Press fitting and hammering assembling tool

A technology for assembling tooling and indenters, which is applied in the direction of manufacturing tools and hand-held tools, etc. It can solve the problems of reducing assembly accuracy, increasing production costs, and high raw material costs, and achieves the effect of reducing tooling design, shortening replacement time, and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

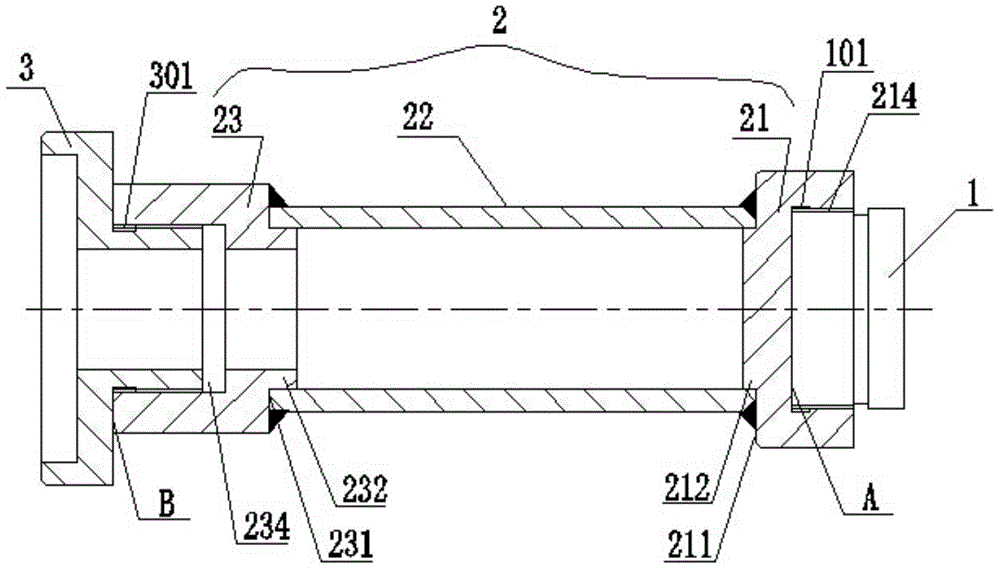

[0058] Such as figure 1 As shown, in the pressing and hammering assembly tooling of Embodiment 1 of the present invention, the pressing and hammering assembly tooling includes an upper pressing head 1, an intermediate body 2 and a lower pressing head 3, and the upper pressing head 1 and the described The intermediate body 2 is connected by a pair of threads, and the intermediate body 2 is connected with the lower pressing head 3 by a pair of threads.

[0059] Specifically, the intermediate body 2 includes an upper connecting piece 21 , a main pillar 22 and a lower connecting piece 23 welded end to end in sequence. According to the needs of the workpiece to be assembled, both ends of the upper pressing head 1 are flat; The cross section of the head 3 is T-shaped.

[0060] The end face of the upper connector 21 welded with the main pillar 202 is the first end face 211, and the first end face 211 is provided with a circular boss 212 (for the convenience of manufacturing and pro...

