High-content and high-elasticity special modifier for asphalt, and preparation method thereof

A high-elasticity and modifier technology, applied in the field of asphalt modifiers, can solve the problems that the performance cannot meet the standard of high-elasticity asphalt, cannot continue processing, and has poor compatibility with asphalt, and achieves good economy and use value, and is easy to popularize. Prospect, effect of improving anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

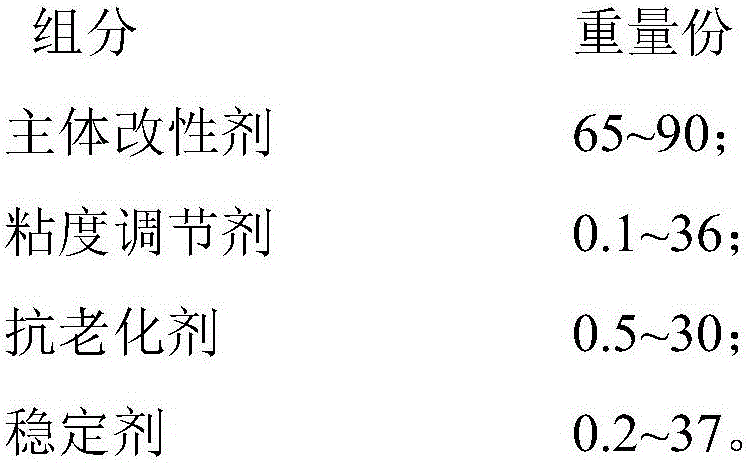

[0028] 1) Add 65 parts of main body modifier, 15 parts of viscosity regulator, 10 parts of anti-aging agent and 10 parts of stabilizer to the pulverizer in turn at -10°C, and then sieve with a 60-mesh sieve to obtain high dosage, high Special modifier for elastic asphalt.

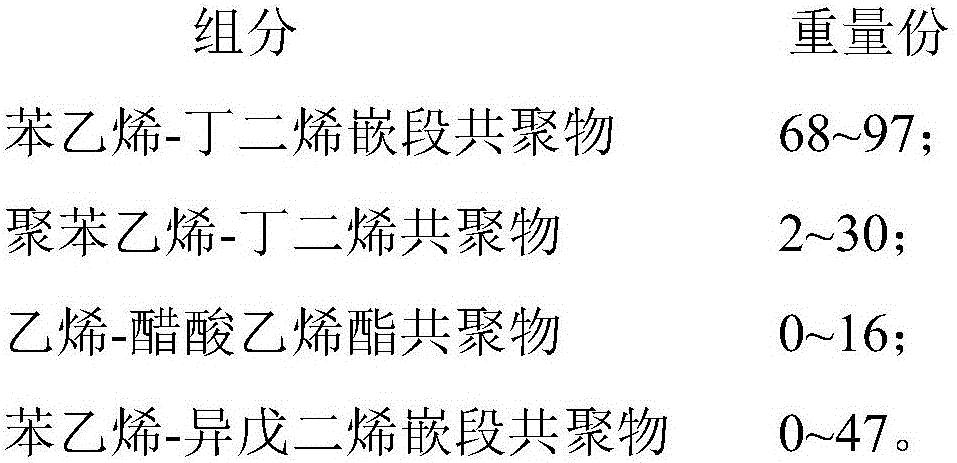

[0029] 2) The main body modifier contains: 68 parts of styrene-butadiene block copolymer, 9 parts of polystyrene-butadiene copolymer, 11 parts of ethylene-vinyl acetate copolymer and 12 parts of styrene-isoamyl Diene block copolymers.

[0030] Wherein the styrene-butadiene block copolymer contains: 20 parts of styrene-butadiene block copolymer modified by sulfonic acid groups, 23 parts of styrene-butadiene graft modified by methacrylic acid Block copolymer, 31 parts of cysteine-terminated modified styrene-butadiene block copolymer, 11 parts of sulfonic acid group-terminated modified styrene-butadiene block copolymer, 15 parts Amide-terminated modified styrene-butadiene block copolymer, the graft modified ...

Embodiment 2

[0035] 1) Add 75 parts of main body modifier, 8 parts of viscosity modifier, 6 parts of anti-aging agent and 11 parts of stabilizer to the pulverizer in sequence at -10°C, and then sieve with a 60-mesh sieve to obtain high dosage, high Special modifier for elastic asphalt.

[0036] 2) The host modifier contains: 68 parts of styrene-butadiene block copolymer, 11 parts of polystyrene-butadiene copolymer, 6 parts of ethylene-vinyl acetate copolymer and 11 parts of styrene-isoamyl Diene block copolymers.

[0037] Among them, the styrene-butadiene block copolymer contains: 16 parts of styrene-butadiene block copolymer modified by hydroxyl group grafting, 28 parts of styrene-butadiene block copolymer modified by carboxyl group 19 parts of maleic anhydride graft modified styrene-butadiene block copolymer, 11 parts of carboxyl-terminated modified styrene-butadiene block copolymer, 15 parts of acrylic acid-terminated modified Styrene-butadiene block copolymer, 11 parts of ester group...

Embodiment 3

[0042] 1) Add 90 parts of main body modifier, 6 parts of viscosity regulator, 2 parts of anti-aging agent and 2 parts of stabilizer to the pulverizer in sequence at -10°C, and then sieve with a 60-mesh sieve to obtain high dosage, high Special modifier for elastic asphalt.

[0043] 2) The main body modifier contains: 68 parts of styrene-butadiene block copolymer, 9 parts of polystyrene-butadiene copolymer, 11 parts of ethylene-vinyl acetate copolymer and 12 parts of styrene-isoamyl Diene block copolymers.

[0044] Wherein the styrene-butadiene block copolymer contains: 7 parts of acrylic acid graft modified styrene-butadiene block copolymer, 9 parts of hydroxyl graft modified styrene-butadiene block copolymer , 28 parts of carboxyl-modified styrene-butadiene block copolymers, 19 parts of maleic anhydride graft-modified styrene-butadiene block copolymers, 11 parts of carboxyl-terminated modified benzene Ethylene-butadiene block copolymer, 15 parts of acrylic acid-terminated m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com