Short flow processing method of aspheric optical element

A technology of optical parts and processing methods, applied in the processing field of aspheric optical parts, can solve the problems of low certainty and long processing cycle, and achieve the effect of improving processing efficiency and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

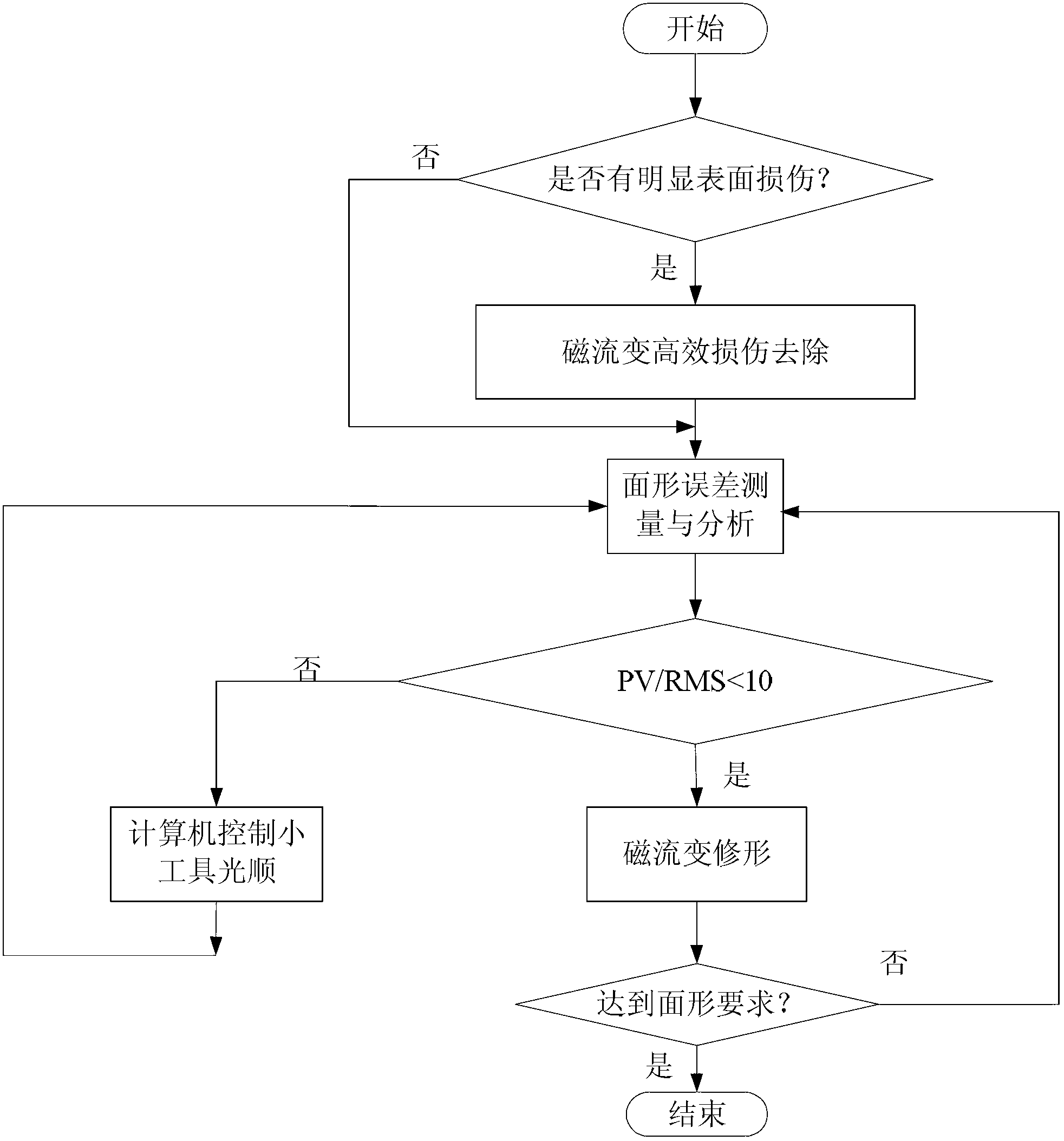

Method used

Image

Examples

Embodiment

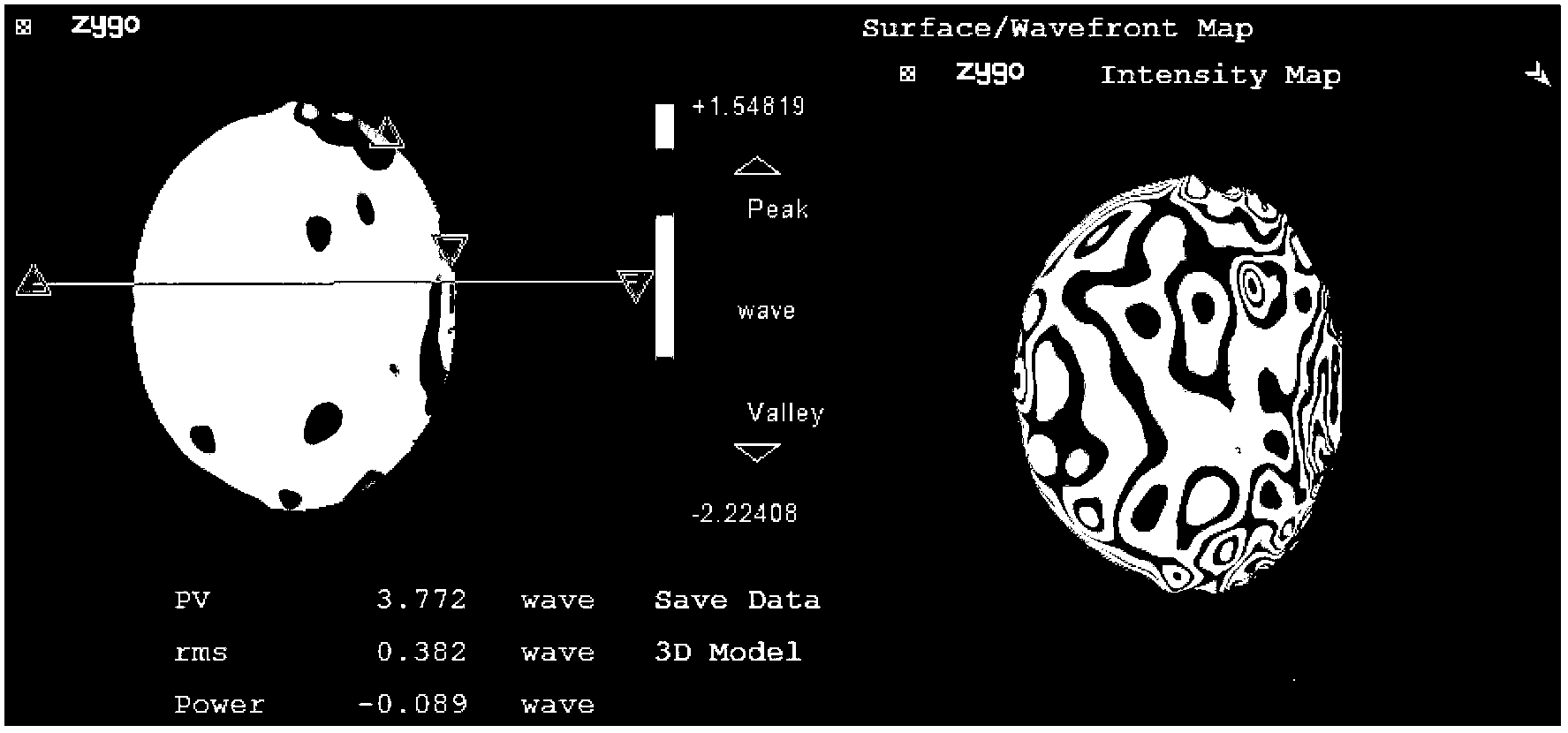

[0027] Choose an off-axis aspheric mirror with φ=290mm for polishing experiment. The off-axis aspheric mirror described in this embodiment is a quadric surface, its geometric dimension φ=290mm, and the effective light aperture Vertex curvature radius R=1006mm, quadratic term constant k=-1, α 1 , α 2 , α 3 , α 4 Both are 0, the off-axis distance is 250mm, and the surface shape accuracy requires the effective light aperture Better than λ / 50RMS, where λ=632.8nm.

[0028] First of all, in the three-dimensional coordinate system, the off-axis aspheric mirror formed by the rotating surface with Z as the axis is usually described by the following formula:

[0029] Z = cr 2 1 + 1 - ( 1 + k ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com