Split-type flat shaft air floating rotary table

An air-floating turntable and split-type technology, which is applied in the direction of bearings, shafts, bearings, bearing components, etc., can solve problems such as self-adjustment, improve over-reliance on processing and assembly accuracy, ensure stability, and improve use flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

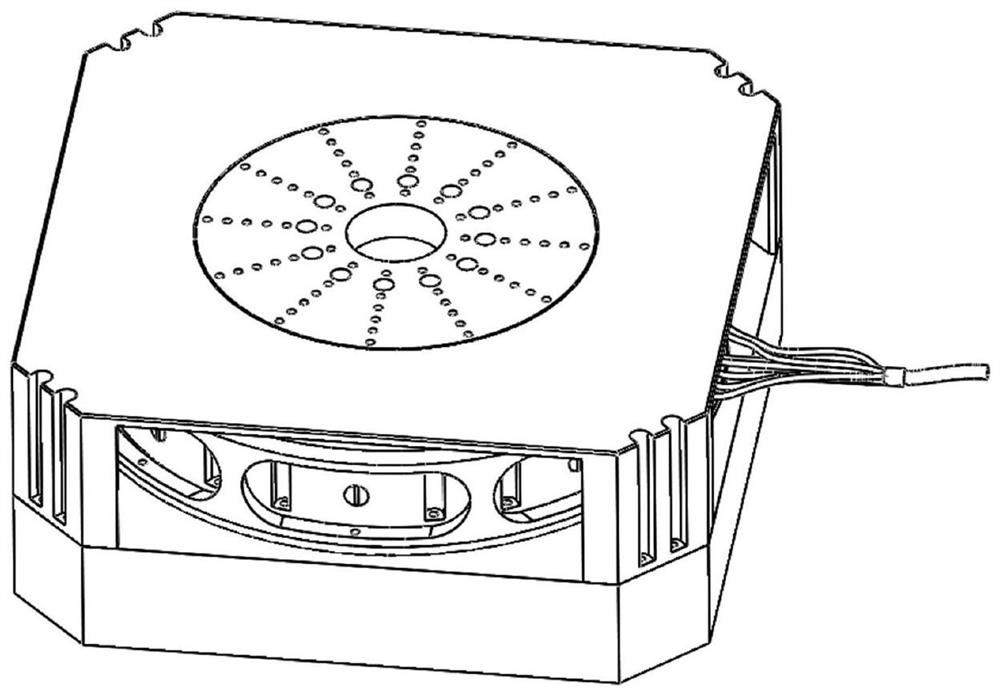

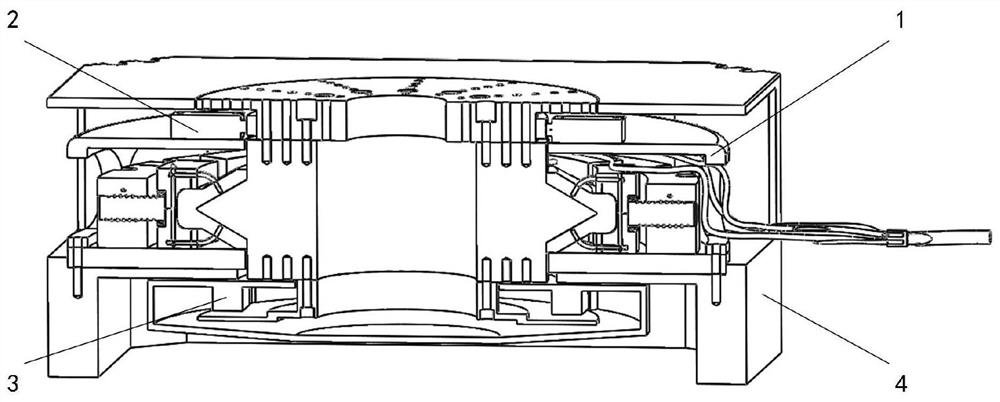

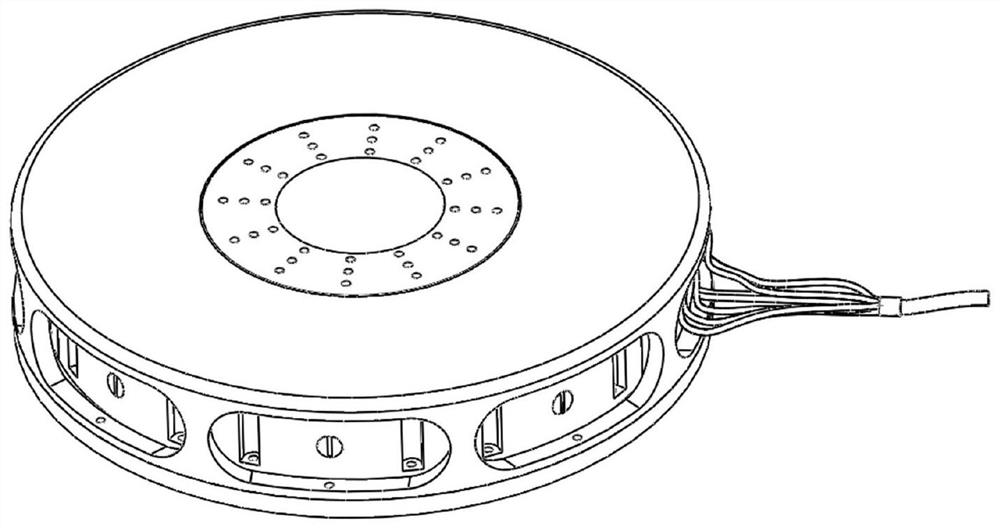

[0030] A split-type flat-axis air-floating turntable, such as figure 1 , figure 2 As shown, it is characterized in that it includes a split flat shaft air bearing shafting 1, a power module 2, an angle measurement module 3 and a support protection module 4;

[0031] The split flat shaft air bearing shafting 1 is the core of the air bearing turntable, providing bearing and lubrication functions for the turntable;

[0032] The power module 2 includes a ceramic ring 5 and an ultrasonic motor 6; the ceramic ring 5 is installed on the upper end of the main shaft 13, and the ultrasonic motor 6 is arranged symmetrically along the circumference of the ceramic ring 5, and placed on the outer cover 21 of the split flat shaft air bearing shafting system , driving the ceramic ring 5 to drive the main shaft 13 to rotate;

[0033] The angle measurement module 3 is an encoder, includi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com