Chain, chain transition chain plate and automatic chain transition chain plate integration punch forming technology

A stamping forming, chain plate technology, applied in the direction of metal chains, belts/chains/gears, chain rings, etc., can solve the problems of easy oxidation of parts surface, inaccurate bending size, poor operation safety, etc., to save processing time, The effect of reducing processing equipment and labor and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0043] see Figure 1-Figure 9 In this embodiment, the chain transition chain plate integrates automatic stamping forming process, as follows:

[0044] During the advancing process of the steel strip 1, the following processing steps are successively realized on the punching machine through the progressive die:

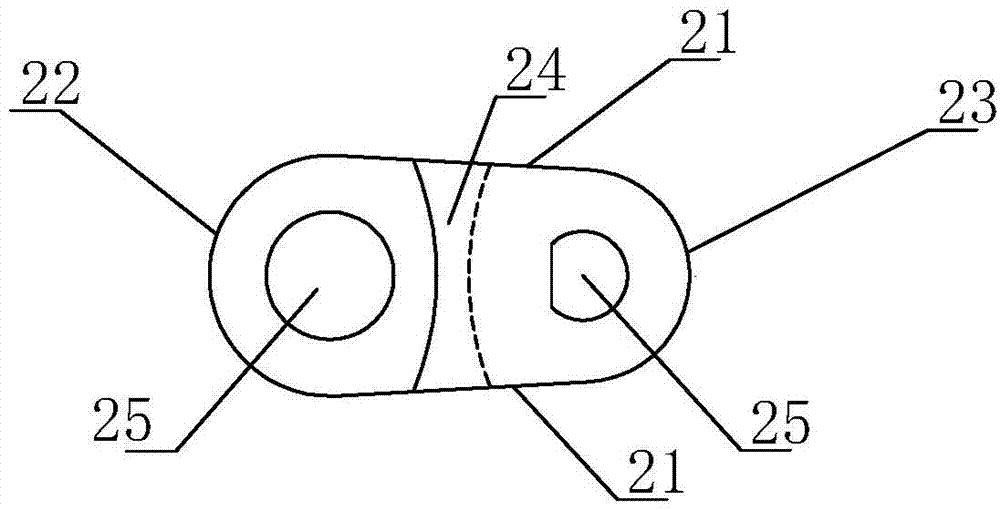

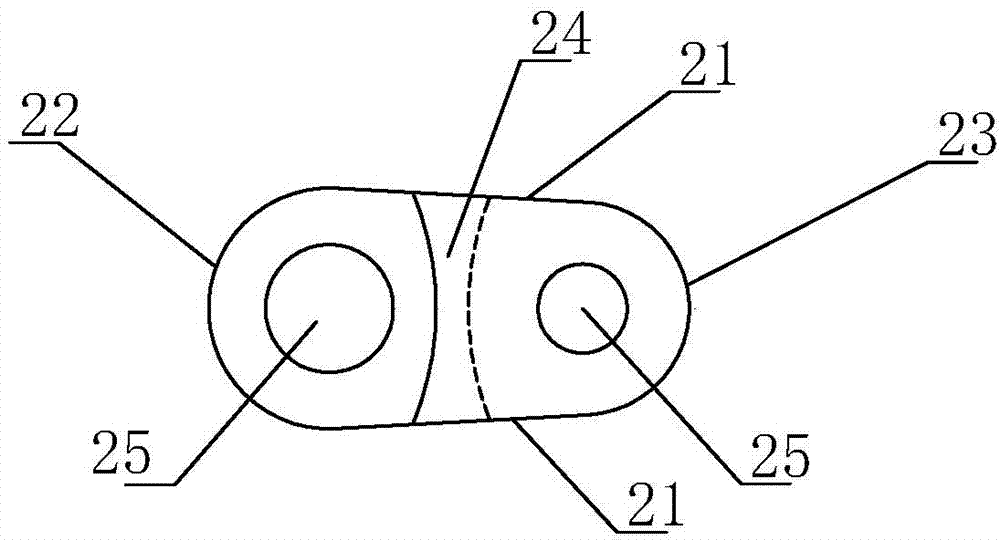

[0045] 1) Punch the positioning hole and cut the edge, which is used to punch out the positioning hole 11, the straight sides 21 on both sides of the chain plate and the partial arc edge 221 of the smaller end of the chain plate;

[0046] 2) trimming, used to punch out the arc edge 23 of the larger end of the chain plate;

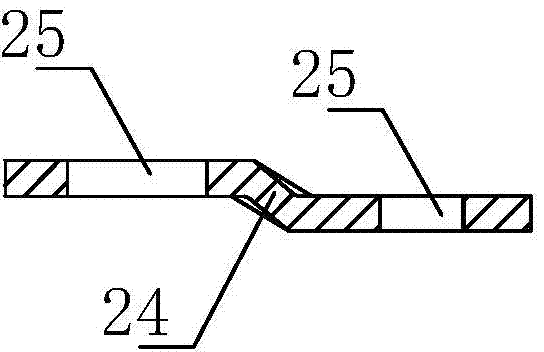

[0047] 3) Initial bending, which is used to stamp the straight chain plate structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com