Automatic pipe end flattening machine

A technology for flat mouth machines and pipe fittings, applied in the field of flat mouth machines, can solve the problems of uneven technical level, proficiency and work attitude, labor consumption, difficult to control, etc., so as to achieve easy control of processing quality, save processing time, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

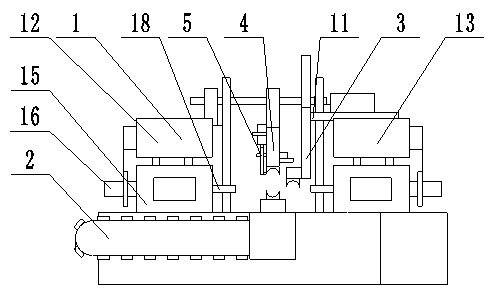

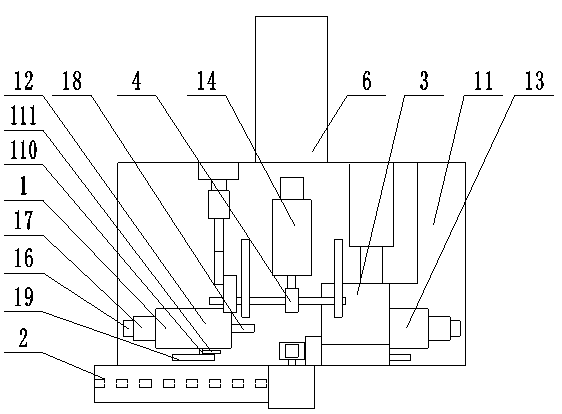

[0033] Such as figure 1 — Figure 9 As shown, the present invention is an automatic flat mouth machine for pipe fittings, comprising a power head assembly 1, a frame 11, an automatic feeding device 2, an automatic material grabbing device 3, an automatic clamping device 4, an automatic unloading device 5 and an automatic receiving device 6. The power head assembly 1 is installed on the frame 11, the frame 11 on one side of the power head assembly 1 is provided with an automatic feeding device 2, and the frame 11 on the other side of the power head assembly 1 is provided with an automatic retracting device. Material device 6, the frame 11 at the feeding end of the automatic feeding device 2 is provided with an automatic grabbing device 3, and the automatic clamping device 4 arranged on the top of the frame 11 fixes the workpiece on the working area of the power head assembly 2.

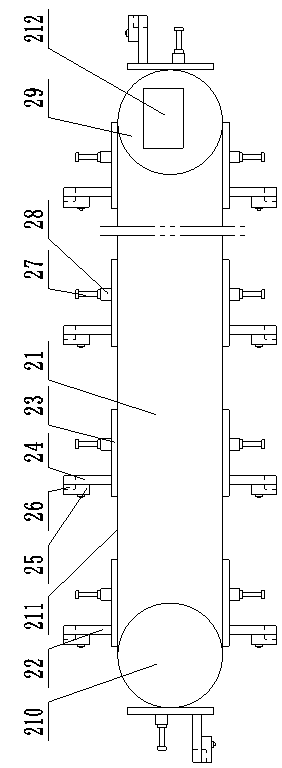

[0034] The structure of the automatic feeding device 2 is as follows: the automatic feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com