Integrated double-output coaxial motor

A coaxial motor and dual output technology, applied in the field of electric motors, can solve the problems of large overhang length of the output shaft, low coaxiality of the rotating shaft, and insufficient compact structure, and achieve compact structure, large radial rigidity and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

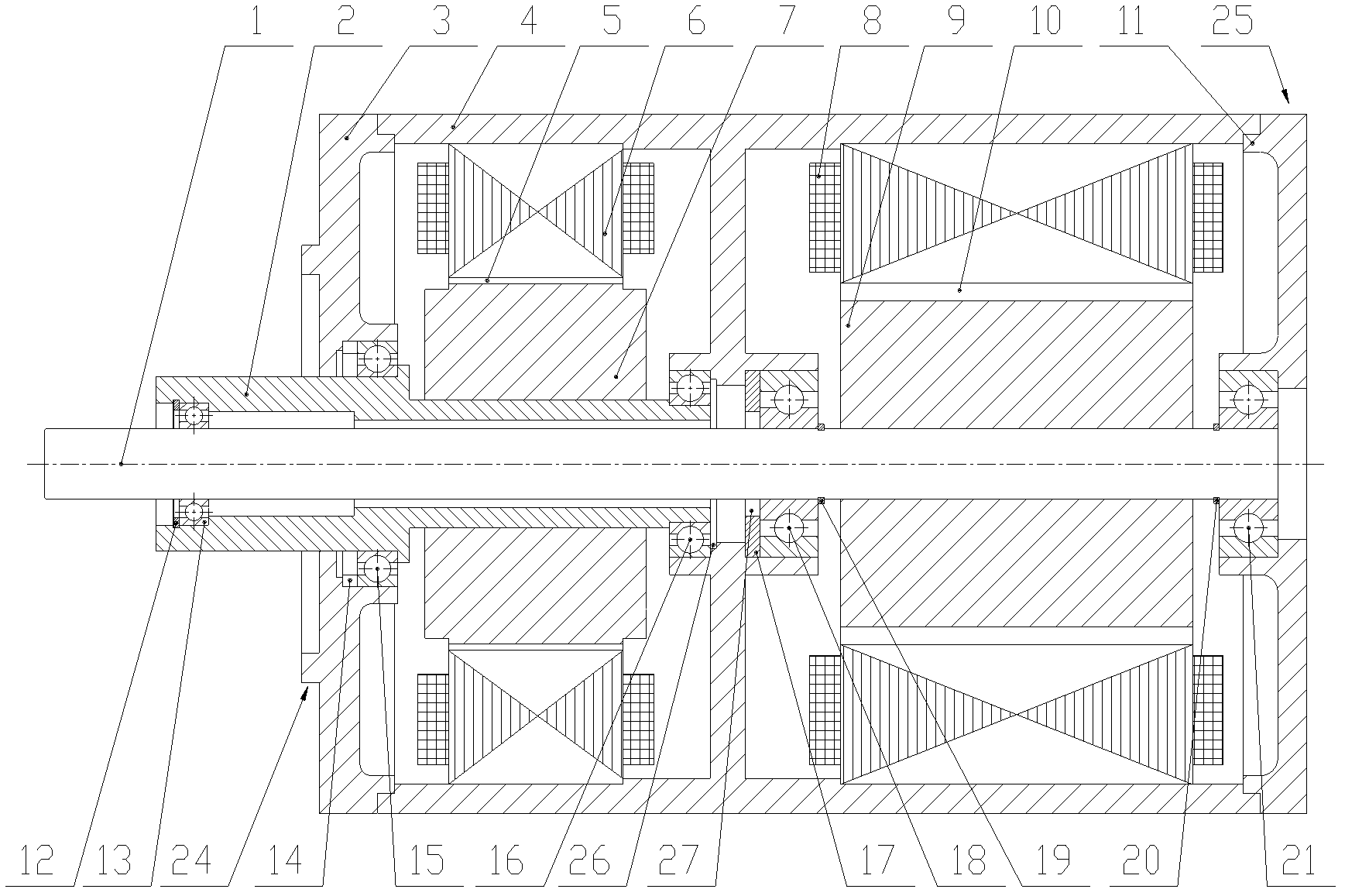

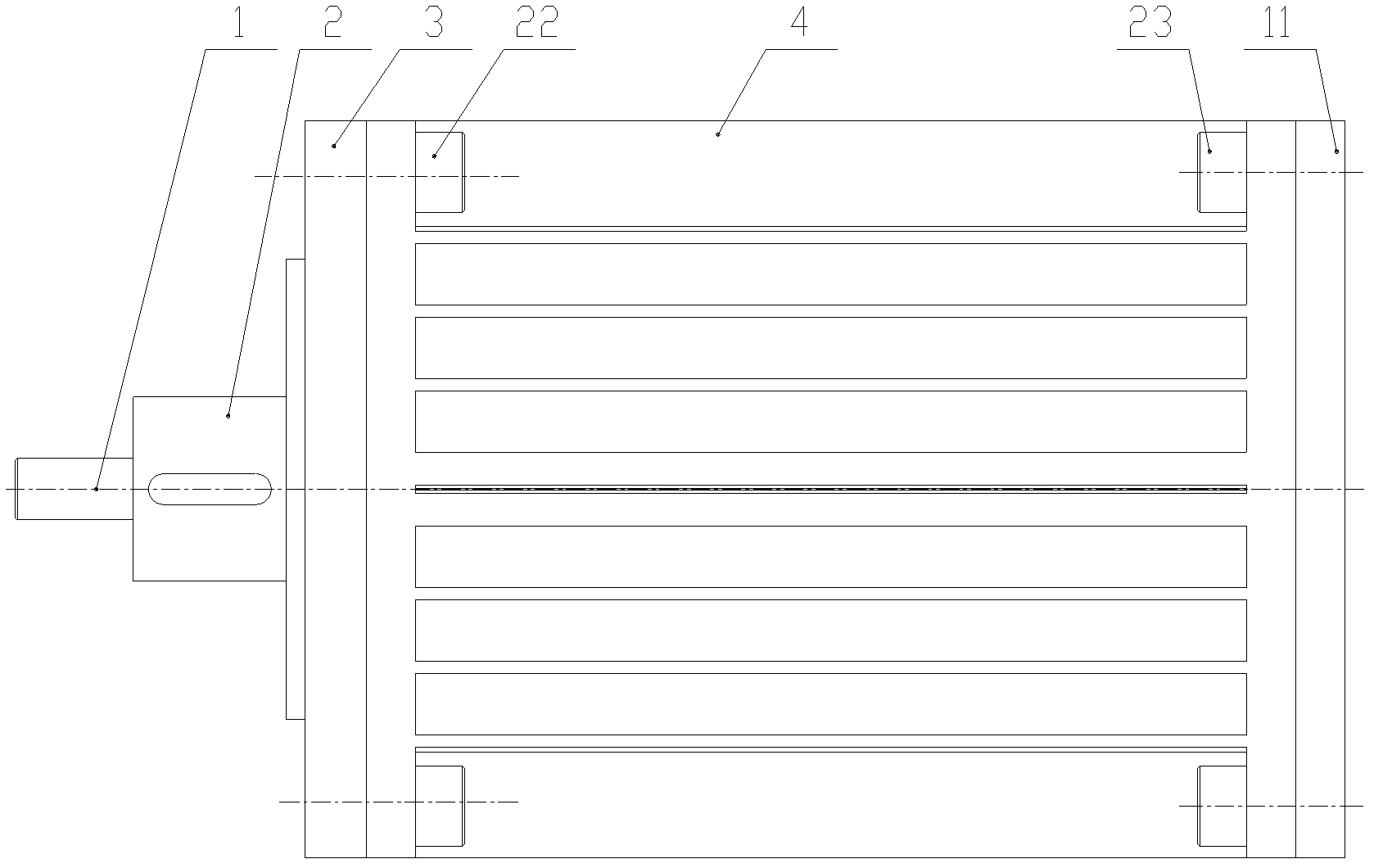

