Patents

Literature

35results about How to "High combination precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

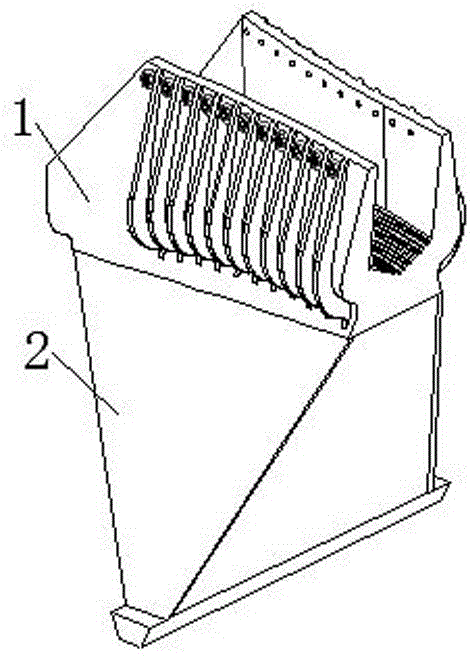

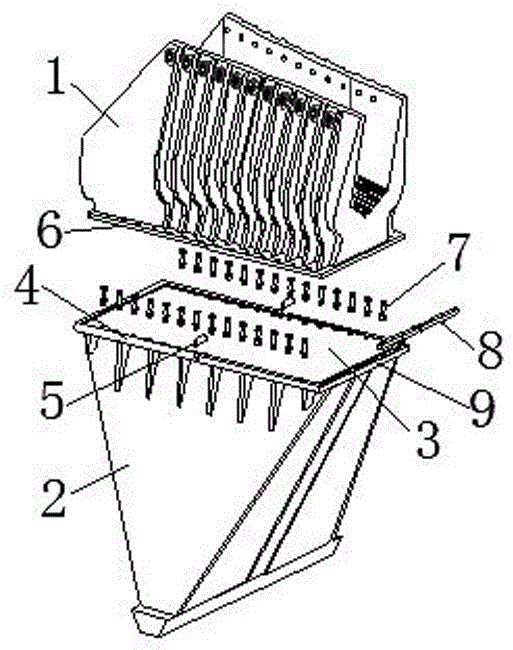

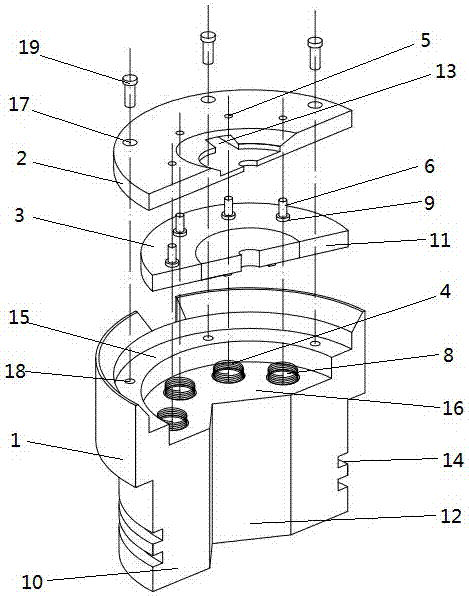

Calculus 3D (three Dimensional) constructing method and device

InactiveCN103465475ABreaking the limitations of difficult 3D manufacturingReduce difficultyData processing systemMathematical Calculus

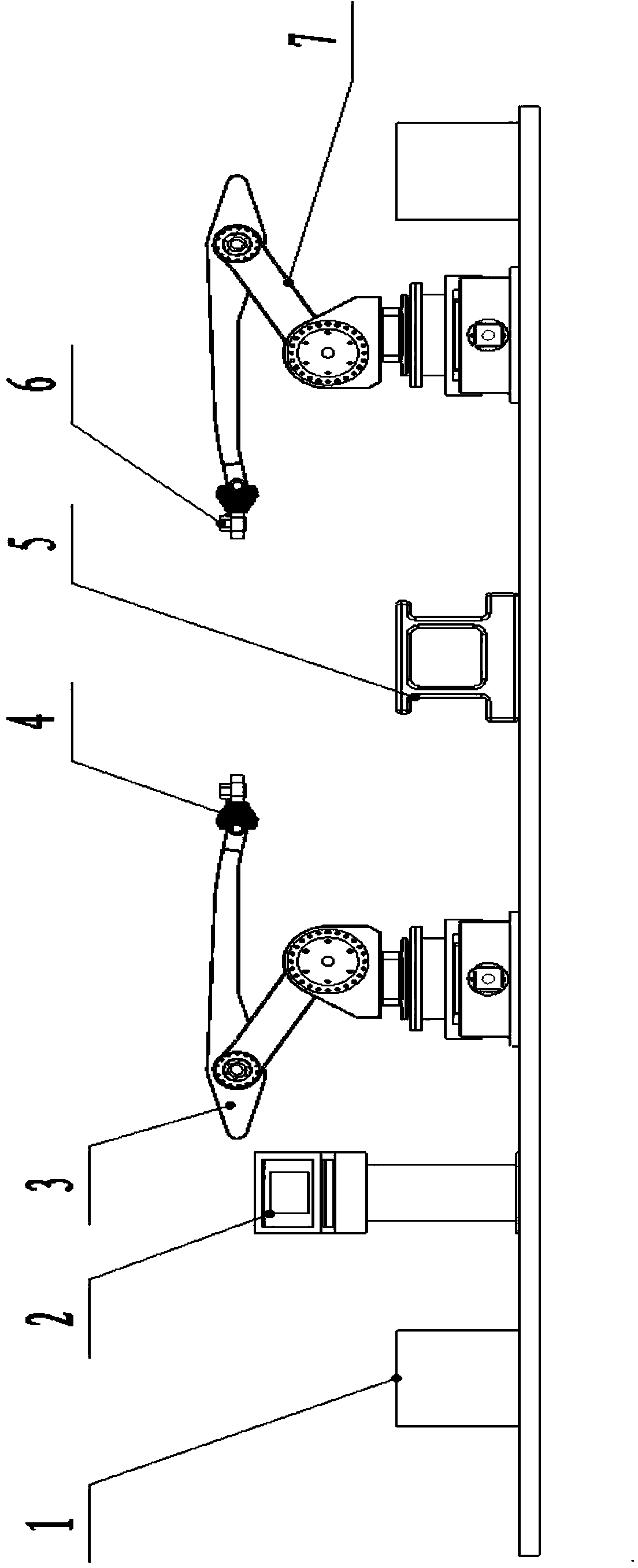

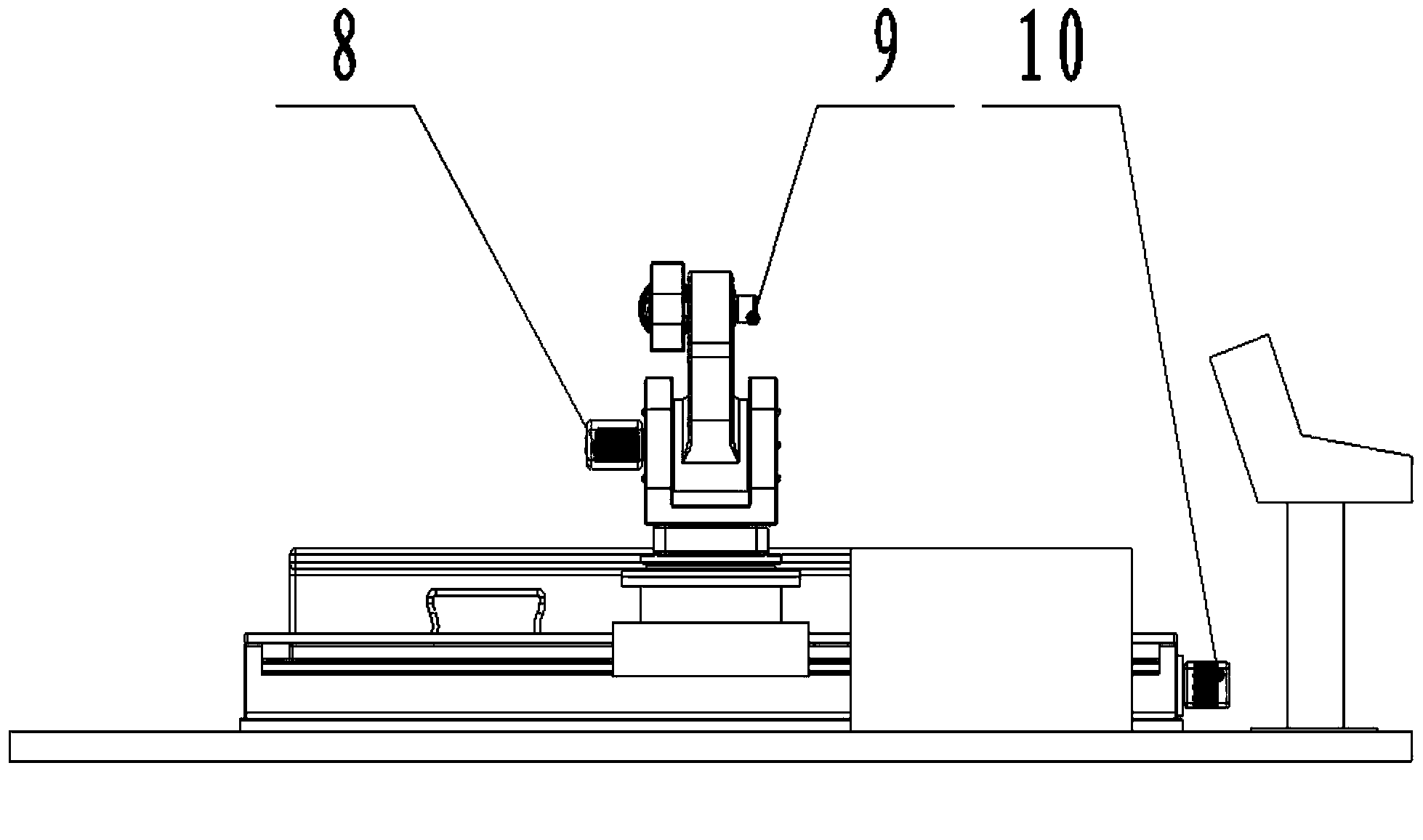

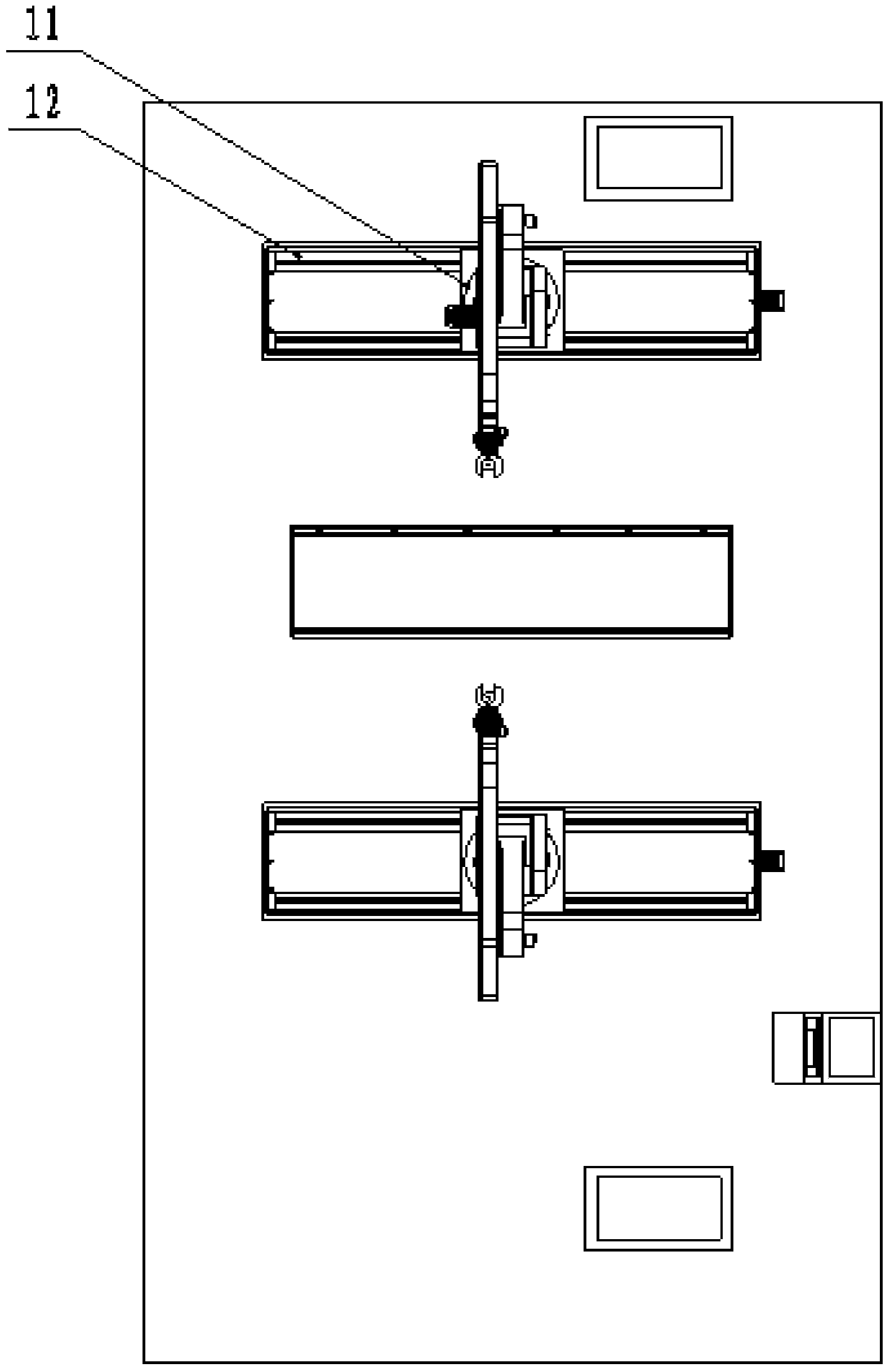

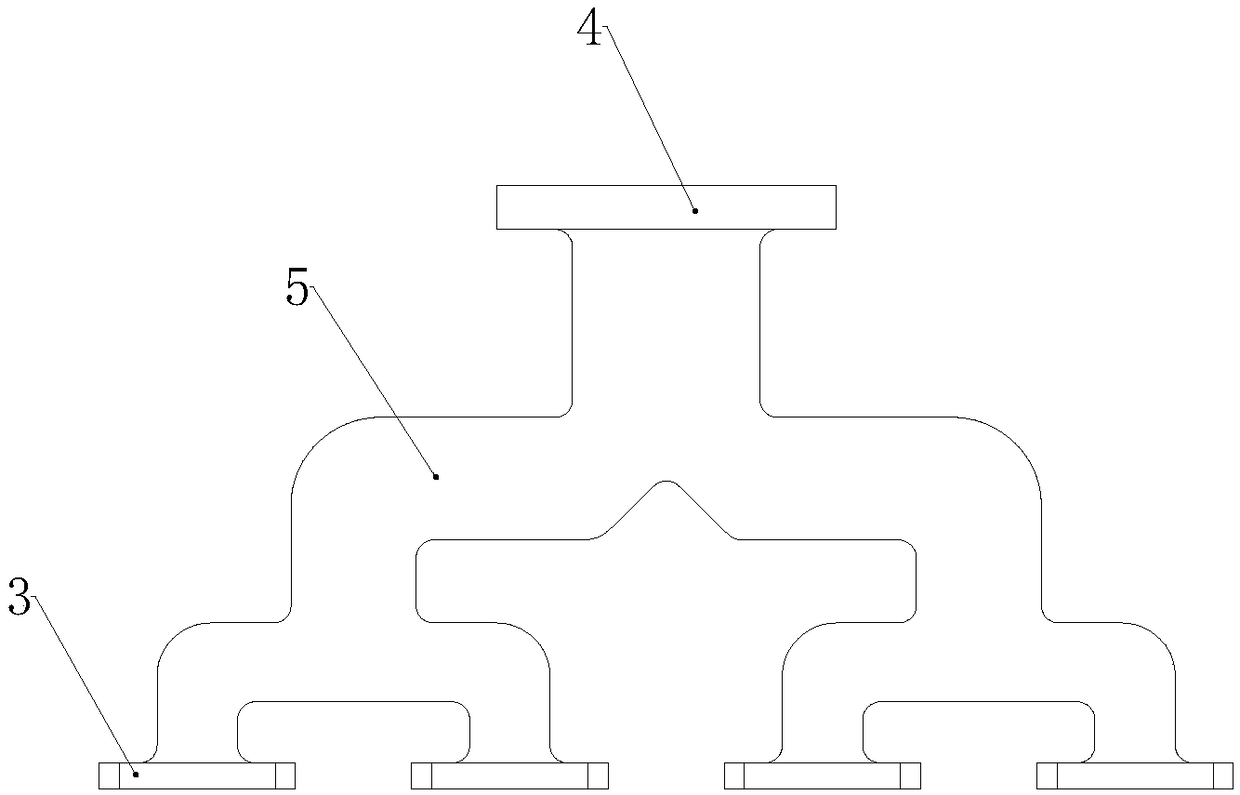

The invention relates to a calculus 3D (three Dimensional) constructing method and device. The calculus 3D constructing method mainly comprises the steps: carrying out unit partitioning on large and complex product moulds into small limited polyhedron units by using a mathematical calculus idea, respectively manufacturing the small limited polyhedron units and storing the small limited polyhedron units in a classifying manner, combining the small limited polyhedron units into a large product by a mechanical arm action executing mechanism under the control of a data processing system, and spraying a hot melting polymer on the surfaces of the small limited polyhedron units in the forming process so as to obtain products integrated into a whole. The calculus 3D constructing device mainly comprises an engine base, the mechanical arm action executing mechanism, a multi-freedom-degree bulb connecting device, a hot melting nozzle device, a manipulator executing end and the data processing system, wherein the machine base and the mechanical arm action executing mechanism commonly form a movement main body which is capable of rotating by 360 DEG, and the mechanical arm action executing mechanism is capable of reciprocating on the machine base horizontally. By adopting the method and the device provided by the invention, the processing and manufacturing time can be greatly shortened, the processing cost is lowered, and the labor intensity of an operator is lightened.

Owner:BEIJING UNIV OF CHEM TECH

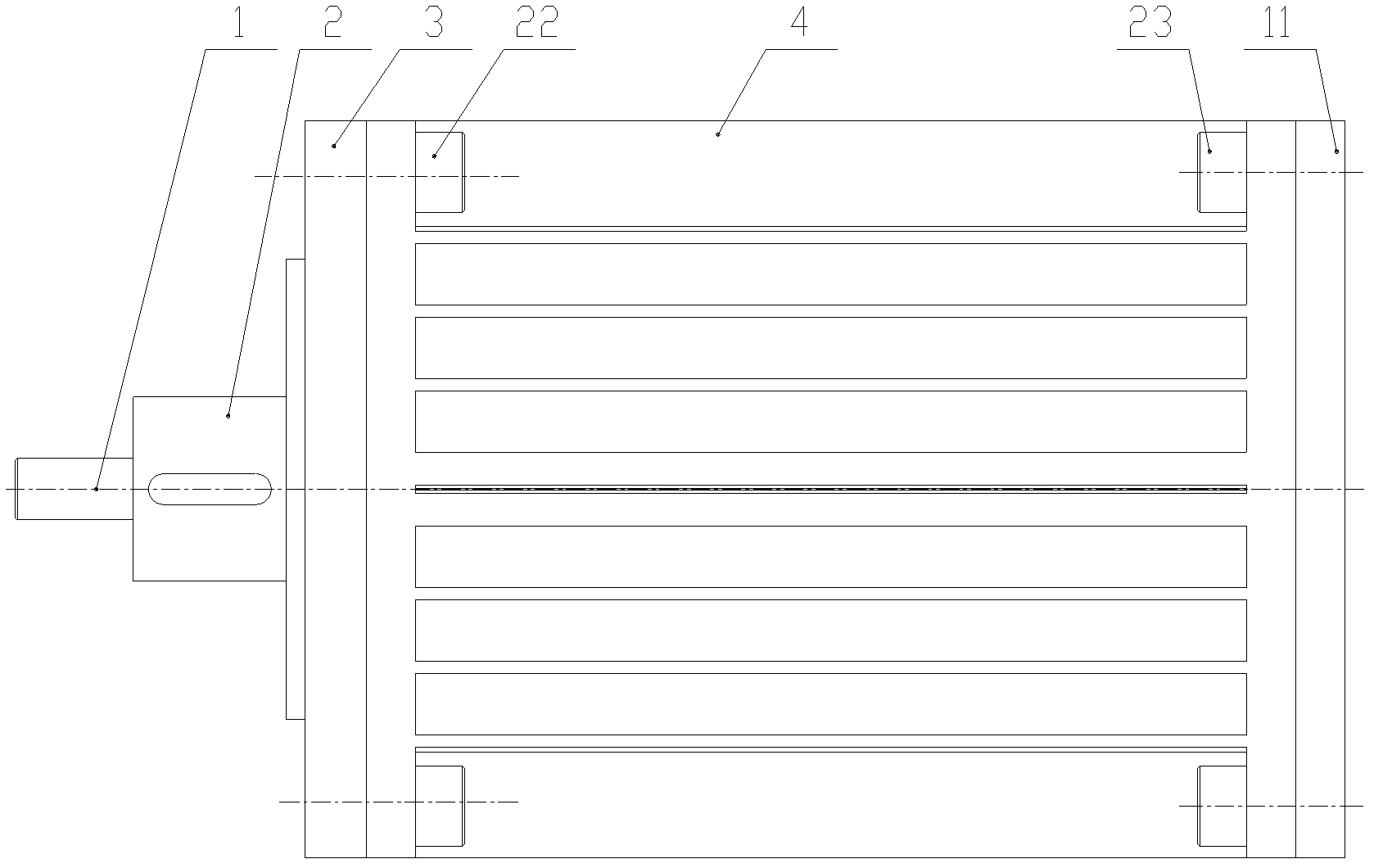

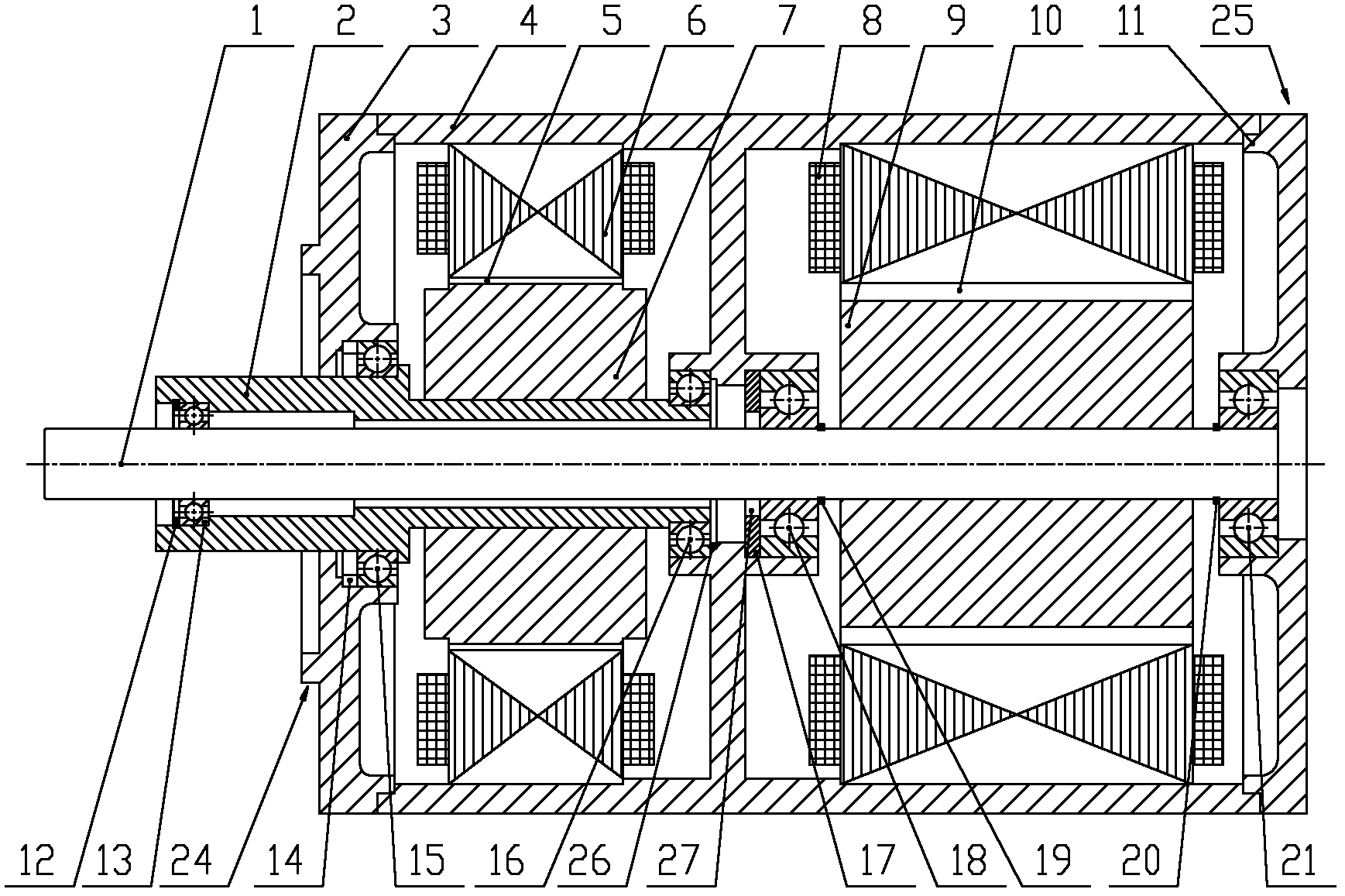

Integrated double-output coaxial motor

InactiveCN102624148AImprove radial stiffnessHigh combination precisionMechanical energy handlingStatorEngineering

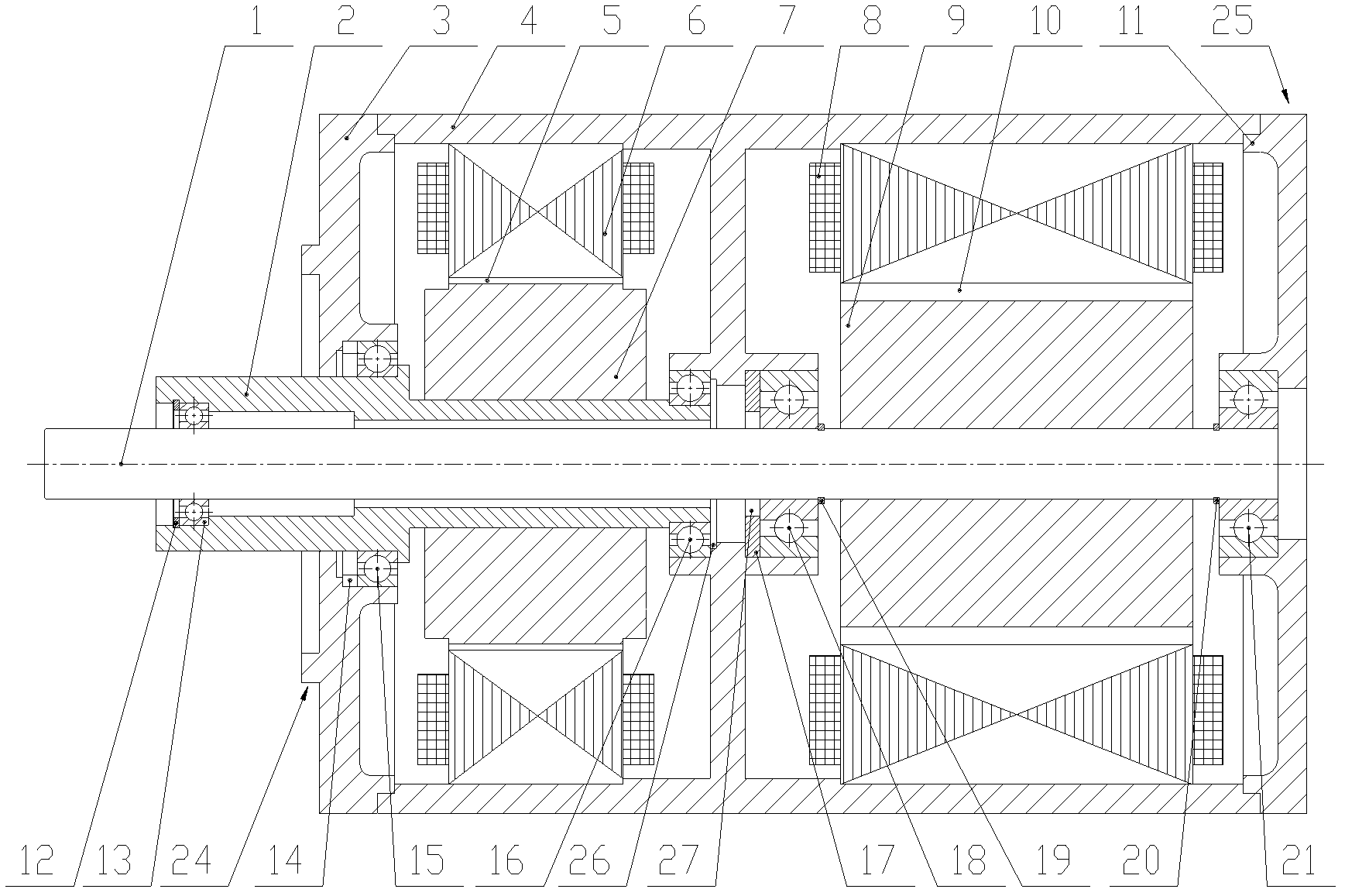

The invention relates to an integrated double-output coaxial motor and belongs to the field of electric motors, in particular to an integrated double-output coaxial motor with two output shafts mounted on the same axis. The coaxial motor comprises a front motor, a rear motor, a housing, a front end cover component and a rear end cover component, wherein the housing is a cylindrical structure with two opening ends, a partition board in the middle of the housing divides the housing structure into a left inner chamber and a right inner chamber; the front motor is mounted in the left inner chamber of the cylindrical housing, and the rear motor is mounted in the right inner chamber of the cylindrical housing; the front motor comprises a front motor stator, a front motor rotor and a front motor rotor output shaft; the front motor rotor output shaft is a stepped hollow shaft; the rear motor comprises a rear motor rotor output shaft, a rear motor stator and a rear motor rotor; and the rear motor rotor output shaft is a solid shaft. The coaxial motor has the characteristics of compact structure and larger output shaft radial stiffness; and the coaxiality of the rear motor rotor output shaft and the front motor rotor output shaft is high.

