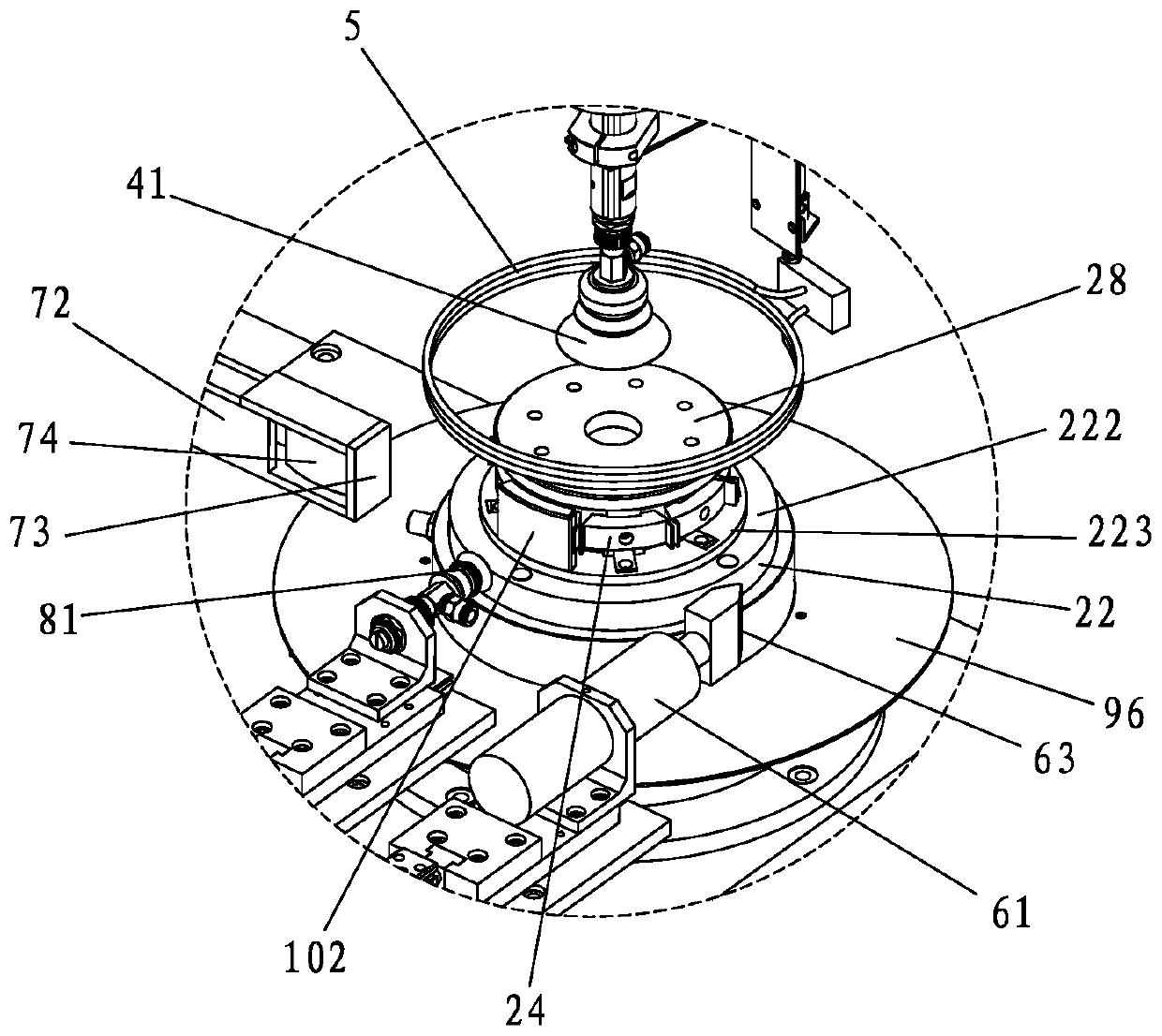

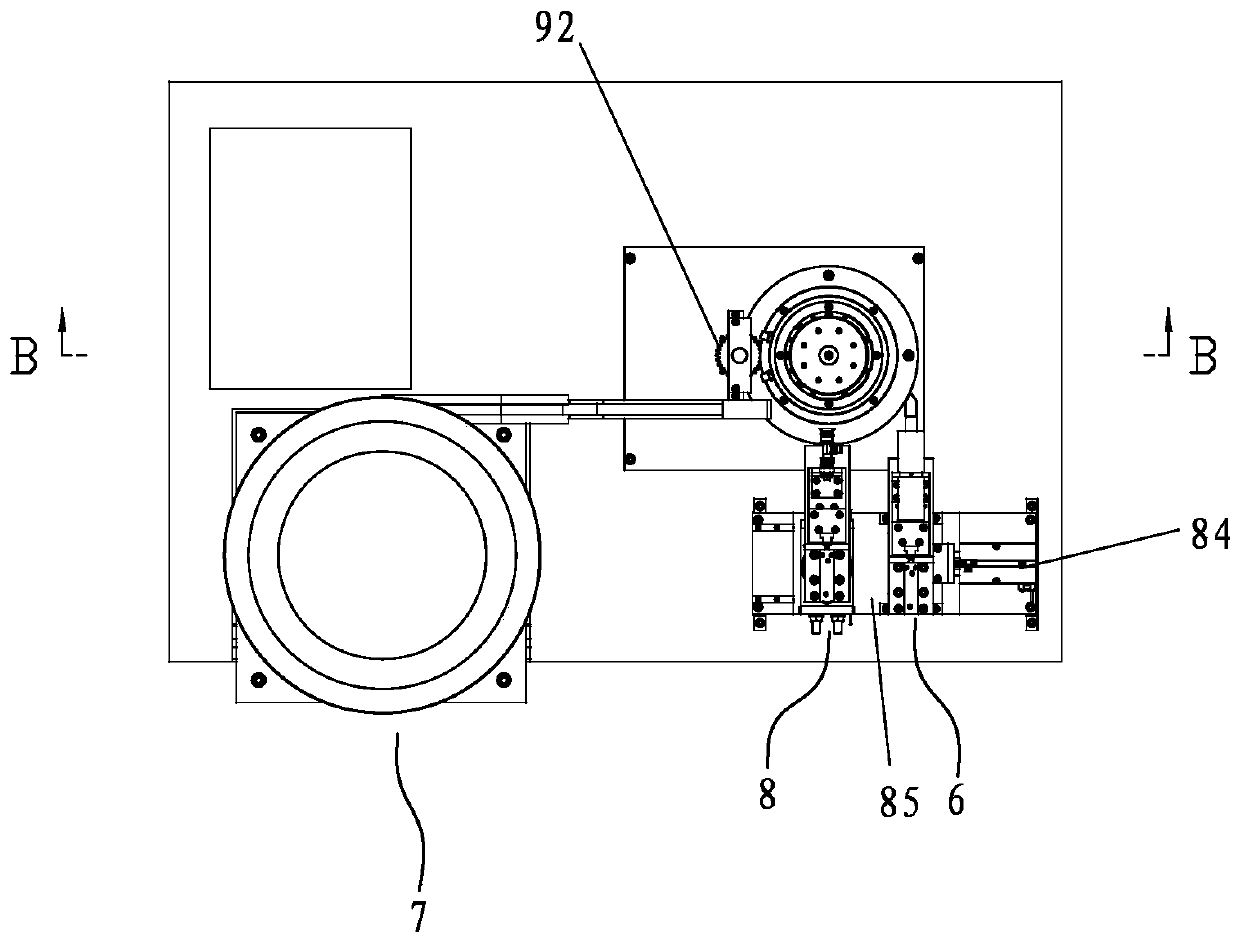

[0045] Such as Figure 1 to Figure 9 The built-in part array assembly machine shown includes a bracket 1. A turntable 21 capable of rotating 360° is provided on the bracket 1. A positioning plate 22 is fixed on the turntable 21. A plurality of The sliding support block 23 that can expand and shrink relative to the center of rotation of the positioning disc 22, then each sliding support block 23 can slide close to or slide away from the center of rotation of the positioning disc 22. One side is provided with a clamp 24 for clamping the array parts 102, the number of the sliding support blocks 23 and the clamps 24 is equal to the number of the array parts 102 in the same circumferential direction, and a plurality of the sliding support blocks 23 surround the positioning plate The center of rotation of 22 is evenly distributed and can be used for the shell 101 to buckle on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com