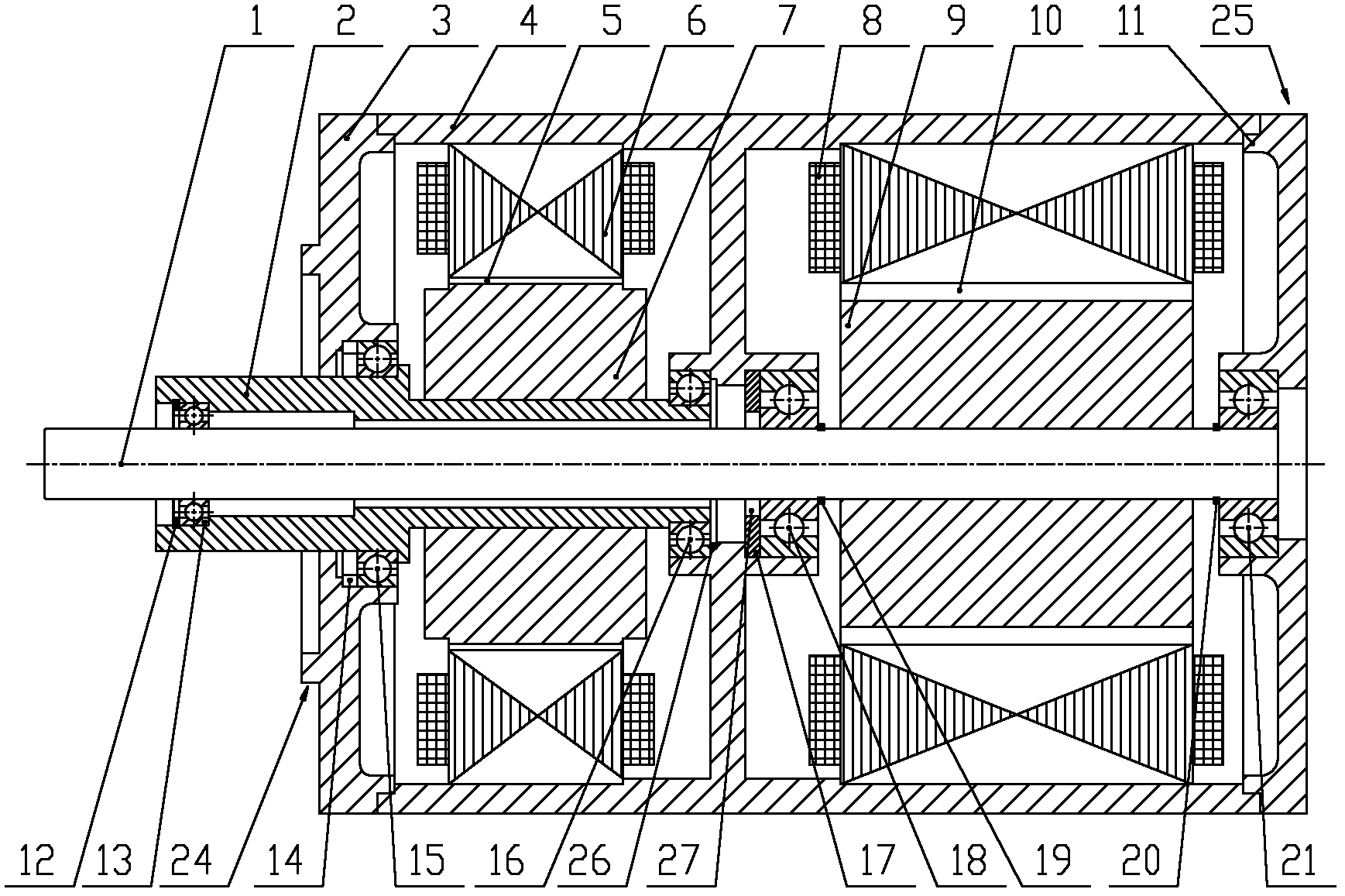

[0010] The specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions. figure 1 It is a cross-sectional view of an integrated dual-output coaxial motor of the present invention, figure 2 for figure 1 As shown in the appearance diagram of the coaxial motor, a set of screws A22 fixes the front end cover 3 to the housing 4 , and a set of screws B23 fixes the rear end cover 11 to the housing 4 .

[0011] The coaxial motor of this embodiment is formed by organically combining the front motor 5 and the rear motor 10 on the same axis. The housing 4 of the coaxial motor is a cylindrical structure with openings at both ends, and a partition in the middle to The cylindrical structure is divided into left and right inner cavities, the front motor 5 is installed in the left inner cavity of the cylindrical structure partition, and the rear motor 10 is installed in the right inner cavity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com