Owner:DALIAN UNIV OF TECH

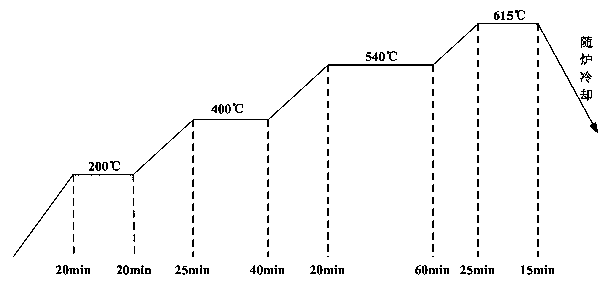

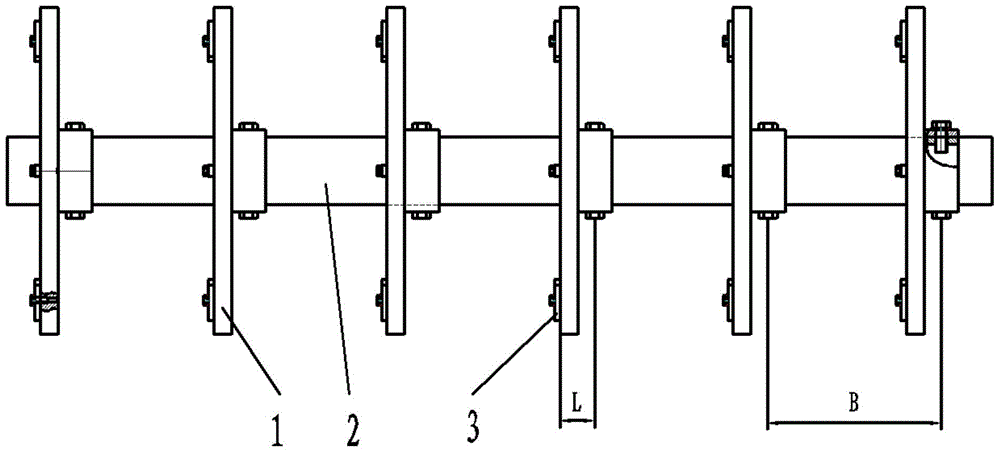

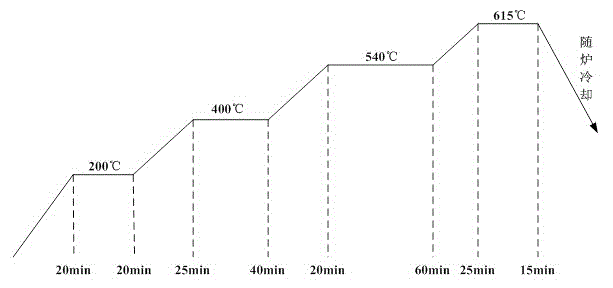

Manufacture method of multi-baffle large-aperture box frame

InactiveCN104209706AReduce processing difficultyImprove the accuracy of frame combinationWelding/cutting auxillary devicesAuxillary welding devicesDisc diameterEngineering

The invention discloses a manufacture method of a multi-baffle large-aperture box frame. The method comprises the steps of firstly, reliably connecting positioning bases and limiting blocks, ensuring that side surfaces of the positioning bases and the limiting blocks are adhered, loading the positioning bases and the limiting blocks into baffle inner holes integrally, then welding the limiting blocks with baffle bearing seats in a spot welding way, secondly, establishing lines on a combined platform to determine positions of all baffles, ensuring that a core shaft penetrates through all the positioning bases, fixing the positions of the positioning bases separately through positioning pins, connecting the positioning bases with the core shaft, thirdly, welding all process supports with inner holes of all the baffles in a spot welding way in weight reduction notch space positions arranged on the positioning bases, fourthly, cutting welding lines of the limiting blocks and the bearing seats, laying the limiting blocks in directions perpendicular to disc diameters of the positioning bases, gradually withdrawing the positioning bases and the core shaft, welding a frame body, welding connecting plates among all the baffles, and fifthly, performing thermal aging on the frame body integrally, and then removing all the process supports. The method improves the frame body combination accuracy and the operating efficiency.

Owner:BAOJI PETROLEUM MASCH CO LTD

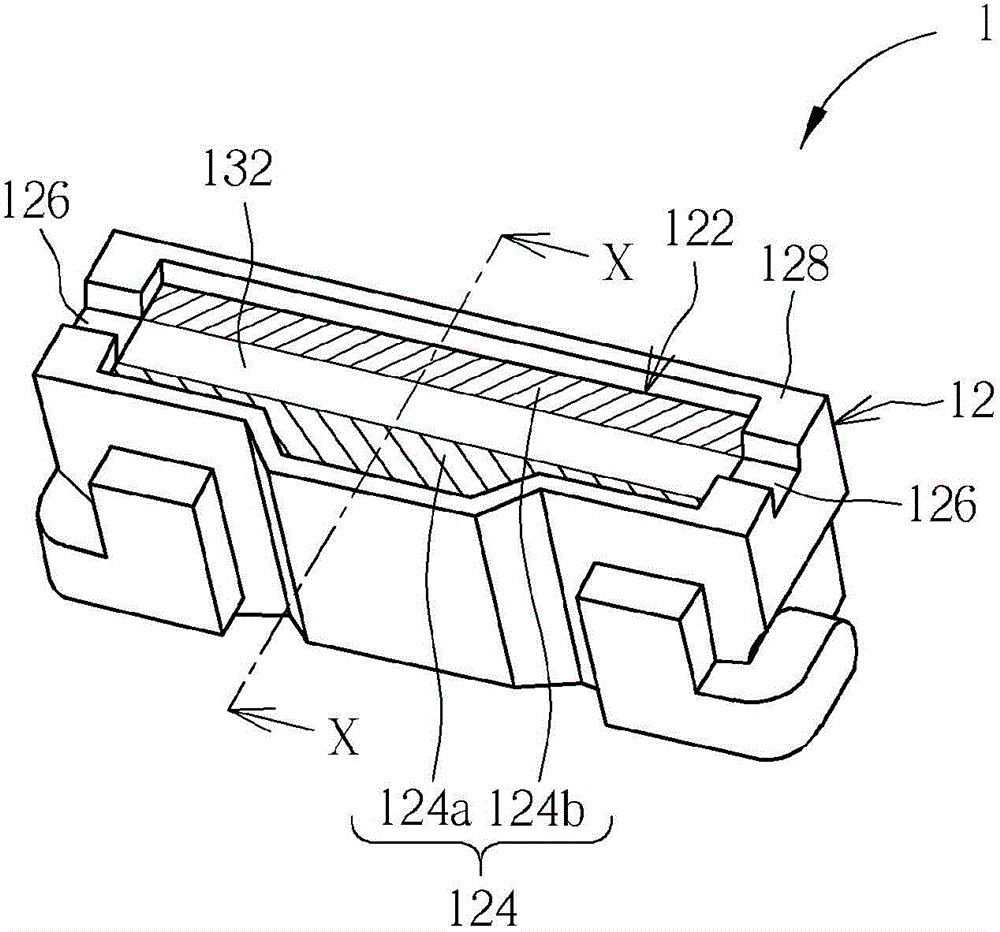

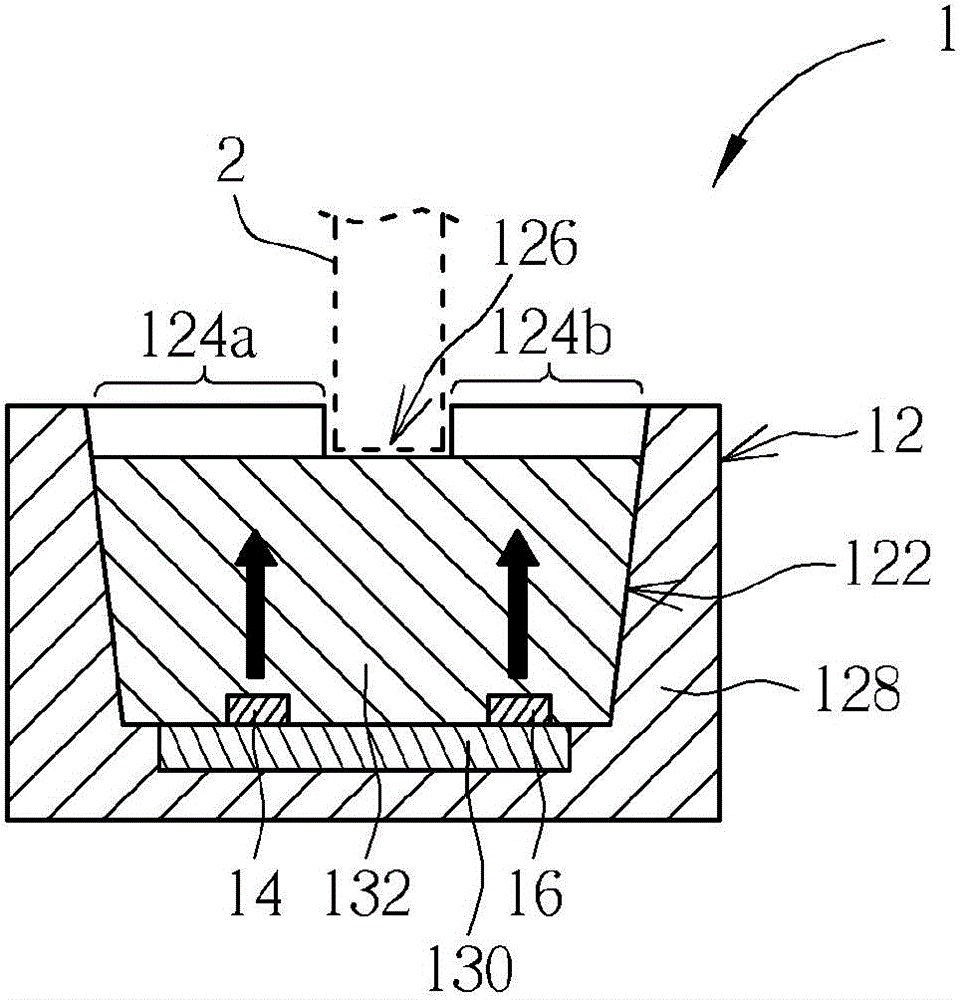

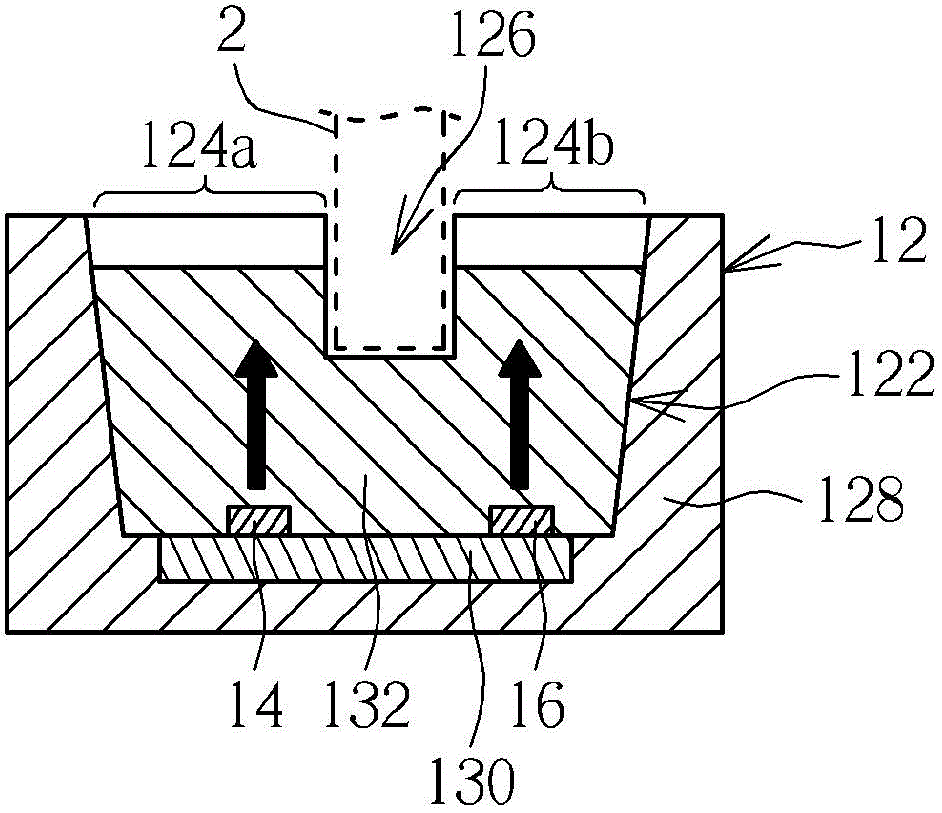

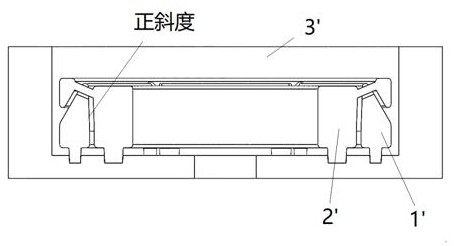

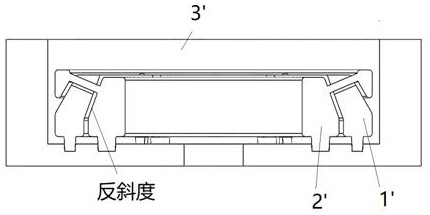

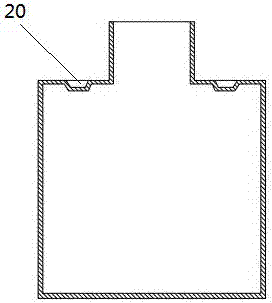

Light emitting device and backlight module

InactiveCN102720995AProvide accuratelyHigh combination precisionLight guides for lighting systemsNon-linear opticsLight guideLight emitting device

The invention discloses a light emitting device and a backlight module provided with the light emitting device. The backlight module includes a light guide structure and the light emitting device, the light guide structure includes two light guide members and a reflection sheet arranged between the light guide members. The light emitting device is arranged adjacent to the light guide structure and includes an insulating carrier and two light sources arranged on the insulating carrier. The insulating carrier includes a positioning groove structure, the edge of the reflecting sheet is arranged in the positioning groove structure, the two light sources are respectively corresponding to the two light guide members, and the light emitted by the two light sources can respectively enter into the corresponding light guide members respectively. Therefore, the light emitting device as a single structure can supply the light required by the two light guide member respectively at the same time, and the combination accuracy of the light guide structure and the light emitting device is improved by means of the positioning structure on the light emitting device.

Owner:AU OPTRONICS CORP

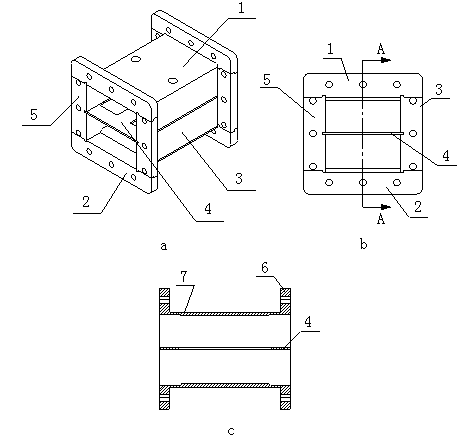

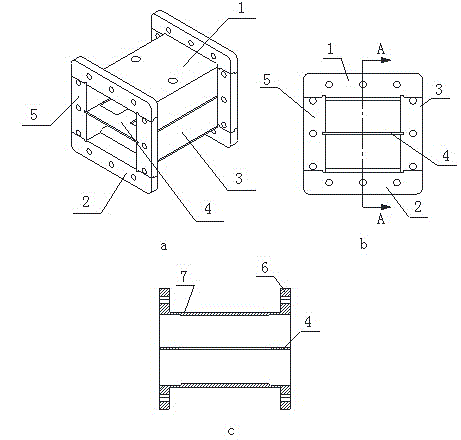

Self-positioning process of plate-type electric bridge waveguide

InactiveCN103394915AReduce assembly processHigh combination precisionSoldering apparatusAssembly machinesControl mannerEngineering

The invention relates to a self-positioning process of plate-type electric bridge waveguide, which comprises the following steps: preparing material to complete preliminary processing of each part of the plate-type electric bridge waveguide; conducting surface treatment on each processed part, so as to remove oil stain, impurities and the like on the surface of the part; assembling a left wallboard, a right wallboard, an upper end plate, a lower end plate, a partition board and brazing alloy; placing the assembled plate-type electric bridge waveguide into a vacuum aluminum soldering stove under the matched use of a tooling clamp; conducting vacuum brazing on the plate-type electric bridge waveguide; machining the shape of the plate-type electric bridge waveguide and a flange plate in a numerically controlled manner; drilling through machining; reaming on the flange plate; carrying out electrochemical treatment; rigging. According to the invention, the flange plate is divided into four parts which are formed on the upper end plate, the lower end plate, the left wallboard and the right wallboard respectively, so that the assembly process of the flange plate is eliminated, and the production efficiency is improved; grooves and convex shoulders, which correspond to each other, are formed on the end plates and the wallboards, so that self-positioning assembly is realized, and the cavity assembling precision of the electric bridge waveguide is high; as vacuum brazing is adopted, brazing flux is not required, which avoids corrosion of brazing flux on a cavity, and prolongs the service life of a product.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

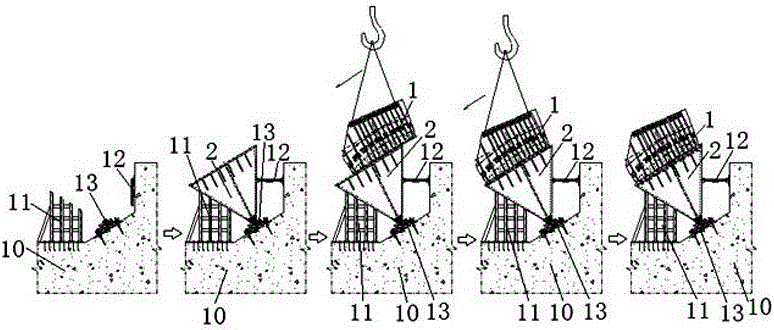

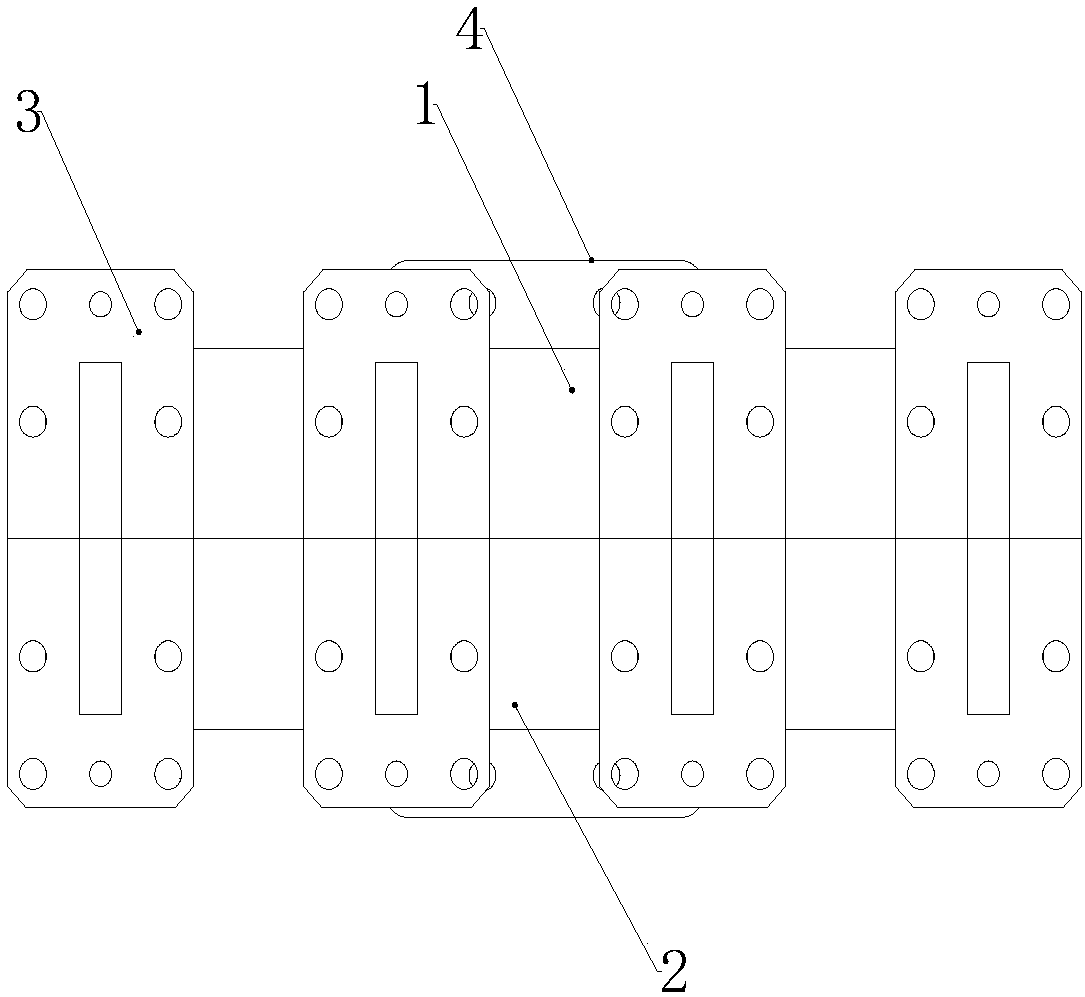

Separate combined type splay saddle and installation method thereof

ActiveCN106436572AReliable alignmentSmall difficulty in groupingBridge structural detailsBridge erection/assemblyBridge engineeringEngineering

The invention discloses a separate combined type splay saddle and an installation method thereof. The split combination type splay saddle comprises a saddle head and a saddle body which are separated. The bottom of the saddle head is provided with a bottom board, the top of the saddle body is provided with a top board, and a plurality groups of bolt holes corresponding to one another are arranged between the bottom board and the top board. A seam allowance groove is concaved inwards, matched with the bottom board and arranged on the top face of the top board, the saddle head is arranged in the seam allowance groove on the top board of the saddle body in an embedded mode through the bottom board, and the bottom board of the saddle head and the top board of the saddle body are locked tightly and combined together though bolt sets penetrating through the bolt holes corresponding to one another. According to the separate combined type splay saddle, the saddle head and the saddle body matched with each other are formed, therefore, the splay saddle can effectively and reliably achieve easy positioning and installation on the premise that manufacture and transportation are facilitated; the difficulty of alignment and assembling between the saddle head and the saddle body is small, the qualification rate and the accuracy of combination of the saddle head and the saddle body are high, the structural strength is high, the quality is reliable, the practicability is high, and the installation method is particularly suitable for formation of a large-tonnage splay saddle of large-scale suspension bridge engineering.

Owner:DEYANG TIANYUAN HEAVY IND

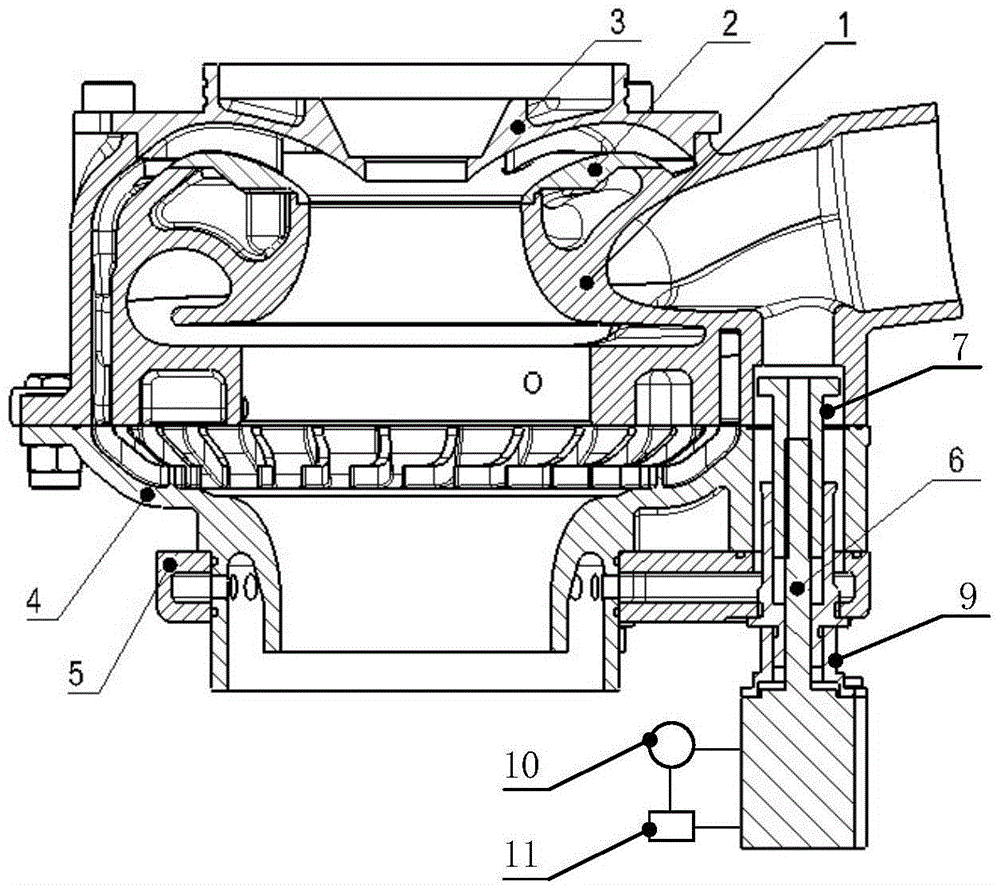

Direct-connected integrated gear pump

InactiveCN102102667AIncrease the required lifeHigh coaxial precisionRotary piston pumpsRotary piston liquid enginesGear pumpEngineering

The invention relates to a direct-connected integrated gear pump which is mainly characterized in that the device comprises a front end cover connection body and a back end cover pump body, wherein the front end cover connection body and the back end cover pump body are fixedly connected; an oil outlet, an oil outlet one-way valve and an overpressure protection valve are arranged on the back end cover pump body; the oil outlet one-way valve and the overpressure protection valve are integrally communicated; an antifriction alloy casting is inlayed in an inner chamber of the back end cover pump body; and the front end cover connection body, the back end cover pump body, an oil inlet, the oil outlet one-way valve and the overpressure protection valve are casted into an integral communication structure. In the invention, the back end cover pump body and the front end cover connection body are integrally assembled; therefore, the direct-connected integrated gear pump has the advantages of high coaxial precision, simple structure and convenience for assembling, and can enhance the cumulative tolerance of the combination of the components and parts of the gear pump, lighten the total weight, enhance the volumetric efficiency and prolong the life by 2 times.

