Driving connection device for motor and oil pump

A drive connection and oil pump technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of reducing the reliability of motor and oil pump movement, increasing the cumulative error of processing, accelerating the wear of spline teeth and teeth, and achieving improvement The effect of motion reliability, reduction of support bearings, and reduction of failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

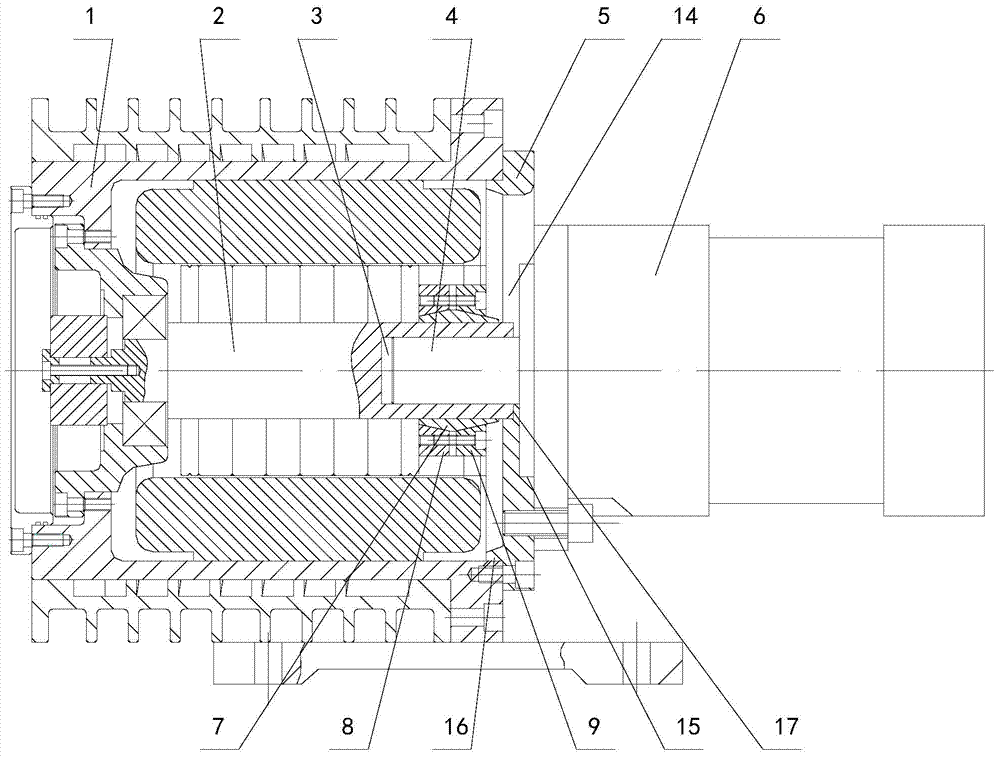

[0035] Depend on Figure 1 to Figure 5 It can be seen from the first structural schematic diagram of the drive connection device of the motor and oil pump of the present invention shown that it includes an end cover 5 connected to the motor 1 and the oil pump 6, the oil pump 6 is connected to the end cover 5, and the end cover 5 is connected to the motor 1 superior. It also includes a locking device that is located at one end of the motor 1 close to the end cover 5 and locks and connects the motor output shaft 2 and the power input shaft 4 of the oil pump 6. The end cover 5 has a locking device for disassembly and assembly. The insertion port 14.

