Glass molds for bottles and cans that open the bottle body and shoulders step by step

A glass mold and bottle body technology, applied in glass blowing molds, glass production, etc., can solve the problems of inability to smoothly open the mold left and right, high assembly requirements, and complicated mold assembly, so as to avoid the impact of efficiency and accuracy. The effect of improving the appearance quality of finished products and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

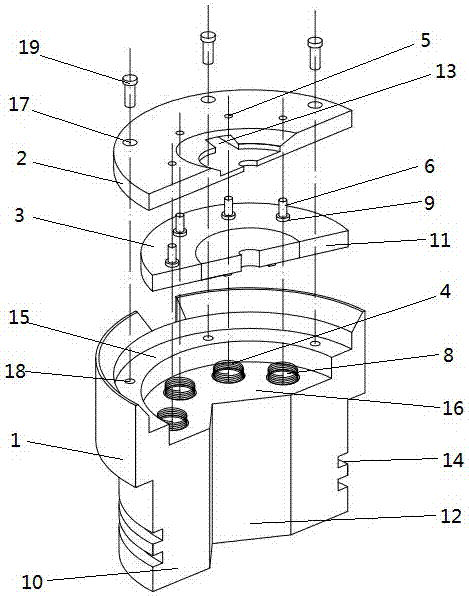

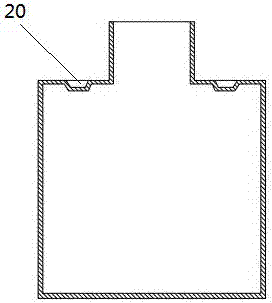

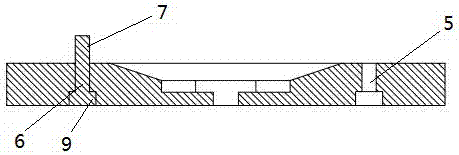

[0017] The bottle body and the bottle shoulder of the bottle and jar glass mold that the bottle body and the bottle shoulder are molded step by step in this embodiment, please combine Figure 1 to Figure 4 , the whole set of molds includes two half-molds arranged symmetrically, which are customarily called the left half-mold and the right half-mold. The first step in the step-by-step mold opening of the mold is carried out inside each mold half. Specifically, each half-mold includes a body 1 and a top cover 2. The body 1 is the main part for forming the bottle body. The body 1 can also include a molding surface for forming part of the bottle shoulder. Line arrangements require design. In this embodiment, the main body 1 only includes the molding surface 12 for molding two adjacent sides of the bottle body, so that the parting line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com