Owner:浙江奥力电机股份有限公司

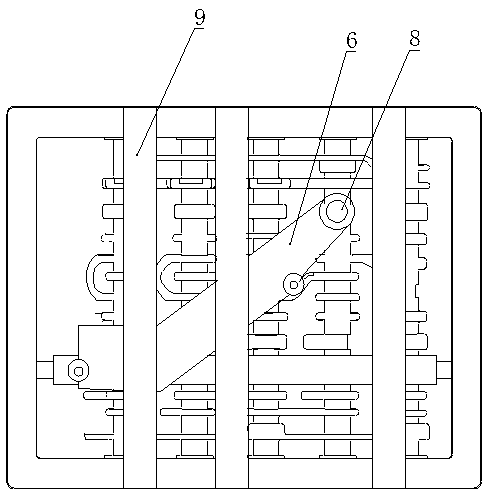

Dedicated core of multipath hydraulic control main body valve for manufacturing heavy duty excavator

ActiveCN103264144AHigh combination precisionSolve the problem of relatively large lossFoundry mouldsFoundry coresEngineeringHeavy duty

The present invention discloses a dedicated core of a multipath hydraulic control main body valve for manufacturing a heavy duty excavator. The main body valve dedicated core is three layers of multipath. The main body valve core is integrally molded by a sheet core through a strip shaped core head as a casting flow path distribution structure, and then mutually positioned through the core head. The strip shaped core heads are connected end to end to form a square structure. An intermediate layer main body valve core is of a long strip shaped core. A bottom layer main body valve core is of three c-type supports parallelly distributed on an upper layer main body valve square structure. The sheet core is formed integrally by the strip core head, and then mutually positioned by the core head. The combination accuracy of the core is improved. The problems that the core is needed to be assembled by core-shell or using tooling previously, efficiency is low and loss of the core is relatively large in the process of core carrying and core drying are solved.

Owner:南通华东油压科技有限公司

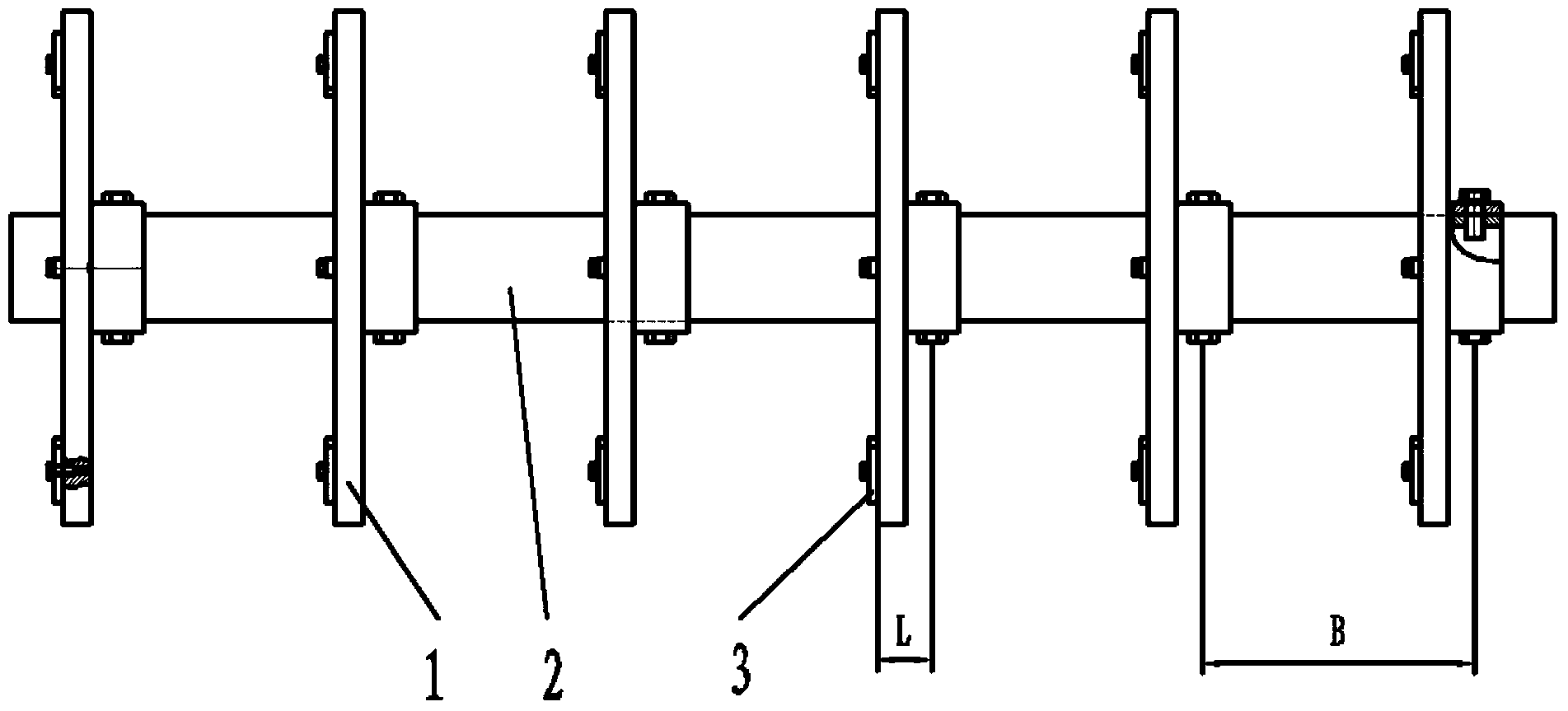

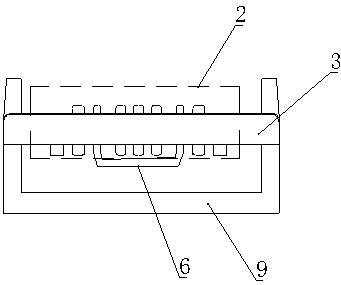

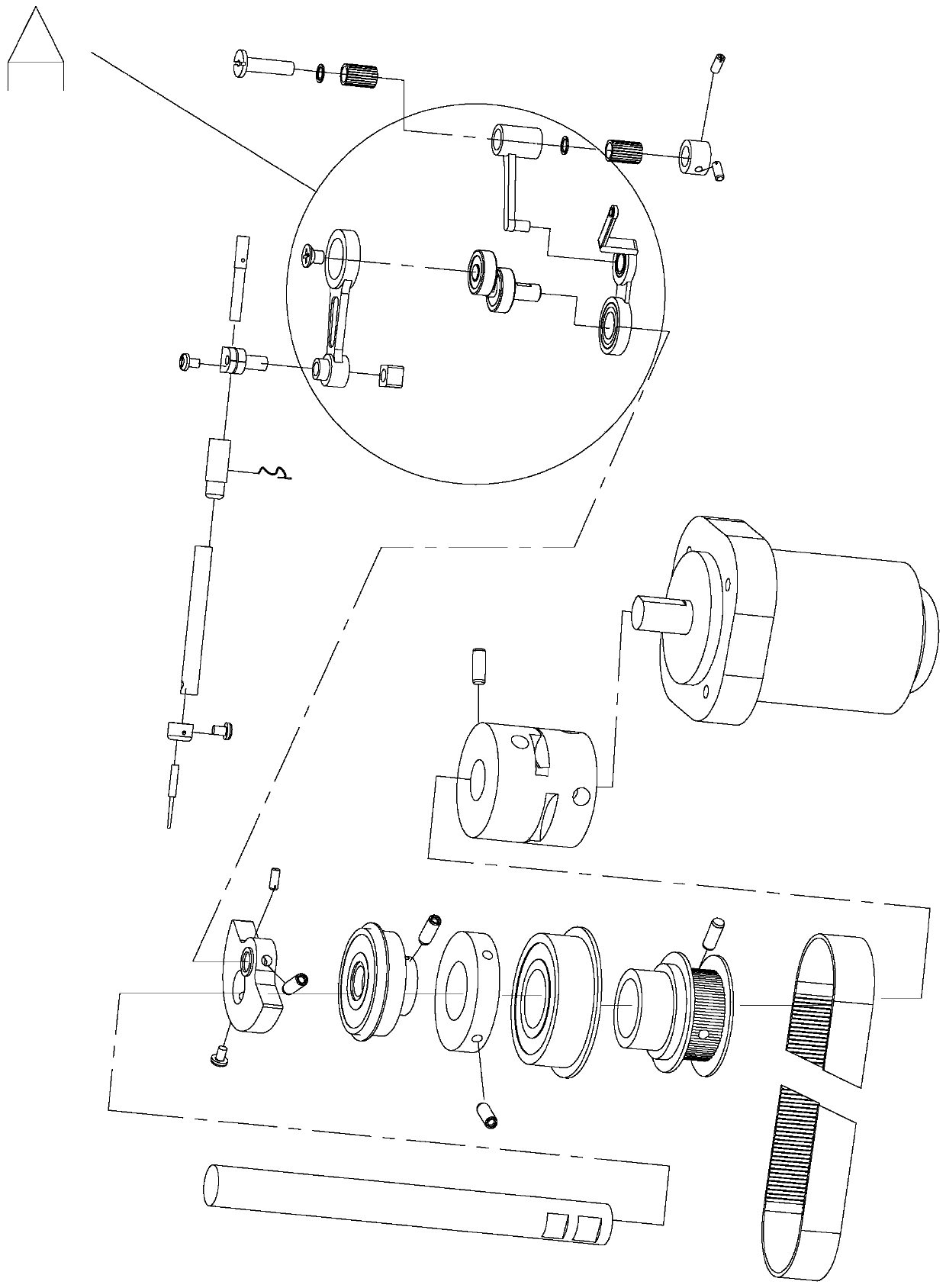

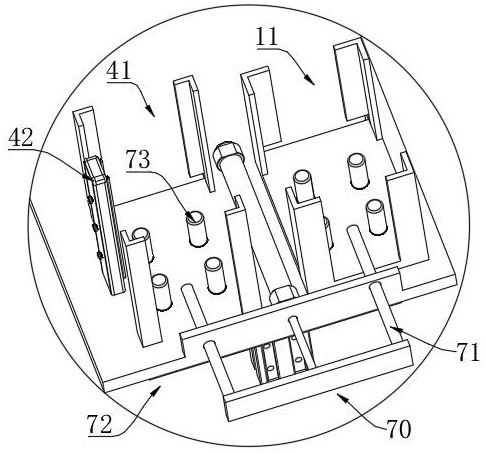

Size-adjustable motor coil winding tool and winding method based on tool

PendingCN110971092AEasy to shapeShorten the production cycleManufacturing dynamo-electric machinesElectric machineClassical mechanics

The invention relates to a motor coil winding tool, in particular to a size-adjustable motor coil winding tool and a winding method based on the tool, and solves the problems that an existing coil winding tool is complex in shape, high in machining difficulty, long in production period and incapable of being universally used for motors with different base numbers. The tool is characterized by comprising N veneer assemblies, a positioning mandrel and a fastening nut; the veneer assembly comprises a bottom plate, two square sliding blocks, two round sliding blocks and six fastening screws; a first through hole and four first strip-shaped holes are vertically formed in the bottom plate; the center of the first through hole and the axes of the four first long-strip-shaped holes in the length direction correspondingly coincide with four line segments of a diagonal intersection point of a first rectangle and two diagonals separated by the diagonal intersection point respectively; the squaresliding blocks and the circular sliding blocks are fixedly connected to the same side of the bottom plate through fastening screws; the positioning mandrel comprises a limiting section and a mountingsection; and the N veneer assemblies are sleeved on the mounting section and are fixedly connected with the positioning mandrel through fastening nuts.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

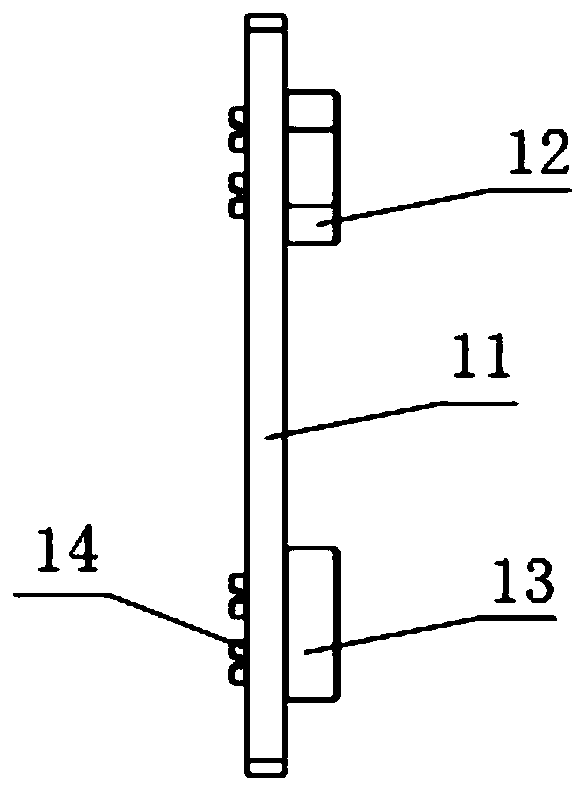

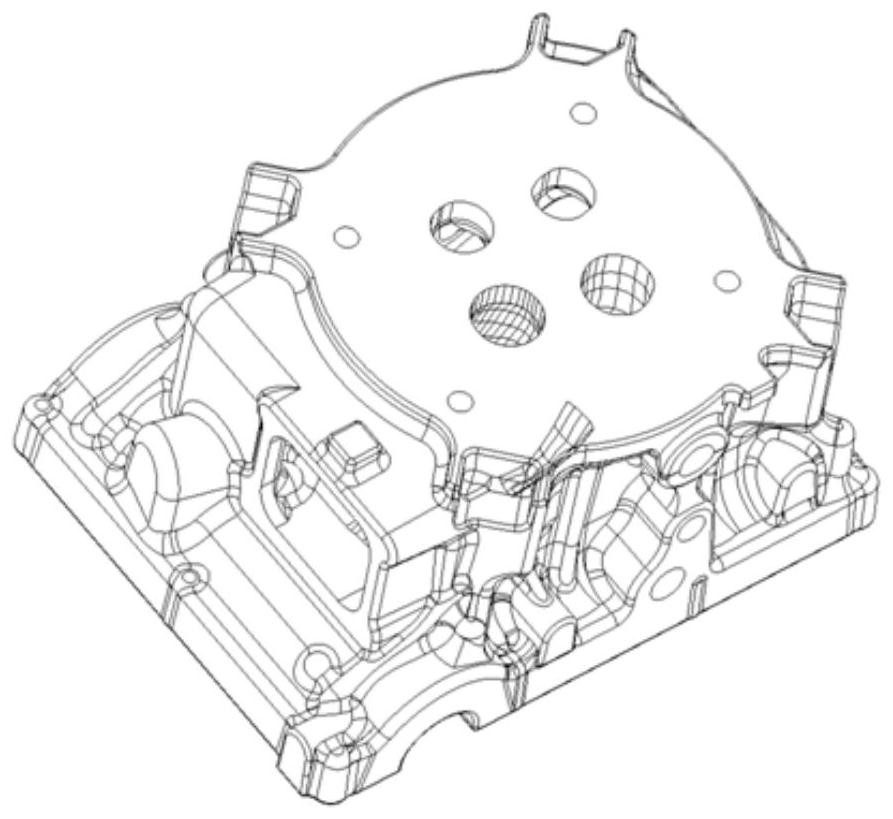

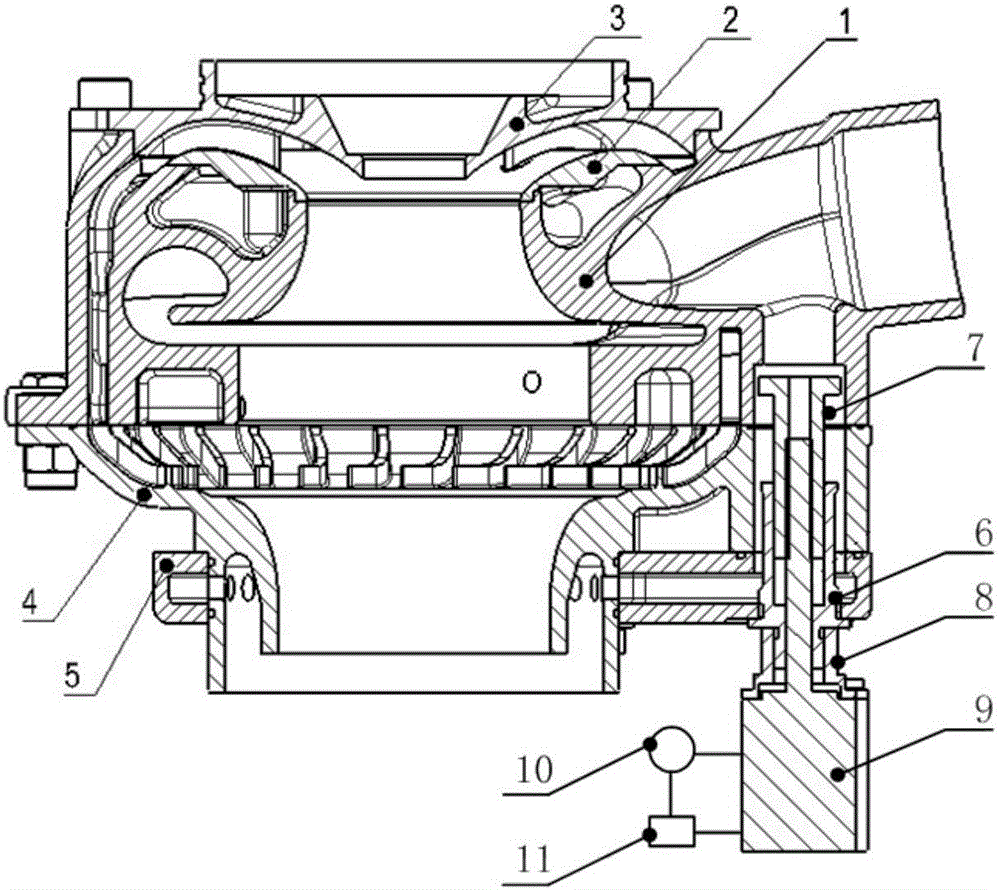

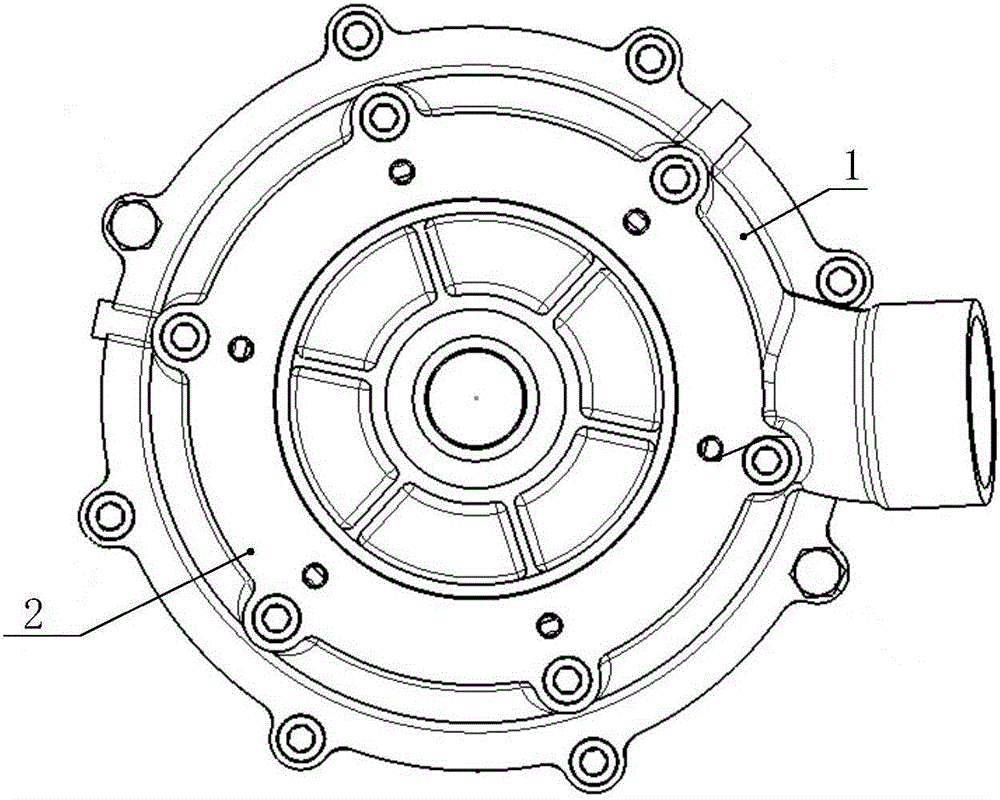

Wide-flow combined type two-stage supercharger gas compressor shell based on mixed pressure spreading

The invention discloses a wide-flow combined type two-stage supercharger gas compressor shell based on mixed pressure spreading. The wide-flow combined type two-stage supercharger gas compressor shell comprises a high-pressure end gas compressor shell assembly, a low-pressure end gas compressor shell assembly and a flow adjusting valve mechanical assembly, a gas flow channel is arranged between a first-stage inlet and a second-stage outlet of the shell, the flow adjusting valve mechanical assembly is arranged in axial space, close to the second-stage outlet, of the gas flow channel, and a second-stage flow way is formed by the high-pressure gas compressor shell, a high-pressure flow-shaped plate, a gas compressor shell connecting plate and a high-pressure gas compressor wheel; a first-stage gas compressor flow way is jointly composed of a low-pressure gas compressor and a low-pressure gas compressor wheel. The coaxiality of a low-pressure end compressor shell flow way and a high-pressure end compressor shell flow way is ensured, the combined precision of a flow way circular-arc face is improved, and the blade pipe mixing pressure spreading technology of an interstage 270-degree large-rotation variable cross-section channel ensures that flow separation is restrained within the full-flow range; a flow adjusting valve is arranged between the first-stage inlet and the second-stage outlet to prevent surging; rotation eliminating blades and flow guide blades are arranged in the high-pressure flow way, and imbalance moment of momentum of compressed gas is effectively reduced.

Owner:北京领动国创科技有限公司

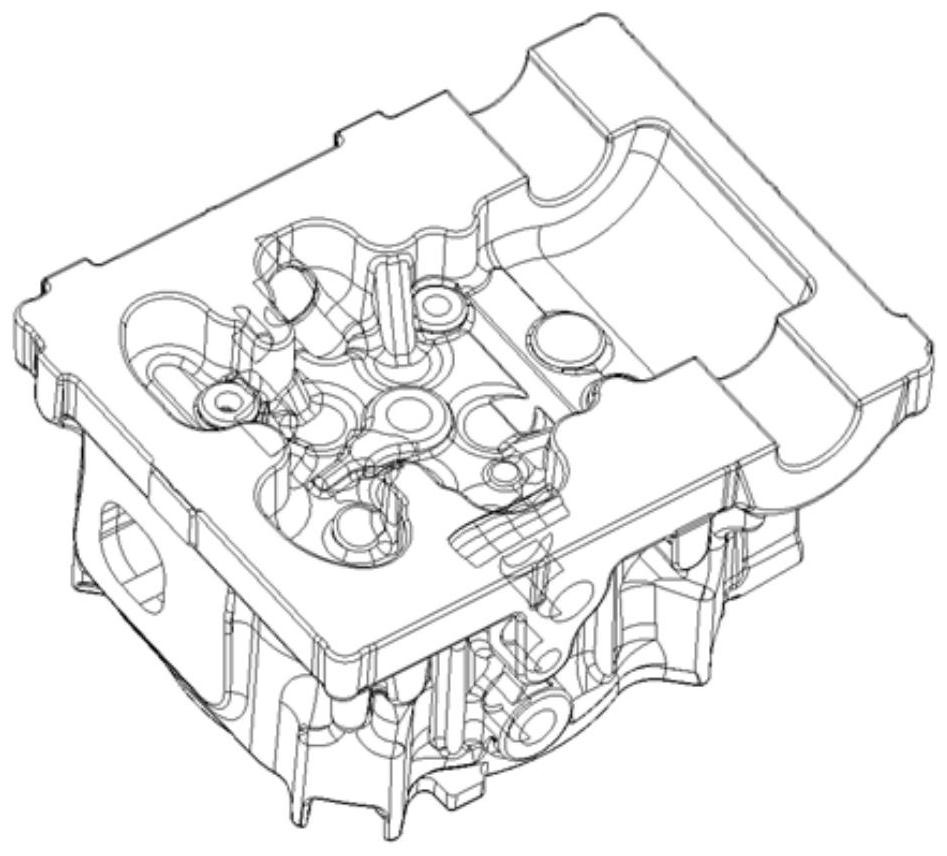

3D printing sand core structure for rapidly developing cylinder cover casting and manufacturing method thereof

InactiveCN111774536AReduce in quantityHigh positioning accuracyAdditive manufacturing apparatusFoundry moulds3d printProcess engineering

The invention relates to a 3D printing sand core structure for rapidly developing a cylinder cover casting. Two lower side edge sand cores of the structure are connected into a whole and are connectedwith a bottom plate sand core, a peripheral core head of an air inlet channel sand core, a peripheral core head of an exhaust channel sand core and a peripheral core head of a lower water jacket sandcore into a whole to form a first sand core set; two upper side edge sand cores are connected into a whole and are connected with a top cover sand core and a peripheral core head of an upper water jacket sand core into a whole to form a second sand core set; observation hole sand cores are arranged on the bottom plate sand core and the top cover sand core; and an exhaust structure for exhaustingair during casting pouring is arranged on the bottom plate sand core. According to the 3D printing sand core structure, the 3D printing sand core technology is adopted, part of the sand cores are combined together, a main body is formed by the two sand cores, the number of the sand cores is reduced, the core manufacturing speed is increased, the development difficulty of the casting is reduced, the development speed of the casting is increased, the 3D printing sand core structure is suitable for development of various cylinder cover castings, and the low manufacturing difficulty and the shortperiod of the cylinder cover castings can be achieved.

