Casing Patch and Seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

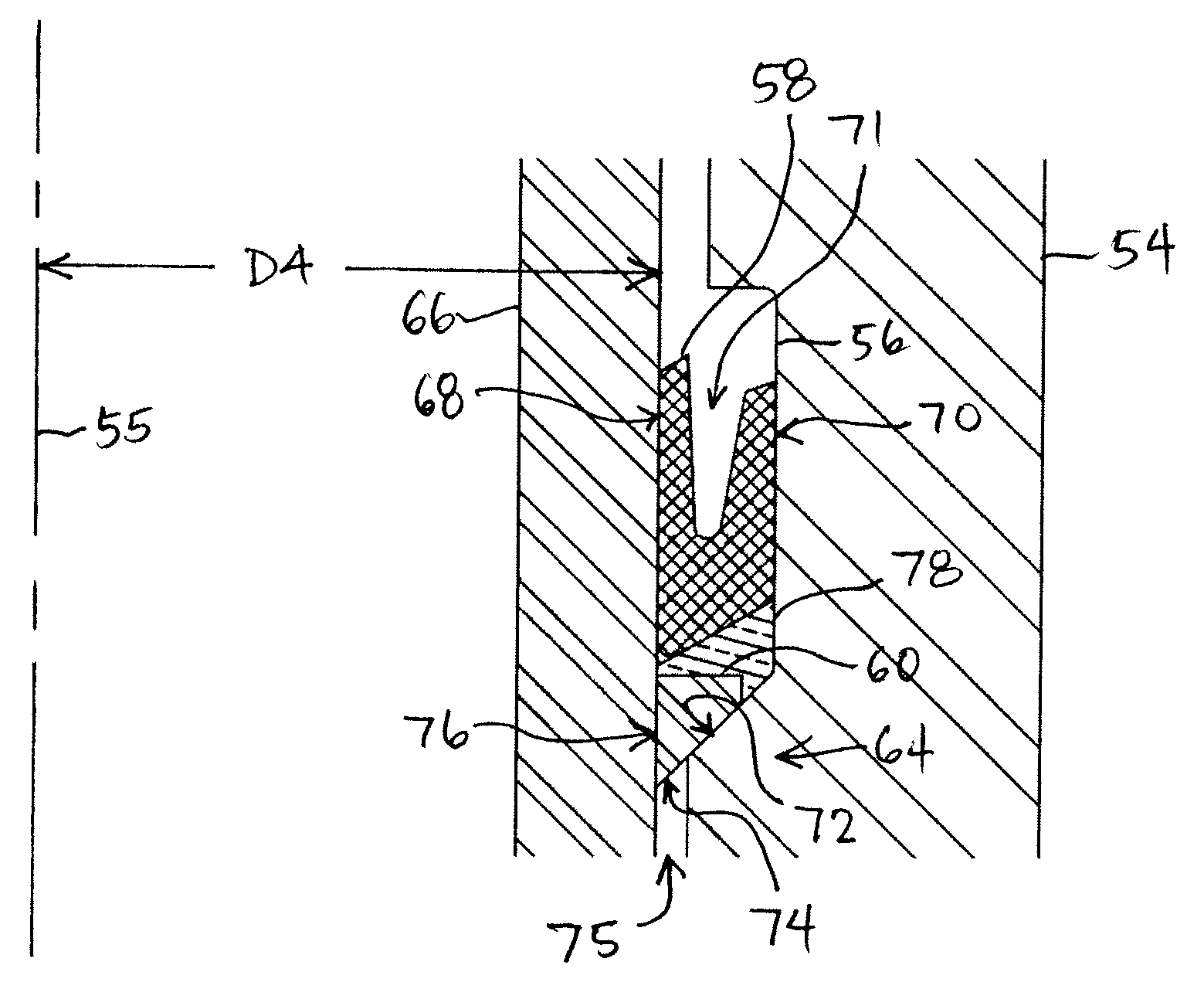

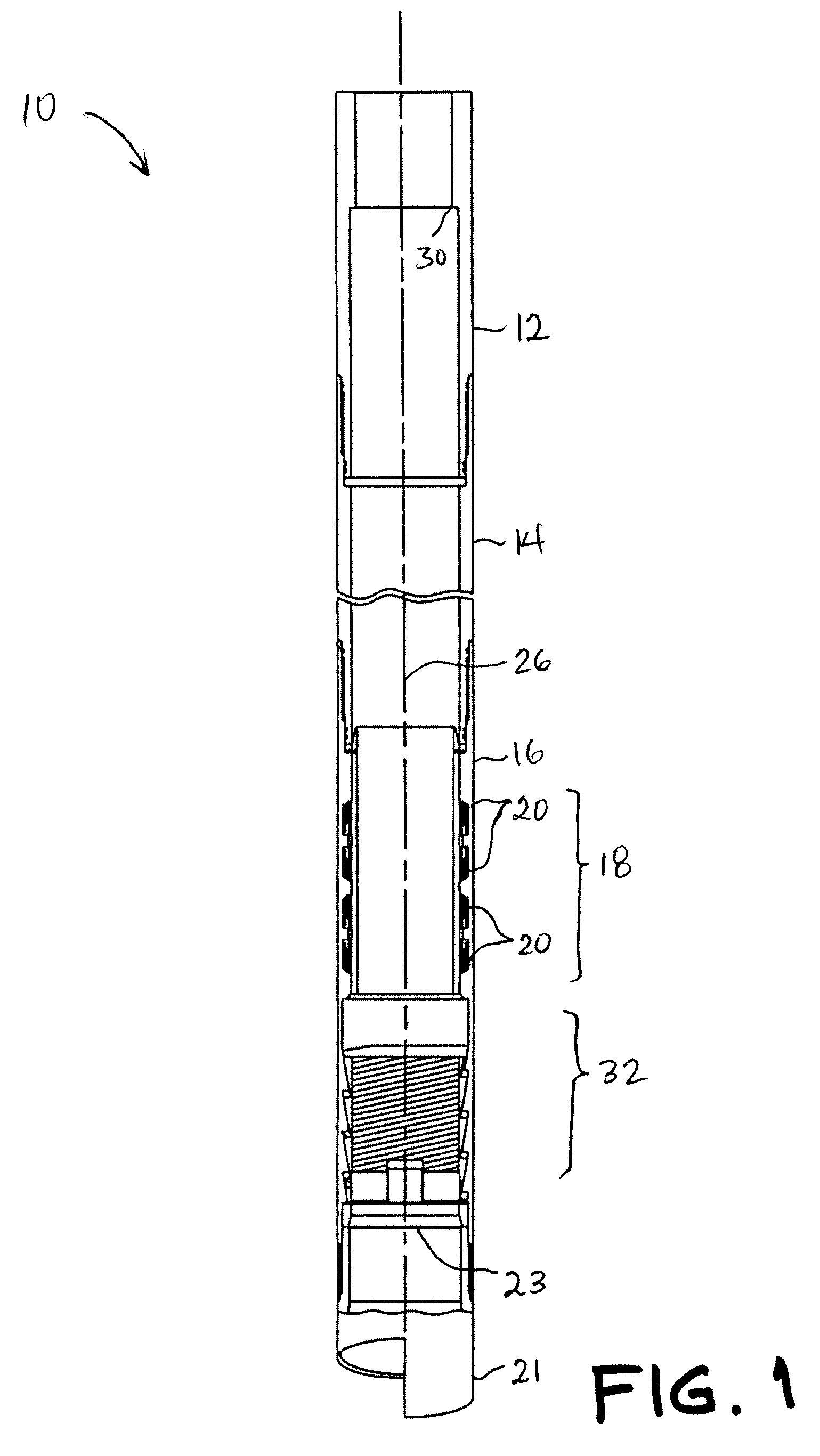

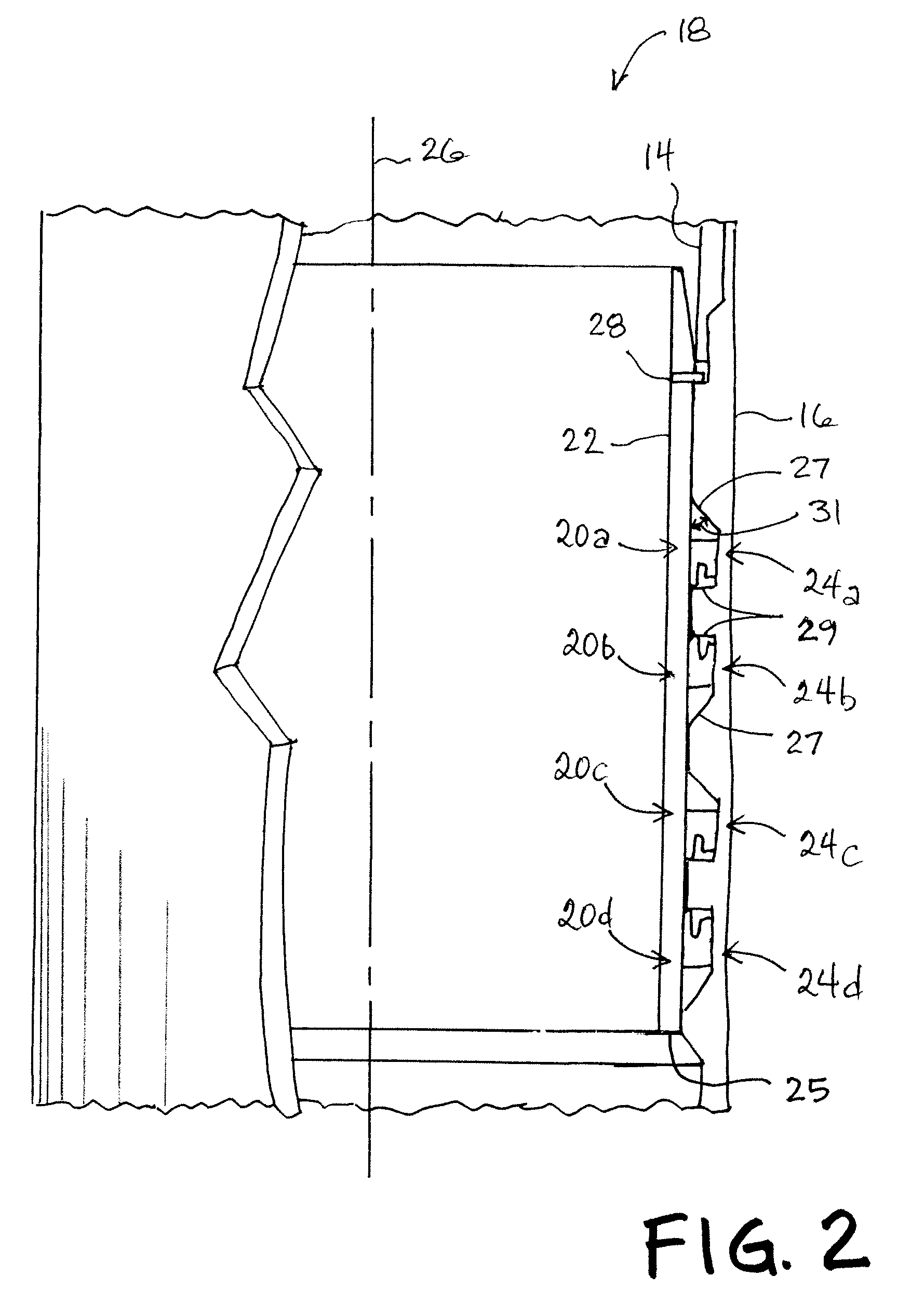

[0021]Referring now in more detail to the exemplary drawings for purposes of illustrating embodiments of the invention, wherein like reference numerals designate corresponding or like elements among the several views, there is shown in FIG. 1 a cylindrical patch assembly 10 before it is placed into a well. The patch assembly is capable of engaging and sealing off a properly prepared casing string in an existing well. When installed, the patch assembly surrounds an outer surface of a casing stub, which is an end segment of the existing casing, and remains in place so as to become part of the casing string that continues up toward the surface of the well.

[0022]It will be appreciated that patch seals of the present invention are not limited to patch assemblies that surround an outer surface of an existing well casing. Patch seals of the present invention may be implemented with casing patches that are installed inside an existing well casing.

[0023]Referring again to FIG. 1, a tubular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com