Electromagnetic forming device and method for micro fuel cell metal bipolar plate microchannel

A technology of micro-fuel cells and metal bipolar plates, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as difficulty in matching between micro-convex and concave dies, shorten processing time, reduce processing costs, and be easy to replace Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

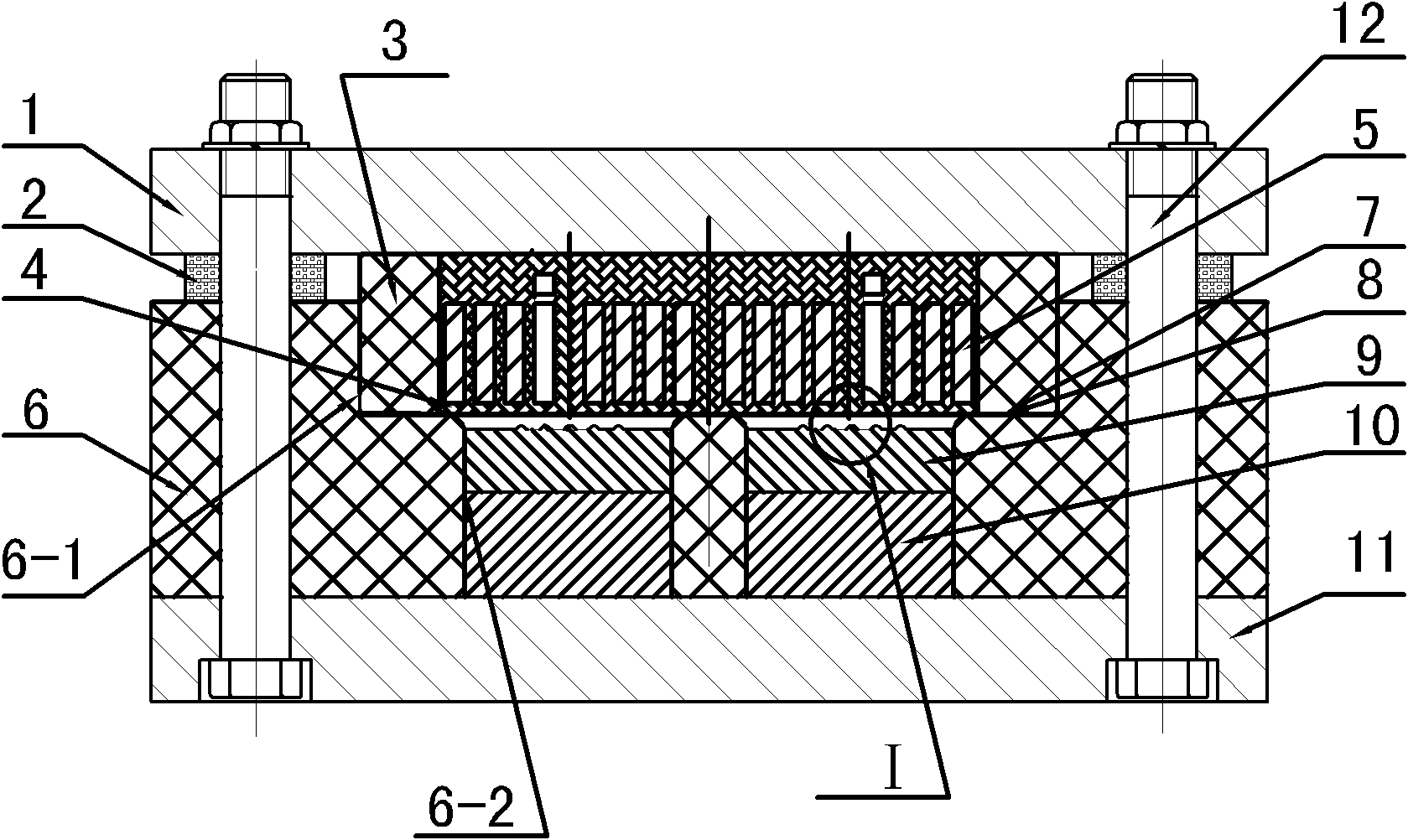

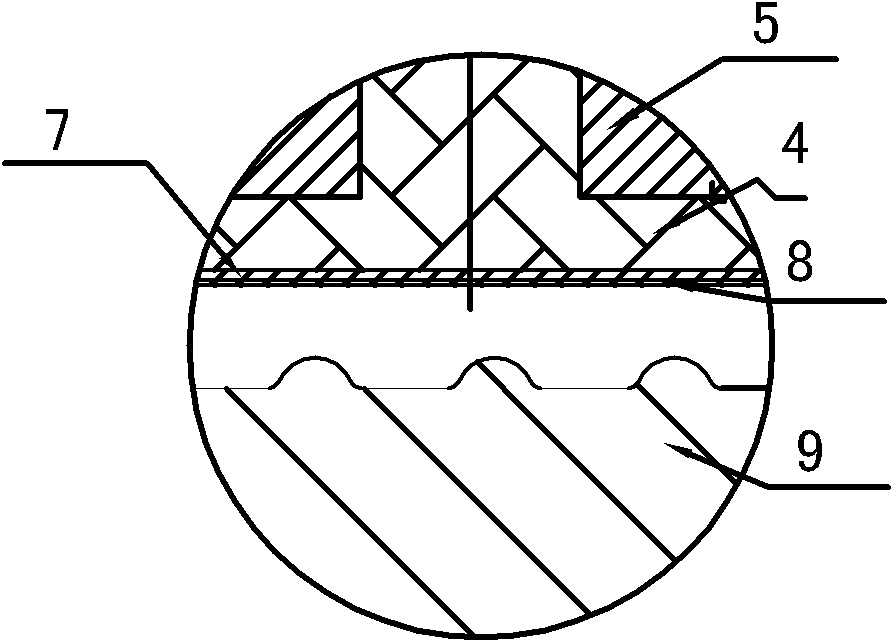

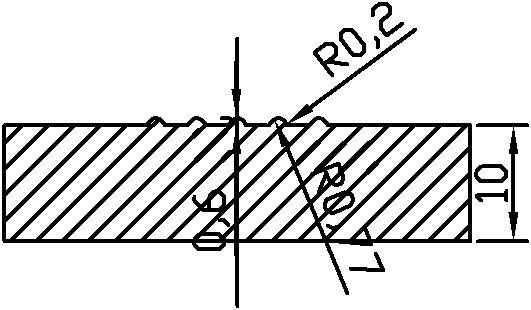

[0009] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment will be specifically described. The electromagnetic forming device of the micro-channel of the metal bipolar plate of the micro-fuel cell of the present embodiment includes an upper template 1, a backing ring 2, a coil frame 3, a potting material 4, a coil 5, a support frame 6, a driving piece 7, and a mold 9. Spacer 10, lower formwork 11 and coil frame 12. The support frame 6 is arranged on the upper surface of the lower formwork 11. There is a groove 6-1 on the upper surface of the support frame 6 to place the coil 5. At the bottom center of the groove 6-1 There is a circular through hole 6-2 to place the mold 9 and the pad 10, the mold 9 and the pad 10 are stacked up and down, and the distance between the mold 9 and the bottom of the groove is regulated by the pad 10. The bottom of the groove 6-1 and the top of the mold 9 are the drive pieces 7, the coil frame 3, the ...

specific Embodiment approach 2

[0012] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes a backing ring 2, and each bolt 12 is provided with a backing ring 2, and the backing ring 2 is arranged between the upper template 1 and the support frame 6, and the backing ring 2 is divided into two parts. There are two kinds of spacer rings and shock-absorbing spacer rings, the spacer spacer ring is made of metal, and the shock-absorbing spacer ring is made of polyurethane material. There is a backing ring 2 that cooperates with bolts above the support frame 6, and the upper formwork is above the backing ring. The fastening force between the support frame 6 and the upper template 1 is realized by bolts 12 . In this embodiment, six backing rings are used in conjunction with six bolts 12, two metal backing rings are used for positioning, and four polyurethane backing ring...

specific Embodiment approach 3

[0013] Specific implementation mode three: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that epoxy resin, polyamide and insulating materials that can provide electrical insulation and mechanical support are used in the gap between the bobbin 3 and the coil 5 and in the gap between the pitches of the coil 5 . Metal oxide hybrid potting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com