Owner:CHINA FIRST AUTOMOBILE +1

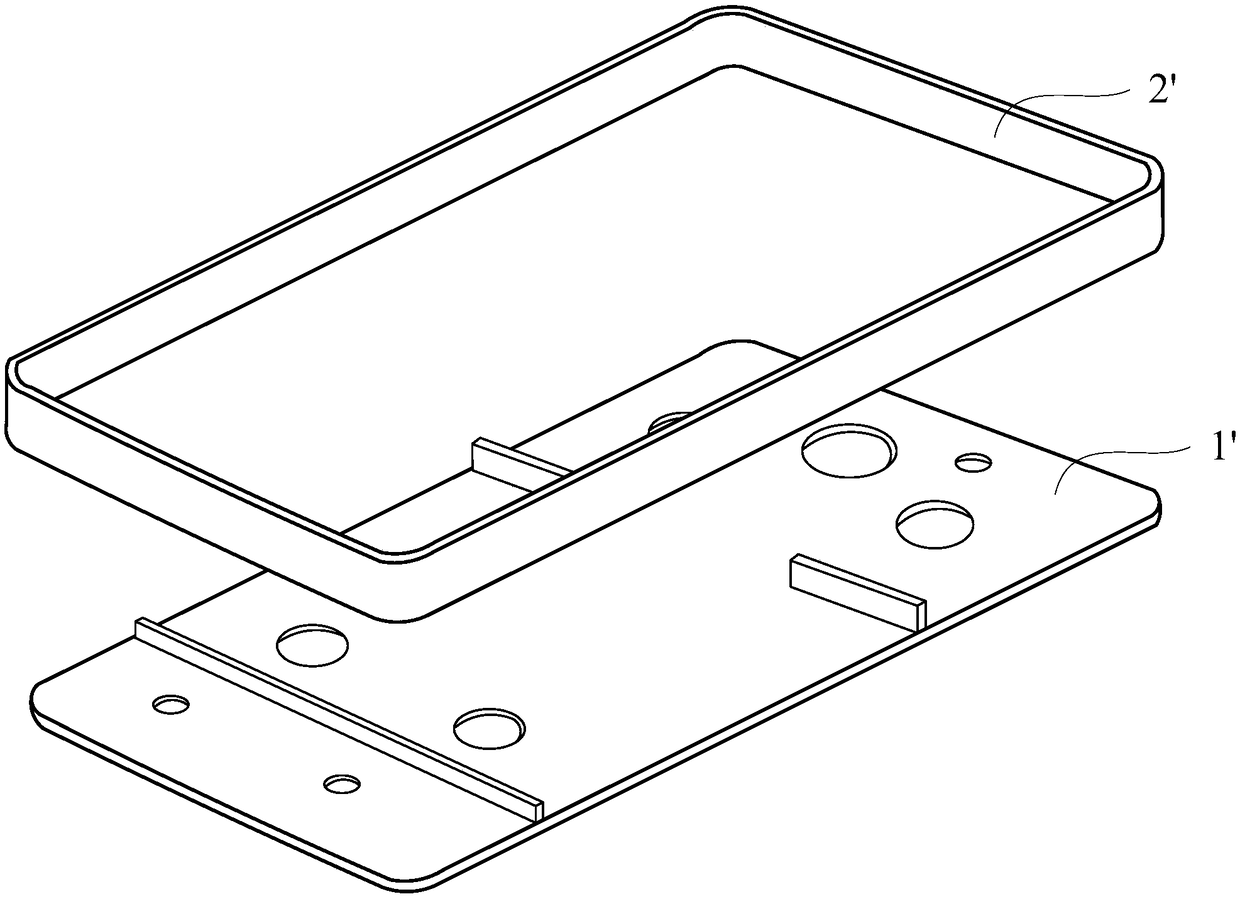

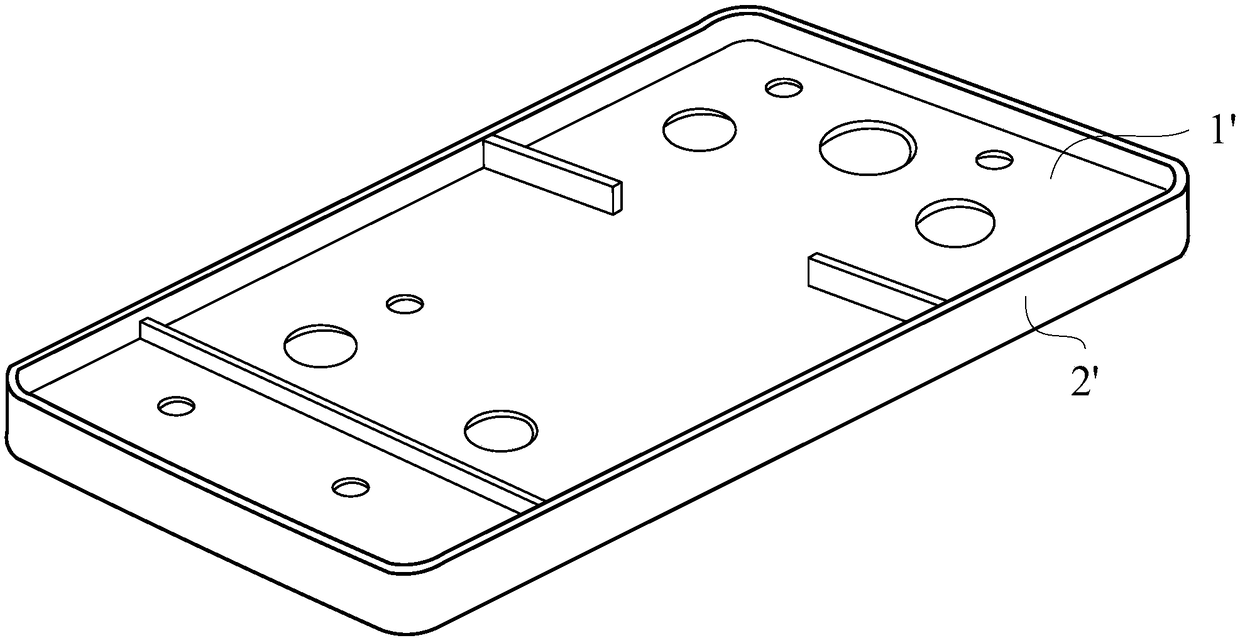

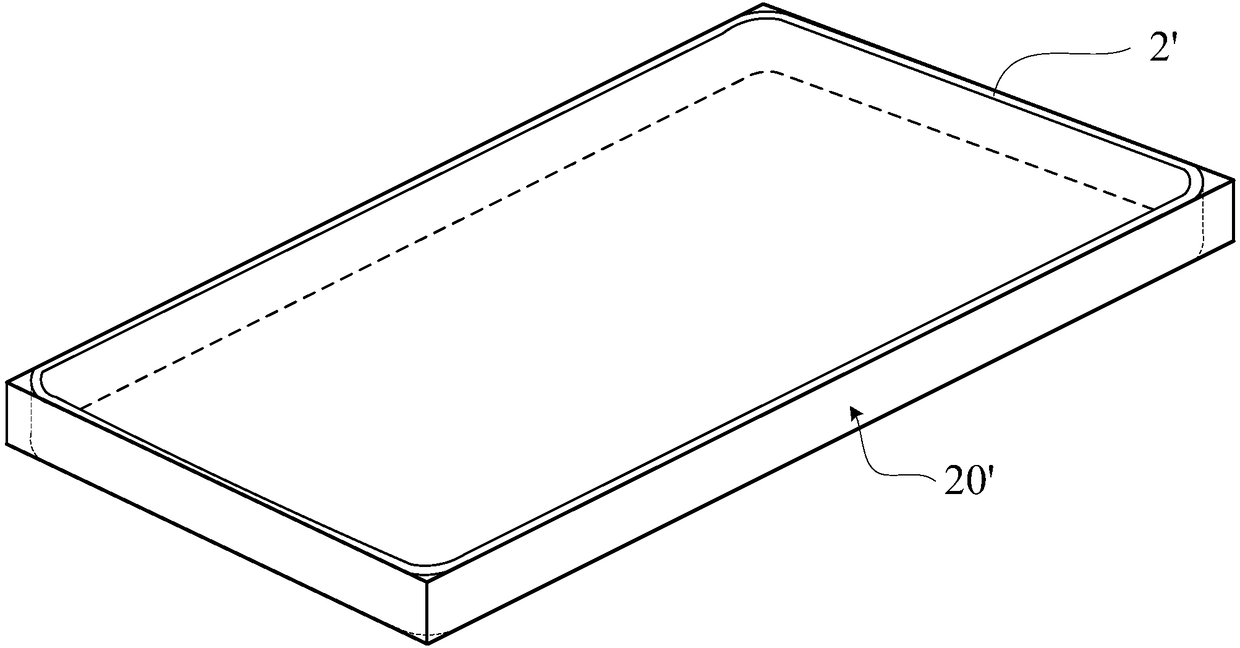

Double-metal compound die casting process and component, electronic device and machining device

InactiveCN108202207AImprove processing efficiencyImprove flatnessOther manufacturing equipments/toolsNumerical controlDie casting

The invention discloses a double-metal compound die casting process and component, an electronic device and a machining device. The double-metal compound die casting process comprises the steps that on a first workblank part based on a first metal material is subject to die casting treatment to obtain a first component; multiple second workblank parts based on a second metal material are subject to numerical control machine tool machining to obtain multiple structural parts, and the multiple structural parts can be combined to form a second component matched with the first component; accordingto the combination relation between the first component and the second component, the first component is connected with each structural part. Through the technical scheme, the raw material losses during machining of the second component can be reduced, machining efficiency of the second component can be improved, the requirement for the tolerance between the first component and the second component is low, the combination precision is high, deformation during assembling of the first component and the second component can be avoided, and the flatness after assembling of a whole component is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

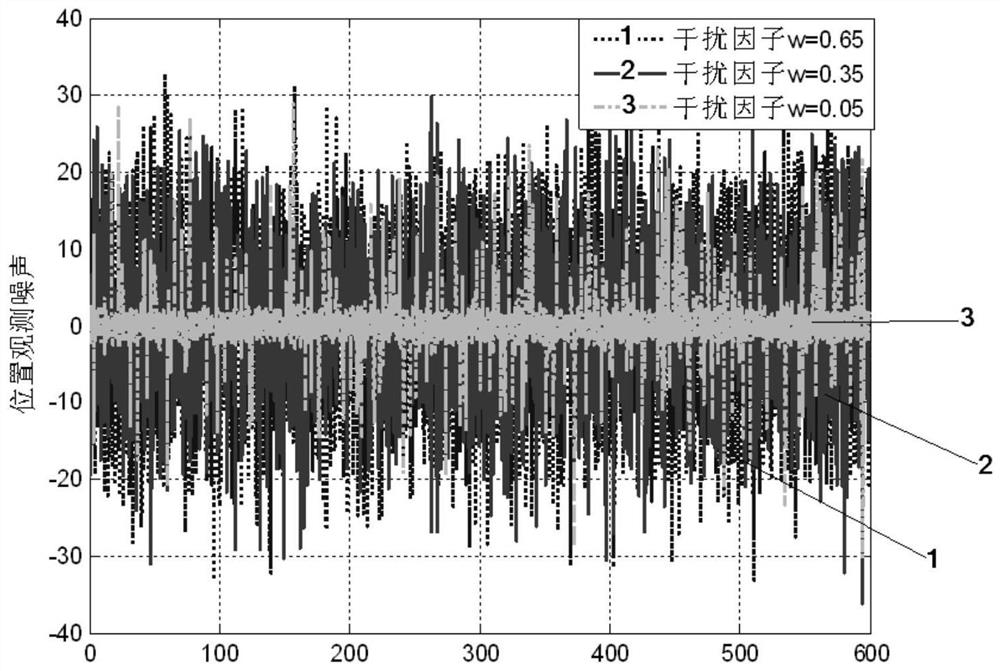

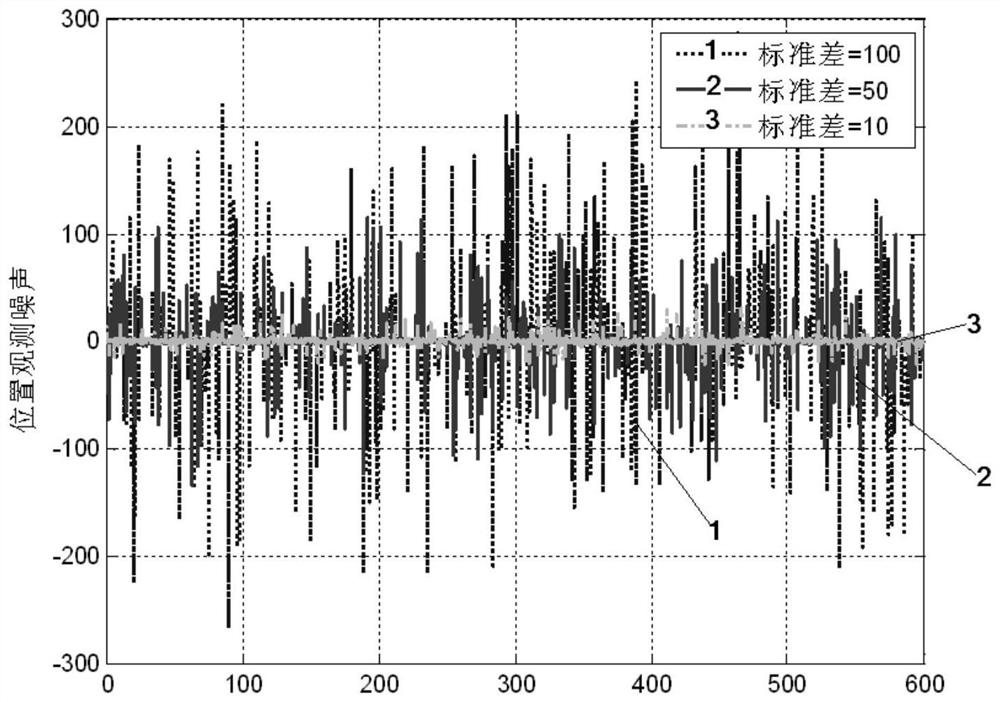

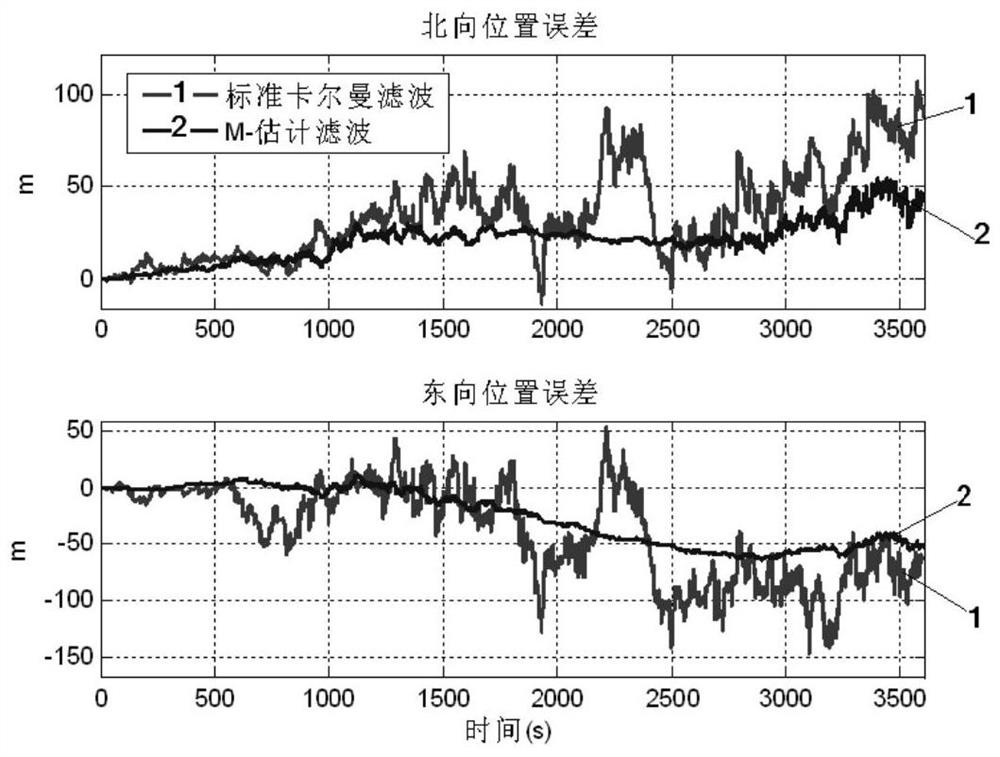

AUV integrated navigation method and system based on M estimation

PendingCN111829511AReduce gainHigh combination precisionNavigational calculation instrumentsNavigation by speed/acceleration measurementsState predictionFilter algorithm

The invention discloses an AUV integrated navigation method and system based on M estimation, and provides a filtering algorithm based on generalized maximum likelihood estimation (M estimation); under the condition that system measurement noise is in non-Gaussian distribution, especially in the case of Gaussian mixture distribution (Gaussian nearby symmetric interference), an M-estimation algorithm is applied, measurement residual errors and state prediction residual errors are weighted through an influence function and a weight function, and the influence of measurement abnormal peak valueson a navigation system is reduced. The algorithm is applied to an SINS / USBL integrated navigation system; under the conditions of non-Gaussian measurement noise and abnormal measurement of the underwater acoustic sensor due to the multipath effect, by comparing the standard Kalman filtering algorithm with the M estimation filtering algorithm, the position and speed error precision of the M estimation filtering algorithm are obviously improved relative to those of the standard Kalman filtering algorithm, and under the condition that the Gaussian mixture model is severely polluted, the filteringeffect of the SINS / USBL integrated navigation system based on M estimation filtering is more obvious, and the robustness and the anti-interference performance are relatively better.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

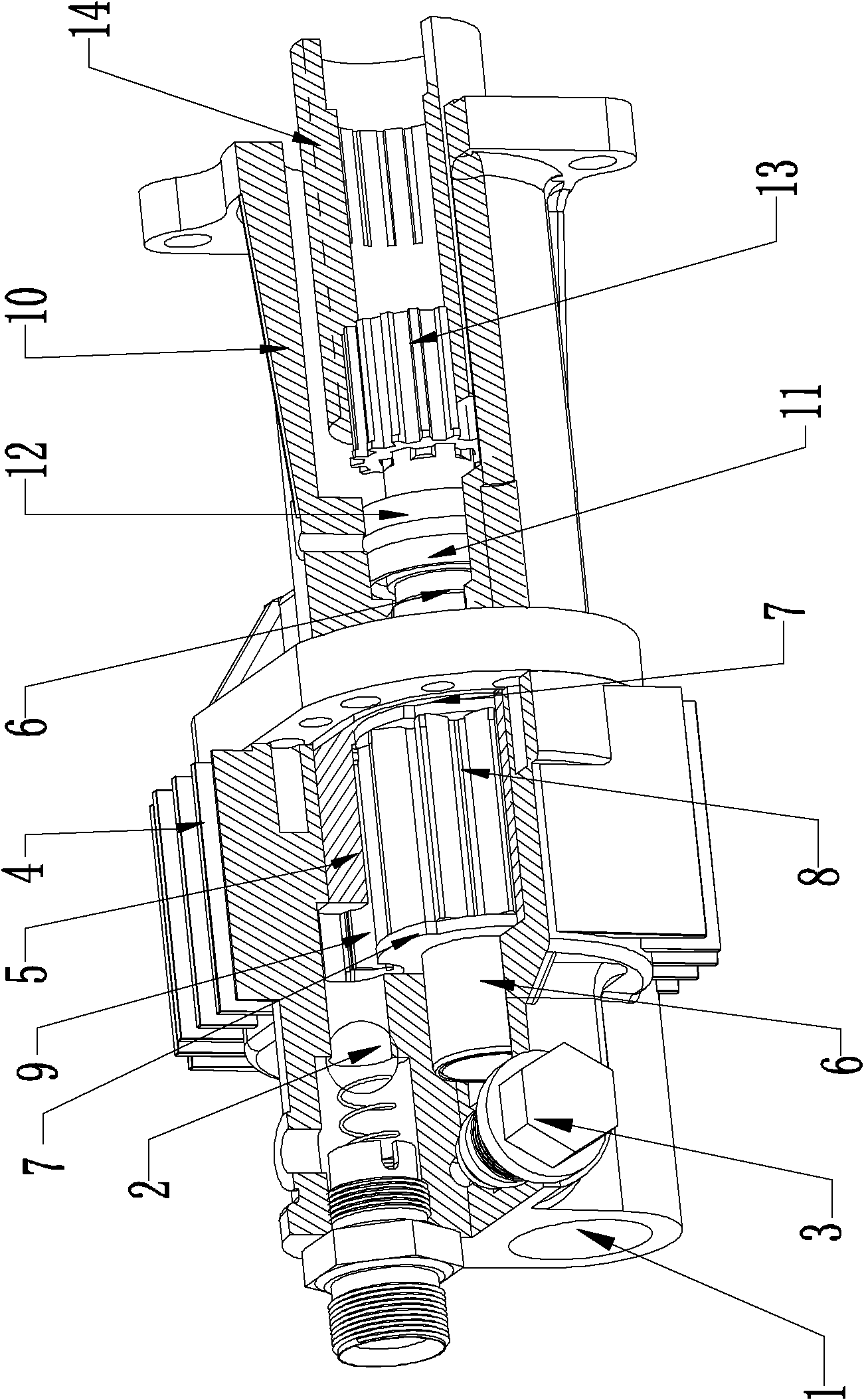

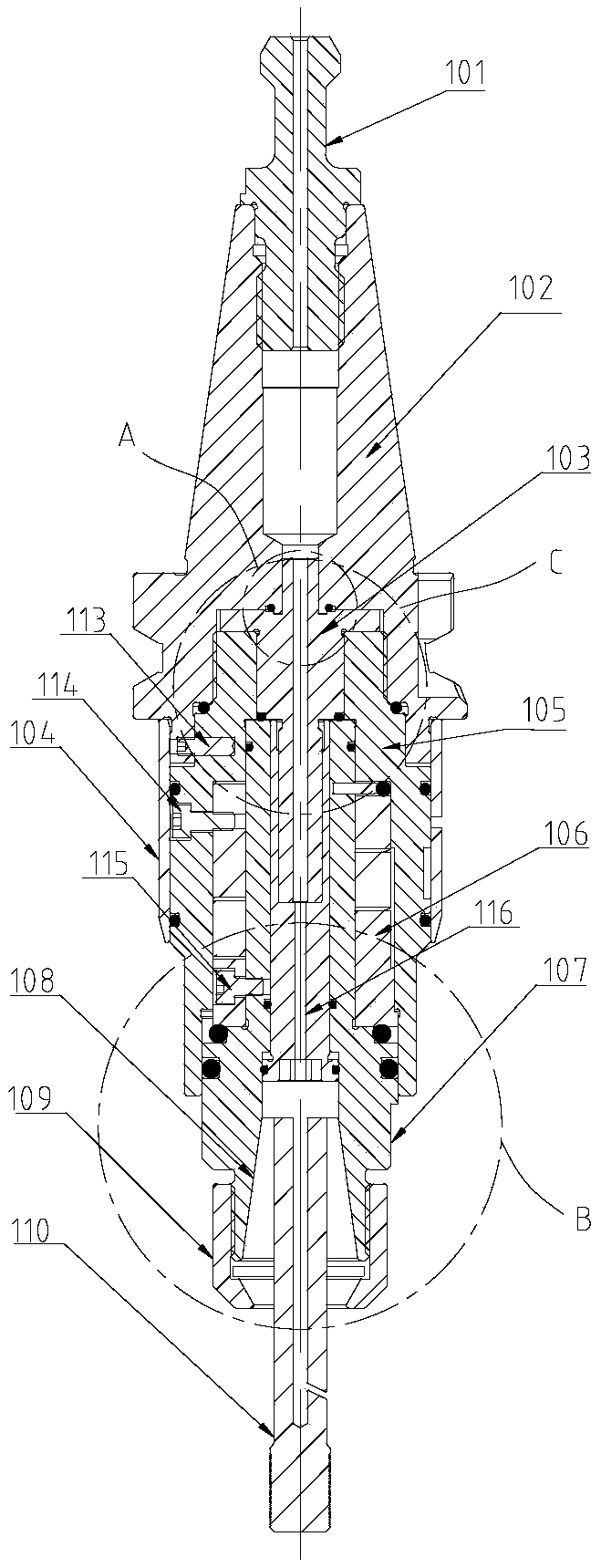

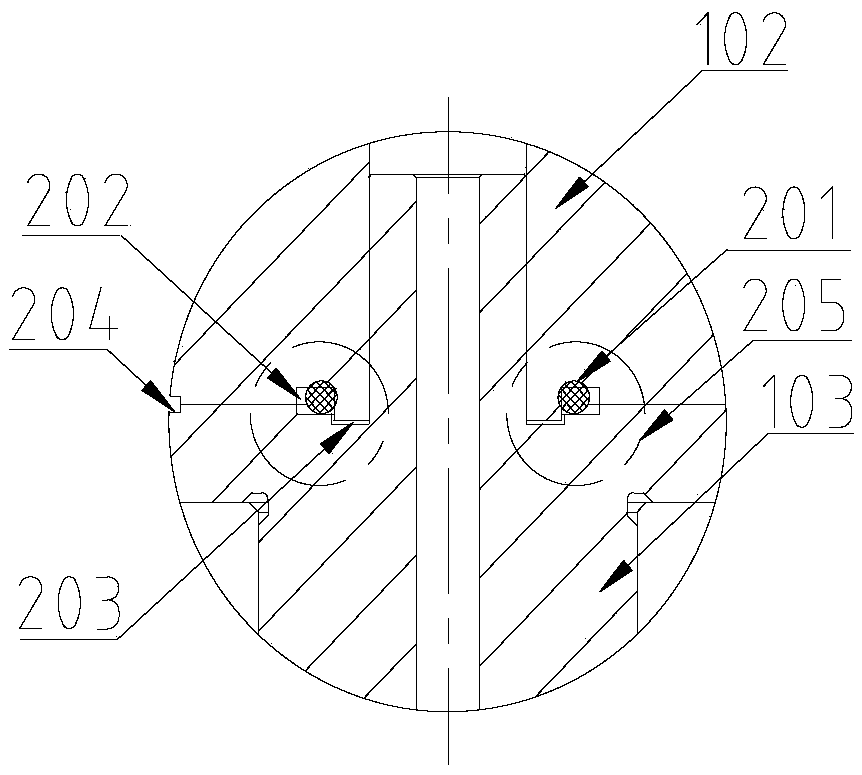

Sealing structure of central water-cooled micro-compensation tapping shank

InactiveCN108714721AWith anti-disassembly effectStrong internal sealingThread cutting toolsThree stageEngineering

The invention discloses a sealing structure of a central water-cooled micro-compensation tapping shank. The central water-cooled micro-compensation tapping shank adopts a three-stage sealing structureconsisting of a central water-cooled sealing structure, damping body elastic sealing and threaded connection sealing by threaded cooperation of a connecting mechanism and Teflon tape. The structure is high in sealing strength, has high flexibility pre-tightening performance, is high in tapping stability and precision, is anti-disassembly, and is compact in structure, long in life and high in reliability. The structure also improves the simplicity and super precision of the tapping, especially small hole tapping, in the mechanical processing industry.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

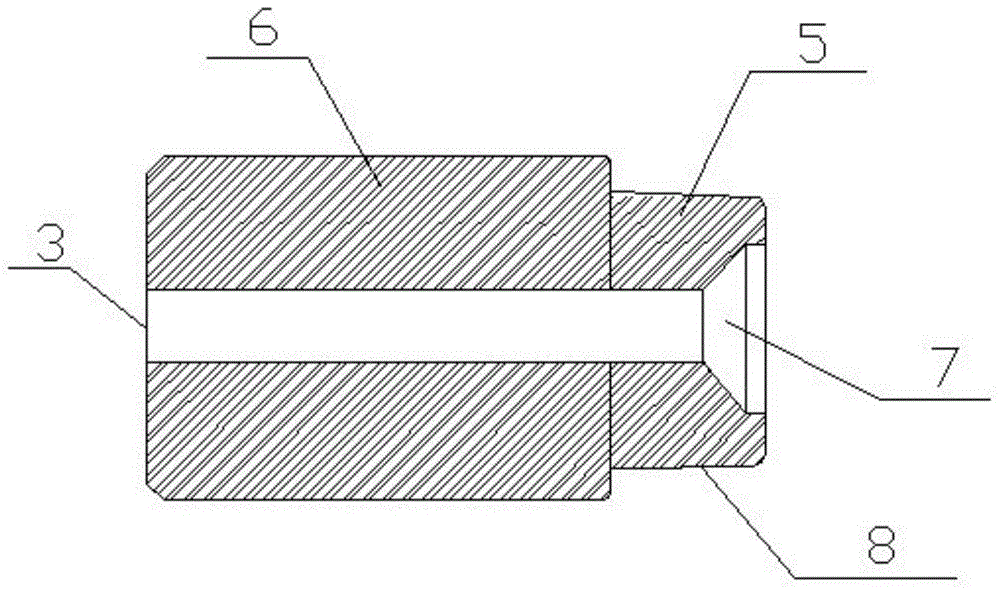

Novel guiding column and guiding sleeve

The invention discloses a novel guiding column and guiding sleeve which comprises a guiding column body and a guiding sleeve body in matched connection with the guiding column body. The guiding column body comprises a cylinder and an external cone arranged on the right side of the cylinder; and a first standard metric internal thread is arranged in the cylinder, an external conical face is arranged on the outer wall of the external cone, and a first screw locating position is arranged in the external cone. A concave cavity is formed in the guiding sleeve body, an internal conical face is arranged on the inner wall of the concave cavity, and a second standard metric internal thread is arranged on the right side of the concave cavity; and a second screw locking position is arranged in the concave cavity, the incremental ratio between the increment and the length of the diameter of the conical face of the external cone is 1:10 to 1:50, and the clearance between the external conical face and the internal conical face is 0.002mm. The guiding column and guiding sleeve is more convenient to install, disassemble and replace, automatic centering is achieved in an installing process of the guiding column and guiding sleeve, the guiding column and guiding sleeve does not need to be adjusted in use, and the combining concentricity is smaller than 0.006mm. The guiding column and guiding sleeve is high in combining accuracy, more excellent in interchangeability, simple to manufacture and convenient to use. In addition, the producing cost is remarkably reduced.

