Apparatus for circumference grinding of workpiece

A technology for processing devices and workpieces, which is applied in the field of peripheral processing devices for workpieces, can solve problems such as inability to be found, and achieve the effects of preventing detection errors, avoiding wasteful processing of unqualified products, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

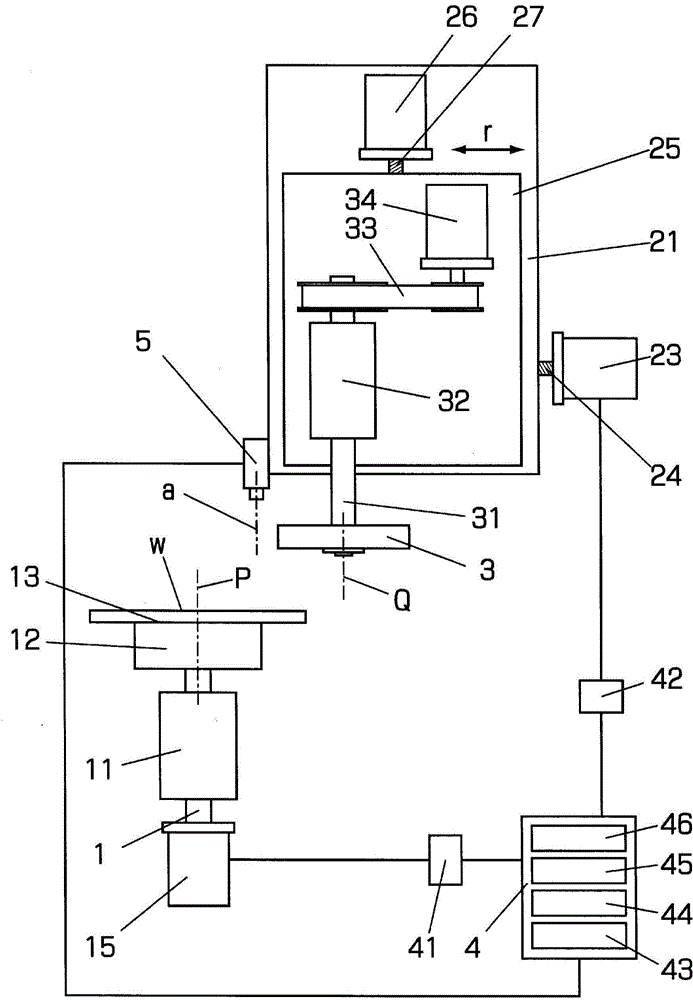

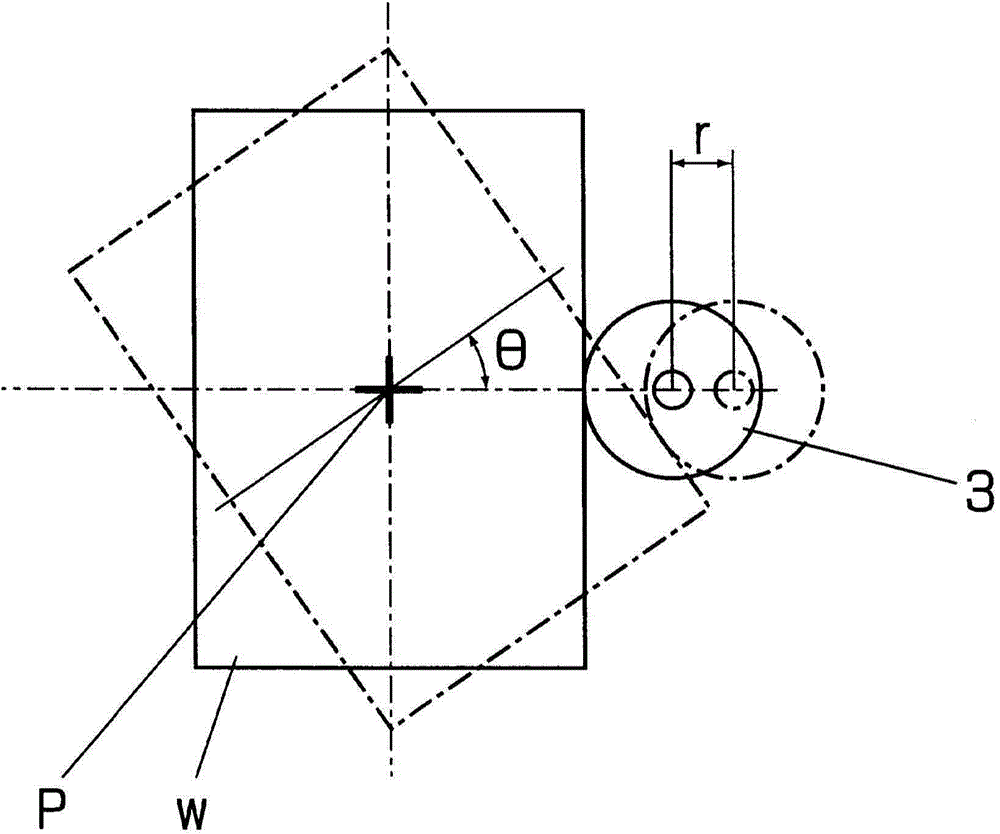

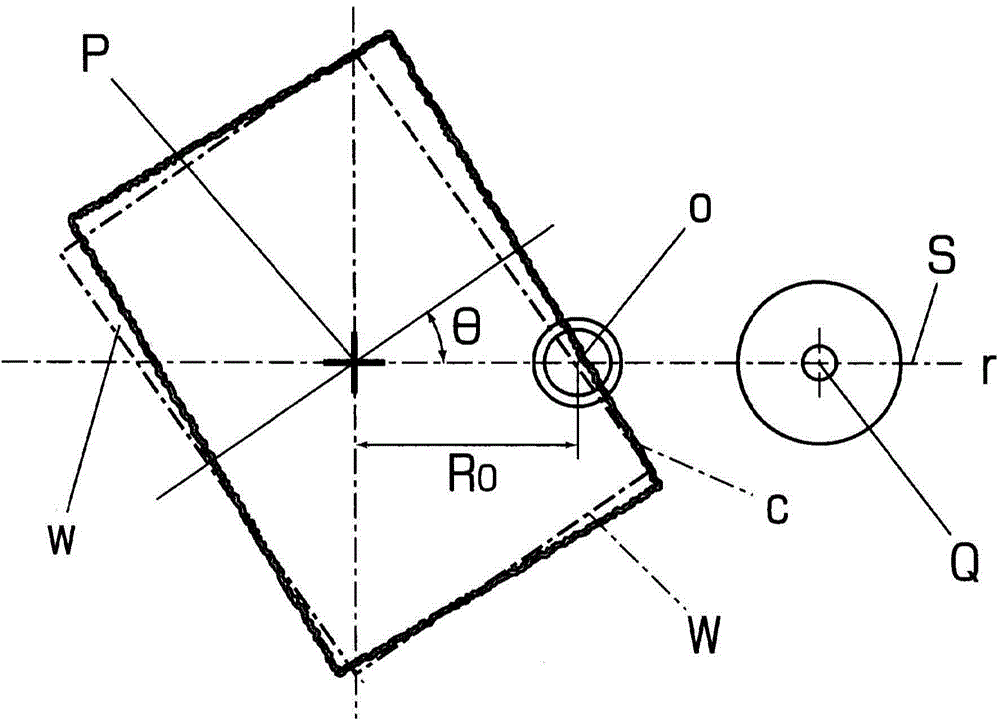

[0052] Hereinafter, embodiments of the peripheral processing device of the present invention will be described with reference to the drawings. figure 1 It is a schematic side view of the peripheral processing apparatus which performs processing in polar coordinates.

[0053] In the figure, the main shaft 1 is a hollow shaft in the vertical direction, and is rotatably supported by a frame (not shown) via a bearing 11 . A table 12 is fixed to the upper end of the spindle 1, and a workpiece is measured and processed while being fixed to a horizontal upper surface 13 of the table. Negative pressure is supplied to the table 12 through the hollow hole of the main shaft 1, and the workpiece sent to the upper surface 13 of the table is fixed to the table 12 so that the lower surface is vacuum-adsorbed. A spindle motor (servo motor) 15 is connected to the lower end of the spindle 1 . The spindle motor 15 is connected to the controller 4 via a servo amplifier 41 , and controls the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com