Embodiment 2

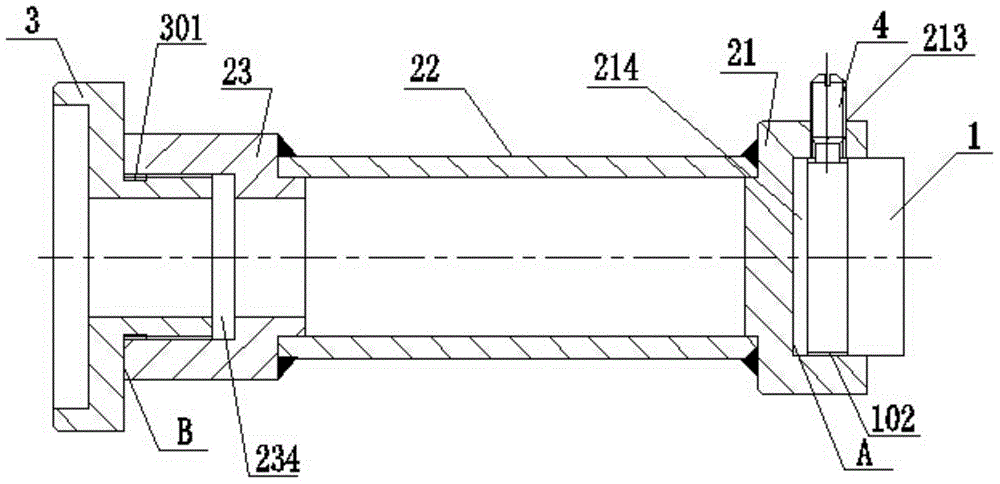

[0065] Such as figure 2 As shown, in the pressing and hammering assembly tooling of Embodiment 2 of the present invention, the pressing and hammering assembly tooling includes an upper pressing head 1, an intermediate body 2 and a lower pressing head 3, and the upper pressing head 1 and the described The intermediate body 2 is connected through a seam, and the intermediate body 2 is connected with the lower pressing head 3 through a thread pair.

[0066] Specifically, the intermediate body 2 includes an upper connecting piece 21 , a main pillar 22 and a lower connecting piece 23 welded end to end in sequence. The difference from Embodiment 1 is that one end of the upper connector 21 connected to the upper indenter 1 is set as a first installation cavity 214, and a stopper 213 is opened on the wall of the first installation cavity 214 , a ring groove 102 is provided at a position corresponding to the notch 213 on the upper pressing head 1 . The upper indenter 1 extends into ...

Embodiment 3

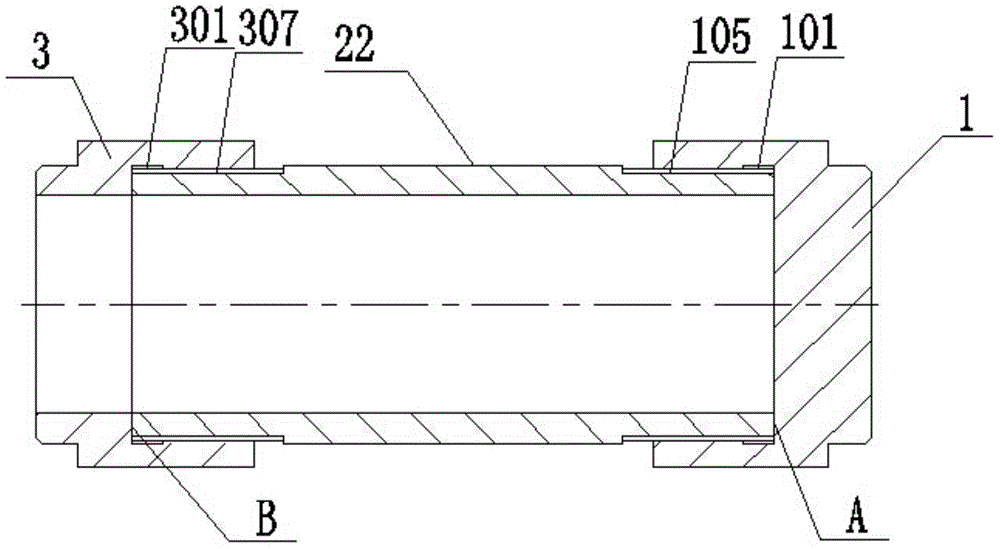

[0068] Such as image 3 As shown, in the press-fitting and hammering assembly tooling of Embodiment 3 of the present invention, the press-fitting and hammering assembly tooling includes an upper pressing head 1, an intermediate body 2 and a lower pressing head 3, and the upper pressing head 1 and the described The intermediate body 2 is connected by a pair of threads, and the intermediate body 2 is connected with the lower pressing head 3 by a pair of threads.

[0069] Specifically, the intermediate body 2 includes a main post 22, and the two ends of the main post 22 are provided with external threads.

[0070] One end of the upper indenter 1 connected to the main post 22 has a third installation cavity 105, and an internal thread cooperating with the external thread of one end of the main post 22 is provided in the third installation cavity 105, The external thread and the internal thread form a thread pair, and the other end of the upper pressing head 1 can be set according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com