Owner:佛山一精模具配件有限公司

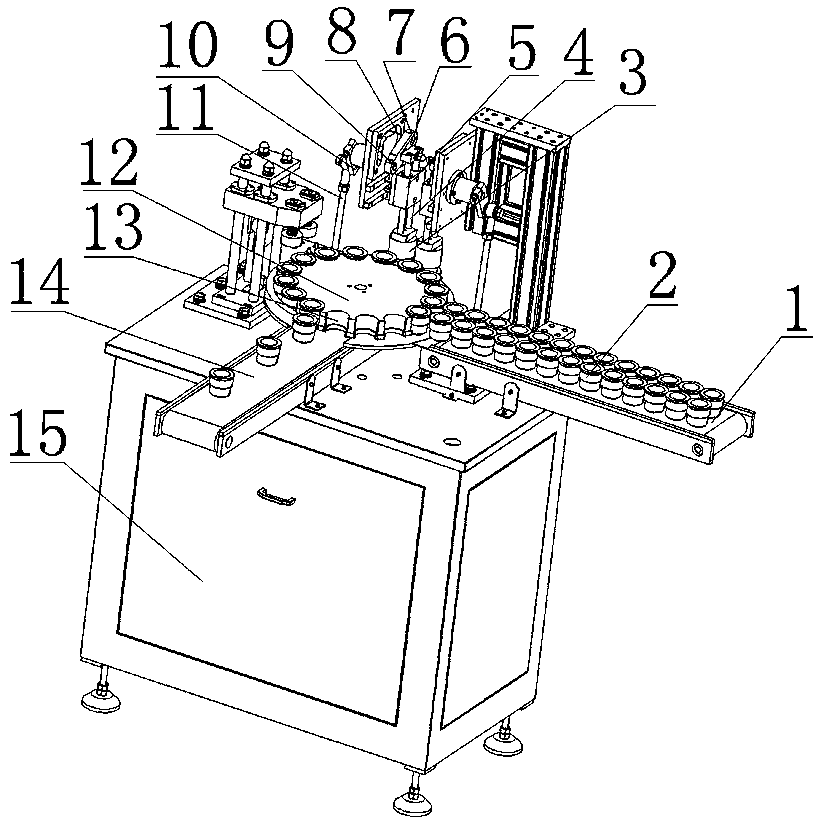

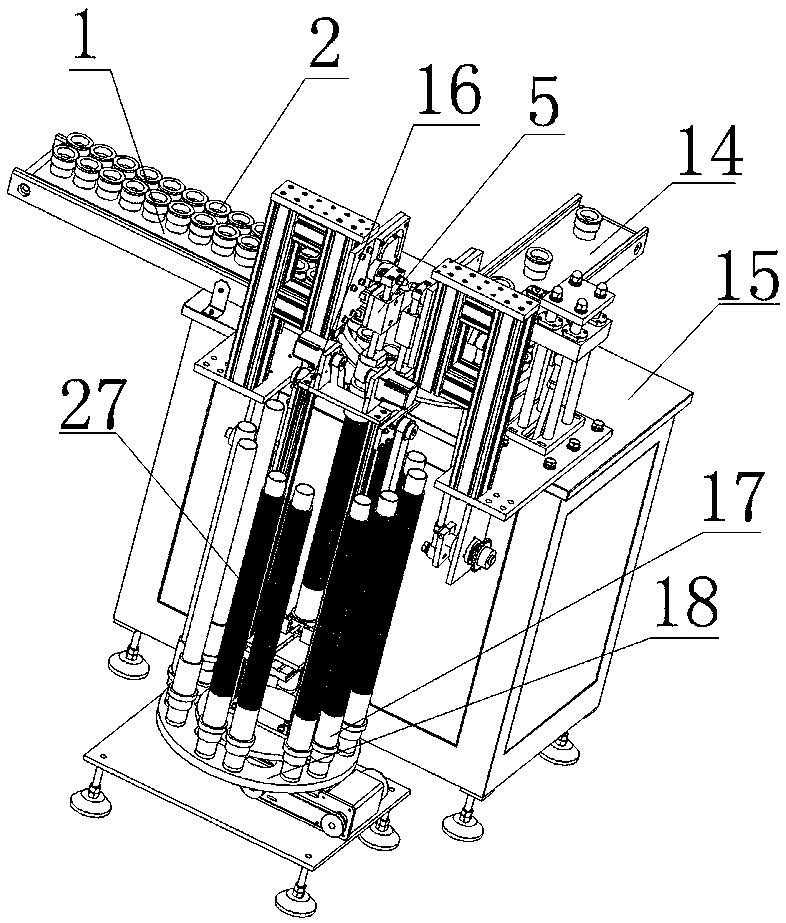

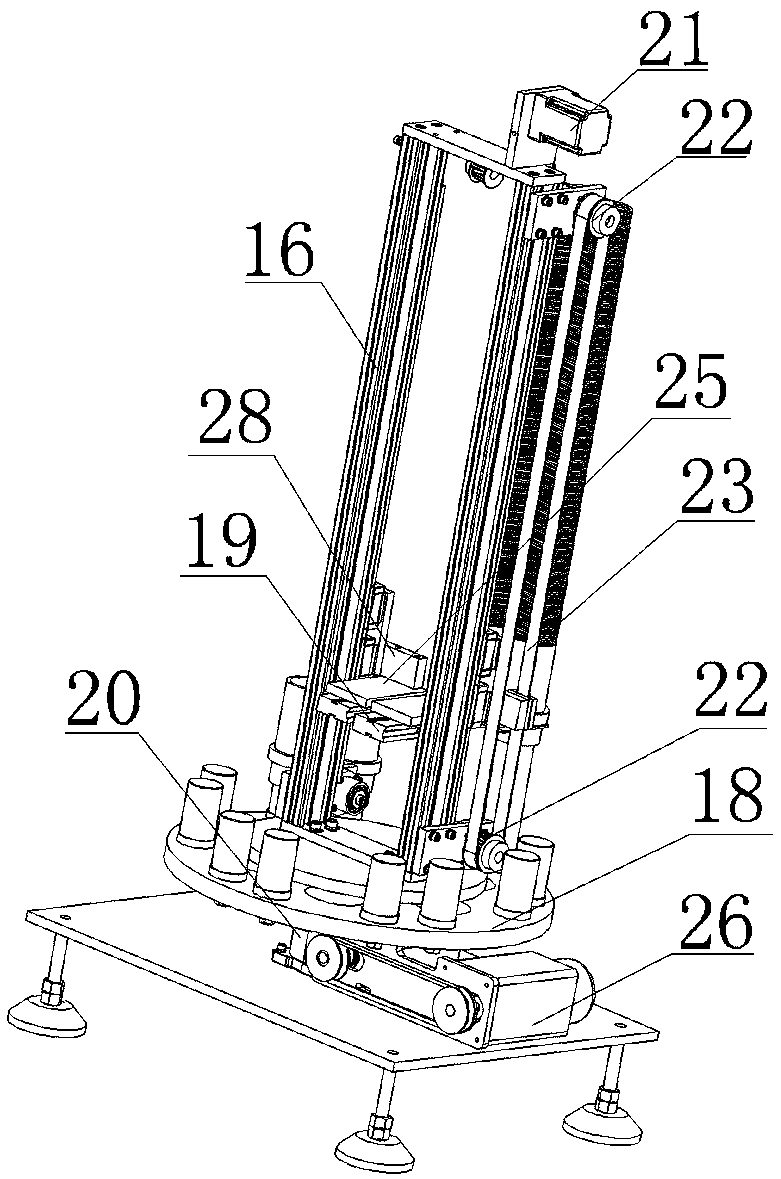

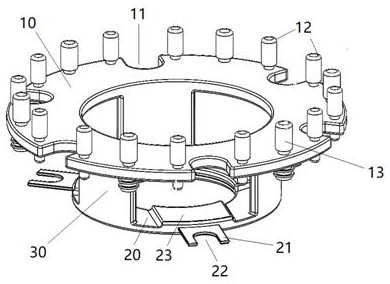

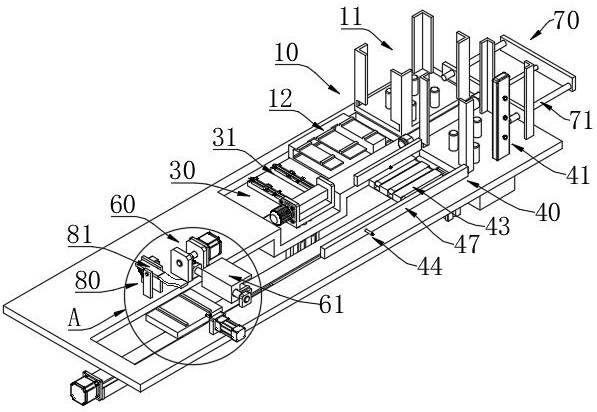

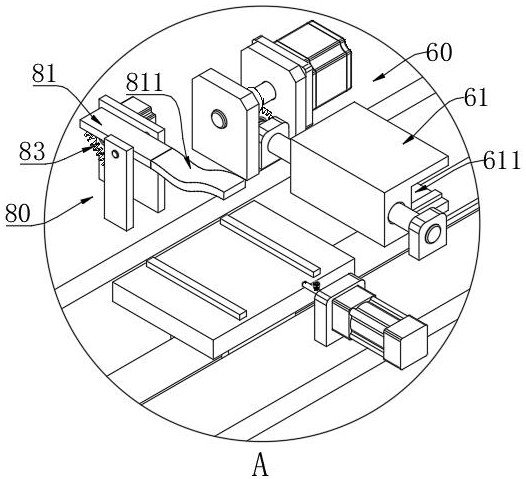

Ring gasket capping machine

InactiveCN110549293AIncrease productivityHigh combination precisionMetal-working hand toolsFixed frameEngineering

The invention discloses a ring gasket capping machine. The ring gasket capping machine comprises a machine body, a bottle cap input belt, a bottle cap output belt and a first rotary dividing plate, wherein circular arc grooves which are matched with bottle caps are uniformly formed in the circumferential surface of the first rotary dividing plate. The ring gasket capping machine is characterized in that a ring gasket storage mechanism is arranged on one side of the machine body, the ring gasket storage mechanism comprises a second rotary dividing plate, ring gasket sleeve rods are uniformly arranged on the second rotary dividing plate, a fixed frame is arranged above the second rotary dividing plate, an air cylinder which slides up and down is arranged on the fixed frame, a top plate is arranged on a push rod of the air cylinder, and a ring gasket transfer manipulator is installed on the machine body. According to the combined machine of the structure, ring gaskets can be effectively put in the bottle caps so as to be combined, so that a sealing effect is achieved when the bottle caps are screwed on bottle bodies, the production efficiency is high, and continuous operation withoutshutdown can be realized.

Owner:RUIAN FURI PACKAGING MACHINERY

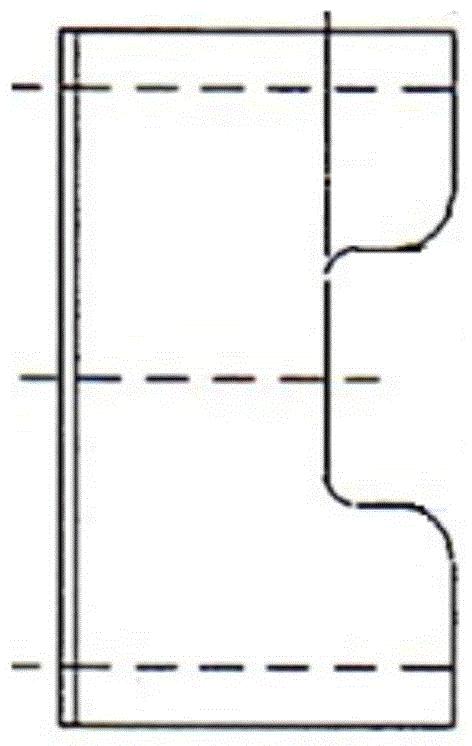

High-precision waveguide power divider and processing method thereof

ActiveCN108232394AHigh combination precisionGuaranteed assembly accuracyCoupling devicesLaser cuttingEngineering

The invention relates to a high-precision waveguide power divider and a processing method thereof. The high-precision waveguide power divider is formed by subjecting an upper chamber and a lower chamber to vacuum soldering; a solder pad is made by laser cutting; a power divider chamber formed includes a main chamber and an auxiliary chamber. The high-precision waveguide power divider is characterized in that a welding face of the upper chamber is provided with a groove, the lower chamber is correspondingly provided with a shoulder, the upper chamber and the lower chamber are positioned duringwelding through the combination of the groove and the shoulder, the main chamber and auxiliary chamber of the lower chamber are integrated separately to main flange half plate I and auxiliary flange half plate II; after the upper chamber and the lower chamber are welded together, the main flange half plate I and a main flange half plate II form a main flange plate; the auxiliary flange half plateI and an auxiliary flange half plate II form an auxiliary flange plate.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

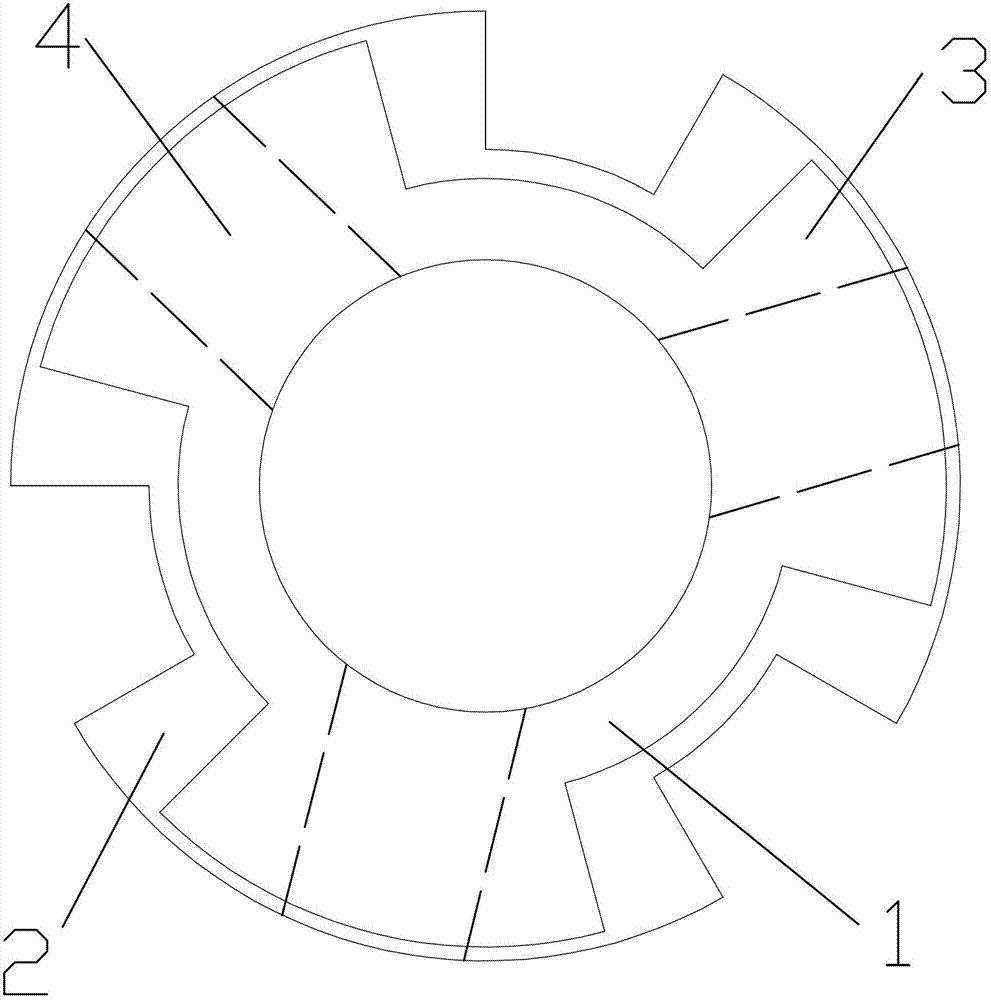

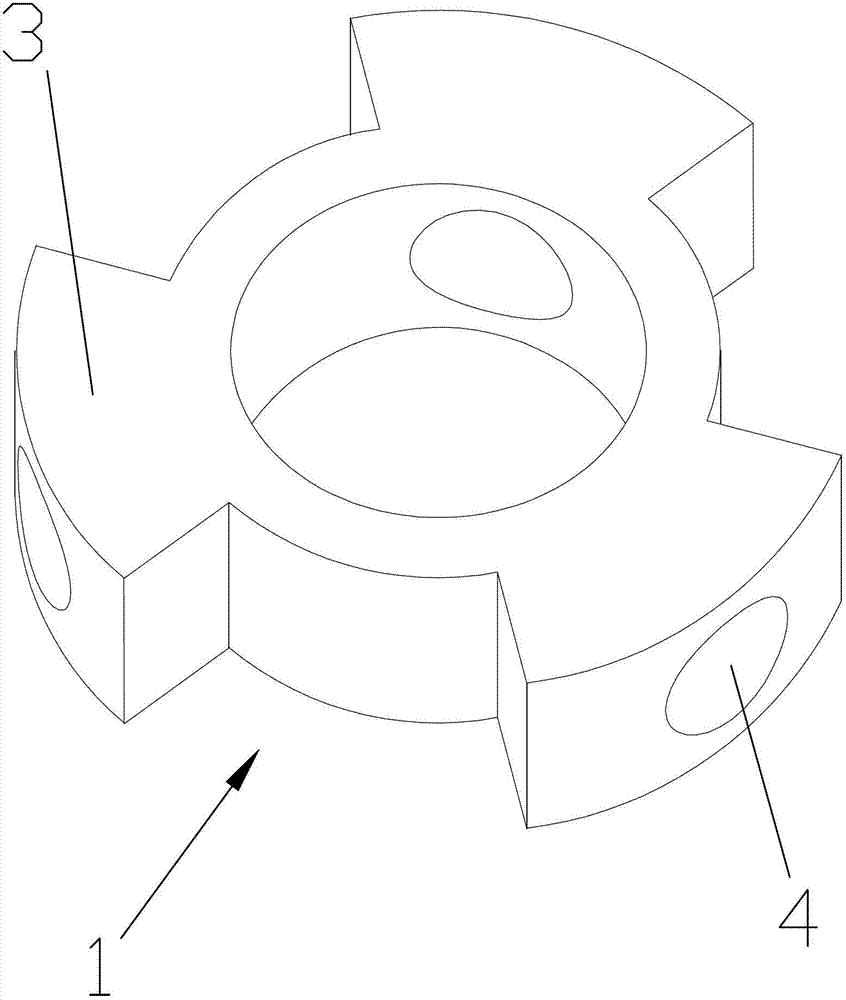

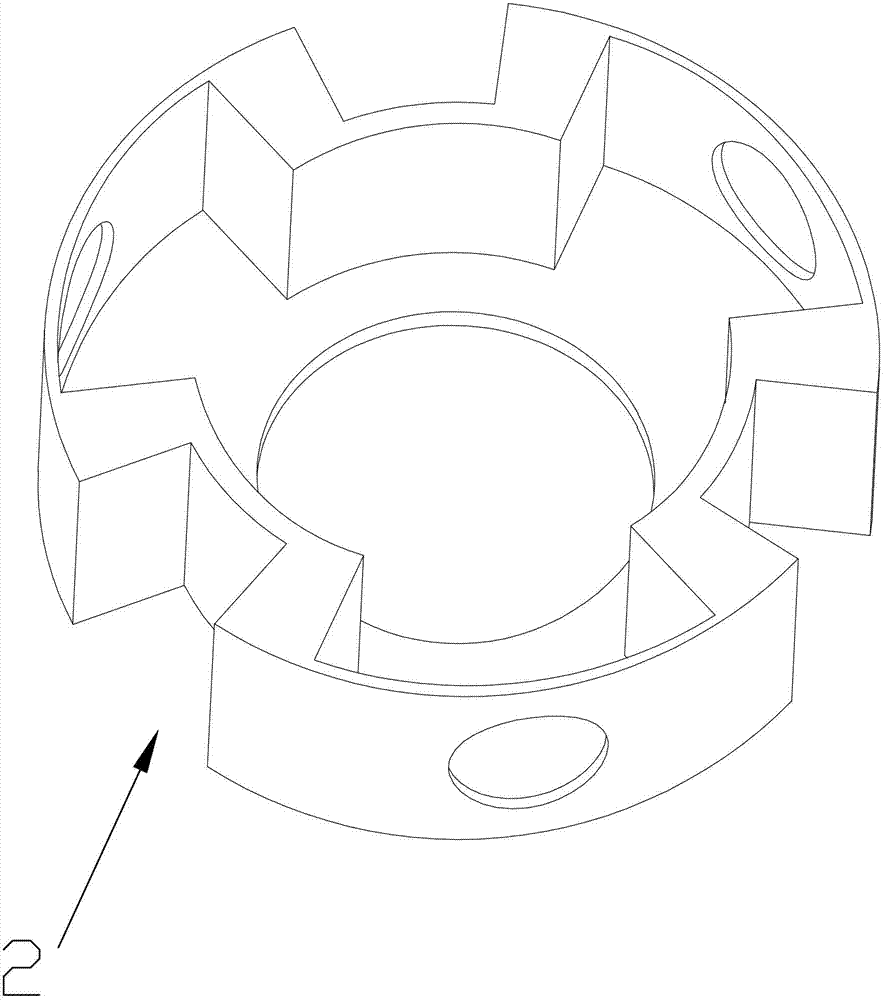

Power inductor core with closed magnetic circuit structure

InactiveCN105788823AReduce lossImprove matching accuracyTransformers/inductances magnetic coresEngineeringInductor

The invention relates to a power inductor core with a closed magnetic circuit structure. The power inductor core comprises a magnetic base and a magnetic cover, wherein the magnetic cover is fastened to the magnetic base; a magnetic core integrated with the magnetic base is arranged at the center part of the magnetic base; a groove for placing a coil is formed in the periphery of the magnetic core; notches for leading out a coil connector are formed in the edge parts of the groove; and gaps for installing a terminal are reserved at the parts, corresponding to the notches, of the magnetic cover. The invention provides a low-loss and high-current Ni-Zn ferrite core applied to a design of a power inductor product; the design of the low-loss power inductor is achieved; and the product achieves simultaneous matching of low loss, high power and production automation.

