Virus penetrating blocking film for operating gown and preparation method of film

A technology for surgical gowns and viruses, which is applied in the field of anti-virus penetration film for surgical gowns and its preparation, which can solve the problems of poor uniformity of fabric protection, failure to meet comfort requirements, poor breathability and moisture permeability, etc., to achieve protection Reliable uniformity, high qualified rate of finished products, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

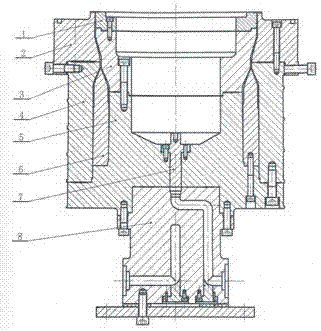

Image

Examples

Embodiment 1

[0021] 1) Ingredients: first choice, raw materials for the preparation of anti-virus penetration film for surgical gowns: 94.9% thermoplastic polyurethane, 1% ABS resin, 4% slip agent, 0.1% antioxidant; among them, the The raw materials for the preparation of thermoplastic polyurethane include: 42 parts of polyester polyol, 17 parts of aromatic isocyanate, 19 parts of propylene glycol, and 5 parts of dibutyltin dilaurate;

[0022] 2) Drying: Mix and stir the above raw materials in the material barrel evenly to obtain the mixture;

[0023] 3) Dehumidification and drying: put the above mixture into a dehumidifier for drying, and control the moisture content to ≤0.01%;

[0024] 3) Screw extruder plasticization: Put the dried mixture into the screw extruder to obtain the melt by extrusion plasticization;

[0025] 4) Die blown film forming: the melt is introduced into the die, and finally the film is blown through the die to form, and after winding and dividing, the virus-penetrat...

Embodiment 2

[0028] 1) Ingredients: First choice, raw materials for the preparation of anti-virus penetration film for surgical gowns: 94% thermoplastic polyurethane, 0.8% ABS resin, 5% slip agent, 0.2% antioxidant; wherein, the The raw materials for the preparation of thermoplastic polyurethane include: 45 parts of polyester polyol, 16 parts of aromatic isocyanate, 20 parts of propylene glycol, and 7 parts of dibutyltin dilaurate;

[0029] 2) Drying: Mix and stir the above raw materials in the material barrel evenly to obtain the mixture;

[0030] 3) Dehumidification and drying: put the above mixture into a dehumidifier for drying, and control the moisture content to ≤0.01%;

[0031] 3) Screw extruder plasticization: Put the dried mixture into the screw extruder to obtain the melt by extrusion plasticization;

[0032] 4) Die blown film forming: the melt is introduced into the die, and finally the film is blown through the die to form, and after winding and dividing, the virus-penetrating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com