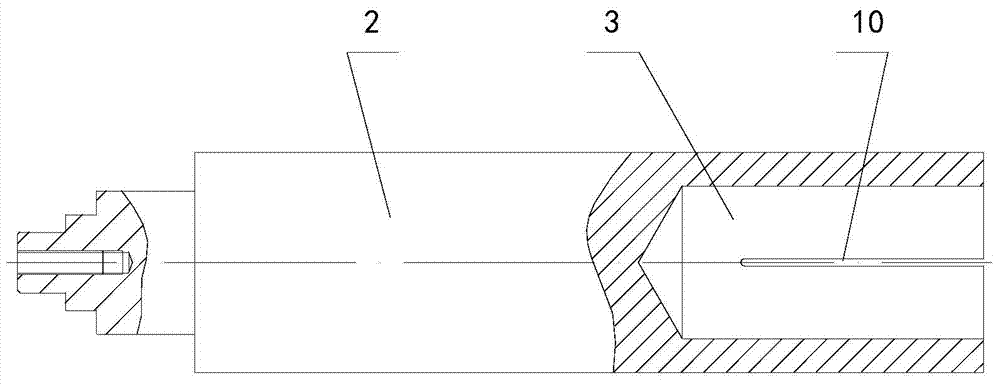

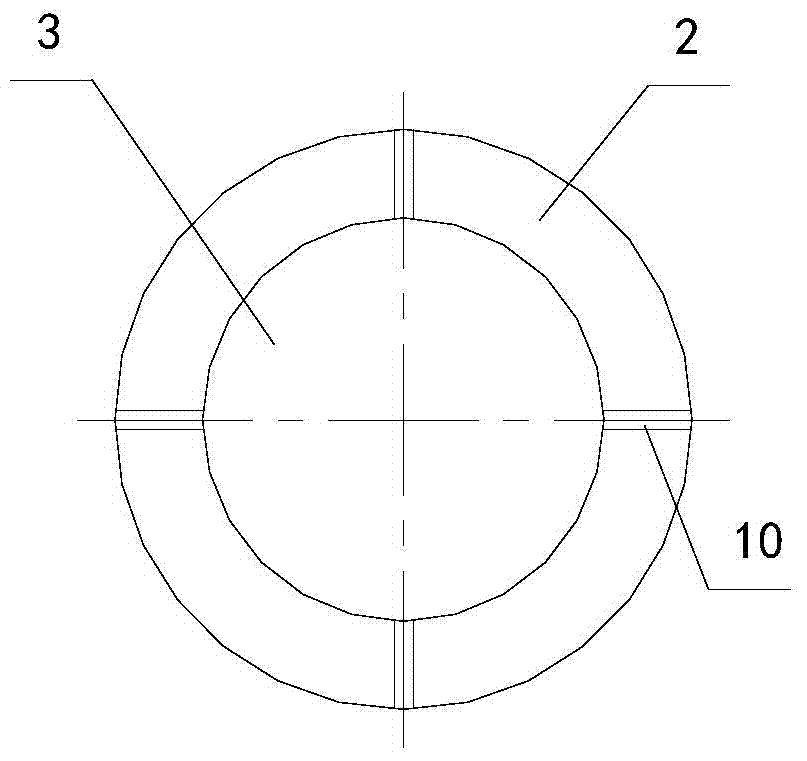

[0036] The power input shaft 4 of the oil pump 6 is located in one end of the motor output shaft 2 of the motor 1, and one end of the motor output shaft 2 has an axial mounting hole 3, and the power input shaft 4 of the oil pump 6 is sleeved in the mounting hole 3 , and at least one axial opening slot 10 is provided on the circumf...

specific Embodiment approach 2

[0040] Depend on Figure 6 and Figure 7 It can be seen from the second structural schematic diagram of the drive connection device of the motor and oil pump of the present invention shown that it includes an end cover 5 connected to the motor 1 and the oil pump 6, the oil pump 6 is connected to the end cover 5, and the end cover 5 is connected to the motor 1 superior. It also includes a locking device that is located at one end of the motor 1 close to the end cover 5 and locks and connects the motor output shaft 2 and the power input shaft 4 of the oil pump 6. The end cover 5 has a locking device for disassembly and assembly. The insertion port 14.

[0041] The power input shaft 4 of the oil pump 6 is located in one end of the motor output shaft 2 of the motor 1, and one end of the motor output shaft 2 has an axial mounting hole 3, and the power input shaft 4 of the oil pump 6 is sleeved in the mounting hole 3 , and at least one axial opening slot 10 is provided on the cir...

specific Embodiment approach 3

[0045] Depend on Figure 8 , Figure 9 and Figure 10 As can be seen from the third structural schematic diagram of the drive connection device of the motor and oil pump of the present invention, it includes an end cover 5 connected to the motor 1 and the oil pump 6, the oil pump 6 is connected to the end cover 5, and the end cover 5 is connected to the motor 1 superior. It also includes a locking device that is located at one end of the motor 1 close to the end cover 5 and locks and connects the motor output shaft 2 and the power input shaft 4 of the oil pump 6. The end cover 5 has a locking device for disassembly and assembly. The insertion port 14.

[0046] The locking device means that the peripheral wall of the mounting hole 3 on the motor output shaft 2 has at least one notch 26 penetrating through the wall thickness and extending axially, and the motor output shaft 2 at the notch 26 is locked and connected by a locking bolt 27 .

[0047] In this embodiment, there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com