Owner:DADONG ELECTRONICS

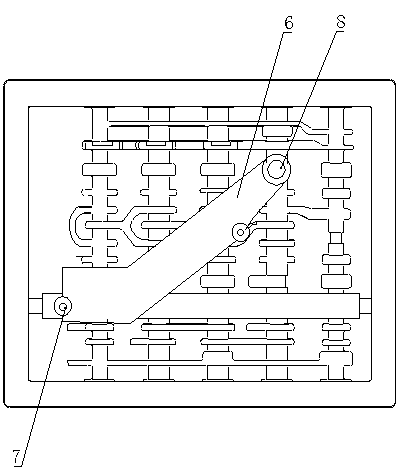

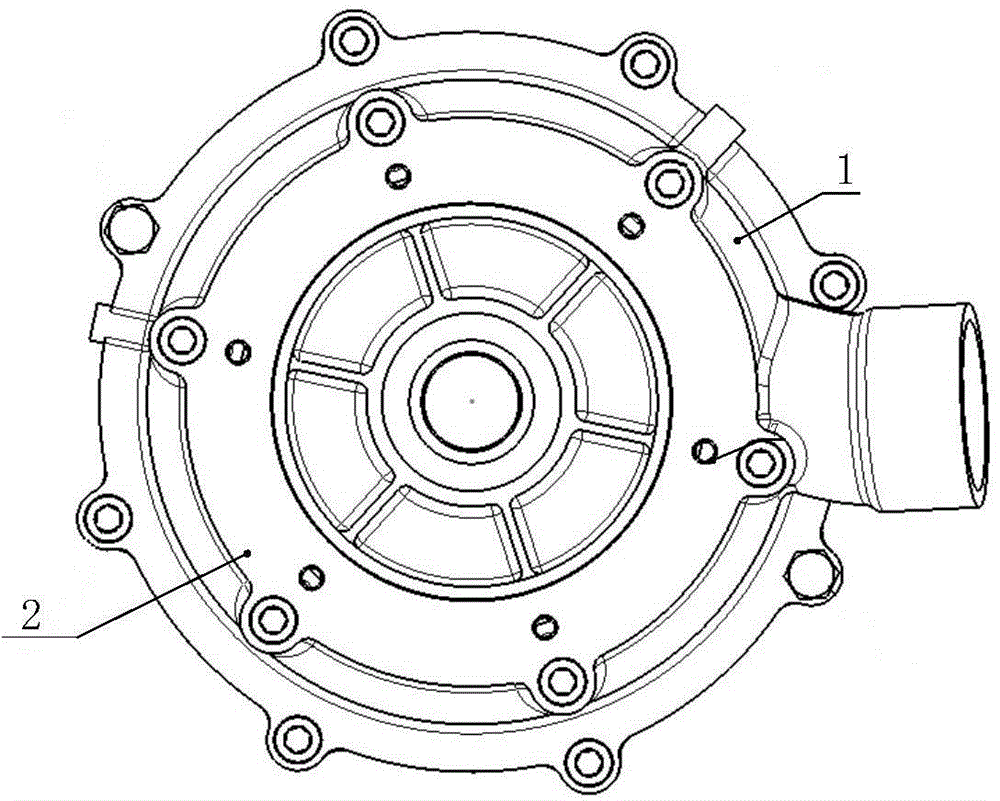

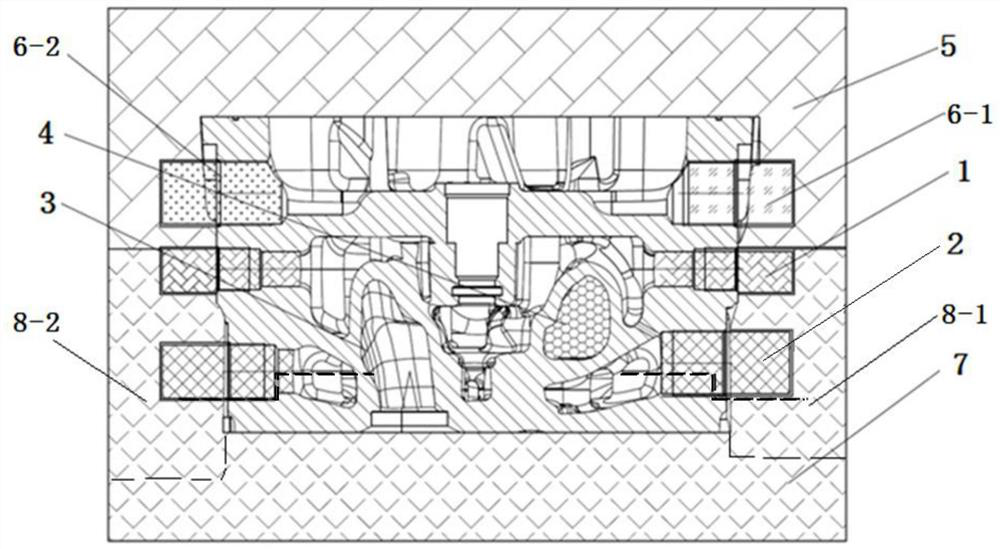

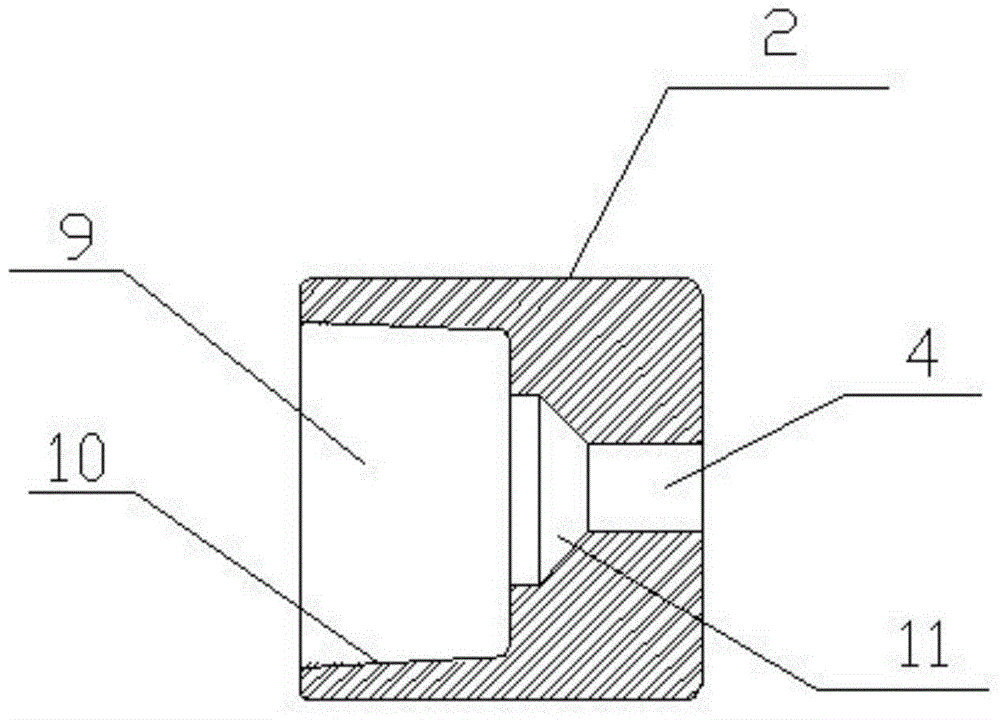

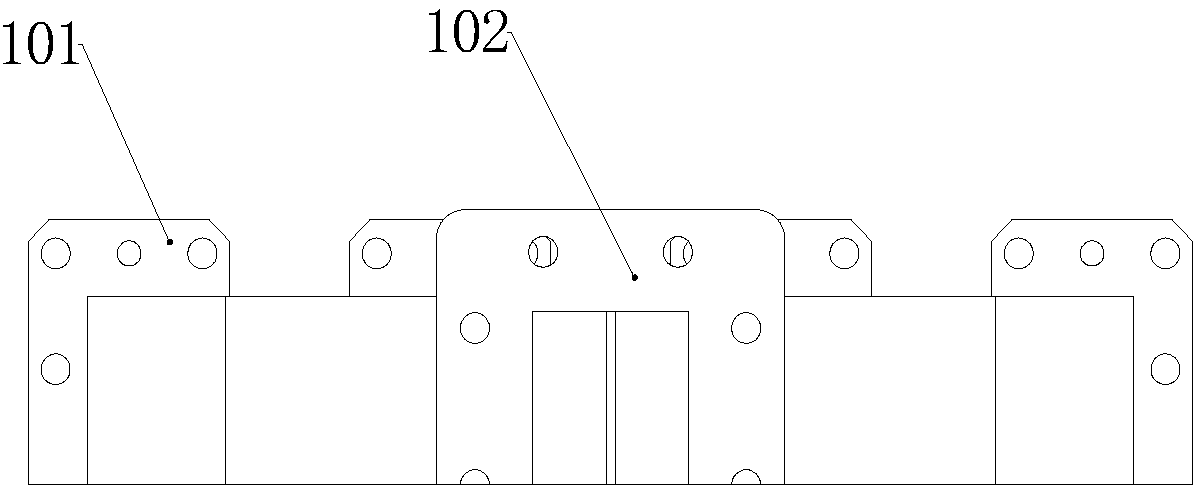

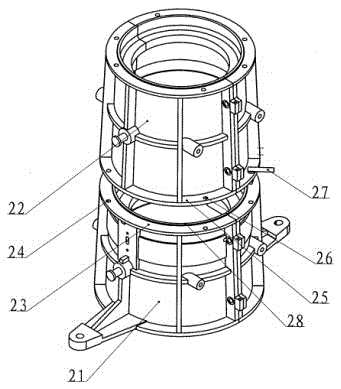

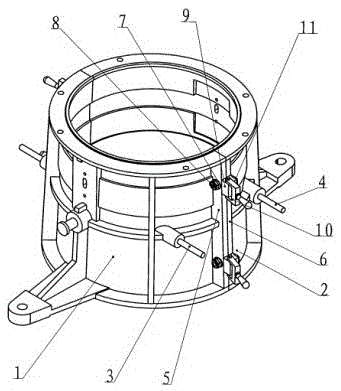

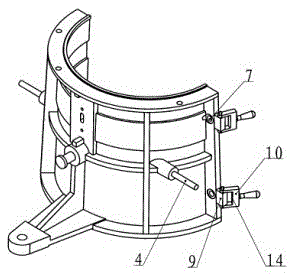

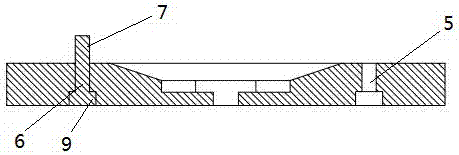

Core box for high-precision assembly foundry

ActiveCN104399879BGuaranteed accuracyGuaranteed concentricityFoundry moulding apparatusLeft halfEngineering

The invention discloses a core box for high precision assembly casting. The provided core box solves the problem that the concentricity of a conventional mould can be easily deviated in the prior art. The core box comprises a first core box unit (21) and a second core box unit (22), wherein the first core box unit (21) and the second core box unit (22) have the same structure. The first core box unit (21) is composed of a left-half core box unit (1) and a right-half core box unit (2). A left-half core box unit combined vertical rib plate (5) is provided with a positioning pin (8). A door-shaped lock seat (9) is fixedly arranged on the external side surface of the left-half core box unit combined vertical rib plate (5), and a door-shaped clasp (10) is movably arranged on the door-shaped lock seat (9). A right-half core box unit combined vertical rib plate (6) is provided with a positioning pin sleeve, a locking block (11) is arranged on the external side surface of the right-half core box unit combined vertical rib plate (6), the positioning pin is inserted into the positioning pin sleeve movably, and the door-shaped clasp (10) is movably clamped with the locking block (11). The provided core box can improve the combination precision of an internal mould.

Owner:SHANXI JIANGHUAI HEAVY IND

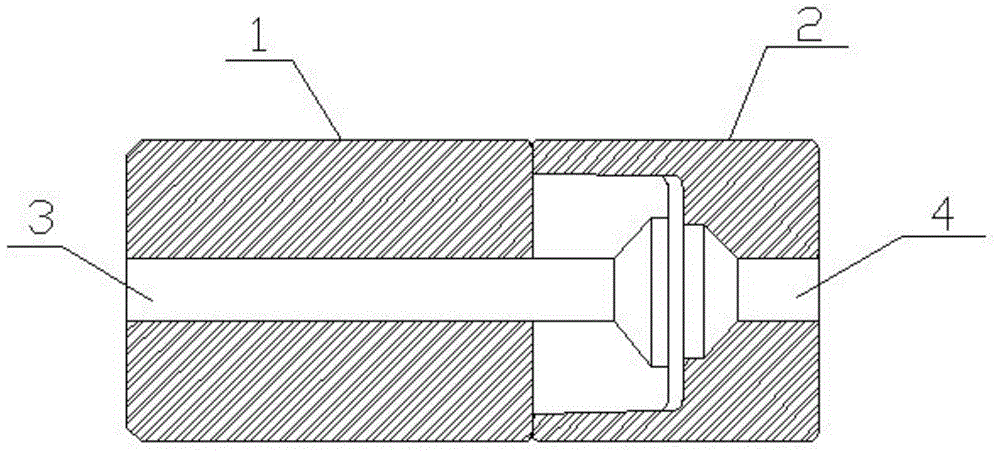

Connector

InactiveCN102758855AStable structureHigh combination precisionYielding couplingEngineeringElectrical and Electronics engineering

The invention relates to the field of mechanical transmission, and in particular relates to a connector which comprises a connector inner ring and shock absorption gaskets, wherein the connector inner ring also comprises a plurality of bulge edges which are distributed uniformly; grooves which are used for the installation of the connector inner ring is formed on the shock absorption gaskets; and the shock absorption gaskets at two sides of the bulge edges are thicker than the rest shock absorption gaskets. The connector provided by the invention can be used for improving the performances of the connector and prolonging the service life of the connector.

