Longitudinal connection structure for superimposed slab concrete shear walls and connection method

A technology of concrete shear wall and longitudinal connection, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex production process of prefabricated components, inability to guarantee the quality of grouting, fast setting and hardening of grouting materials, etc., and it is easy to achieve construction quality. Guarantee, improve the installation efficiency and quality, and the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

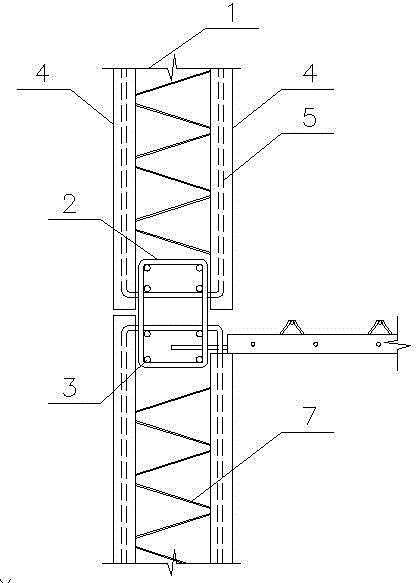

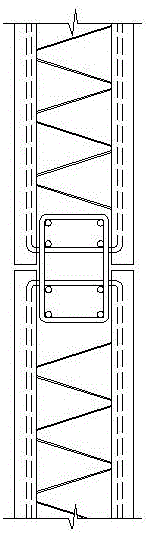

[0025] A longitudinal connection structure of a laminated slab concrete shear wall, which consists of: a closed ring-shaped connecting stirrup 2, and the connecting stirrup extends into the upper and lower two connected laminated slab concrete shear walls 1 Among them, the annular longitudinal bars 5 of the upper and lower layers of laminated slab concrete shear walls form a handover space, and the pinned longitudinal bars 3 penetrate into the handover space perpendicular to the plane where the connecting stirrups are located. The upper and lower two The annular longitudinal reinforcement of the laminated slab concrete shear wall forms an integral body with the pinned longitudinal reinforcement through the connecting stirrup.

Embodiment 2

[0027] According to the longitudinal connection structure of the laminated slab concrete shear wall described in Example 1, the laminated slab concrete shear wall is a hollow prefabricated component, and the described laminated slab concrete shear wall includes two layers of prefabricated concrete layers 4 , the two long sides of the ring-shaped longitudinal reinforcement are respectively pre-embedded in the two precast concrete layers, and the lattice steel bar 7 connects the two precast concrete layers together. like figure 1 shown.

Embodiment 3

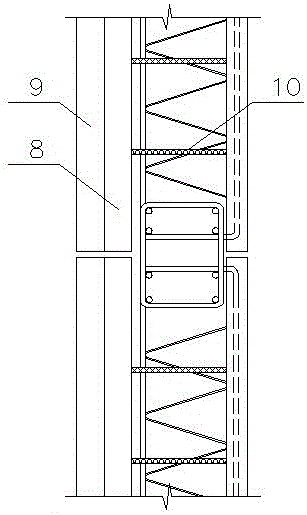

[0029] According to the longitudinal connection structure of the laminated slab concrete shear wall described in embodiment 1 or 2, the laminated slab concrete shear wall is a hollow prefabricated component, and the described laminated slab concrete shear wall includes a prefabricated concrete layer and Finishing thermal insulation layer, described decorative finishing thermal insulation layer comprises decorative surface layer 9 and thermal insulation layer 8, steel mesh is arranged in described decorative surface layer, connector 10 penetrates described thermal insulation layer and described decorative surface layer connected with the prefabricated concrete layer, one long side of the annular longitudinal bar is pre-embedded in the precast concrete layer, and the other long side of the annular longitudinal bar is connected with the lattice steel bar , the lattice reinforcement is connected to the prefabricated concrete layer. like image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com