Automatic electrode slice current-collection and conductive tab welding equipment

A technology for welding equipment and electrode sheets, which is applied in the field of automatic electrode sheet current collecting and conducting electrode ear welding equipment, can solve problems such as physical injury of workers, low processing efficiency, and difficulty in guaranteeing product quality, so as to avoid pollution, improve work efficiency, The effect of saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

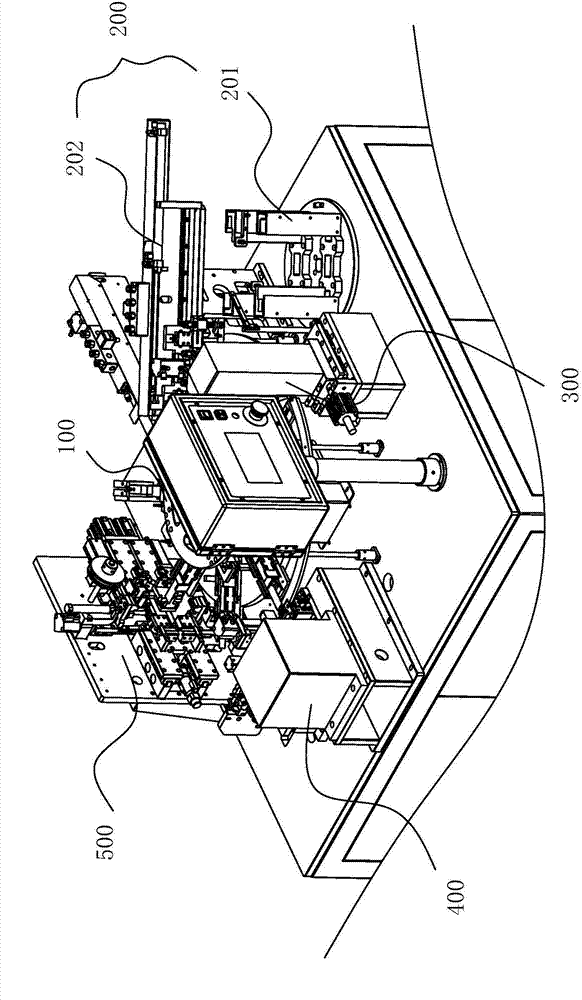

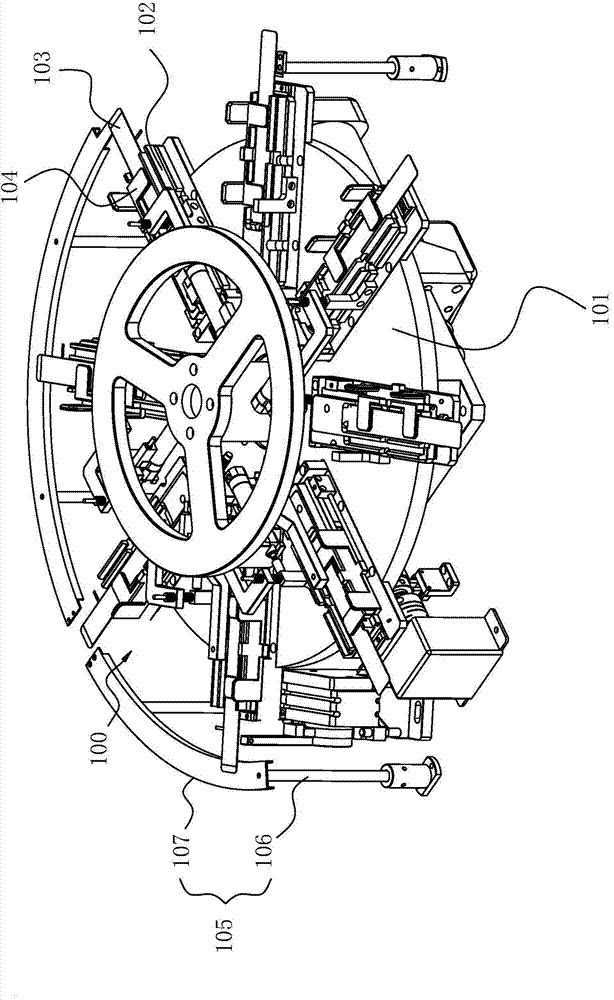

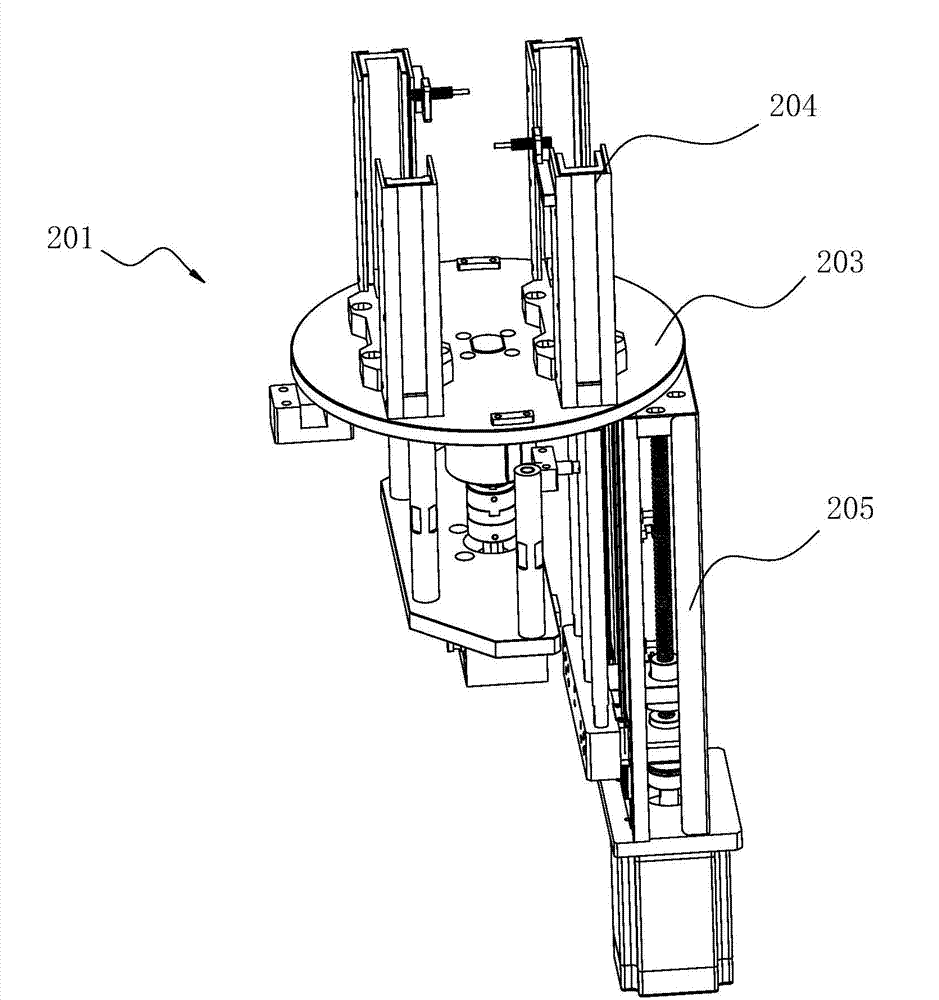

[0038] Such as Figure 1-7 As shown, in this embodiment, an automatic electrode sheet current collecting and conducting ear welding equipment according to the present invention includes a rotary table 100 for transporting electrode sheets 103, and the rotary table 100 includes a central turntable 101 , the central turntable 101 is provided with eight pole piece jigs 102, each pole piece jig 102 can be installed with an electrode piece 103, the pole piece jig 102 is provided with for fixedly placed on the pole piece jig 102 The pole piece holder 104 of the electrode piece 103. In this embodiment, the pole piece fixture 102 is detachably mounted on the central turntable 101, and the pole piece fixture can be replaced.

[0039] A pole piece bracket 105 is provided on the periphery of the central turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com