Owner:浙江博盟精工机械有限公司

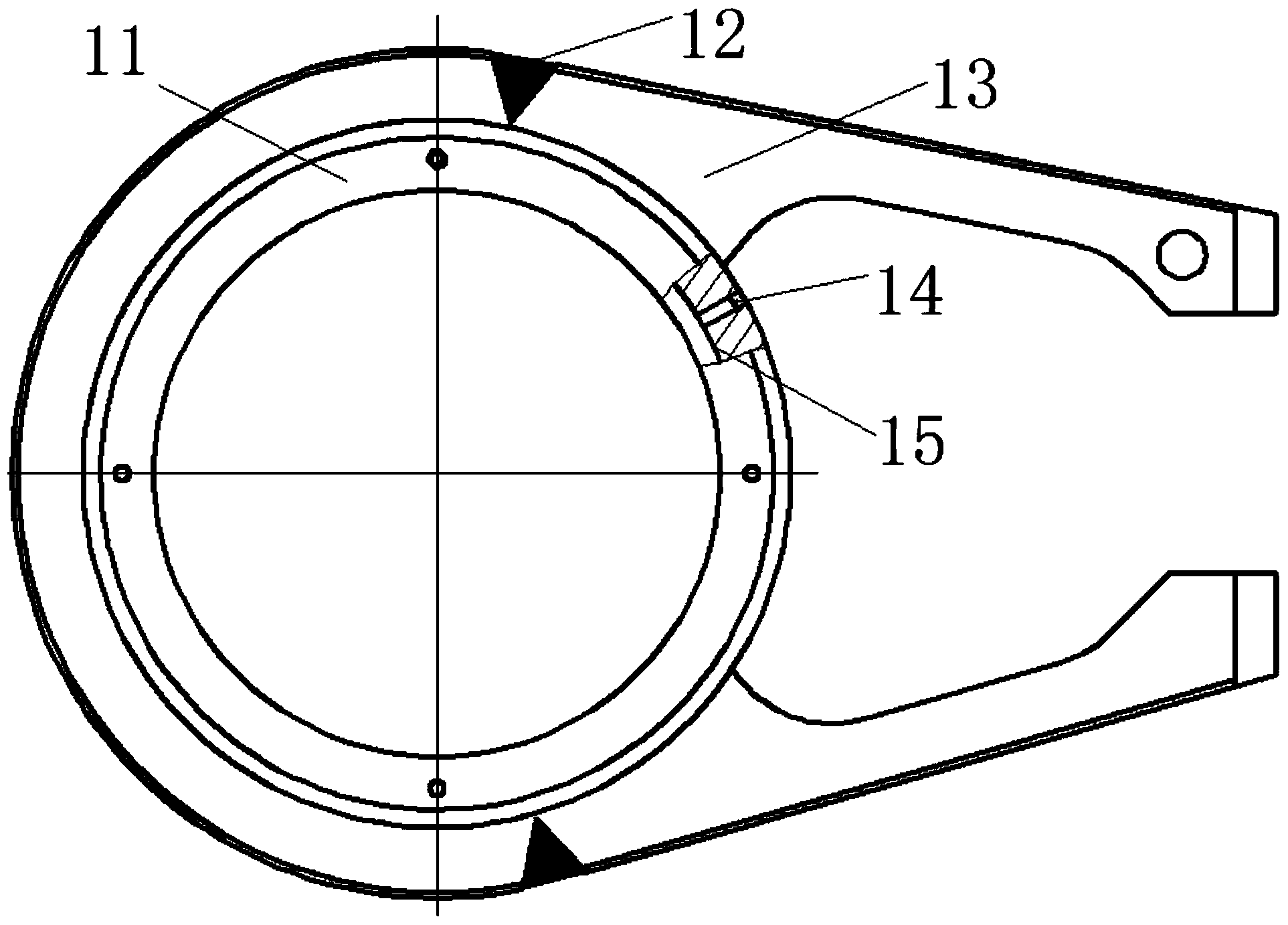

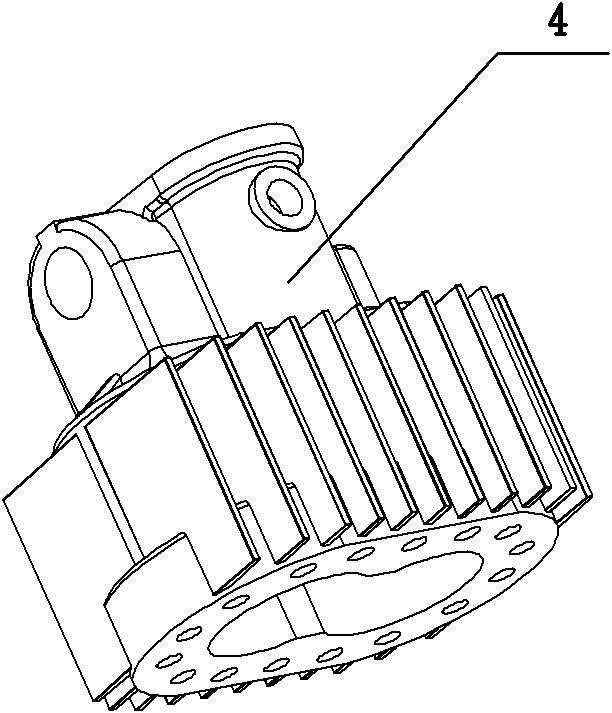

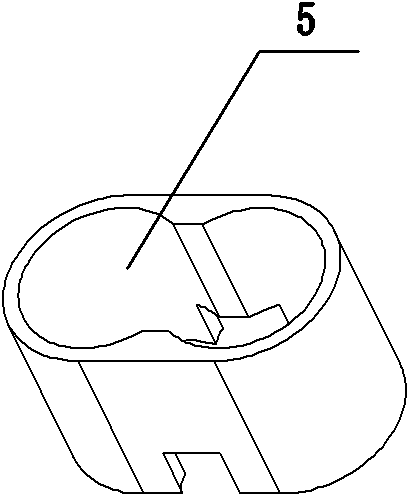

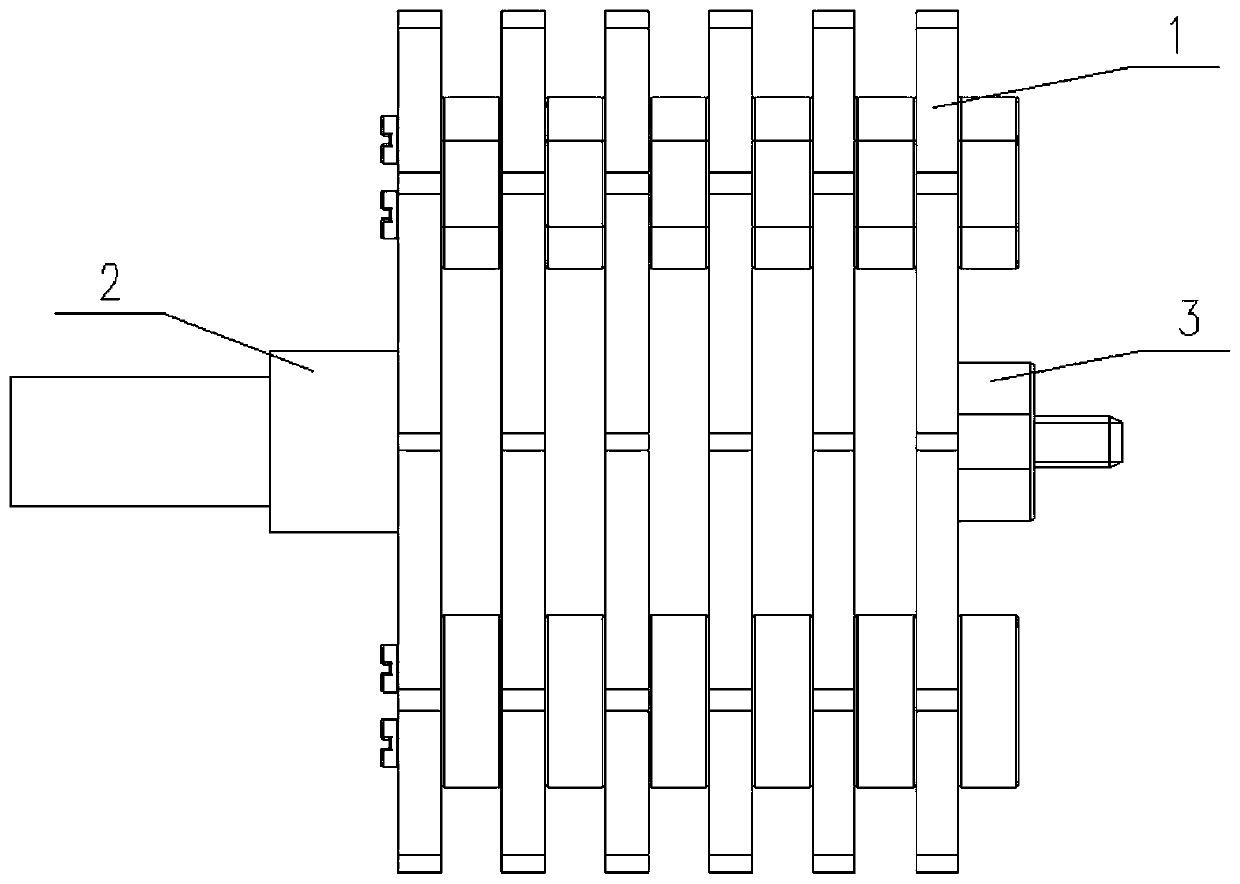

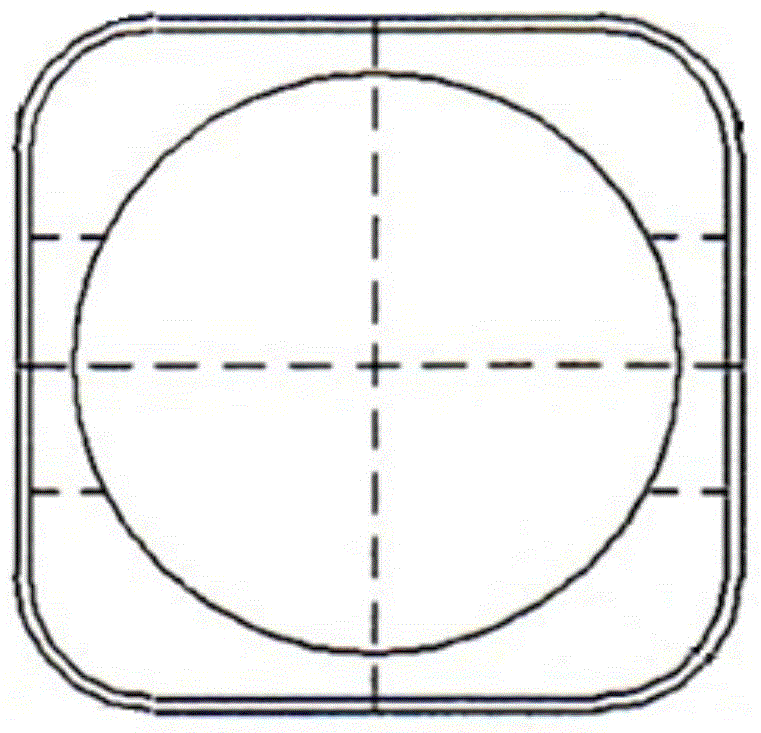

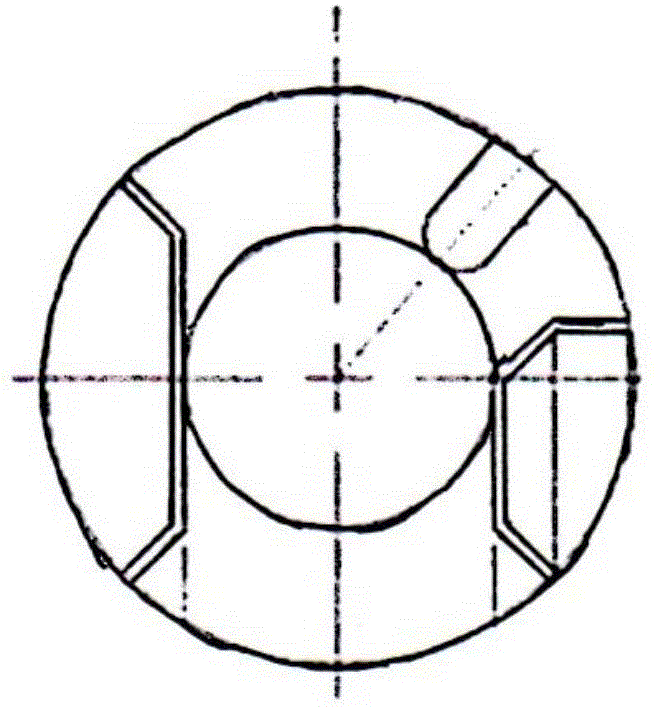

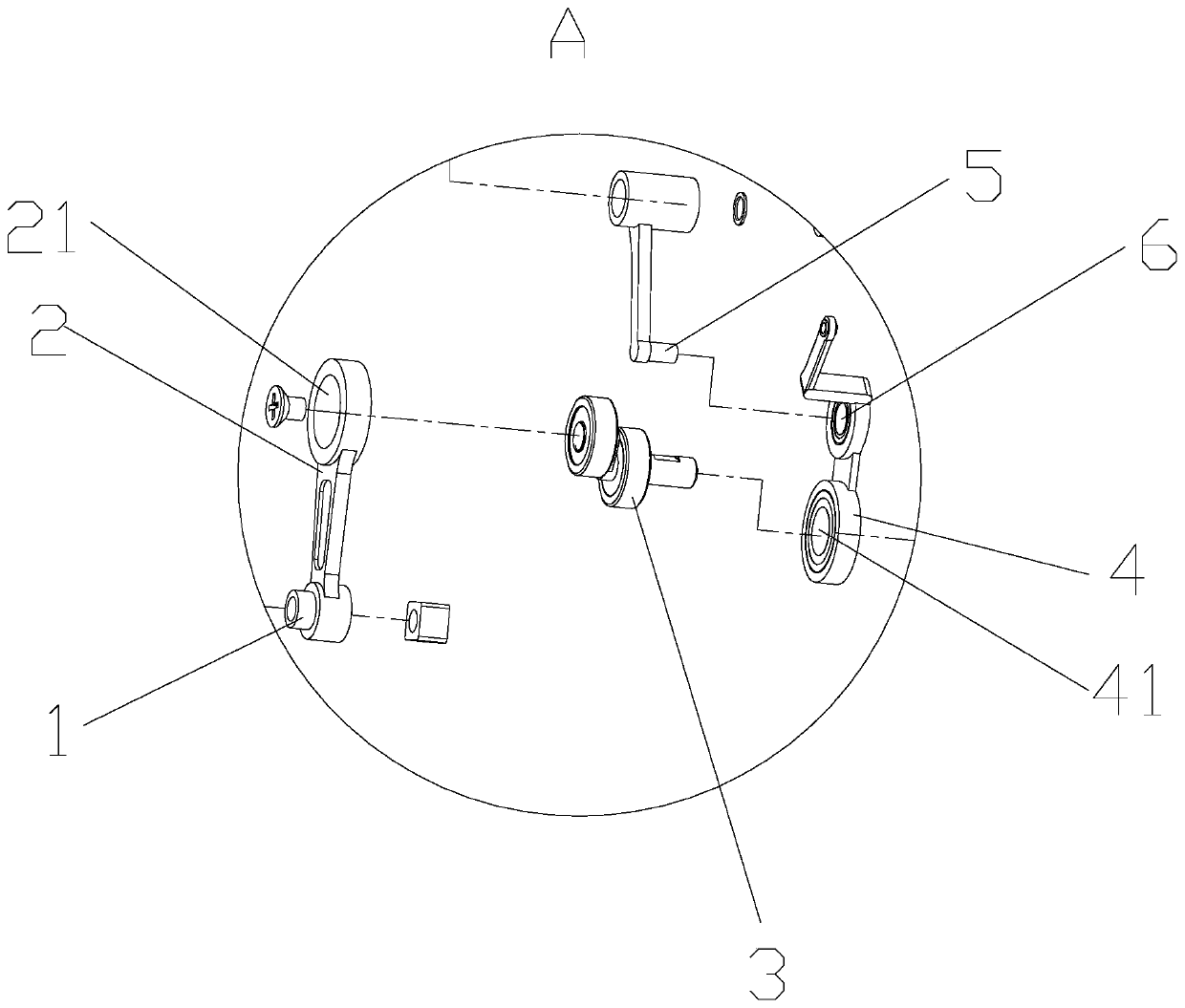

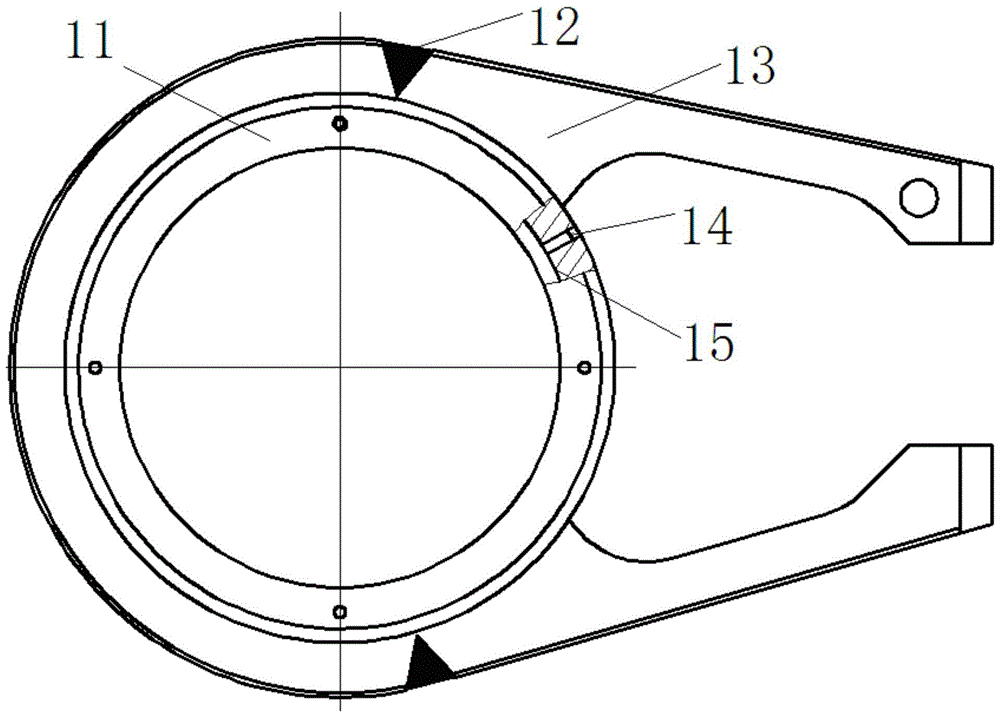

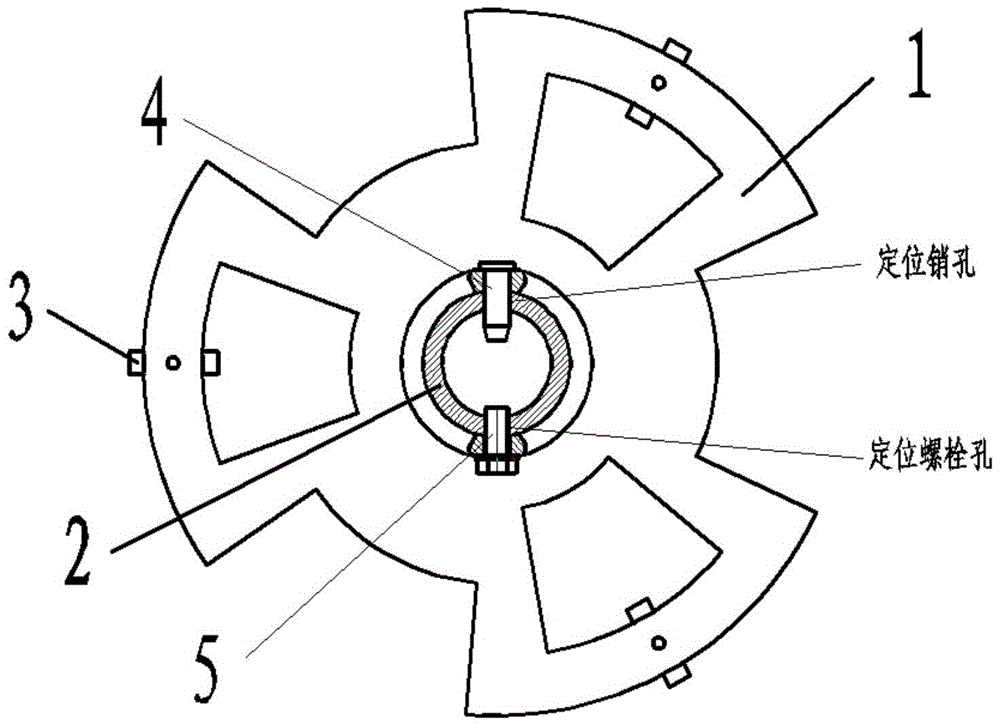

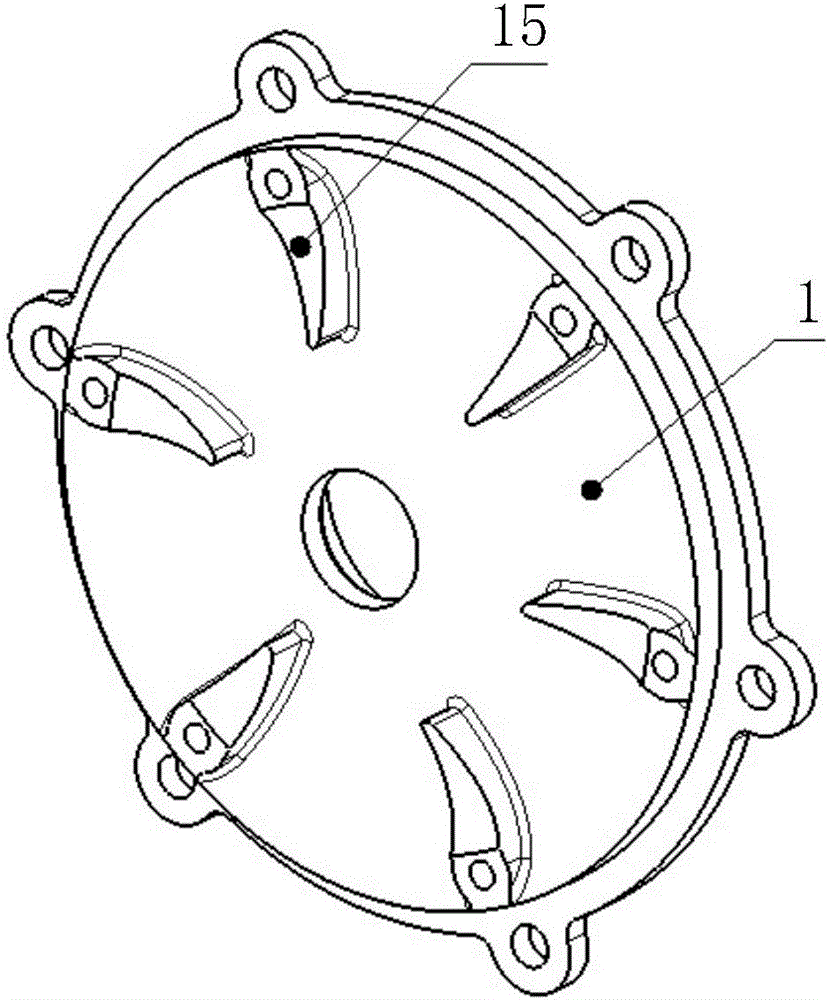

Tool for combining reverse-inclination resin sand mold core and combining and assembling method of tool

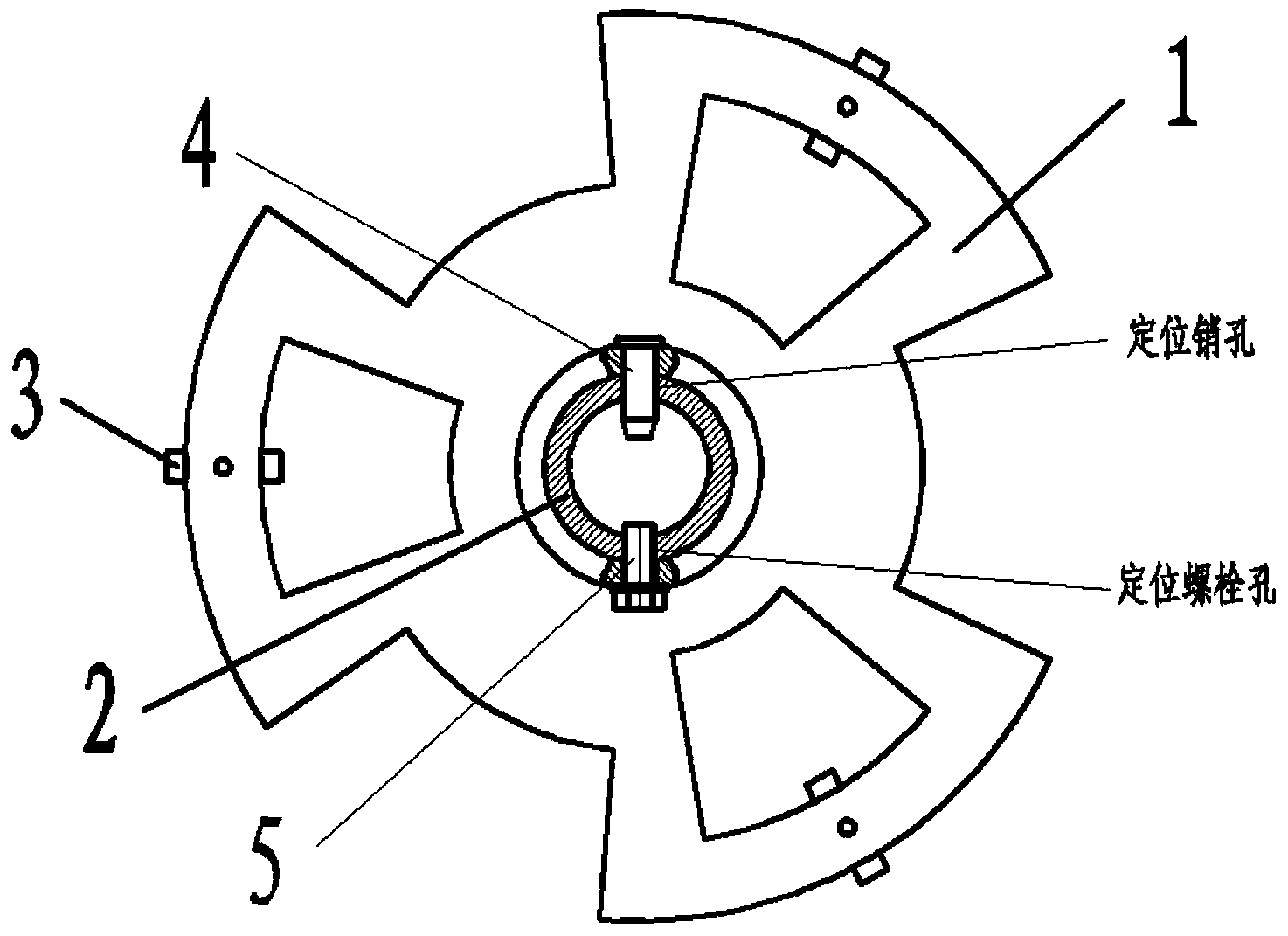

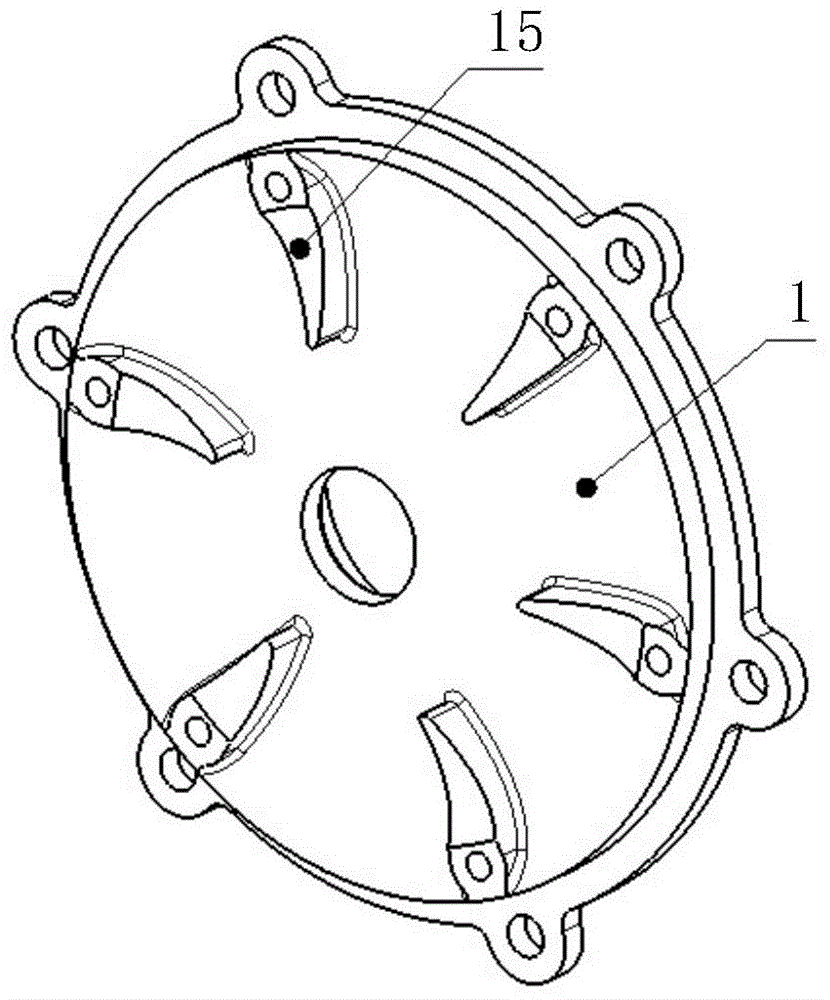

ActiveCN114871386AHigh combination precisionRealize combined assemblyFoundry mouldsFoundry coresCircular discEngineering

The invention discloses a reverse-inclination resin sand mold core combination tool and a combination assembling method thereof.The combination tool is used for installing a first mold core and a second mold core and comprises an upper-layer disc, a lower-layer disc and a supporting column located between the upper-layer disc and the lower-layer disc, and the diameter of the upper-layer disc is larger than that of the lower-layer disc; a plurality of opening grooves horizontally extending towards the center direction are formed in the outer side of the upper-layer disc in the circumferential direction, and the multiple opening grooves enable the upper-layer disc to form a plurality of sector structures. The mold core pre-combined through the tool has high combination precision, the whole mold core can be accurately assembled into an outer mold, precise combination and assembly of the reverse-inclination resin sand mold core and an outer mold sand mold are achieved, and the tool can be applied to production of complex aluminum alloy casing castings.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

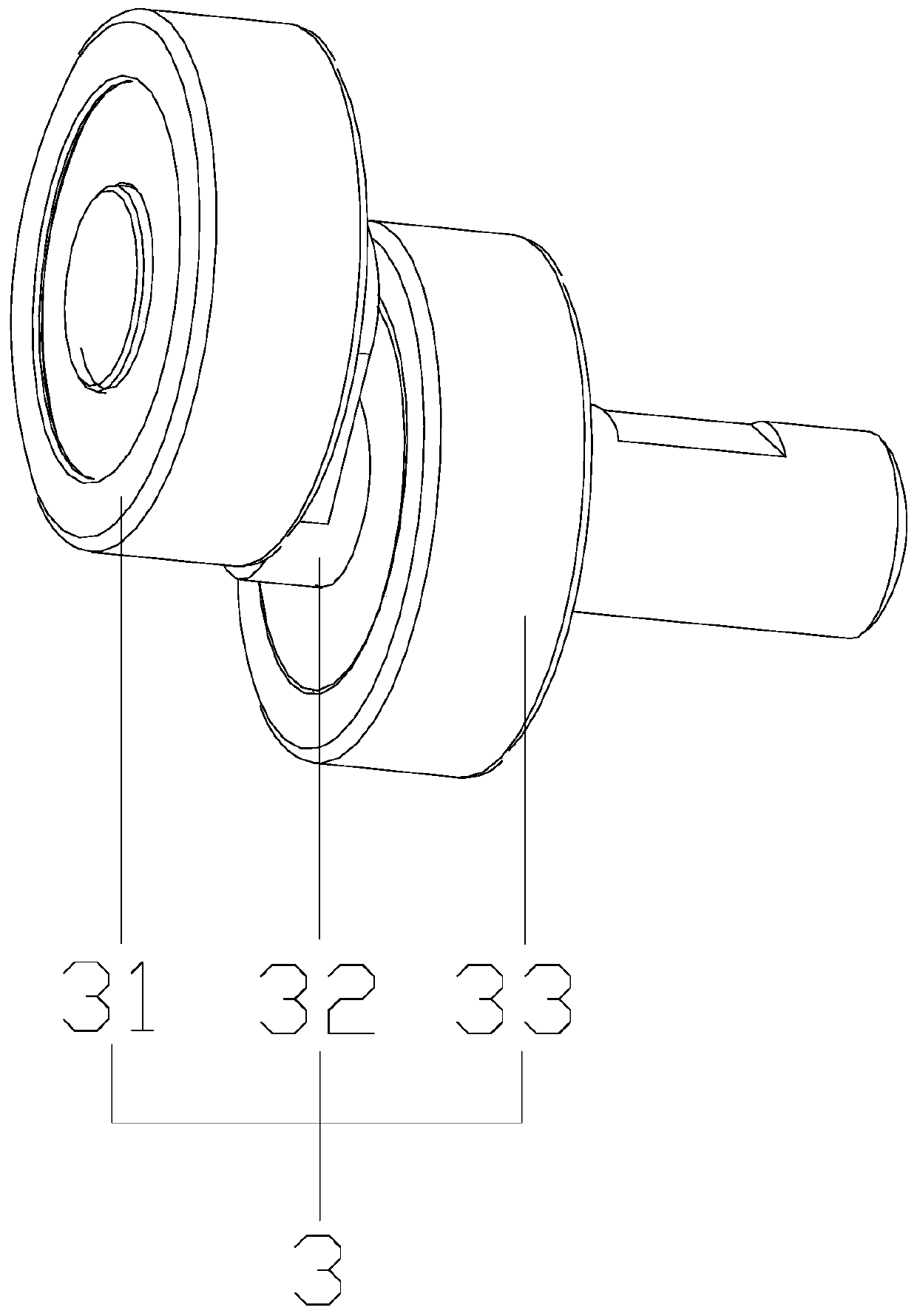

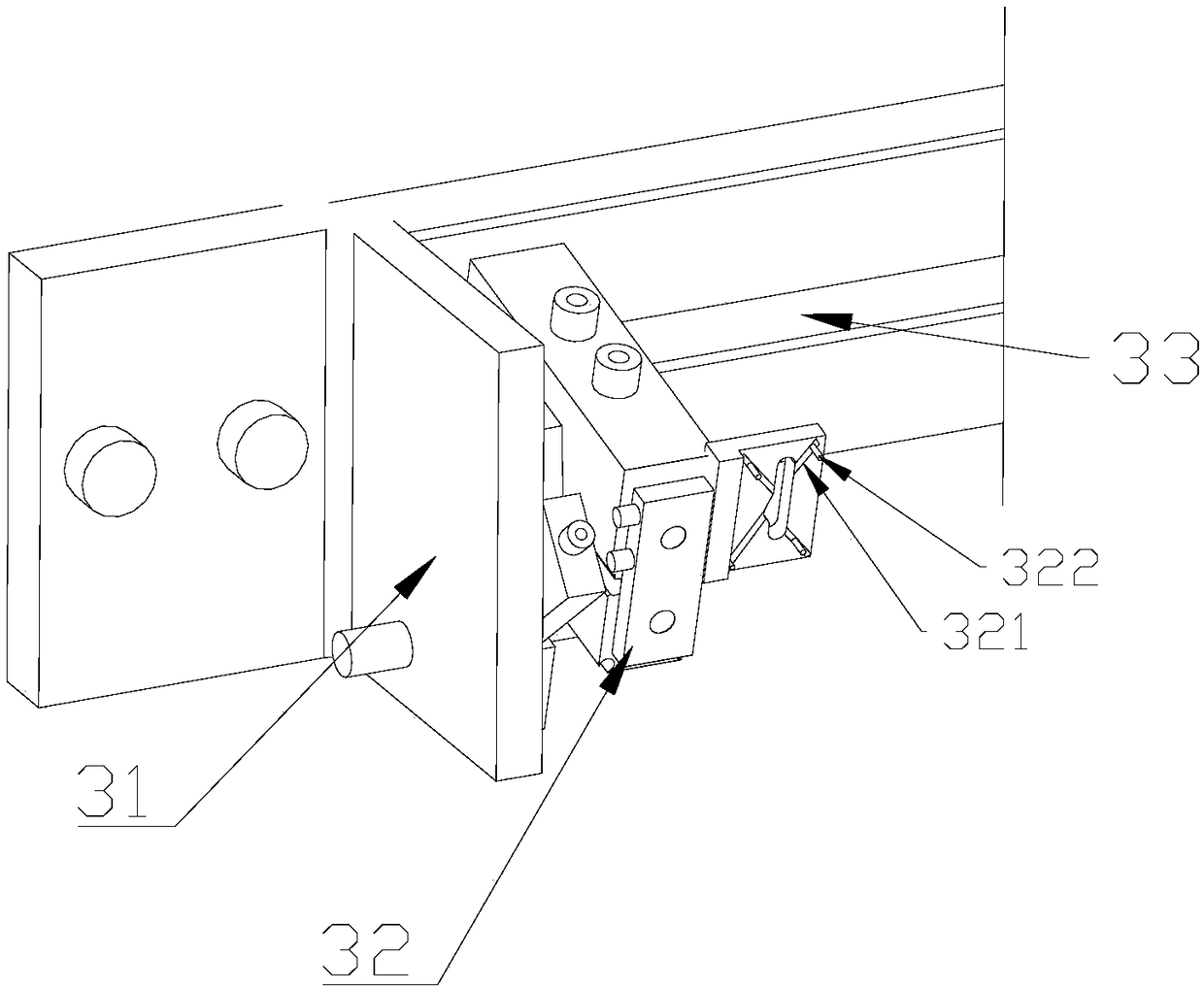

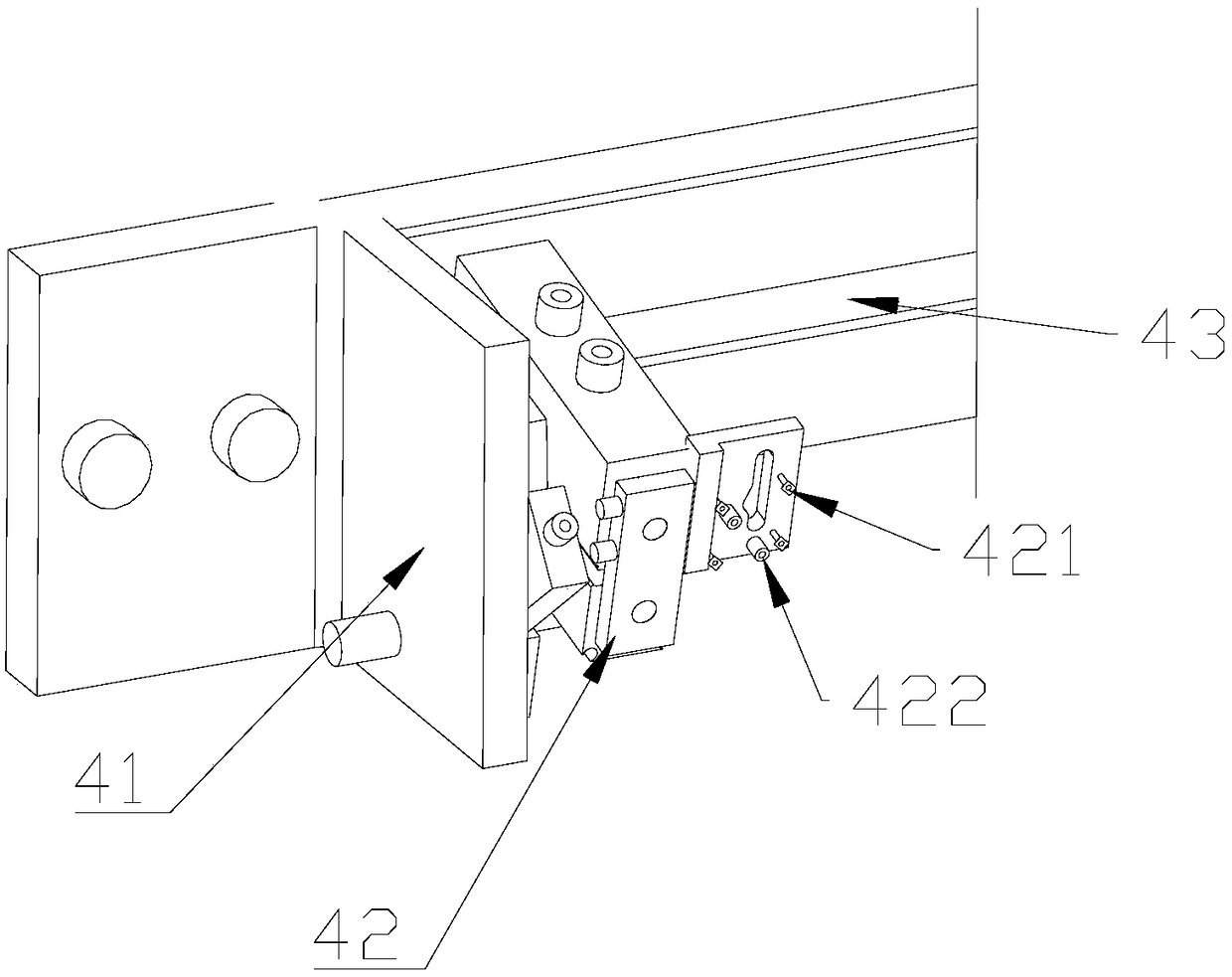

Take-up lever device, link mechanism and production process of link mechanism

PendingCN111101298AOptimize space sizeHigh combination precisionTake-up devicesLow noiseStructural engineering

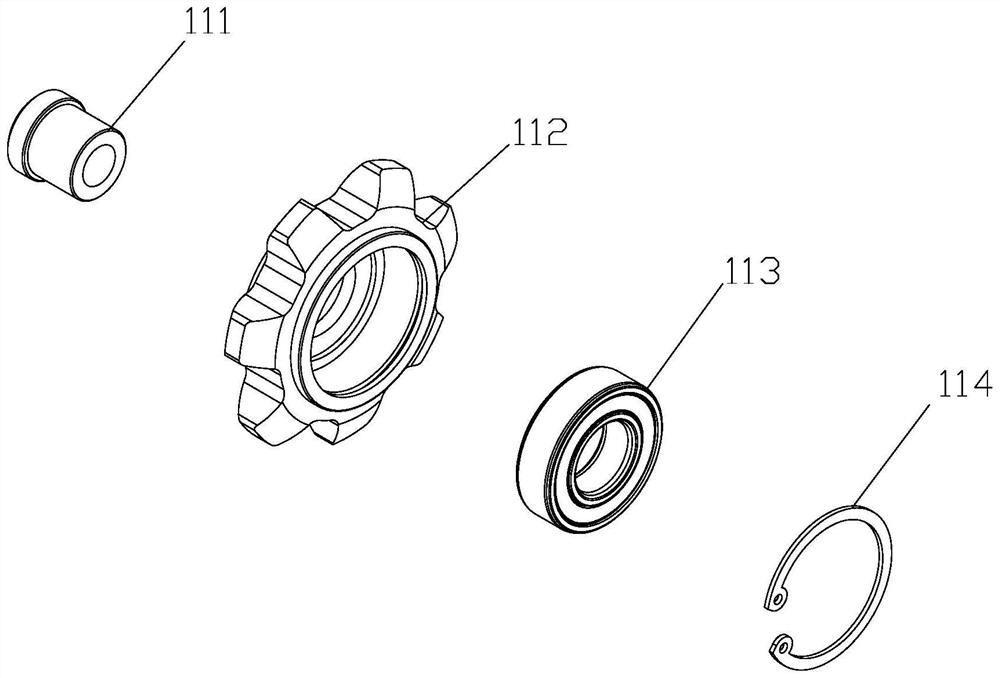

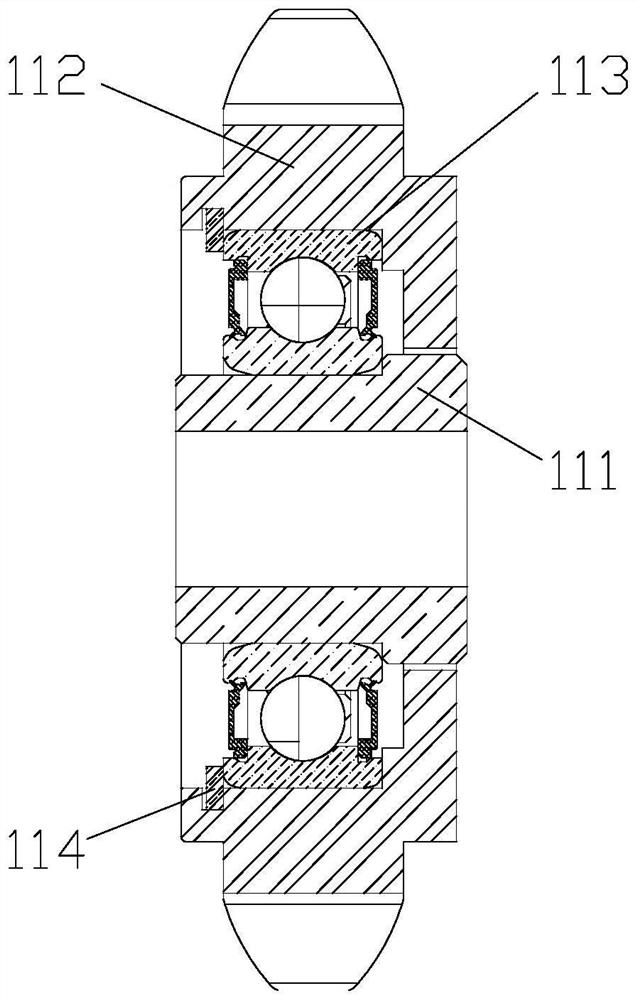

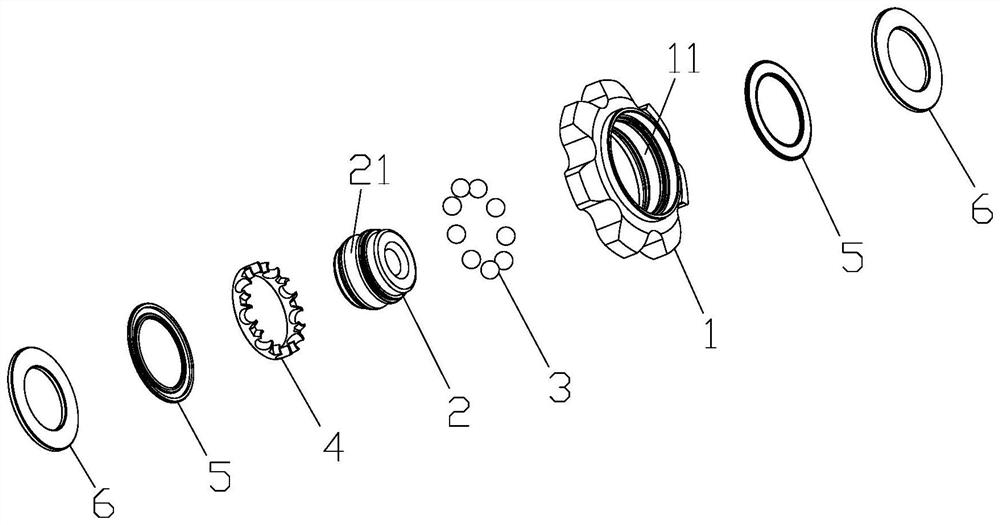

The invention relates to the field of take-up levers and discloses a take-up lever device, a link mechanism and a production process of the link mechanism. The take-up lever device comprises a rollingcomponent, wherein the rolling component comprises a first rolling component part, a special-shaped shaft and a second rolling component part, the first rolling component part is connected with the second rolling component part through the special-shaped shaft, the special-shaped shaft comprises a first shaft body, a connecting block and a second shaft body, the first shaft body is connected withthe second shaft body through the connecting block, the first shaft body is provided with a first channel, a first ball is arranged on the first channel, the second shaft body is provided with a second channel, and a second ball is arranged on the second channel. According to the take-up lever device, the shaft bodies and bearing components are rearranged, so that the spatial size of the rollingcomponent is optimized, and the rolling component has the advantages of high combination precision, high strength and low noise; and moreover, the rolling component has better rotating flexibility.

Owner:浙江博盟精工轴承有限公司

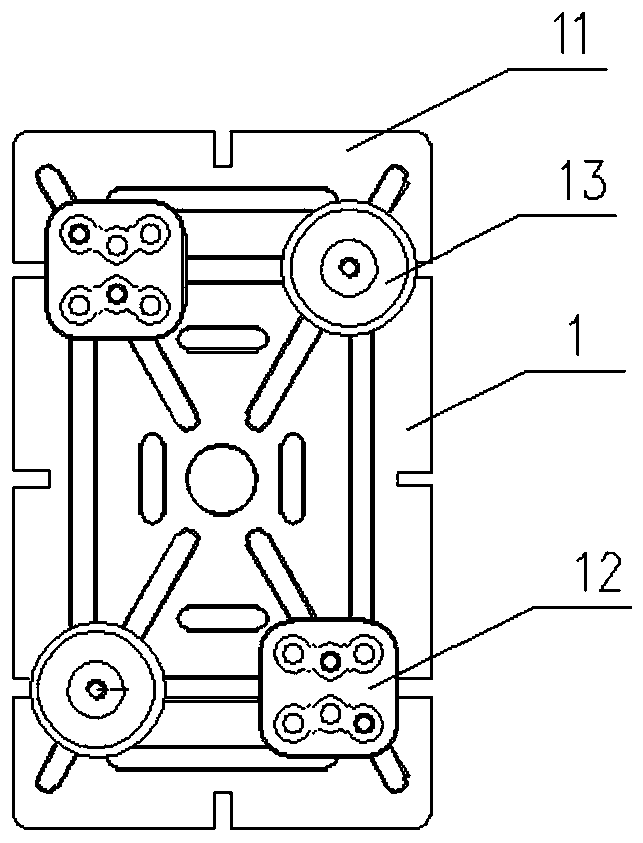

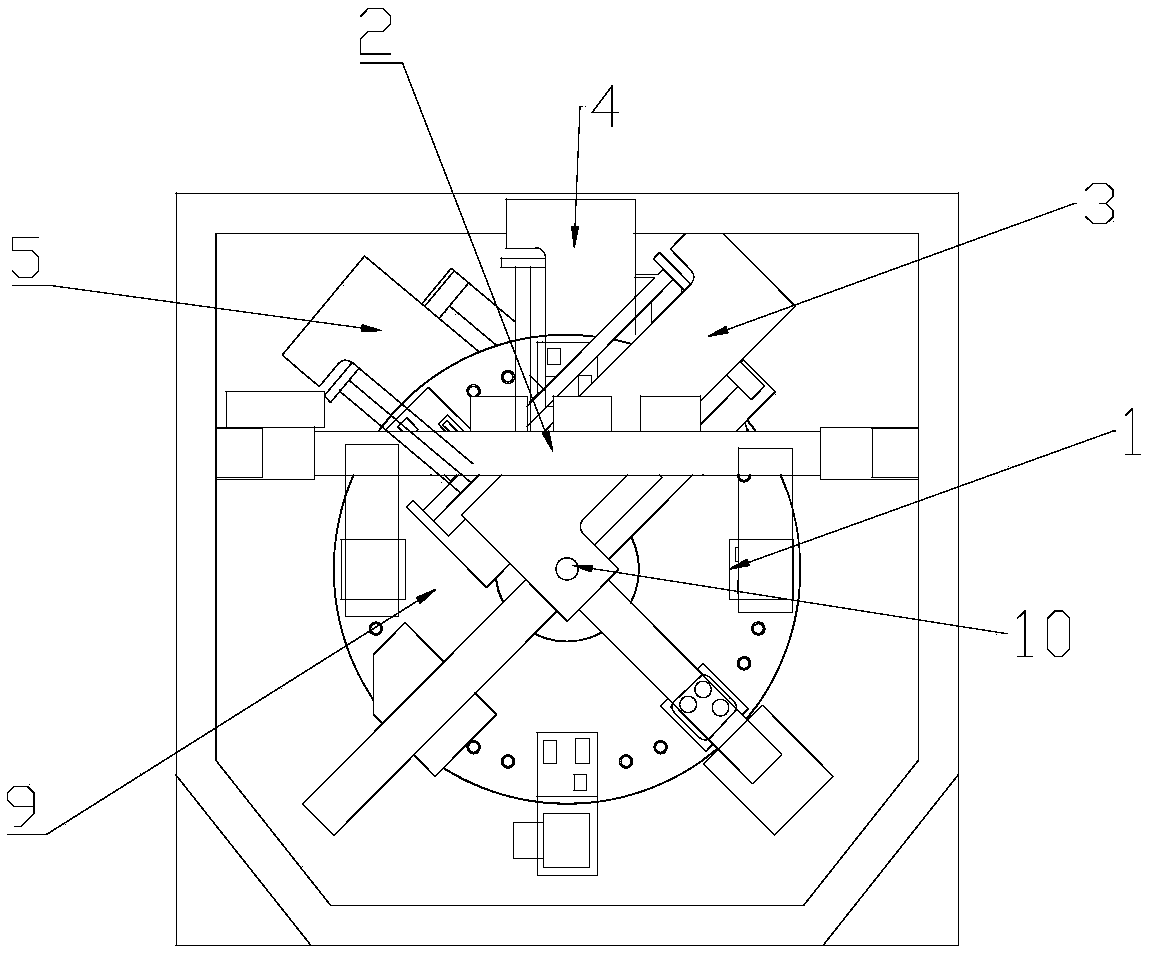

Combined tool used for assembling air quality sensor

PendingCN108971973AHigh degree of automationImprove yieldAssembly machinesMetal working apparatusEngineeringWorkbench

The invention relates to a combined tool used for assembling an air quality sensor. The air quality sensor is formed by assembling a PCBA board, a thin film shell and a connection piece shell; the combined tool comprises a workbench (1), a pneumatic source (2), a correcting part (3), a PCBA board feeding part (4) and a thin film shell feeding part (5); the workbench (1) is provided with a PCBA board fixing groove (11), a thin film shell fixing groove (12) and a connection piece shell fixing groove (13); the PCBA board is placed in the PCBA board fixing groove (11); the thin film shell is placed in the thin film shell fixing groove (12); and the connection piece shell is placed in the connection piece shell fixing groove (13). Compared with the prior art, the combined tool used for assembling the air quality sensor has the beneficial effects that the automation degree in the air quality sensor assembling process is improved, the assembling efficiency is improved, and the combination precision is further improved.

Owner:上海新奥林汽车传感器有限公司

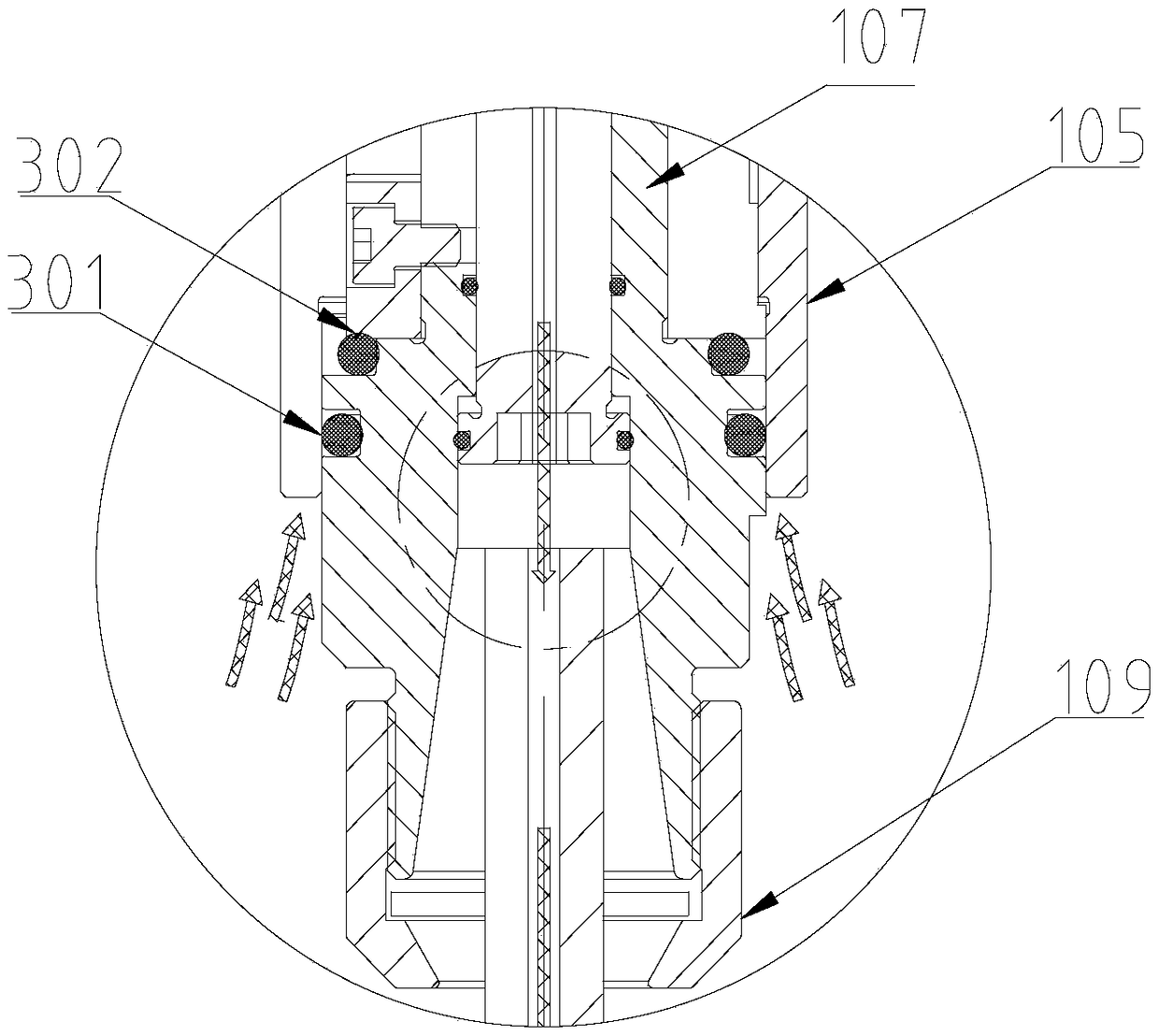

Driven reel

PendingCN114514827AIncrease wall thicknessHigh combination precisionHarvestersBall bearingsSpatial structureEngineering

The invention relates to the technical field of bearings, in particular to a reel with a bearing structure. The driven reel comprises a reel body and is characterized in that the reel body is a chain wheel outer ring (1), and a first channel (11) is formed in the inner hole wall of the chain wheel outer ring (1); the chain wheel further comprises a chain wheel inner ring (2), and a second channel (21) is formed in the outer wall of the chain wheel inner ring (2). The second channel (21) of the chain wheel inner ring (2) is matched with the first channel (11) of the chain wheel outer ring (1) to form a channel space, the steel ball (3) is placed in the channel space, and an inner hole of the chain wheel inner ring (2) is a shaft hole (9). According to the technical scheme, the reel body is transformed into the outer ring of the chain wheel, namely, an integrated design is adopted, the combination precision is improved, the space structure is optimized based on the size of the reel, the used steel balls are enlarged, the wall thickness from the bottom of the channel to the inner ring is increased, and the bearing performance is improved. Meanwhile, a double-layer sealing structure is adopted, and the sealing performance is higher.

Owner:浙江博盟精工轴承有限公司

A method for manufacturing a large-aperture box frame with multiple partitions

InactiveCN104209706BReduce processing difficultyHigh combination precisionWelding/cutting auxillary devicesAuxillary welding devicesProcess supportEngineering

The invention discloses a manufacture method of a multi-baffle large-aperture box frame. The method comprises the steps of firstly, reliably connecting positioning bases and limiting blocks, ensuring that side surfaces of the positioning bases and the limiting blocks are adhered, loading the positioning bases and the limiting blocks into baffle inner holes integrally, then welding the limiting blocks with baffle bearing seats in a spot welding way, secondly, establishing lines on a combined platform to determine positions of all baffles, ensuring that a core shaft penetrates through all the positioning bases, fixing the positions of the positioning bases separately through positioning pins, connecting the positioning bases with the core shaft, thirdly, welding all process supports with inner holes of all the baffles in a spot welding way in weight reduction notch space positions arranged on the positioning bases, fourthly, cutting welding lines of the limiting blocks and the bearing seats, laying the limiting blocks in directions perpendicular to disc diameters of the positioning bases, gradually withdrawing the positioning bases and the core shaft, welding a frame body, welding connecting plates among all the baffles, and fifthly, performing thermal aging on the frame body integrally, and then removing all the process supports. The method improves the frame body combination accuracy and the operating efficiency.

Owner:BAOJI PETROLEUM MASCH CO LTD

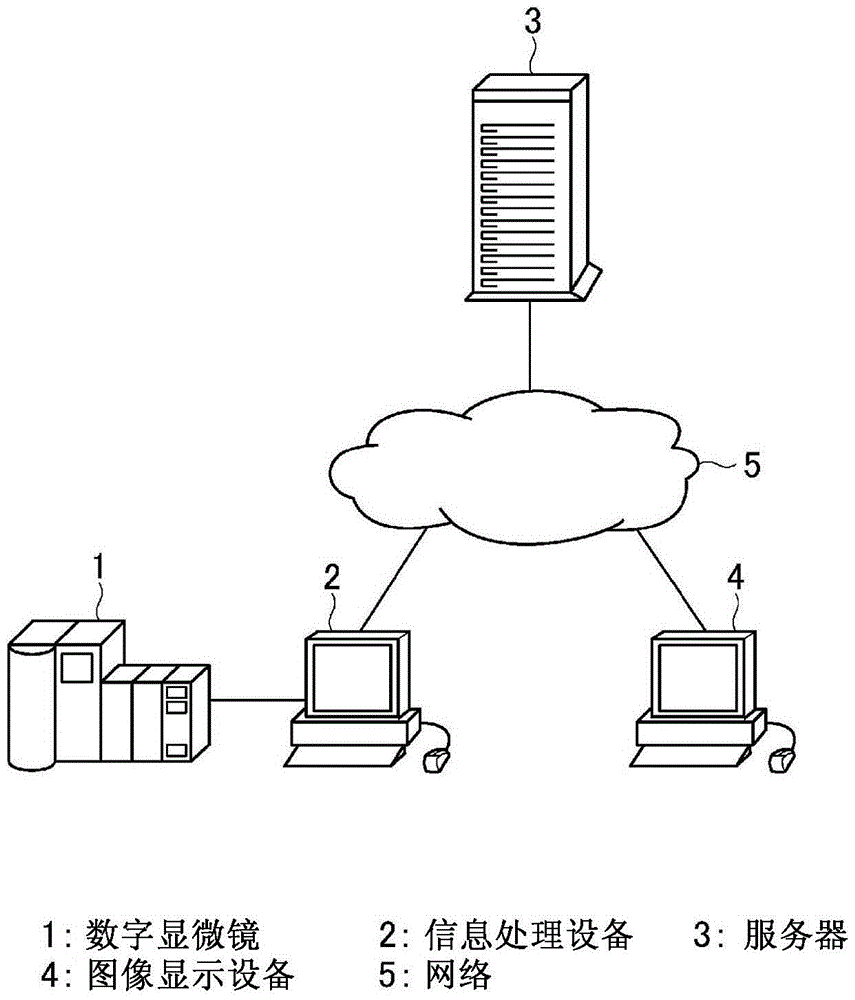

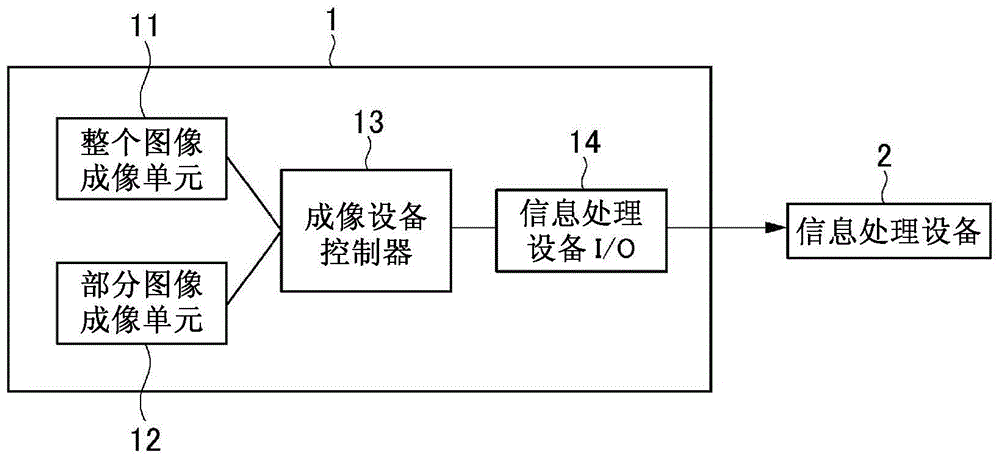

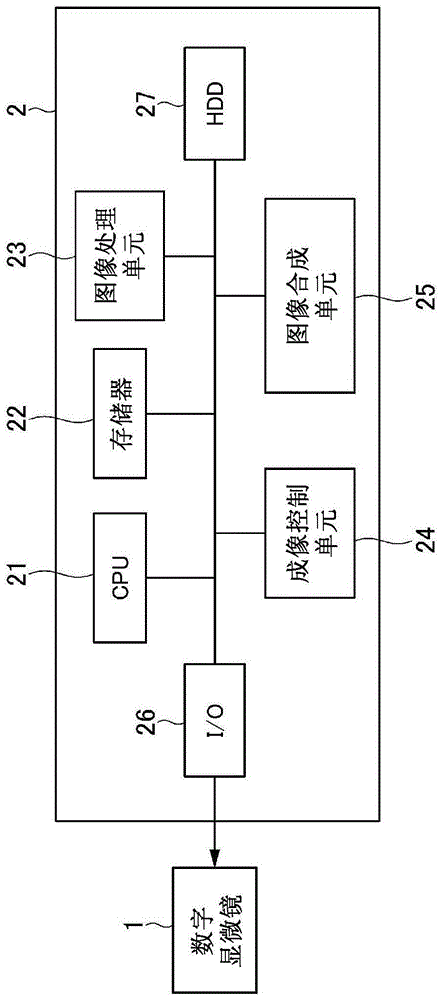

Information processing equipment, information processing method and microscope system

ActiveCN104335098BHigh combination precisionHigh resolutionGeometric image transformationMicroscopesInformation processingMicroscopic image

Provided are an information processing device, an information processing method, a program, and a microscope system capable of combining a plurality of high-precision digital images and synthesizing a wide-field, high-resolution microscope image. By the image analysis unit provided in this information processing apparatus, the entire image imaging the entire observation object region is divided into a plurality of regions, and whether or not the observation object exists in each region is judged. Then, when a partial image of each region is imaged at a magnification higher than that of the entire image, based on the judgment result of the image analysis unit, the driving of the microscope is controlled so that the first partial image is imaged in which the observed object may exist and is related to An area adjacent to an area in which an observation object may exist, and then the second partial image is an imaged area in which an observation object may exist and adjacent to an area in which an observation object does not exist.

Owner:SONY CORP

Glass molds for bottles and cans that open the bottle body and shoulders step by step

ActiveCN104609703BIncrease productivityImprove appearance qualityBlowing mouldsGlass productionBottleEngineering

The invention discloses a bottle glass mold adopting separate mold opening for a bottle body and a bottle shoulder. The bottle glass mold comprises two symmetrical half molds, wherein each half mold comprises a body and a top cover which are arranged at an interval, a shoulder part molding block capable of moving upwards and downwards is arranged in the interval, an elastic piece is arranged between the bottom surface of the shoulder part molding block and the body, a stamping positioning hole is formed in the top cover, a stamping positioning dowel is arranged on the top surface of the shoulder part molding block and penetrates the stamping positioning hole to form a bulge, and the height of the bulge is larger than or equal to the thickness difference of the interval and the shoulder part molding block. According to the mold, the bottle body and the bottle shoulder part are subjected to separate mold opening automatically, manual intervention is not required, the combination accuracy is high, the appearance quality of a finished product is improved, and the processing efficiency is increased.

Owner:CHANGSHU JINGGONG MOLD MFG

A lead frame jumper combination device

ActiveCN113421842BHigh degree of automationIncrease productivitySemiconductor/solid-state device manufacturingConveyor partsStructural engineeringLead frame

The present application provides a lead frame jumper combination device, including: a first conveying mechanism, a first turning mechanism, a second conveying mechanism and a second turning mechanism. The first conveying mechanism includes a first storage mechanism and a conveying plate. The first overturning mechanism is located at the end of the moving direction of the conveying plate; the first overturning mechanism includes a pair of rotating rods for turning the frame sucker on the conveying board 180°; the bottom of the frame sucker is provided with a ventilation hole; the top of the rotating rod faces The vent hole should be provided with a vent pipe. The second conveying mechanism includes a second storage mechanism and a vacuum tube, and a pipe valve is provided on one side of the jumper suction cup; the vacuum tube is provided with a suction hole corresponding to each layer of jumper suction cups in the stack; the outlet end of the second storage mechanism is along the output direction A transfer board is provided for the movement, and the first turning mechanism is located on one side of the middle section of the transfer board's moving track. The second turning mechanism is arranged at the end of the moving direction of the transfer plate. The second turning mechanism includes a rotating block, which has a high degree of automation and greatly improves the production efficiency.

Owner:四川旭茂微科技有限公司

A wide-flow combined two-stage supercharger compressor casing based on hybrid diffuser

The invention discloses a wide-flow combined type two-stage supercharger gas compressor shell based on mixed pressure spreading. The wide-flow combined type two-stage supercharger gas compressor shell comprises a high-pressure end gas compressor shell assembly, a low-pressure end gas compressor shell assembly and a flow adjusting valve mechanical assembly, a gas flow channel is arranged between a first-stage inlet and a second-stage outlet of the shell, the flow adjusting valve mechanical assembly is arranged in axial space, close to the second-stage outlet, of the gas flow channel, and a second-stage flow way is formed by the high-pressure gas compressor shell, a high-pressure flow-shaped plate, a gas compressor shell connecting plate and a high-pressure gas compressor wheel; a first-stage gas compressor flow way is jointly composed of a low-pressure gas compressor and a low-pressure gas compressor wheel. The coaxiality of a low-pressure end compressor shell flow way and a high-pressure end compressor shell flow way is ensured, the combined precision of a flow way circular-arc face is improved, and the blade pipe mixing pressure spreading technology of an interstage 270-degree large-rotation variable cross-section channel ensures that flow separation is restrained within the full-flow range; a flow adjusting valve is arranged between the first-stage inlet and the second-stage outlet to prevent surging; rotation eliminating blades and flow guide blades are arranged in the high-pressure flow way, and imbalance moment of momentum of compressed gas is effectively reduced.

Owner:北京领动国创科技有限公司

Self-positioning Technology of Plate Bridge Waveguide

InactiveCN103394915BHigh combination precisionReduce assembly processSoldering apparatusAssembly machinesControl mannerBraze alloy

The invention relates to a self-positioning process of plate-type electric bridge waveguide, which comprises the following steps: preparing material to complete preliminary processing of each part of the plate-type electric bridge waveguide; conducting surface treatment on each processed part, so as to remove oil stain, impurities and the like on the surface of the part; assembling a left wallboard, a right wallboard, an upper end plate, a lower end plate, a partition board and brazing alloy; placing the assembled plate-type electric bridge waveguide into a vacuum aluminum soldering stove under the matched use of a tooling clamp; conducting vacuum brazing on the plate-type electric bridge waveguide; machining the shape of the plate-type electric bridge waveguide and a flange plate in a numerically controlled manner; drilling through machining; reaming on the flange plate; carrying out electrochemical treatment; rigging. According to the invention, the flange plate is divided into four parts which are formed on the upper end plate, the lower end plate, the left wallboard and the right wallboard respectively, so that the assembly process of the flange plate is eliminated, and the production efficiency is improved; grooves and convex shoulders, which correspond to each other, are formed on the end plates and the wallboards, so that self-positioning assembly is realized, and the cavity assembling precision of the electric bridge waveguide is high; as vacuum brazing is adopted, brazing flux is not required, which avoids corrosion of brazing flux on a cavity, and prolongs the service life of a product.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com